Abstract

N-methylated amino acids are found in Nature in various biological compounds. N-methylation of amino acids has been shown to improve pharmacokinetic properties of peptide drugs due to conformational changes, improved proteolytic stability and/or higher lipophilicity. Due to these characteristics N-methylated amino acids received increasing interest by the pharmaceutical industry. Syntheses of N-methylated amino acids by chemical and biocatalytic approaches are known, but often show incomplete stereoselectivity, low yields or expensive co-factor regeneration. So far a one-step fermentative process from sugars has not yet been described. Here, a one-step conversion of sugars and methylamine to the N-methylated amino acid N-methyl-l-alanine was developed. A whole-cell biocatalyst was derived from a pyruvate overproducing C. glutamicum strain by heterologous expression of the N-methyl-l-amino acid dehydrogenase gene from Pseudomonas putida. As proof-of-concept, N-methyl-l-alanine titers of 31.7 g L−1 with a yield of 0.71 g per g glucose were achieved in fed-batch cultivation. The C. glutamicum strain producing this imine reductase enzyme was engineered further to extend this green chemistry route to production of N-methyl-l-alanine from alternative feed stocks such as starch or the lignocellulosic sugars xylose and arabinose.

Similar content being viewed by others

Introduction

N-alkylation of amino acids occur in bacteria and eukaryotes. In green tea leaves, the N5-ethylated L-glutamine derivative theanine was shown to be responsible for their umami taste1,2. N-methylated amino acids are also found in depsipeptides that are used as drugs e.g. vancomycin, actinomycin D and cyclosporine. N-methylamino acid containing peptides often show higher stability against proteolytic degradation and/or increased membrane permeability as compared to non-methylated peptides3,4,5. Accordingly, the substitution of an N-terminal glycine residue for sarcosine in an angiotensin II analog enhanced in vivo activity as a potential result of longer half-life against proteolytic degradation6. Similar to l-proline, N-methylated amino acids are known to stabilize discrete conformations of peptides as shown for the exchange of l-pipecolic acid by N-methyl-l-alanine in the ATPase inhibitor efrapeptin C7.

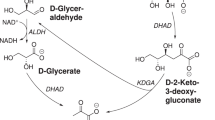

In certain bacteria, utilization of mono-methylamine (MMA) may lead to N-methylated amino acids. Some bacteria that can grow with reduced carbon substrates without carbon-carbon bonds such as methane or methanol can utilize MMA as sole source of carbon. The N-methylated amino acid N-methylglutamate occurs as an intermediate of the so-called monomethylamine catabolic pathway in representatives of these methylotrophic bacteria, e.g. Methylocella silvestris, Methyloversatilis universalis or Methylobacterium extorquens8,9,10,11. In cell free extracts of Pseudomonas MS N-methylalanine (NMeAla) was observed when MMA was added to the growth medium12. An enzyme which catalyzes the reductive methylamination of pyruvate to NMeAla in the presence of MMA was isolated and named N-methylalanine dehydrogenase (Fig. 1)13. Based on its native function of reducing piperideine-2-carboxylate in addition to the asymmetric synthesis of chiral amines this enzyme belongs to the class of imine reductases (IREDs)14,15. The corresponding gene dpkA from Pseudomonas putida ATCC12633 was identified and characterization of the encoded enzyme revealed a somewhat relaxed substrate spectrum. Since α-keto acids such as phenylpyruvate, ketohexanoate and ketoisobutyrate were accepted aside from pyruvate and the enzyme also converts other alkylamines such as N-ethylamine, it was named N-methyl-l-amino acid dehydrogenase or NMAADH16,17,18. Reductive alkylamination of α-keto acids by DpkA using MMA appears similar to reductive amination by amino acid dehydrogenases using ammonium. Yet, the structure of DpkA shows similarities to a new subclass of Nicotinamide adenine dinucleotide phosphate (NADPH)-dependent oxidoreductases with the rare SESAS (seven-stranded predominantly antiparallel β-sheet) fold for NADPH-binding19. The physiological role of NMAADH activity in pseudomonads, however, remains elusive.

Schematic overview of the reaction catalyzed by DpkA (A) and its integration into the central carbon metabolism in C. glutamicum NMeAla1 (B). The gene deletions for improved pyruvate production are shown by black arrows with red double bars: deletion of aceE (encoding PDHE1p, the E1p subunit of the PDHC) and pqo (encoding pyruvate-quinone oxidoreductase, PQO) and both genes coding both major enzymes for l-alanine supply by pyruvate aminotransferases (alaT and avtA, encoding the alanine aminotransferase AlaT and the valine-pyruvate aminotransferase AvtA, respectively) were deleted. In addition, the acetohydroxyacid synthase (AHAS) activity was downregulated by deletion of the C-terminal part of ilvN (small subunit of AHAS) shown by red dashed arrow. Enzymes highlighted by red background indicate missing or down regulated enzymes. The thick arrow displays the NMeAla formation by heterologous expressed dpkA from P. putida KT2440 coding for the N-methylated amino acid dehydrogenase DpkA (green shadowed Enzyme).

Although the formation of N-alkylated amino acids such as NMeAla has been shown during the characterization of NMAADH16,17,18, efficient production via biocatalysis or by fermentation has not yet been described. Biocatalytic approaches may offer advantages over chemical methods such as N-alkylation of amino acids or the asymmetric Strecker synthesis since the chemical methods may use hazardous chemicals, give only incomplete stereoselectivity and low yields, while side reactions like dimethylation of the amino group may occur20.

Fermentative production of amino acids, mainly l-glutamate and l-lysine, occurs at the million-ton-scale21. For more than fifty years, C. glutamicum has been used for the safe production of food and feed amino acids22,23. Besides the flavor enhancing l-glutamate24 and the feed additive l-lysine25, further amino acids and related compounds can efficiently be produced by glucose- and ammonium-based fermentation using recombinant C. glutamicum strains26,27. Metabolic engineering of C. glutamicum has not been restricted to amino acids but also production of the α-keto acids pyruvate, ketoisovalerate and ketoisocaproate28,29,30,31 were established. Taking the broad substrate range of the NMAADH from P. putida into account, it is important to engineer a host such as C. glutamicum to overproduce only one α-keto acid, in this study pyruvate.

