Abstract

This study aimed to evaluate the Staphylococcus aureus biofilm formation and Nε-carboxymethyl-lysine generation ability under food heat processing conditions including pH (5.0–9.0), temperature (25 °C, 31 °C, 37 °C, 42 °C and 65 °C), NaCl concentration (10%, 15% and 20%, w/v) and glucose concentration (0.5%, 1%, 2%, 3%, 5%, 10%, w/v). S. aureus biofilm genetic character was obtained by PCR detecting atl, ica operon, sasG and agr. Biofilm biomass and metabolic activity were quantified with crystal violet and methyl thiazolyl tetrazolium staining methods. S. aureus biofilm was sensitive to food heat processing conditions with 37 °C, pH 7.0, 2% glucose concentration (w/v) and 10% NaCl concentration (w/v) were favorable conditions. Besides, free and bound Nε-carboxymethyl-lysine level in weak, moderate and strong biofilm were detected by optimized high performance liquid chromatography tandem mass spectrometry. Nε-carboxymethyl-lysine level in S. aureus biofilm possessed a significant gap between strong, moderate and weak biofilm strains. This investigation revealed the biological and chemical hazard of Staphylococcus aureus biofilm to food processing environment.

Similar content being viewed by others

Introduction

To date, thermal processes have been extensively employed in food technology1,2,3. Due to the aggregation of glucose, protein and lipid, Maillard reaction and lipid oxidation are promoted during heat treatment, which leads to browning, unpleasant flavors, even chemical hazard. According to World Health Organization (WHO), defined as poisonous and harmful substances in food to human body, food hazardous substances have been concerned over the sustainability4,5,6,7. As a pillar industry in China, the output value of food industry was 11.1 billion Yuan in 2016.

It’s recognized that over 80% microbial contamination was confirmed to be trigger by microbial biofilm formed on food processing equipment or raw material8,9. Among all bacteria retaining biofilm formation ability, Staphylococcus aureus (S. aureus) is a notorious foodborne pathogen capable of causing a spectrum acute food poisoning affairs and food processing equipment contamination. Considerable foodborne outbreaks caused by S. aureus were frequently reported over the years. From 1998 to 2008, 87% vomiting cases were led by S. aureus outbreaks in USA10,11,12. In China mainland, according to a recent investigation from 2006–2015, microbiological hazard have been considered as main food safety issues in China, with the proportion of 61.3%13. Similarly, another investigation revealed that S. aureus related food poisoning entailed a total morbidity of 2,431 people, among which meat (65.71%) and cereal & oil (34.29%) were main contributors14,15,16. In food industry, contamination caused by S. aureus biofilm mainly distributes in the following three aspects: (a) raw materials, especially the frozen food and animal food17; (b) processing environment and equipment, including meat abattoir and pipeline18 (Fig. 1, S. aureus biofilm on PVC pipeline surface); and (c) commodity circulation19,20,21,22.

Biofilm is a common strategy employed by bacteria to survive in varied adverse environment conditions to develop into a community of cells23 encased by extracellular polymeric substances (EPS). For S. aureus, its biofilm development is conducted in four stages24: attachment, microcolony formation, maturation and detachment. EPS is one of the most vital substances that essential for cellular encasement and community function in different stages. In Staphylococcus species, the primary matrix components consists of polysaccharide, proteins and extracellular DNA (eDNA)23. The first extensively studied matrix component is the exopolysaccharide termed PIA (Polysaccharide Intercellular Adhesin), which is produced and secreted by the proteins encoded in the ica (intercellular adhesion) operon icaADBC25, which include a N-acteylglucosamine transferase (IcaA and IcaB), a predicted exporter (IcaC)26,27, and a deacetylase (IcaD)28,29. The ica operon is important for biofilm formation in S. aureus with expression induced by environmental conditions including low oxygen, glucose, osmotic pressure and temperature30,31. Besides, some surface components were recognized contributing to adhesion in S. aureus biofilm including Staphylococcus protein A (Spa)32 and fibronectin binding protein (FnBP)33. Encoded by atl, Atl is a wall-anchored bifunctional peptidoglycan hydrolase responsible for cell separation following cell division34,35, which is required for biofilm development during early adhesion stage. In extracellular matrix, S. aureus surface protein G (SasG) contributes to the maturation phase of biofilm36,37. The eDNA is considered as an important structure component in bacterial biofilm38. The contribution could be retrospect in structural integrity maintenance, horizontal gene transfer and antagonism from antibiotics and the host immune system39,40. It has been proved that eDNA could bridge the energy barrier that separates the cell from the substratum, thereby facilitating irreversible adhesion41. Besides, eDNA also influences the hydrophobicity of bacterial cell surface and boost the tendency of a bacterium attachment42,43,44. Thus, in S. aureus, autolytic activity from a subpopulation of cells results in the release of eDNA that contributes to cell adhesion during biofilm maturation45. Quorum sensing (QS) system contributes greatly to cell density46 in cell communities encased in biofilm. Accessory gene regulator (agr) system is one of typical QS systems responsible for increased expression of various toxins and degradative exoenzymes, and decreased expression of several colonization factors, which resulted in degrading protein components of the S. aureus biofilm matrix47,48,49,50 and cell dispersion. The agr-mediated dispersion of S. aureus biofilm provides capacity of transfer in ideal environment such as food processing pipeline, which increased the difficulty in biofilm elimination.

