Abstract

The microalgae-based technology has been developed to reduce biogas slurry nutrients and upgrade biogas simultaneously. In this work, five microalgal strains named Chlorella vulgaris, Scenedesmus obliquus, Selenastrum capricornutum, Nitzschia palea, and Anabaena spiroides under mono- and co-cultivation were used for biogas upgrading. Optimum biogas slurry nutrient reduction could be achieved by co-cultivating microalgae (Chlorella vulgaris, Scenedesmus obliquus, and Nitzschia palea) with fungi using the pelletization technology. In addition, the effects of different ratio of mixed LED light wavelengths applying mixed light-emitting diode during algae strains and fungi co-cultivation on CO2 and biogas slurry nutrient removal efficiency were also investigated. The results showed that the COD (chemical oxygen demand), TN (total nitrogen), and TP (total phosphorus) removal efficiency were 85.82 ± 5.37%, 83.31 ± 4.72%, and 84.26 ± 5.58%, respectively at red: blue = 5:5 under the co-cultivation of S. obliquus and fungi. In terms of biogas upgrading, CH4 contents were higher than 90% (v/v) for all strains, except the co-cultivation with S. obliquus and fungi at red: blue = 3:7. The results indicated that co-cultivation of microalgae with fungi under mixed light wavelengths treatments was most successful in nutrient removal from wastewater and biogas upgrading.

Similar content being viewed by others

Introduction

Increasing energy demands and declining supplies of fossil energy resources have attracted significant attention worldwide1. In many places, biogas, as an environmentally friendly renewable energy, is a promising substitute for fossil fuel2,3,4. Biogas produced from landfill and anaerobic digestion processes mainly consists of CH4 (50–75% by volume) and CO2 (25–50% by volume)5. Crude biogas also contains trace amounts of other gases, such as H2S, NH3, N2, O2, CO, and H2O6. Some of these impurities represent health risks for humans and result in increased gas emissions7. A number of applications, such as grid injection and vehicle use, require the removal of the high proportions of CO2 in biogas to produce a gas with characteristics similar to natural gas8. In order to increase the calorific value and decrease the relative density of biogas, it is important to upgrade raw biogas by removing CO2 to reach a higher fuel standard9.

Biogas is currently experiencing a rapid development, and biogas upgrading is going to be an increasing concern in the bioenergy industry of the future. Biogas upgrading is facing the challenges of energy consumption, operating costs, and environmental risks such as eutrophication4. Biogas slurry is a vital byproduct of biogas development, and its processing remains a significant challenge10.

The use of microalgae plays a vital role in reducing biogas slurry nutrients and in upgrading biogas, representing a promising technology. Simultaneously, biogas slurry can supply high concentrations of nutrients such as carbon, nitrogen, and phosphorus to produce high microalgae biomass for the production of biochemicals and biofuels11. Bhatnagar et al.12, and Yan et al.13 suggested that CO2 in biogas and nutrients in biogas slurry could be directly removed by microalgae. Both inorganic carbons derived from biogas or organic carbon from biogas slurry could be used to improve microalgae production. Microalgae have extremely high photosynthetic efficiency and carbon biofixation rates, thereby removing CO2 and upgrading biogas; they also show a synergistic effect between biogas CO2 assimilation and nutrient removal from biogas.

To harvest microalgae, an integrated approach of co-cultivating microalgae with fungi was used in one study; during flocculation, the dispersed algae cells could aggregate and form larger particles14. To effectively harvest algae biomass and to establish this symbiosis, it is necessary to develop an effective fungal-algal symbiosis system to assist bioflocculation and to support the removal of wastewater nutrients through immobilized cells15. Wrede et al.16 and Muradov et al.17 investigated the co-cultivation of microalgae with fungi to remove nutrients from wastewater and generate biomass. Their results indicated that this technique has an exceptional ability to purify wastewater and generate biomass; such obtained biomass represents a renewable and sustainable feedstock for biofuel production. Manheim et al.18 and Van Den Hende et al.19 studied the co-cultivation of microalgae with activated sludge to remove nutrients from wastewater, to decrease gas discharge levels, and to produce biomass; the large potential for the application of microalgal bacterial flocs for flue gas sparged sewage treatment. Many factors influence the efficiency of biogas purification and biogas slurry nutrient removal in a photobioreactor (PBR). Combining these two processes is a practical technique since they could promote each other13. In a previous study, the effects of mixed light-emitting diode (LED) wavelengths on microalgae growth rates, biogas slurry nutrient removal, and biogas CO2 removal were larger than those of monochromatic light wavelengths. A LED is an ideal tool to emit radiation of specific wavelengths to study the influence of light quality on microalgae cultures20. Chen et al.21 and Das et al.22 stated that red light and blue light were the most important light qualities for microalgal growth. A mix of these two lights could improve growth rates and lipid accumulation of microalgae by enhancing the effects of photosystems I and II.

So far, only a limited number of studies have assessed the combination of three different treatments, microalgae mono-cultivation, microalgae co-cultivation with fungi, and microalgae co-cultivation with activated sludge, in biogas upgrade and biogas slurry nutrients removal. The present study therefore focuses on microalgal strain growth, biogas upgrade, and biogas slurry nutrient reduction using five selected microalgae strains in three cultivation treatments. These five strains used in this work were selected on account of their high growth rates (in the range of 0.327–0.451 d−1) and strong nutrient removal ability (more than 60% removal of COD) in wastewater on the basis of our previous research11. In the first step, we select the optimal microalgal strains in terms of growth rate and mean daily productivity and then choose the optimum cultivation technology. Subsequently, we evaluate CO2 removal and slurry nutrient reduction under different mixed LED light wavelengths, red light and blue light treatments, based on the studied biogas upgrading and biogas slurry purification methods. Based on the results, we then select the optimal strain under the appropriate ratio of red light and blue light for biogas upgrading and biogas slurry nutrient removal. The optimal parameters are determined by analyzing growth rates and mean daily productivity as well as nutrient removal efficiency and biogas purification.