Here we describe the one-step production of the N-methylated amino acid NMeAla from glucose and methylamine by a newly constructed C. glutamicum whole cell biocatalyst. The NMAADH gene dpkA from P. putida was expressed in a pyruvate overproducing C. glutamicum strain31. This pyruvate producing strain, named ELB-P, is able to secrete up to 17.6 g L−1 pyruvate with low by-product formation in shake flasks31. To achieve high titers of pyruvate, the genome of this strain carries deletions of the genes encoding pyruvate-converting enzymes. Starting with a pyruvate dehydrogenase gene (aceE encoding the E1p subunit) deficient strain32, which accumulates high titers of pyruvate33, additional deletion of the pyruvate-quinone oxidoreductase gene (pqo)34 and deletion of the C-terminal regulatory domain of the acetohydroxyacid synthase gene (ilvN)35,36 further increased pyruvate availability. To prevent the reduction of pyruvate to lactic acid, the ldhA (NAD-dependent l-lactic acid dehydrogenase)35 was deleted. Additionally, formation of the by-product l-alanine was reduced by deletion of the alanine aminotransferase gene (alaT) and valine-pyruvate aminotransferase gene (avtA)37 (Fig. 1). C. glutamicum ELB-P requires acetate for biomass formation as consequence of the aceE deletion and uses glucose for production of pyruvate31,38. A derivative of C. glutamicum ELB-P expressing dpkA from P. putida was constructed here and demonstrated to be suitable for the one-step production of NMeAla from MMA and glucose or alternative feedstocks.

Results

Corynebacterium glutamicum as suitable host for NMeAla production

To determine if C. glutamicum is a suitable host for the production of the N-methylated amino acid NMeAla, the growth behavior of the wild type strain was analyzed under different conditions. To test whether C. glutamicum is able to utilize MMA or NMeAla as sole carbon or nitrogen source it was grown in minimal medium with either 50 mm MMA, NMeAla or glucose as sole carbon source or with either 50 mm MMA, 50 mm NMeAla or 30 mm ammonium sulfate and 17 mm urea as nitrogen source. This growth experiment revealed that C. glutamicum could neither use MMA nor NMeAla as sole carbon or nitrogen source (data not shown).

Possible effects due to substrate or product toxicity were detected in growth experiments with C. glutamicum wild type in minimal medium with glucose and increasing concentrations of MMA (0.05 m to 1.5 m) or NMeAla (0.05 m to 0.25 m). The growth rate was diminished at higher concentrations to about half-maximal rates at 1.8 m MMA and 0.4 m NMeAla, respectively (Fig. 2). In order to determine if MMA affects global gene expression in C. glutamicum, the transcriptomes were compared during growth in glucose minimal medium containing either 250 mm MMA or 125 mm ammonium sulfate. The finding that very few genes changed expression and none had a function in nitrogen metabolism (Supplementary Table) indicated that MMA does not elicit a specific gene expression response.

Growth rates of C. glutamicum wild type in the presence of varying concentrations of MMA or NMeAla. C. glutamicum wild type was grown in presence of increasing MMA (0.05 m to 1.5 m) or NMeAla (0.05 m to 0.25 m) concentrations and specific growth rates were determined. Half maximal growth rates were obtained by extrapolation.

Metabolic engineering of C. glutamicum for fermentative production of NMeAla

The relatively small impacts of the substrate MMA and the product NMeAla on growth make C. glutamicum a suitable host organism for the fermentative production of NMeAla if a) sufficient pyruvate is available and b) NMeAla is transported out of the C. glutamicum cell. Therefore, the pyruvate overproducing C. glutamicum strain ELB-P31 was chosen as platform strain for engineering fermentative production of NMeAla. Since NMAADH activity had not been reported for C. glutamicum, the NMAADH gene dpkA from P. putida was cloned into the expression vector pVWEx1 and used to transform C. glutamicum ELB-P (Fig. 1). The resulting strain ELB-P(pVWEx1-dkpA) was designated as NMeAla1. Crude extracts of cells carrying either the empty vector or the dpkA expression vector were assayed for reductive N-methylamination of pyruvate. As presumed, no activity was detected for C. glutamicum carrying the empty vector whereas a specific activity of 24 ± 1 mU (mg protein−1) for reductive N-methylamination of pyruvate was detected in the dpkA expressing strain. This result indicates functional expression of dpkA from P. putida in C. glutamicum.

In order to test C. glutamicum strain NMeAla1 for NMeAla production, the strain was cultivated in minimal medium supplemented with 16.6 g L−1 potassium acetate, 2 mm l-Ala, 30 g L−1 glucose and 3.1 g L−1 MMA. HPLC analysis of supernatants after cultivation for 72 h revealed that C. glutamicum NMeAla1 produced 7.6 ± 0.1 g L−1 NMeAla (Fig. 3). Only 0.2 ± 0.1 g L−1 pyruvate were produced, but the by-product l-alanine accumulated to considerable concentrations (4.3 ± 0.9 g L−1; Fig. 3).

NMeAla, l-alanine, l-valine and pyruvate production data (A) and carbon balance (B) of C. glutamicum strain NMeAla1 under different conditions. Cells were cultivated in minimal medium CGXII containing 30 g L−1 or 20 g L−1 glucose and 16.6 g L−1 potassium acetate, 2 mm l-Ala and 1 mm IPTG for induction of gene expression. The nitrogen amount of the minimal medium was reduced to 50% or 10% respectively, the glucose and MMA amount were optimized to finally 20 g L−1 glucose and 10.9 g L−1 MMA. The culture supernatants were harvested after incubation for 72 h and analyzed by HPLC. (A) Concentrations are given as means with standard deviation of three replicates. n.d.: not detected. (B) To assess the fate of carbon from glucose and acetate as substrates their concentrations in gram carbon per liter is plotted. The gram carbon per liter concentrations of biomass formed (green) and of the formed products l-alanine (blue), l-valine (black), pyruvate (grey), and NMeAla (red) are plotted. For NMeAla, the carbon derived from MMA was not considered. The gram carbon per liter concentrations of CO2 and unknown byproducts are depicted in open columns. Amines < 0.1 g L−1 and carbohydrates < 0.5 g L−1 were not considered.