The biological and chemical hazard of biofilm has been regarded as a public concern. Biofilm is easily formed under food processing conditions, especially heat processing with eutrophic condition, as well as chemical hazard within biofilm. Advanced glycation end products (AGEs) form in food during heating (especially in dry heat) and cause oxidative stress and chronic inflammation leading to increased risk for metabolic and cardiovascular events51. AGEs are products of the Maillard reaction, where sugar moieties react with proteins resulting in protein cross linking and product browning, together with formation of flavor and aroma compounds52. Since EPS consists of a matrix of polysaccharide and proteins with biological activity, AGEs could be accumulated within biofilm. Thus biofilm maintain the ability of both biological and chemical contamination during food processing. Nε-carboxymethyl-lysine (CML) is one of the most widely studied AGEs, and is frequently used as a marker for AGEs formation in food53, which is stable and exists both in free and bound form54. Free AGEs (glycated amino acids) and protein-bound AGEs (protein glycation adducts) may have different bioavailability and physiological effects55. CML in free AGEs (free CML) are much more bioavailable and harmful than CML in protein or peptide-bound AGEs (bound CML), since they are more easily released from a food system and absorbed into serum56. Studies have shown statistical association between accumulation of CML in the human body and diseases such as cardiovascular diseases, sarcopenia, and renal diseases57. Therefore, accurate quantification of free and bound CML is of great importance to reduce the intake of dietary CML and lower the risk of AGEs-related diseases9,58,59,60,61.

Food processing environments are easily continuously contaminated by microbes and harmful substances. Contamination of S. aureus is a vital public concern in consumers, to our knowledge, biofilm could generate CML under food heat processing while no study focused on it. This is the first report that biofilm formation character and CML level within biofilm under various food processing condition were investigated.

Results

S. aureus biofilm formation ability

As the result shown in Table 1, all three strains were identified as S. aureus and 4506, 120184 possessed the potential of strong biofilm formation ability (ica+, atl+, sasG+ and agr+). For biofilm phenotype, all three strains were submitted to CV staining and MTT staining assay. According to the PCR and staining results, strain 4506, 120184 and 10071 were considered maintaining strong, moderate and weak biofilm formation ability respectively. Though 120184 lacked icaA, which was directly responsible for PIA synthesis62 in S. aureus biofilm, biofilm biomass and metabolic activity were still observed.

CML level in biofilm

For S. aureus strain 4506, free and bound CML level were quantified by HPLC-MS. Besides, CV and MTT staining assay as well as CFU counting were employed for quantification of biomass, metabolic activity and live cells in biofilm accordingly. In general, free CML level experienced a sharp increase since 24 h inoculation comparing to the stable bound CML level. For S. aureus biofilm, three stages were observed in this study accordingly (Fig. 2D). The number of live cells and biofilm metabolic activity reached peak at 16 h, with sharp decrease until 2 d. From 8 h to 1 d, free CML level increased with a slow rate while increased fast during 1 d-3 d when S. aureus biofilm turned to maturation. For bound CML level, as expected, the correlation between bound CML level and biofilm incubation time was observed, especially after biofilm adhesion stage (>24 h). Although the bound CML level was witnessed a steady increase, the concentration was far less than that of free CML (Fig. 2). Compare the results above, free and bound CML generation were significantly increased since maturation stage (>24 h). However, after the processing at 100 °C for 15 min, the bound CML was released from biofilm and was significantly higher than free CML (Fig. 2). It should be noticed that free CML showed the coordination with biomass of biofilm (Fig. 2B), instead of the number of live cells (Fig. 2A) and biofilm metabolic activity (Fig. 2C), which verified the assumption that CML was generated from the reaction of sugar moieties and proteins instead of direct cell synthesis and secretion.

Free and bound CML level comparing with (A) live cells, (B) biomass, (C) metabolic activity. (D) Live cells, biomass and metabolic activity during incubation of S. aureus biofilm. ■ free CML, ● bound CML, ▼ CFU counting, ▲ MTT staining, ◆ CV staining. ***significantly different from bound CML (P < 0.001) as determined by one-way ANOVA.

According to several studies, the CML level in breast milk was lower than 0.150 μg/mL63, which was at same magnitude of free CML level in biofilm supernatant by strong biofilm formation ability strain 4506. However, there was a significant disparity of CML level in serum of 4.754 μg/mL63, which was at same magnitude of CML level since biofilm maturation started. Since the planktonic and supernatant were easy to remove and clearance while biofilm not, the CML in biofilm was accumulating until the heating process began. Thus, the bound CML was selected as a marker in the following study. As the results indicated (Fig. 3), a significant gap of bound CML level between strong, moderate and weak biofilm strains was observed. The bound CML level was significantly positive correlated with biofilm formation ability, in other words, biofilm biomass and metabolic activity.