Improvement of precursor conversion and reduction of by-product formation

The formation of l-alanine as by-product may be due to the high concentrations of ammonium sulfate and urea present as nitrogen sources in CGXII minimal medium. CGXII minimal medium was optimized for production of l-lysine which contains two ammonium groups and reducing the nitrogen content in CGXII medium has previously been shown to improve production of l-proline and γ-aminobutyric acid that only contain a single ammonium group39,40. For production of NMeAla, MMA is used for reductive N-methylamination of pyruvate while ammonium sulfate and urea are required solely to support biomass formation. Therefore, the nitrogen amount of the minimal medium was reduced by half (2.5 instead of 5 g L−1 urea and 10 instead of 20 g L−1 ammonium sulfate) and to 10% (0.5 instead of 5 g L−1 urea and 2 instead of 20 g L−1 ammonium sulfate). Under the latter condition formation of the by-product l-alanine was diminished, however, increased pyruvate concentrations and decreased NMeAla concentrations in the supernatants indicated incomplete reductive N-methylamination of pyruvate to NMeAla (Fig. 3A). Subsequently, the MMA concentration was increased to 10.9 g L−1 and in addition the glucose concentration was reduced to 20 g L−1. As a result, only low concentrations of pyruvate, l-alanine and l-valine accumulated as by-products while a titer of 10.5 ± 0.4 g L−1 of NMeAla was obtained within 72 h (Fig. 3). To obtain an idea of the fate of carbon from glucose and acetate as substrates the concentrations of carbon present in the biomass and products formed were plotted (Fig. 3B). While E. coli shows overflow metabolism at high glucose concentrations, C. glutamicum does not22,23. Specifically, the strain used here did neither secrete acetate nor lactate due to gene deletions introduced by metabolic engineering (ΔaceE, Δpqo, ΔldhA). As expected for aerobic processes, about 50% of carbon from the growth substrates will end up in CO2. For example under the condition with 20 g L−1 glucose and 16.6 g L−1 potassium acetate (together 12 g carbon L−1), 11% carbon was found in biomass, 2% in L-alanine, 1% in L-valine, 1% in pyruvate and 31% NMeAla, while CO2 formation likely explains the fate of 55% of the carbon.

Thus, after balancing concentrations of the nitrogen and carbon sources for growth (ammonium sulfate, urea and acetate) with the substrates for production (glucose and MMA), NMeAla was produced by fermentation using C. glutamicum strain ELB-P(pVWEx1-dkpA) with a volumetric productivity of 0.15 g L−1 h−1 and a yield of 0.53 g g−1 glucose.

Fed-Batch bioreactor process of NMeAla production

To evaluate an enhancement of NMeAla production by feeding glucose and MMA a fed-batch cultivation in 4 L scale (initial volume) was performed. For higher cell density and higher production titers the fed-batch cultivation was performed with two independent feed phases (Fig. 4). The first feeding solution contained acetate and was coupled to the relative dissolved oxygen saturation (rDOS) signal with the intent to increase the biocatalyst concentration and to improve growth-associated production of NMeAla. The second feeding phase started after 22 h with an initial supply of 162 mL followed by a linear feed (12.3 mL h−1) of glucose and MMA (ratio 1:3) to boost growth-decoupled production of NMeAla. At the end of the fed-batch bioreactor process (98 h) 86.7 g acetate and 178.8 g glucose were consumed and the residual glucose concentration was 16.3 g L−1. A yield of 0.48 g NMeAla per g of acetate and glucose was achieved. Considering that growth of C. glutamicum NMeAla1 depends on acetate whereas production does not, a product yield on glucose was calculated to be 0.71 g g−1 glucose at a final titer of 31.7 g L−1 NMeAla and a volumetric productivity of 0.35 g L−1 h−1. The side-product l-alanine and the precursor pyruvate only accumulated to low concentrations (0.5 g L−1 and 2.1 g L−1, respectively). Thus, fermentative production of NMeAla in a fed-batch process resulted in enhanced final titer, volumetric productivity and yield in comparison to shake flask experiments.

Fed-batch cultivation with C. glutamicum NMeAla1 in minimal medium supplemented with potassium acetate and glucose as carbon and energy sources. A fermenter with an initial start volume of 4 L was used. First feed phase (potassium acetate) was coupled to the rDOS value. After 22 h the second feed phase was started by the initial addition of 162 mL of a glucose/MMA solution followed by a linear feed of 12.3 mL h−1. The biomass formation (black open squares), concentrations of NMeAla (red circles), l-alanine (blue squares), pyruvate (grey squares), acetate (green filled triangles) and glucose (green open triangles) were depicted. The volume of both feeds is shown as black lines. All depicted concentrations and the biomass formation was related to the initial volume.

Establishing production of NMeAla from alternative feedstocks

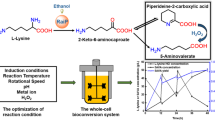

Sustainable production from sugars that have competing uses in human and animal nutrition have to be succeeded by production processes based on second generation feedstocks such as lignocellulosic hydrolysates. Fermentative production of amino acids is typically based on glucose present in molasses or obtained from starch by hydrolysis. Direct utilization of starch as well as of the pentose sugars xylose and arabinose that can be obtained by hydrolysis of lignocellulosics required metabolic engineering of C. glutamicum41. Based on these strategies the C. glutamicum strains NMeAla1(pEXCT99A-amyA), NMeAla1(pEKEx3-xylAXc-xylBCg), and NMeAla1(pEXCT99A-araBAD) were constructed and tested for production of NMeAla from starch, arabinose and xylose, respectively. Upon expression of the α-amylase gene amyA from Streptomyces griseus, C. glutamicum can utilize starch42 and C. glutamicum strain NMeAla1(pEXCT99A-amyA) produced 7.5 ± 0.1 g L−1 NMeAla in minimal medium containing 30 g L−1 starch and 16.6 g L−1 potassium acetate (Fig. 5). Heterologous expression of the arabinose utilization operon araBAD from E. coli enables C. glutamicum to utilize arabinose as carbon and energy source43,44. C. glutamicum strain NMeAla1(pEXCT99A-araBAD) produced 4.2 ± 0.5 g L−1 NMeAla in minimal medium containing 30 g L−1 arabinose and 16.6 g L−1 potassium acetate (Fig. 5). Efficient utilization of the lignocellulose pentose sugar xylose was enabled by expression of the xylose isomerase gene xylA from Xanthomonas campestris combined with overexpression of the endogenous xylulokinase gene xylB45. In CGXII minimal medium containing 30 g L−1 xylose and 16.6 g L−1 potassium acetate, C. glutamicum strain NMeAla1(pEKEx3-xylAB) produced 7.0 ± 0.1 g L−1 of NMeAla (Fig. 5). Taken together, efficient production of NMeAla from three alternative feedstocks was shown.

Production of NMeAla from alternative carbon sources. The CGXII minimal medium with 16.6 g L−1 potassium acetate contained 30 g L−1 starch for cultivation production experiments using C. glutamicum strain NMeAla1(pECXT99A-amyA), 30 g L−1 arabinose using C. glutamicum strain NMeAla1(pECXT99A-araBAD) and 30 g L−1 xylose using C. glutamicum strain NMeAla1(pEKEx3-xylAB). Concentrations were determined after 72 h and are given as means with standard deviations of three replicates.

Discussion

Fermentative access to the N-methylated amino acid NMeAla was achieved by introduction of the NMAADH gene dpkA from P. putida into the pyruvate overproducing C. glutamicum strain ELB-P. N-methyl-l-alanine titers of 31.7 g L−1 with a yield of 0.71 g per g glucose were achieved in fed-batch cultivation. The described C. glutamicum strains allow, to the best of our knowledge, the first fermentative production of NMeAla reported to date. Di-N-methyl-l-alanine, a frequent by-product in chemical methylation of l-alanine, was not observed. However, pyruvate and l-alanine accumulated as minor by-products.

l-Alanine was also a by-product of pyruvate31 and l-serine production46 although the genes alanine aminotransferase (alaT) and valine-pyruvate aminotransferase (avtA) have been deleted. Thus, at least one further l-alanine forming transaminase must be active in C. glutamicum.

Abolishing export of pyruvate and l-alanine was not possible since the export systems have not been identified. Deletion of export genes has been shown to be valuable to improve production of γ-aminobutyric acid (deletion of cgmA to abolish putrescine export)47, 5-aminovalerate and ectoine (deletion of lysine export gene lysE)48,49,50. As is the case for l-alanine, the export system for NMeAla is unknown. Given their similar structure it is conceivable that both l-alanine and NMeAla are exported by the same unknown export system. Alternatively, NMeAla may be substrate of the export system of C. glutamicum for branched-chain amino acids and l-methionine BrnEF51,52,53. The transcriptional regulator Lrp is activating transcription of brnFE at elevated intracellular concentrations of branched-chain amino acids and l-methionine54. Since N-methylation increases lipophilicity55,56, diffusion of the more lipophilic NMeAla across the cytoplasmic membrane of C. glutamicum is more relevant as compared to l-alanine. However, diffusion of amino acids across the cytoplasmic membranes of bacteria cannot explain transport processes against concentration gradients which require active transport systems. This not only holds true for charged amino acids such as l-lysine57, but also for uncharged amino acids such as l-isoleucine51,52. Future work will have to unravel the export systems of NMeAla, l-alanine and pyruvate in C. glutamicum.

In contrast, uptake of MMA into the C. glutamicum cell has been studied to some detail. The uncharged ammonia (NH3) is able to diffuse across the membrane, but its protonated form ammonium (NH4+) is actively imported by the transport proteins AmtA and AmtB58,59. Notably, as a probe for ammonium uptake, 14C-labelled MMA was used to determine uptake rates. Ammonium uptake in enteric bacteria such as E. coli operates by a comparable mechanism as shown for E. coli protein AmtB60.

The one-step process of NMeAla production will benefit from more efficient reductive N-methylamination of pyruvate by increasing the amount and/or the activity of NMAADH. Here, the NMAADH gene dpkA was cloned into the medium copy vector pVWEx1 and transcription initiated from the IPTG inducible promoter Ptrc and translation initiated from a standard ribosome binding site. Thus, as shown for expression of other genes in recombinant C. glutamicum, dpkA expression may benefit from the choice of the expression vector, the promoter and the ribosome binding site61,62,63,64.

Engineering of DpkA for more efficient reductive N-methylamination of pyruvate to yield NMeAla will also increase fermentative NMeAla production. The NMAADH DpkA used here for reductive N-methylamination of pyruvate has been shown to be part of the d-lysine degradation pathway in pseudomonads where it acts as imine reductase (IRED) reducing its native substrate piperideine-2-carboxylate18. IREDs that catalyze the asymmetric reduction of prochiral imines to chiral amines by using NAD(P)H as a hydride source are gaining increasing interest in bioorganic chemistry65,66,67,68. The substrate range is not restricted to cyclic imines and as shown for DpkA16,17,18, the (S)-selective IRED from Streptomyces sp. GF354669 and the (R)-selective IRED from Streptosporangium roseum70 also catalyze asymmetric reductive amination from suitable ketone and amine precursors. The latter reaction is expected to proceed via an imine either in solution or in the active site of the enzyme. Structure-function analysis of DkpA and other IREDs to improve asymmetric reductive amination from suitable ketone and amine precursors has not yet been described, but would be valuable to increase reductive N-methylamination of pyruvate to NMeAla by DkpA or derived variants. This approach has successfully been applied to the P450 oxidoreductase BM3 from B. megaterium71. By mutagenesis the enzyme was engineered to oxidize not only fatty acids72, but also N-alkanes73,74, the more sterically demanding β-ionone75, indole76,77 and others.

Here, we have developed a fermentative route to the N-methylated amino acid NMeAla. The biocatalytic route was based on N-methyl-l-amino acid dehydrogenase (NMAADH), which was integrated into the central metabolism of a pyruvate overproducing C. glutamicum strain. A final NMeAla titer of 31.7 g L−1 was achieved in fed-batch fermentation after balancing the ratio of the major substrates glucose and MMA. Additionally, NMeAla production from the alternative carbon sources xylose, arabinose and starch was enabled, thus, providing the basis for sustainable NMeAla production from second generation feedstocks.

Experimental

Bacterial strains and growth conditions

The strains and plasmids used in this study are listed in Table 1. E. coli DH5α78 was used for vector construction. C. glutamicum pre-cultures were grown in Lysogeny Broth (LB) medium containing 7 g L−1 sodium acetate in 500 mL baffled flask at 30 °C inoculated from a fresh LB agar plate. When necessary, the medium was supplemented with kanamycin (25 µg mL−1), spectromycin (100 µg mL−1) and/or tetracyclin (5 µg mL−1). The gene expression from the vectors pVWEx1, pEKEx3 and pECXT99A was induced by adding Isopropyl-β-D-1-thiogalactopyranoside (IPTG) (1 mm). For growth experiments or fermentative production of C. glutamicum cells were incubated in LB medium containing 7 g L−1 sodium acetate overnight on a rotary shaker, harvested (4000 × g, 7 min) and washed with TN buffer pH 6.3 (50 mm TrisHCl, 50 mm NaCl). The cells were inoculated to an optical density at 600 nm (OD600) of 1 in 50 mL CGXII minimal medium22 supplemented with 40 g L−1 glucose (wild type) or with blends of 20 or 30 g L−1 glucose, 16.6 g L−1 potassium acetate and 2 mm L-alanine (ELB-P). Growth in 500 mL baffled flasks was followed by measuring the OD600 using V-1200 Spectrophotometer (VWR, Radnor, PA, USA). The Biolector microfermentation system (m2p-labs, Aachen, Germany) was used for determination of the growth behavior in the presence of MMA or NMeAla and the carbon and nitrogen source growth tests. The shaking frequency was adjusted to 1200 rpm and 48-well flower plate wells with cultivation volumes of 1 mL were used and growth was followed by backscattered light at 620 nm and a signal gain factor of 20.