Influence of food processing conditions to S. aureus biofilm

Four typical food processing condition were simulated including pH, eutrophy (glucose concentration), high-salinity (NaCl concentration) and temperature. S. aureus 4506 was selected in this part for its strong CML formation ability. As shown in result (Fig. 4), the suitable incubation temperature and pH were 37 °C and pH 7.0, with highest biomass and metabolic activity. Alkaline condition showed superior influence to the metabolic activity than acidic condition. Specifically, biofilm metabolic activity nearly lost under 65 °C and pH 9.0 incubation, which led a significant loss of biofilm biomass. For eutrophy condition, the biofilm metabolic activity showed a highly similar trend and peak except 5% and 10% glucose concentration. With the increase of glucose concentration, the peak of metabolic activity decreased sharply to 0.57 (5%, 16 h) and 0.55 (10%, 8 h). To 10% glucose concentration, the peak of metabolic activity occurred at 8 h, which was ahead of other concentration, and continuous declined. For biomass, biofilm showed an up-regulation with the increase of the glucose concentration at 8 h. A steady increase of biomass under 0.5%-3.0% glucose concentration was observed while a stable trend occurred to 5% and 10% glucose concentration and was less than 0% glucose concentration since 24 h. A hypotheses was conducted that S. aureus biofilm suffered earlier growth due to the increase of glucose concentration, but still need further study. A similar trend of metabolic activity in high-salinity condition was observed while 15% and 20% NaCl concentration showed a sharp decrease of biomass compare with control sample. The phenomenon was assumed to the osmotic pressure but still need further study.

Influence of food processing environment to S. aureus biofilm biomass (series 1) and metabolic activity (series 2) in various (A) temperature, (B) pH, (C) glucose concentration (w/v) and (D) NaCl concentration (w/v). **/***significantly different from other columns (P < 0.01/P < 0.001) as determined by one-way ANOVA.

Discussion

To date, evidences of ica-independent pathways for biofilm forming have been confirmed63, and this phenomenon was observed frequently under various conditions64,65. In ica-independent pattern, extracellular matrix such as Spa and Bap act as compensatory substances for PIA in S. aureus biofilm25. Besides, FnBP, which was verified as a matrix regulated by autolysin and sigB in biofilm formation26 also contributes in ica-independent S. aureus biofilm. In this study, although strain 120184 was able to develop biofilm and maintain metabolic activity in biofilm, successfully without icaA, whether it was an ica-independent strain still need further investigation.

For CML level in S. aureus biofilm, according to our previous study, active metabolism was conducted inside the biofilm for colony proliferation, eDNA and EPS synthesis, as well as their secretion in maturation stage65, which may lead a dramatic increasement of CML level. However, there’s no evidences indicating that the accumulation of CML was accompanied by the metabolic activity of S. aureus biofilm. In fact, the number of live cells and biofilm metabolic activity decrease sharply while biomass of biofilm experienced a great increase since both free and bound CML came to accumulate in a rapid velocity (1 d, see Fig. 2). S. aureus biofilm turned to form a three-dimensional space structure containing eDNA, skeleton proteins, surface proteins and differentiated cells from maturation stage to maintain the stability, antagonize exogenous disturbances and prepare for the detachment and dispersal. The shield structure maintained integrality of biofilm, in which the bioactive proteins and polysaccharides were in close proximity to each other. With the heat processing of 100 °C for 15 min, CML accumulated inside the biofilm duo to protein and polysaccharide interactions while planktonic cells not, which illustrates a significant gap between free and bound CML level.

In food industry, most of the foodborne pathogens possess the ability of escaping from routine sterilization (such as high temperature and pressure, mechanical flushing) by forming biofilm, especially matured biofilm. Moreover, food components provides a eutrophic environment for biofilm formation, as well as the metabolism inside the biofilm, which leads an accumulation of metabolite such as CML. The most active stage in biofilm formation was 16 h, at which biofilm was at adhesion stage with the rapid proliferation and metabolism inside. The optimal environment for S. aureus biofilm formation was 37 °C, pH 7.0, with the glucose and NaCl concentration of 2% and 10% respectively. Although biofilm maintained resistance to adverse environment66, our study illustrated that S. aureus biofilm was sensitive to various temperature, pH and osmotic pressure conditions, which is commonly exist in food processing industry. Specifically, processing conditions of some typical staple food and snacks, such as noodle, rice cake and preserved fruit67,68,69,70, are under thermal, eutrophic and hyper osmosis processing conditions, which may accumulate S. aureus biofilm formation and CML level. Though daily cleansing is supposed to be conducted with regular mechanical cleansing methods (brush and jet cleaning with high temperature and high pressure), evidence has indicated the low efficiency in biofilm removal71, especially matured biofilm. The remnant nidus leads continuous formation and dispersion of biofilm, thus triggers sustained contamination in processing equipments, which caused the potential safety hazard.