Fed-Batch cultivation

Fermentation of C. glutamicum NMeAla1 was performed in an initial working volume of 4 L in a bioreactor (7 L NLF, Bioengineering AG, Switzerland) at 30 °C, 0.2 bar overpressure, and an aeration rate of 5 NL min−1. Stirrer speed was controlled to maintain relative dissolved oxygen saturation at 30% during growth phase. Due to controlled addition of KOH (4 m) and phosphoric acid (10% (w/w)) the pH was maintained at 7.0. To avoid foaming the antifoam Struktol® J647 was added manually when necessary. The first feeding phase with 26.7 g L−1 potassium acetate solution (total volume: 500 mL) was depending on the relative dissolved oxygen saturation, it was activated when the rDOS signal rose above 60% and stopped when rDOS felt below 60%. The second feeding phase (164 g L−1 glucose and 84 g L−1 MMA (total volume: 1000 mL)) was started manually after 22 h. Samples were taken automatically every 2 hours within the first 24 h and every 8 hours afterwards and cooled to 4 °C until analysis. For fermentation a modified CGXII minimal medium was used: 5 g L−1 (NH4)2SO4, 1.25 g L−1 urea, 1 g L−1 K2HPO4, 1 g L−1 KH2PO4, 5 g L−1 yeast extract in addition to the same concentrations of trace elements and vitamins as described elsewhere18. Modified CGXII was supplemented with 15 g L−1 KAc, 20 g L−1 glucose, 9.3 g L−1 MMA and 25 µg mL−1 kanamycin. The fermenter was inoculated by addition of 450 mL of a shake flask culture grown in the described media with extra 42 g L−1 MOPS buffer.

Molecular genetic techniques and strain construction

The standard molecular genetic techniques were performed as described in Grenn and Sambrook, 2012. Transformation of E. coli DH5α78 was performed by heat shock79, plasmid DNA transfer into C. glutamicum by electroporation22.The gene dpkA was amplified from P. putida KT2440 genomic DNA by using the primers dpkA-fw (GCCAAGCTTGCATGCCTGCAGAAAGGAGGCCCTTCAGATGTCCGCACCTTCCACCAG) and dpkA-rv (GGGATCCTCTAGAGTCGACCTGCATCAGCCAAGCAGCTCTTTCA); dpkA-fw carries the RBS sequence (italicized). For higher expression rates the start codon of dpkA was changed from GTG to ATG (underlined). The vector pVWEx1 was restricted with BamHI and incubated in a Gibson assembly80 with the PCR product for construction of plasmid pVWEx1-dpkA which was used to transform C. glutamicum strains. For construction of the expression plasmid harboring the genes for arabinose degradation araBAD from E. coli was amplified using genomic DNA of E. coli MG1655 with the primers araBAD-fw (CATGGAATTCGAGCTCGGTACCCGGGGAAAGGAGGCCCTTCAGATGGCGATTGCAATTGGCCT) and araBAD-rv (GCCTGCAGGTCGACTCTAGAGGATCTTACTGCCCGTAATATGCCT); araBAD-fw carries the RBS sequence (italicized). The vector pECXT99A was incubated with BamHI for restriction and incubated with the PCR product in an Gibson assembly80 for plasmid construction. The constructed plasmid was used to transform C. glutamicum strains.

Crude extract preparation and enzyme assays

Cells for crude extracts were inoculated as described above and harvested after 20 h and stored at −20 °C. From this step cell pellets and crude extract were handled at 4 °C or on ice. 150 to 200 mg cells were resuspended in 1 mL 100 mm glycine buffer (pH 10) and sonicated (UP 200 S, Dr. Hielscher GmbH, Teltow, Germany) at an amplitude of 60% and a duty cycle of 0.5 for 9 min. Protein concentration of the cell free extracts obtained by centrifugation (20200 × g, 30 min, 4 °C) was determined by the Bradford method81 with bovine serum albumin as reference.

For determination of the reductive N-methylamination activity the assay was performed as described18. In a total volume of 1 mL containing 100 mm glycine buffer (pH 10), 60 mm MMA, 10 mm pyruvate and 0.3 mm NADPH the consumption of NADPH (epsilon = 6200 L mol−1 cm−1) was detected at 340 nm at 30 °C for 3 min. The assay was performed in at least triplicates.

Quantification of amino acids and organic acids

Extracellular amino acids and pyruvate were quantified by high-performance liquid chromatography (HPLC) (1200 series, Agilent Technologies Deutschland GmbH, Böblingen, Germany). The culture supernatants were collected and centrifuged (20200 × g, 15 min) for further analysis.

For the detection of NMeAla and l-alanine the samples were derivatised with 9-fluorenylmethyl chlorocarbonate (Fmoc-Cl) according to published methods82 with modifications39. l-proline was used as internal standard. The separation was carried out by a reversed phase HPLC using a pre-column (LiChrospher 100 RP8 EC-5 μ (40 mm × 4.6 mm), CS-Chromatographie Service GmbH, Langerwehe, Germany) and a main column (LiChrospher 100 RP8 EC-5 μ (125 mm × 4.6 mm), CS Chromatographie Service GmbH). The detection was performed with a fluorescence detector (FLD G1321A, 1200 series, Agilent Technologies) with the excitation and emission wavelength of 263 nm and 310 nm respectively.

Analysis of l-valine was performed by an automatic pre-column derivatization with ortho-phthaldialdehyde (OPA)83 and separated on a reversed phase HPLC using pre- and main column (LiChrospher 100 RP8 EC-5μ, 125 mm × 4.6 mm, CS Chromatographie Service GmbH) with l-asparagine as internal standard. Detection of the fluorescent derivatives was carried out with a fluorescence detector with an excitation wavelength of 230 nm and an emission wavelength of 450 nm. Concentrations exceeding 0.1 g L−1 were considered further.

Pyruvate, acetate and glucose concentrations were measured with an amino exchange column (Aminex, 300 mm × 8 mm, 10 μm particle size, 25 Å pore diameter, CS Chromatographie Service GmbH) under isocratic conditions for 17 min at 60 °C with 5 mm sulfuric acid and a flow rate of 0,8 mL min−1. The detection was carried out with a Diode Array Detector (DAD, 1200 series, Agilent Technologies) at 210 nm. Concentrations exceeding 0.5 g L−1 were considered further.

Transcriptome analysis using DNA microarrays

For the transcriptome analysis in the presence of MMA, C. glutamicum wild type cells were grown in minimal medium supplemented with 250 mm MMA or 125 mm ammonium sulfate to exponential growth phase and harvested at an OD600 of 4. The RNA was isolated and transcriptome analysis using whole genome microarrays were performed as described previously84.

Data availability

All data generated or analyzed during this study are included in this published article (and its Supplementary Information files).

References

Cartwright, R. A., Roberts, E. A. H. & Wood, D. J. Theanine, an amino-acid N-ethyl amide present in tea. J. Sci. Food Agric. 5, 597–599 (1954).