During food heat processing, salt and glucose addition and pH adjustment are commonly conducted72 as well as the CML generation. Studies have been conducted to quantify CML level in food samples. But to our knowledge, there’s no study has been carried out for CML level quantification and influence of food processing conditions in foodborne pathogen S. aureus biofilm. Overall, current results indicated that S. aureus biofilm was sensitive to various temperature, pH and osmotic pressure conditions, with 37 °C, pH 7.0, 2% glucose concentration (w/v) and 10% NaCl concentration (w/v) were favorable conditions for biofilm formation. Besides, CML level in S. aureus biofilm possessed a significant gap between strong, moderate and weak biofilm strains. Based on the findings in current study, it’s supposed to raise the concern of S. aureus biofilm for its biological and chemical contamination in food heat processing condition.

Material and Methods

Strains and references

Three S. aureus strains (4506, 10071, 120184) were isolated from food samples. Standard strain USA300 and CML with 98% purity (Toronto Research Chemicals, Canada) were employed as reference substance.

Identification and screening of S. aureus

Genomic DNA from S. aureus strains for PCR amplification were extracted from overnight tryptic soy broth (TSB) cultures at 37 °C with shaking. Culture was then performed according to the instructions of DNA extraction kit (Dongsheng Bio, Guangzhou) strictly. In short, harvested cells were subjected to the treatment of lysozyme, proteinase K and lysate orderly. Suspension was then purified after the removal of proteins and salts etc. The highly purified DNA was strictly stored under −20 °C.

Biofilm formation and quantification

The overnight culture of S. aureus was diluted 1:100 into pre-warmed TSB and incubated at 37 °C until exponential growth began. The 200 μL exponential-phase culture was then inoculated into 6-well microtiter polystyrene plates (Corning, USA) for biofilm formation. After incubation for 48 h under 37 °C, the supernatants were removed and washed the plates three times with 200 μL sterile normal saline.

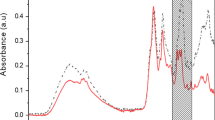

Cristal violet (CV) staining and AQueous One Solution Cell Proliferation (MTT) Assay (Promega, USA) were employed for quantification of biofilm biomass and metabolic activity. Targeting to both viable and non-viable cells, CV is a basic dye that binds to negatively charged molecules present on both the surface of bacteria and the extracellular matrix of biofilm by measuring absorbance at 540 nm. MTT is a yellowish aqueous solution and yields a water insoluble violet-blue formazan if suffer reduction by dehydrogenases and reducing agents present in metabolically active cells. According to several investigations, MTT is mainly reduced with NAD(P)H-dependent cellular oxidoreductase activity (in cytoplasm) and dehydrogenases in active organelles73. Thus, biofilm metabolic activity has been shown to be proportional to production of formazan by measuring absorbance at 490nm74.

Besides, CFU counting was employed for free and bound CML quantification of 4506 strain as assistance. For biofilm biomass, 100 μL of 99% methanol was added to each well for a 15 min incubation. After CV staining (150 μL, 0.01%) for 15 min, washing twice with 200 μL sterile normal saline before re-eluting the CV dye with 100% ethanol and shake gently until all crystal violet is dissolved. For biofilm metabolic activity, staining the biofilm with MTT working solution (150 μL, 1:10 diluted) in dark for 2 h after removing loosely attached biofilm cells. Optical density (OD) represented biomass and metabolic activity under OD540nm and OD490nm. All the operations above were proceeded under room temperature unless otherwise noted. The absorbance of an uninoculated well serves as a negative control (ODc) should be subtracted from the value of the inoculated wells. The following classification was applied for biofilm biomass and metabolic activity determination: no biofilm production (OD ≤ ODc), weak biofilm production (ODc < OD ≤ 2ODc), moderate biofilm production (2ODc < OD ≤ 4ODc) and strong biofilm production (4ODc < OD)75.

Preparation and pretreatment of S. aureus biofilm

S. aureus biofilm was incubated under 37 °C for certain time (8 h, 16 h, 1 d, 2 d, 3 d, 7 d and 14 d) before submitting to HPLC-MS analysis. Six-well polystyrene plate was slightly titled to remove the planktonic bacteria and liquids. Biofilm was collected into ultrapure water by scrapping with pipette tips after washed twice with ultrapure water. The solution of biofilm samples were sucked out and stored in sterile PEP tube under −4 °C for the subsequent test.

For free CML analysis, the biofilm sample was dissolved by heating process (100 °C, 15 min) which is common employed as food processing condition. The solution was then loaded into the conditioned 18C SPE column (2,000 mg/12 mL, Agela Technologies, China), which was then eluted with ultrapure water. The eluent was collected and filtered with nylon 0.22 μm membrane before submitting to HPLC-MS analysis. For bound CML analysis, modified pretreatment procedures was employed in this study based on Assar’s protocol53. Biofilm sample was dissolved by heating process (100 °C, 15 min), which was mixed with sodium borate buffer (0.5 M, pH 9.2) to a final concentration of 0.2 M. Sodium borohydride (2 M in 0.1 M NaOH) was added to reach a final concentration of 0.1 M, followed by vortexing for 30 s and stand for 4 h. Adding trichloroacetic acid (TCA, 60%, v/v) to a final concentration for 20%. After a 30 min standing, solution was vortexing for 15 min under 4 °C, 7000 rpm for protein extraction and repeated twice for purification. Extracted proteins and peptides were hydrolyzed in 6 M HCl at 110 °C for 24 h before blowing by Nitrogen Evaporators (N-EV, Organomation, USA) and re-dissolved by ultrapure water. HCl was then removed under vacuum and hydrolysate was purified by 18C SPE column, dried under vacuum and dissolved in 300 μL methanol-distilled water (1:9, v/v) prior to analysis by HPLC-MS. All the operations above were proceeded under room temperature unless otherwise noted.

Quantification of CML by HPLC-MS

The HPLC-MS method for CML analysis has been well described in several studies28,30. In this study, HPLC (Waters 1525, Waters, USA) tandem single quadrupole mass spectrometer (Waters Micromass ZQ, Waters, USA) was employed for free and bound CML quantification. Atlantis 18C column (150 × 4.6 mm, 5 μm particle size, Waters, USA) was selected as separation chromatographic column for HPLC with a mixture of methanol-water-formic acid (10:90:0.1, v/v/v) was selected as mobile phase of 0.5 mL/min flow rate. Separated analytes were detected by the MS operated in electrospray ionization (ESI) positive mode with single ion recording (SIR). Significant MS operating parameters were as follows: capillary voltage 3.0 kV, cone voltage 20 V, source temperature 100 °C and desolvation temperature 300 °C. The mass charge ratio of CML was 205 (M+). The matrix effects in biofilm samples (mixing four representative commercial brand at equal amounts) prepared by the pretreatment methods for free CML analysis and the optimal pretreatment conditions for bound CML analysis were investigated under the above HPLC-MS conditions. All of these prepared biofilm samples had no significantly matrix effects (P > 0.05, data not shown). The injection volume was 10 μL with a retention time of CML 3.3 min. The mass spectrum was calibrated with CML standard substance at levels of 0.5 μg/mL, 1 μg/mL, 10 μg/mL, 50 μg/mL and 100 μg/mL to obtain standard curve. Analytes were quantified by reference to an external standard calibration curve.

Influence of food processing conditions to S. aureus biofilm

To investigate the influence of food processing environment to S. aureus biofilm, strain 4506 was submitted to biofilm incubation under simulated typical food processing environment including pH (5.0, 6,0, 7.0 and 8.0), glucose (0.5%, 1.0%, 2.0%, 3.0%, 5.0% and 10.0%, m/v), NaCl (10.0%, 15.0% and 20.0%, m/v) and temperature (25 °C, 31 °C, 37 °C, 42 °C and 65 °C) for 8 h, 16 h, 1 d, 2 d, 3 d, 7 d and 14 d respectively. Biofilm incubation condition and quantification of biomass and metabolic activity with CV and MTT staining assays were described above.

Statistical Analysis

All experiments were performed in triplicate and reported as mean ± standard deviation (SD). Statistical treatments and analysis of variance (ANOVA) were carried out by Microsoft Excel (v2013), Origin Pro (v8.0) and SPSS (v19.0). Significant differences were defined as p < 0.05 and were based on one-way ANOVA.

References

Boekel, M. V. et al. A review on the beneficial aspects of food processing. Molecular Nutrition & Food Research 54(9), 1215–1247 (2010).

Xu, Z. et al. Development and application of loop-mediated isothermal amplification assays on rapid detection of various types of staphylococci strains. Food Research International 47, 166–173 (2012).

Liu, J. et al. Complete sequence of pBM413, a novel multi-drug-resistance megaplasmid carrying qnrVC6 and blaIMP-45 from Pseudomonas aeruginosa. International Journal of Antimicrobial Agents 51, 145–150 (2018).

Organization, World Health. Food safety and foodborne illness. Nutrition Newsletter (2003).

Miao, J. et al. Current methodologies on genotyping for nosocomial pathogen methicillin-resistant Staphylococcus aureus (MRSA). Microbial Pathogenesis. 107, 17–28 (2017).

Xie, J. et al. A 16-year retrospective surveillance report on the pathogenic features and antimicrobial susceptibility of Pseudomonas aeruginosa isolates from FAHJU in Guangzhou representative of Southern China. Microbial Pathogenesis 110, 37–41 (2017).