Sakato, Y. Studies on the Chemical Constituents of Tea. Journal of the agricultural chemical society of Japan 23, 262–267 (1950).

Chatterjee, J., Rechenmacher, F. & Kessler, H. N-methylation of peptides and proteins: an important element for modulating biological functions. Angewandte Chemie (International ed. in English) 52, 254–269 (2013).

Miller, S. M. et al. Comparison of the proteolytic susceptibilities of homologous l-amino acid, d-amino acid, and N-substituted glycine peptide and peptoid oligomers. Drug Dev. Res. 35, 20–32 (1995).

Ostresh, J. M. et al. “Libraries from libraries”: chemical transformation of combinatorial libraries to extend the range and repertoire of chemical diversity. Proceedings of the National Academy of Sciences of the United States of America 91, 11138–11142 (1994).

Turker, R. K., Hall, M. M., Yamamoto, M., Sweet, C. S. & Bumpus, F. M. A new, long-lasting competitive inhibitor of Angiotensin. Science 177, 1203–1205 (1972).

Dutt Konar, A. et al. Conformational properties of secondary amino acids: replacement of pipecolic acid by N-methyl-l-alanine in efrapeptin C. Chemistry & biodiversity 10, 942–951 (2013).

Chen, Y. et al. Glutamylmethylamide is an essential intermediate in the metabolism of methylamine by Methylocella silvestris. Applied and environmental microbiology 76, 4530–4537 (2010).

Gruffaz, C. et al. Genes of the N-methylglutamate pathway are essential for growth of Methylobacterium extorquens DM4 with monomethylamine. Applied and environmental microbiology 80, 3541–3550 (2014).

Latypova, E. et al. Genetics of the glutamate-mediated methylamine utilization pathway in the facultative methylotrophic beta-proteobacterium Methyloversatilis universalis FAM5. Molecular microbiology 75, 426–439 (2010).

Nayak, D. D. & Marx, C. J. Methylamine utilization via the N-methylglutamate pathway in Methylobacterium extorquens PA1 involves a novel flow of carbon through C1 assimilation and dissimilation pathways. Journal of bacteriology 196, 4130–4139 (2014).

Kung, H.-F. & Wagner, C. The enzymatic synthesis of N-methylalanine. Biochimica et Biophysica Acta (BBA) - General Subjects 201, 513–516 (1970).

Lin, M. C. & Wagner, C. Purification and characterization of N-methylalanine dehydrogenase. The Journal of biological chemistry 250, 3746–3751 (1975).

Mangas-Sanchez, J. et al. Imine reductases (IREDs). Current opinion in chemical biology 37, 19–25 (2017).

Schrittwieser, J. H., Velikogne, S. & Kroutil, W. Biocatalytic imine reduction and reductive amination of ketones. Adv. Synth. Catal. 357, 1655–1685 (2015).

Mihara, H. et al. N-methyl-l-amino acid dehydrogenase from Pseudomonas putida. A novel member of an unusual NAD(P)-dependent oxidoreductase superfamily. The FEBS journal 272, 1117–1123 (2005).

Muramatsu, H. et al. Enzymatic synthesis of N-methyl-l-phenylalanine by a novel enzyme, N-methyl-l-amino acid dehydrogenase, from Pseudomonas putida. Tetrahedron: Asymmetry 15, 2841–2843 (2004).

Muramatsu, H. et al. The putative malate/lactate dehydrogenase from Pseudomonas putida is an NADPH-dependent Δ1-piperideine-2-carboxylate/ Δ1-pyrroline-2-carboxylate reductase involved in the catabolism of d-lysine and d -proline. The Journal of biological chemistry 280, 5329–5335 (2005).

Goto, M. et al. Crystal structures of Δ1-piperideine-2-carboxylate/Δ1-pyrroline-2-carboxylate reductase belonging to a new family of NAD(P)H-dependent oxidoreductases: conformational change, substrate recognition, and stereochemistry of the reaction. The Journal of biological chemistry 280, 40875–40884 (2005).

Aurelio, L., Brownlee, R. T. C. & Hughes, A. B. Synthetic preparation of N-methyl-alpha-amino acids. Chemical reviews 104, 5823–5846 (2004).

Lee, J.-H. & Wendisch, V. F. Biotechnological production of aromatic compounds of the extended shikimate pathway from renewable biomass. Journal of biotechnology 257, 211–221 (2017).

Eggeling, L. & Bott, M. Handbook of Corynebacterium glutamicum (Taylor & Francis, Boca Raton, 2005).

H. Yukawa & M. Inui eds. Corynebacterium glutamicum (Springer Berlin Heidelberg, Berlin, Heidelberg, 2013).

Shimizu, H. & Hirasawa, T. In Amino Acid Biosynthesis ~ Pathways, Regulation and Metabolic Engineering, edited by Wendisch, V. F., pp. 1–38. (Springer Berlin Heidelberg, Berlin, Heidelberg, 2007).

Wendisch, V. F. In Industrial Biotechnology, edited by Wittmann, C. & Liao, J. C., pp. 361–390 (Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, Germany, 2017).

Becker, J. & Wittmann, C. Advanced biotechnology: metabolically engineered cells for the bio-based production of chemicals and fuels, materials, and health-care products. Angewandte Chemie (International ed. in English) 54, 3328–3350 (2015).

Heider, S. A. E. & Wendisch, V. F. Engineering microbial cell factories: Metabolic engineering of Corynebacterium glutamicum with a focus on non-natural products. Biotechnology journal 10, 1170–1184 (2015).

Bückle-Vallant, V., Krause, F. S., Messerschmidt, S. & Eikmanns, B. J. Metabolic engineering of Corynebacterium glutamicum for 2-ketoisocaproate production. Applied microbiology and biotechnology 98, 297–311 (2014).

Krause, F. S., Blombach, B. & Eikmanns, B. J. Metabolic engineering of Corynebacterium glutamicum for 2-ketoisovalerate production. Applied and environmental microbiology 76, 8053–8061 (2010).

Wendisch, V. F. Microbial production of amino acid-related compounds. Advances in biochemical engineering/biotechnology 159, 255–269 (2017).

Wieschalka, S., Blombach, B. & Eikmanns, B. J. Engineering Corynebacterium glutamicum for the production of pyruvate. Applied microbiology and biotechnology 94, 449–459 (2012).

Schreiner, M. E., Fiur, D., Holátko, J., Pátek, M. & Eikmanns, B. J. E1 enzyme of the pyruvate dehydrogenase complex in Corynebacterium glutamicum: molecular analysis of the gene and phylogenetic aspects. Journal of bacteriology 187, 6005–6018 (2005).

Blombach, B. et al. l-valine production with pyruvate dehydrogenase complex-deficient Corynebacterium glutamicum. Applied and environmental microbiology 73, 2079–2084 (2007).