Lin, J. et al. Durably Antibacterial and Bacterially Antiadhesive Cotton Fabrics Coated by Cationic Fluorinated Polymers. ACS Applied Materials & Interfaces 10(7), 6124–6136 (2018).

Shirtliff, M & J. G. Leid. The Role of Biofilms in Device-Related Infections. Springer Berlin Heidelberg (2009).

Liu, j. et al. Induction and Recovery of the Viable but Nonculturable State of Hop-Resistance Lactobacillus brevis. Frontiers in Microbiology 9 (2018).

Bennett, S. D., Walsh, K. A. & Gould, L. H. Foodborne Disease Outbreaks Caused by Bacillus cereus, Clostridium perfringens, and Staphylococcus aureus-United States, 1998–2008. Clinical Infectious Diseases 57(3), 425–433 (2013).

Liu, J. et al. Discovery and control of culturable and viable but non-culturable cells of a distinctive Lactobacillus harbinensis strain from spoiled beer. Scientific Reports 8, 1 (2018).

Xu, Z. et al. First confirmation of class 1 integron-bearing methicillin-resistant Staphylococcus aureus in South China. Current Microbiology 57, 264–268 (2009).

Wang, P. et al. Characteristics of food poisoning in mainland China, 2006-2015. Practical. Preventive Medicine 25(3), 257–260, https://doi.org/10.3969/j.issn.1006-3110.2018.03.001 (2018).

Li, G. et al. Epidemiological Analysis of Staphylococcus aureus Food Poisoning Events in China during 2003-2015. Food Research and Development 6(39), 200–203, https://doi.org/10.3969/j.issn.1005-6521.2018.06.037 (2018).

Xu, Z. et al. First report of class 2 integron in clinical Enterococcus faecalis and class 1 integron in Enterococcus faecium in South China. Diagnostic Microbiology and Infectious Disease 68(3), 315–317 (2010).

Zhao, X. et al. Development and application of a loop-mediated isothermal amplification method on rapid detection of Pseudomonas aeruginosa strains. World Journal of Microbiology and Biotechnology 27, 181–184 (2011).

De Souza, E. L. et al. Biofilm formation by Staphylococcus aureus from food contact surfaces in a meat-based broth and sensitivity to sanitizers. Brazilian Journal of Microbiology 45(1), 67–75 (2014).

Møretrø, T., Langsrud, S. & Heir, E. Bacteria on Meat Abattoir Process Surfaces after Sanitation: Characterisation of Survival Properties of and the Commensal Bacterial Flora. Advances in Microbiology 3(3), 255–264 (2013).

Llorens, A. et al. Metallic-based micro and nanocomposites in food contact materials and active food packaging. Trends in Food Science & Technology 24(1), 19–29 (2012).

Liu, J. et al. Staphylococcal chromosomal cassettes mec (SCCmec): A mobile genetic element in methicillin-resistant Staphylococcus aureus. Microbial Pathogenesis 101, 56–67 (2016).

Miao, J. et al. Formation and development of biofilm: With focus on food safety. Journal of Food Safety 37(4), e12358 (2017).

Resistance class 1 integron in clinical methicillin-resistant Staphylococcus aureus strains in southern China. 2001–2006. Clinical Microbiology and Infection, 17, 714–718 (2011).

Payne, D. E. & Boles, B. R. Emerging interactions between matrix components during biofilm development. Current Genetics 62(1), 137–141 (2016).

Rosenthal, C. B., Mootz, J. M. & Horswill, A. R. Staphylococcus aureus, Biofilm Formation and Inhibition. Antibiofilm Agents. Springer Berlin Heidelberg, 233–255 (2014).

Cramton, S. E. et al. The intercellular adhesion (ica) locus is present in Staphylococcus aureus and is required for biofilm formation. Infection & Immunity 67(10), 5427–5433 (1999).

Gerke, C. et al. Characterization of the N-acetylglucosaminyltransferase activity involved in the biosynthesis of the Staphylococcus epidermidis polysaccharide intercellular adhesin. Journal of Biological Chemistry 273(29), 18586 (1998).

Xu, Z., Li, L., Shi, L. & Shirtliff, M. E. Class 1 integron in staphylococci. Molecular Biology Reports 38(8), 5261–5279 (2011).

Vuong, C. et al. A crucial role for exopolysaccharide modification in bacterial biofilm formation, immune evasion, and virulence. Journal of Biological Chemistry 279(52), 54881–54886 (2004).

Zhao, X. et al. Rapid detection of Vibrio parahaemolyticus strains and virulent factors by loop-mediated isothermal amplification assays. Food Science and Biotechnology 19(5), 1191–1197 (2010).

Fitzpatrick, F., Humphreys, H. & O’Gara, J. P. The genetics of staphylococcal biofilm formation–will a greater understanding of pathogenesis lead to better management of device-related infection? Clinical Microbiology &. Infection 11(12), 967–973 (2005).

Clinical features and antimicrobial resistance profiles of important Enterobacteriaceae pathogens in Guangzhou representative of Southern China, 2001–2015. Microbial Pathogenesis. 107, 206–211 (2017).

Lasa, I. & Penadés, J. R. Bap: a family of surface proteins involved in biofilm formation. Research in Microbiology. 157(2), 99–107 (2006).

Ams, F. et al. The role of biofilms in persistent infections and factors involved in ica-independent biofilm development and gene regulation in Staphylococcus aureus. Critical Reviews in Microbiology 43(5), 602–620 (2017).

Houston, P. et al. Essential Role for the Major Autolysin in the Fibronectin-Binding Protein-Mediated Staphylococcus aureus Biofilm Phenotype. Infection & Immunity 79, 11533 (2011).

Liu, J. et al. Shirtliff ME Viable but non-culturable state and toxin gene expression of enterohemorrhagic Escherichia coli O157 Under Cryopreservation. Research in Microbiology 101, 56–67 (2016).

Geoghegan, J. A. et al. Role of surface protein SasG in biofilm formation by Staphylococcus aureus. Journal of Bacteriology 192(21), 5663–73 (2010).

Corrigan, R. M. et al. The role of Staphylococcus aureus surface protein SasG in adherence and biofilm formation. Microbiology 153(8), 2435 (2007).

Vorkapic, D., Pressler, K. & Schild, S. Multifaceted roles of extracellular DNA in bacterial physiology. Current Genetics 62(1), 71–79 (2016).

Okshevsky, M. & Meyer, R. L. The role of extracellular DNA in the establishment, maintenance and perpetuation of bacterial biofilms. Critical Reviews in Microbiology 41(3), 341 (2015).

Xu, Z. et al. Longitudinal surveillance on antibiogram of important Gram-positive pathogens in Southern China, 2001 to 2015. Microbial Pathogenesis 103, 80–86 (2017).

Das, T. et al. DNA-mediated bacterial aggregation is dictated by acid–base interactions. Soft Matter 7(6), 2927–2935 (2011).

Das, T. et al. Role of extracellular DNA in initial bacterial adhesion and surface aggregation. Applied &. Environmental Microbiology 76(10), 3405 (2010).

Wang, L., Li, Y., Chu, J., Xu, Z. & Zhong, Q. Development and application of a simple loopmediated isothermal amplification method on rapid detection of Listeria monocytogenes strains. Molecular Biology Reports 39(1), 445–449 (2012).

Liu, J. et al. Transcriptomic analysis on the formation of the viable putative non-culturable state of beer-spoilage Lactobacillus acetotolerans. Scientific Reports 6, 1 (2016).

Qin, Z. et al. Role of autolysin-mediated DNA release in biofilm formation of Staphylococcus epidermidis. Microbiology 153(7), 2083–92 (2007).

Le, K. Y. & Otto, M. Quorum-sensing regulation in staphylococci-an overview. Frontiers in Microbiology 6 (2015).

Lauderdale, K. J. et al. Interconnections between Sigma B, agr, and proteolytic activity in Staphylococcus aureus biofilm maturation. Infection &. Immunity 77(4), 1623 (2009).

Integron-bearing methicillin-resistance staphylococci in South China. 2001–2004. FEMS Microbiology Letters, 278, 223–230 (2008).

Liu, J. et al. Complete genomic analysis of multidrug-resistance Pseudomonas aeruginosa Guangzhou-Pae617, the host of megaplasmid pBM413. Microbial Pathogenesis 117, 265–269 (2018).

Liu, J. et al. Identification of the KPC plasmid pCT-KPC334: New insights on the evolutionary pathway of epidemic plasmids harboring fosA3-blaKPC-2 genes. International Journal of Antimicrobial Agents 52(4), 510–511 (2018).

Angoorani, P. et al. Dietary consumption of advanced glycation end products and risk of metabolic syndrome. International Journal of Food Sciences & Nutrition 67(2), 1–7 (2016).

Saha, A. et al. Increased odds of metabolic syndrome with consumption of high dietary advanced glycation end products in adolescents. Diabetes & Metabolism. 43(5), 469–471 (2017).

Assar, S. H. et al. Determination of Nε-(carboxymethyl)lysine in food systems by ultra performance liquid chromatography-mass spectrometry. Amino Acids 36(2), 317–326 (2009).

Ames, J. M. Determination of N epsilon-(carboxymethyl)lysine in foods and related systems. Annals of the New York Academy of Sciences 1126(1), 20–24 (2010).

Rabbani, N. Glycation research in amino acids: a place to call home. Amino Acids 42(4), 1087–1096 (2012).

Zhang, G. et al. Determination of advanced glycation endproducts by LC-MS/MS in raw and roasted almonds (Prunus dulcis). Journal of Agricultural & Food Chemistry 59(22), 12037 (2011).