Schreiner, M. E., Riedel, C., Holátko, J., Pátek, M. & Eikmanns, B. J. Pyruvate:quinone oxidoreductase in Corynebacterium glutamicum: molecular analysis of the pqo gene, significance of the enzyme, and phylogenetic aspects. Journal of bacteriology 188, 1341–1350 (2006).

Blombach, B. et al. Corynebacterium glutamicum tailored for efficient isobutanol production. Applied and environmental microbiology 77, 3300–3310 (2011).

Blombach, B., Hans, S., Bathe, B. & Eikmanns, B. J. Acetohydroxyacid synthase, a novel target for improvement of l-lysine production by Corynebacterium glutamicum. Applied and environmental microbiology 75, 419–427 (2009).

Marienhagen, J., Kennerknecht, N., Sahm, H. & Eggeling, L. Functional analysis of all aminotransferase proteins inferred from the genome sequence of Corynebacterium glutamicum. Journal of bacteriology 187, 7639–7646 (2005).

Wieschalka, S., Blombach, B., Bott, M. & Eikmanns, B. J. Bio-based production of organic acids with Corynebacterium glutamicum. Microbial biotechnology 6, 87–102 (2013).

Jensen, J. V. K. & Wendisch, V. F. Ornithine cyclodeaminase-based proline production by Corynebacterium glutamicum. Microbial cell factories 12, 63 (2013).

Jorge, J. M. P., Leggewie, C. & Wendisch, V. F. A new metabolic route for the production of gamma-aminobutyric acid by Corynebacterium glutamicum from glucose. Amino acids 48, 2519–2531 (2016).

Goodfellow, M. et al. Bergey’s Manual of Systematic Bacteriology. Volume Five The Actinobacteria, Part A and B (Springer New York; Imprint: Springer, New York, NY, 2012).

Seibold, G., Auchter, M., Berens, S., Kalinowski, J. & Eikmanns, B. J. Utilization of soluble starch by a recombinant Corynebacterium glutamicum strain: growth and lysine production. Journal of biotechnology 124, 381–391 (2006).

Kawaguchi, H., Sasaki, M., Vertès, A. A., Inui, M. & Yukawa, H. Engineering of an l-arabinose metabolic pathway in Corynebacterium glutamicum. Applied microbiology and biotechnology 77, 1053–1062 (2008).

Schneider, J., Niermann, K. & Wendisch, V. F. Production of the amino acids l-glutamate, l -lysine, l -ornithine and l -arginine from arabinose by recombinant Corynebacterium glutamicum. Journal of biotechnology 154, 191–198 (2011).

Meiswinkel, T. M., Gopinath, V., Lindner, S. N., Nampoothiri, K. M. & Wendisch, V. F. Accelerated pentose utilization by Corynebacterium glutamicum for accelerated production of lysine, glutamate, ornithine and putrescine. Microbial biotechnology 6, 131–140 (2013).

Zhu, Q. et al. l-Serine overproduction with minimization of by-product synthesis by engineered Corynebacterium glutamicum. Applied microbiology and biotechnology 99, 1665–1673 (2015).

Jorge, J. M. P., Nguyen, A. Q. D., Pérez-García, F., Kind, S. & Wendisch, V. F. Improved fermentative production of gamma-aminobutyric acid via the putrescine route: Systems metabolic engineering for production from glucose, amino sugars, and xylose. Biotechnology and bioengineering 114, 862–873 (2017).

Rohles, C. M., Gießelmann, G., Kohlstedt, M., Wittmann, C. & Becker, J. Systems metabolic engineering of Corynebacterium glutamicum for the production of the carbon-5 platform chemicals 5-aminovalerate and glutarate. Microbial cell factories 15, 154 (2016).

Becker, J. et al. Systems metabolic engineering of Corynebacterium glutamicum for production of the chemical chaperone ectoine. Microbial cell factories 12, 110 (2013).

Pérez-García, F., Ziert, C., Risse, J. M. & Wendisch, V. F. Improved fermentative production of the compatible solute ectoine by Corynebacterium glutamicum from glucose and alternative carbon sources. Journal of biotechnology 258, 59–68 (2017).

Ebbighausen, H., Weil, B. & Krmer, R. Transport of branched-chain amino acids in Corynebacterium glutamicum. Arch. Microbiol. 151, 238–244 (1989).

Kennerknecht, N. et al. Export of l-Isoleucine from Corynebacterium glutamicum: a two-gene-encoded member of a new translocator family. Journal of bacteriology 184, 3947–3956 (2002).

Trötschel, C., Deutenberg, D., Bathe, B., Burkovski, A. & Krämer, R. Characterization of methionine export in Corynebacterium glutamicum. Journal of bacteriology 187, 3786–3794 (2005).

Lange, C. et al. Lrp of Corynebacterium glutamicum controls expression of the brnFE operon encoding the export system for l-methionine and branched-chain amino acids. Journal of biotechnology 158, 231–241 (2012).

Biron, E. et al. Improving oral bioavailability of peptides by multiple N-methylation: somatostatin analogues. Angewandte Chemie (International ed. in English) 47, 2595–2599 (2008).

Teixidó, M. et al. Evolutionary combinatorial chemistry, a novel tool for SAR studies on peptide transport across the blood-brain barrier. Part 2. Design, synthesis and evaluation of a first generation of peptides. Journal of peptide science: an official publication of the European Peptide Society 11, 789–804 (2005).

Vrljic, M., Sahm, H. & Eggeling, L. A new type of transporter with a new type of cellular function: l-lysine export from Corynebacterium glutamicum. Molecular microbiology 22, 815–826 (1996).

Meier-Wagner, J. et al. Multiplicity of ammonium uptake systems in Corynebacterium glutamicum: role of Amt and AmtB. Microbiology (Reading, England) 147, 135–143 (2001).

Siewe, R. M. et al. Functional and genetic characterization of the (methyl)ammonium uptake carrier of Corynebacterium glutamicum. The Journal of biological chemistry 271, 5398–5403 (1996).

Soupene, E., He, L., Yan, D. & Kustu, S. Ammonia acquisition in enteric bacteria: Physiological role of the ammonium/methylammonium transport B (AmtB) protein. Proceedings of the National Academy of Sciences of the United States of America 95, 7030–7034 (1998).

Pérez-García, F., Max Risse, J., Friehs, K. & Wendisch, V. F. Fermentative production of l-pipecolic acid from glucose and alternative carbon sources. Biotechnology journal 12 (2017).

Pátek, M., Holátko, J., Busche, T., Kalinowski, J. & Nešvera, J. Corynebacterium glutamicum promoters: a practical approach. Microbial biotechnology 6, 103–117 (2013).

Rytter, J. V. et al. Synthetic promoter libraries for Corynebacterium glutamicum. Applied microbiology and biotechnology 98, 2617–2623 (2014).

Yim, S. S., An, S. J., Kang, M., Lee, J. & Jeong, K. J. Isolation of fully synthetic promoters for high-level gene expression in Corynebacterium glutamicum. Biotechnology and bioengineering 110, 2959–2969 (2013).

Gand, M. et al. A NADH-accepting imine reductase variant: Immobilization and cofactor regeneration by oxidative deamination. Journal of biotechnology 230, 11–18 (2016).

Grogan, G. & Turner, N. J. InspIRED by Nature: NADPH-dependent imine reductases (IREDs) as catalysts for the preparation of chiral amines. Chemistry (Weinheim an der Bergstrasse, Germany) 22, 1900–1907 (2016).

Maugeri, Z. & Rother, D. Reductive amination of ketones catalyzed by whole cell biocatalysts containing imine reductases (IREDs). Journal of biotechnology 258, 167–170 (2017).

Matzel, P., Krautschick, L. & Höhne, M. Photometric characterization of the reductive amination scope of the imine reductases from Streptomyces tsukubaensis and Streptomyces ipomoeae. Chembiochem: a European journal of chemical biology 18, 2022–2027 (2017).

Huber, T. et al. Direct reductive amination of ketones: Structure and activity of S -selective imine reductases from Streptomyces. ChemCatChem 6, 2248–2252 (2014).

Scheller, P. N., Lenz, M., Hammer, S. C., Hauer, B. & Nestl, B. M. Imine reductase-catalyzed intermolecular reductive amination of aldehydes and ketones. ChemCatChem 7, 3239–3242 (2015).

Whitehouse, C. J. C., Bell, S. G. & Wong, L.-L. P450(BM3) (CYP102A1): connecting the dots. Chemical Society reviews 41, 1218–1260 (2012).

Boddupalli, S. S., Pramanik, B. C., Slaughter, C. A., Estabrook, R. W. & Peterson, J. A. Fatty acid monooxygenation by P450 BM-3: product identification and proposed mechanisms for the sequential hydroxylation reactions. Archives of biochemistry and biophysics 292, 20–28 (1992).

Farinas, E. T., Schwaneberg, U., Glieder, A. & Arnold, F. H. Directed Evolution of a Cytochrome P450 Monooxygenase for Alkane Oxidation. Adv. Synth. Catal. 343, 601–606 (2001).

Peters, M. W., Meinhold, P., Glieder, A. & Arnold, F. H. Regio- and enantioselective alkane hydroxylation with engineered cytochromes P450 BM-3. Journal of the American Chemical Society 125, 13442–13450 (2003).

Zehentgruber, D., Urlacher, V. B. & Lütz, S. Studies on the enantioselective oxidation of β-ionone with a whole E. coli system expressing cytochrome P450 monooxygenase BM3. Journal of Molecular Catalysis B: Enzymatic 84, 62–64 (2012).

Li, Q. S., Schwaneberg, U., Fischer, P. & Schmid, R. D. Directed evolution of the fatty-acid hydroxylase P450 BM-3 into an indole-hydroxylating catalyst. Chemistry (Weinheim an der Bergstrasse, Germany) 6, 1531–1536 (2000).

Li, H.-m, Mei, L.-h, Urlacher, V. B. & Schmid, R. D. Cytochrome P450 BM-3 evolved by random and saturation mutagenesis as an effective indole-hydroxylating catalyst. Applied biochemistry and biotechnology 144, 27–36 (2008).

Hanahan, D. Studies on transformation of Escherichia coli with plasmids. Journal of molecular biology 166, 557–580 (1983).

Green, M. R. & Sambrook, J. Molecular cloning. A laboratory manual. 4th ed. (Cold Spring Harbor Laboratory Press, Cold Spring Harbor, N.Y., 2012).

Gibson, D. G. et al. Enzymatic assembly of DNA molecules up to several hundred kilobases. Nature methods 6, 343–345 (2009).

Bradford, M. M. A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Analytical biochemistry 72, 248–254 (1976).

Schneider, J., Eberhardt, D. & Wendisch, V. F. Improving putrescine production by Corynebacterium glutamicum by fine-tuning ornithine transcarbamoylase activity using a plasmid addiction system. Applied microbiology and biotechnology 95, 169–178 (2012).

Schneider, J. & Wendisch, V. F. Putrescine production by engineered Corynebacterium glutamicum. Applied microbiology and biotechnology 88, 859–868 (2010).

Wendisch, V. F. Genome-wide expression analysis in Corynebacterium glutamicum using DNA microarrays. Journal of biotechnology 104, 273–285 (2003).

Peters-Wendisch, P. G. et al. Pyruvate carboxylase is a major bottleneck for glutamate and lysine production by Corynebacterium glutamicum. Journal of molecular microbiology and biotechnology 3, 295–300 (2001).

Stansen, C. et al. Characterization of a Corynebacterium glutamicum lactate utilization operon induced during temperature-triggered glutamate production. Applied and environmental microbiology 71, 5920–5928 (2005).

Kirchner, O. & Tauch, A. Tools for genetic engineering in the amino acid-producing bacterium Corynebacterium glutamicum. Journal of biotechnology 104, 287–299 (2003).

Acknowledgements

We want to thank Irene Kran from the Department of Genetics of Prokaryotes for cloning the plasmid pECXT99A-araBAD and Thomas Schäffer from the Department of Fermentation Technology for his support during fed-batch fermentations. We acknowledge support for the Article Processing Charge by the Deutsche Forschungsgemeinschaft and the Open Access Publication Fund of Bielefeld University.

Author information

Authors and Affiliations

Contributions

M.M. and H.G. performed experiments. M.M., V.F.W., J.M.R., N.S. and B.J.E. planned the study. M.M. and V.F.W. drafted the manuscript, all authors revised the manuscript and agreed to the final version.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mindt, M., Risse, J.M., Gruß, H. et al. One-step process for production of N-methylated amino acids from sugars and methylamine using recombinant Corynebacterium glutamicum as biocatalyst. Sci Rep 8, 12895 (2018). https://doi.org/10.1038/s41598-018-31309-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-018-31309-5

This article is cited by

-

Formamide-based production of amines by metabolically engineering Corynebacterium glutamicum

Applied Microbiology and Biotechnology (2023)

-

Insect antimicrobial peptides: potential weapons to counteract the antibiotic resistance

Cellular and Molecular Life Sciences (2021)

-

Enhancement of substrate supply and ido expression to improve 4-hydroxyisoleucine production in recombinant Corynebacterium glutamicum ssp. lactofermentum

Applied Microbiology and Biotechnology (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.