Baumann, M. Role of advanced glycation end products in hypertension and cardiovascular risk: human studies. Journal of the American Society of Hypertension Jash 6(6), 427 427–435 (2012).

Li, Y. et al. Optimization of Pretreatment for Free and Bound Nε-(carboxymethyl)lysine Analysis in Soy Sauce. Food Analytical. Methods 8(1), 195–202 (2015).

Xu, Z. et al. Occurrence and Characteristics of Class 1 and 2 Integrons in Pseudomonas aeruginosa Isolates from Patients in Southern China. Journal of Clinical Microbiology 47(1), 230–234 (2009).

Xu, Z. et al. Nosocomial infection caused by class 1 integron-carrying Staphylococcus aureus in a hospital in South China. Clinical Microbiology and Infection 13(10), 980–984 (2007).

Liu, j. et al. (2018) Transcriptomics Study on Staphylococcus aureus Biofilm Under Low Concentration of Ampicillin. Frontiers in Microbiology 10 (2018).

O’Neill, E. et al. Association between Methicillin Susceptibility and Biofilm Regulation in Staphylococcus aureus Isolates from Device-Related Infections. Journal of Clinical Microbiology 45(5), 1379–1388 (2007).

Wagner, Z. et al. Serum Carboxymethyllysine Predicts Mortality in Hemodialysis Patients. American Journal of Kidney Diseases the Official Journal of the National Kidney Foundation 47(2), 294–300 (2006).

Archer, N. K. et al. Staphylococcus aureus biofilms: properties, regulation, and roles in human disease. Virulence 2(2), 445–459 (2011).

Xu, Z. et al. Crystal Violet and MTS Assays on Staphylococcus aureus Biofilm Quantification. Current Microbiology 73(4), 1–9 (2016).

Costerton, J. W., Stewart, P. S. & Greenberg, E. P. Bacterial Biofilms: A Common Cause of Persistent Infections. Science 284(5418), 1318–1322 (1999).

Lee, J. C. et al. Production of black rice cake using ground black rice and medium-grain brown rice. International Journal of Food Science & Technology 43(6), 1078–1082 (2008).

Choi, E. et al. Effect of steaming, freezing, and re-steaming on the texture properties of non-glutinous rice cakes. Food Science & Biotechnology 25(4), 1053–1058 (2016).

Siah, S. & Quail, K. J. Factors affecting Asian wheat noodle color and time‐dependent discoloration—A review. Cereal Chemistry. 7, 50 (2018).

Raghuram, S. et al. Optimization of osmotic dehydration of melons followed by air-drying. International Journal of Food Science & Technology 41(6), 674–680 (2006).

Simões, M. L. C. & Simões, M. J. Vieira. A review of current and emergent biofilm control strategies. LWT - Food Science and Technology 43(4), 573–583 (2010).

Mizan, M. F. R. et al. Effects of NaCl, Glucose, and their combinations on Biofilm Formation on Black Tiger Shrimp (Penaeus monodon) Surfaces by Vibrio parahaemolyticus. Food Control 89, 203–209 (2018).

Stockert, J. C. et al. MTT assay for cell viability: Intracellular localization of the formazan product is in lipid droplets. Acta Histochemica 114(8), 785–796 (2012).

Alonso, B. et al. Comparison of the XTT and resazurin assays for quantification of the metabolic activity of Staphylococcus aureus biofilm. Journal of Microbiological Methods 139, 135–137 (2017).

Smith, K. et al. Biofilm formation by Scottish clinical isolates of Staphylococcus aureus. Journal of Medical Microbiology 57(8), 1018–1023 (2008).

Acknowledgements

This work was supported by the National Key Research and Development Program of China (2016YFD04012021), Guangdong Province Key Laboratory for Green Processing of Natural Products and Product Safety (KL-2018-16), and the 111 Project (B17018).

Author information

Authors and Affiliations

Contributions

J.M., J.H. and Z.X. conceived of the study, participated in its design and coordination, B.P., M.S., and Y.L. instructed biofilm incubation, J.M. and S.L. carried out Genetic character identification, biofilm incubation as well as HPLC-MS analysis. J.S., T.S, and H.C. carried out biofilm biomass and metabolic activity quantification and statistical analysis, L.L. and B.L. conducted the DNA extraction. All authors reviewed and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Miao, J., Lin, S., Soteyome, T. et al. Biofilm Formation of Staphylococcus aureus under Food Heat Processing Conditions: First Report on CML Production within Biofilm. Sci Rep 9, 1312 (2019). https://doi.org/10.1038/s41598-018-35558-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-018-35558-2

This article is cited by

-

Synthesis, theoretical analysis, and biological properties of a novel tridentate Schiff base palladium (II) complex

BioMetals (2024)

-

Characterization on gut microbiome of PCOS rats and its further design by shifts in high-fat diet and dihydrotestosterone induction in PCOS rats

Bioprocess and Biosystems Engineering (2021)

-

Isolation and characterization of bacteria from fermented cooked-rice

Biologia (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.