Results and Discussion

Growth of the five selected strains under different treatments

Table 1 shows the experimental data for the five microalgal strains (C. vulgaris, S. obliquus, S. capricornutum, N. palea, and A. spiroides) in terms of growth rates and mean daily productivity under cultures 1, cultures 2, and cultures 3. In general, growth rates were lower under cultures 1 compared to cultures 2 and cultures 3. Cultures 2 has higher growth rates, which was in agreement with the findings of Zhou et al.15 and Wrede D.16, who observed that cultures 2 is highly effective in terms of bioflocculation of microalgal cells and did not require additional chemicals and low energy inputs. Cultures 3 resulted in higher growth rates than cultures 1, but lower than cultures 2. This is because filamentous fungi and activated sludge can potentially entrap or immobilize the microalgae by forming bioflocculation due to their unique filamentous properties23, 24. Similar results have been reported by Manheim et al.18 and Oh et al.25, who found that bioflocculation by bacteria and their exudates could improve the microalgae settling. Among the five studied microalgal strains in cultures 1, C. vulgaris and S. obliquus had the relatively high growth rates in all microalgae, respectively, while A. spiroides showed the lowest rate. Similarly, mean daily productivity of C. vulgaris and S. obliquus were higher than A. spiroides. S. obliquus and C. vulgaris had the highest growth rates in cultures 2 and 3, respectively, and A. spiroides showed the lowest. Lee et al.26 increased the tolerance of microalgae to high levels of CO2 and nutrients by enhancing the initial microalgal cells density. Microalgal growth could be controlled by microalgae cell density, CO2 levels in the biogas, and nutrients in the biogas slurry. Biomass productivity can therefore be a vital parameter to evaluate the CO2 and organic carbon removal potential of systems. As seen in Table 1, the cultures 2 and cultures 3 had higher microalgae biomass values than the cultures 1, resulting in higher growth rates. In all three treatments, C. vulgaris and S. obliquus had the highest mean daily productivity values, while A. spiroides had the lowest values. These results suggest that co-cultivation significantly can promote microalgal growth. The fungi improve the microalgal growth mainly on account of the characteristic of fungal cell self-pelletization, which are usually applied for pollutants removal from wastewater27, 28. The fungal cell self-pelletization capacity is connected with amphipathic and hydrophobic protein on the hyphal surface, which are adhered to the hyphae29. Although the detailed mechanisms of fungal-algal interactions were still unclear, the consensus is the interaction between oppositely charged surfaces may accelerate microalgae absorption by fungal cell wall16, 17, 27. Besides, microscopic analysis of algal-fungal pellets demonstrated algal cells was twined by fungal filaments and stick to them16, 17.

Nutrient removal efficiencies of the different treatments

Nutrient removal from the biogas slurry varied between the three treatments. Table 2 shows the mean COD, TN and TP removal efficiency over 10 days. The combinations Gl/C. vulgaris and Gl/S. obliquus were most effective in COD removal (P < 0.05), while the lowest removal efficiencies were observed for S. capricornutum and A spiroides. In cultures 2 and cultures 3, COD reduction efficiency of S. obliquus reached 75.67 ± 5.78 and 71.76 ± 5.71%, respectively. The five microalgal strains can survive depending on the supply of organic substrates from biogas slurry, and sustain both heterotrophic and autotrophic growth with CO2 as the sole carbon source30. The carbon content in microalgal biomass exceeds 50%, which demonstrates the importance of carbon assimilation into biomass on microalgal cells formation30, 31. Based on our results, the strains C. vulgaris, S. obliquus, and N. palea can be effectively used in the removal of COD from biogas slurry. This indicates that the appropriate selection of microalgae strains in cultures 2 were effective strategies to enhance COD removal efficiency.

Among the five strains, S. obliquus achieved a significantly higher (P < 0.05) TN removal efficiency of 74.57 ± 5.87 and 76.44 ± 5.93% in cultures 2 and cultures 3, respectively, while S. capricornutum and A. spiroides showed the lowest TN removal efficiencies in the three treatments. The TN is the sum concentration of organic, nitrate, and ammonia nitrogen, while the nitrogen supporting microalgal growth in biogas slurry is ammonia nitrogen32. Microalgal reproduction requires sufficient ammonia nitrogen to build nucleic acids and proteins33. The combinations Gl/C. vulgaris, Gl/S. obliquus, and Gl/N. palea did not significantly vary with respect to TN removal efficiency (P > 0.05). However, their efficiencies were significantly higher (P < 0.05) than those of Gl/S. capricornutum and Gl/A. spiroides. The TN removal efficiencies of S. capricornutum and A. spiroides were significantly lower (P < 0.05) than those of the other microalgal species in cultures 1 and cultures 3 treatments. Tan et al.32 evaluated the diluted biogas slurry TN removal and C. vulgaris showed the highest of 65.87 ± 4.71, which was close to our results. However, when C. vulgaris was cultivated with fungus or activated sludge, the TN removal efficiencies reached more than 71% and 75%, which revealed the superiority of cocultivation technology. It is claimed that microalgal-bacterial doesn’t produce NH4 + because the photoautotrophic microalgae assimilate NH4 + as their most preferred nitrogen source, which is unlike the biological treatment processes based on bacterial only34.

Phosphorus plays a pivotal role in algal production as a constituent of phospholipids and adenosine triphosphate. The highest TP removal efficiency can be found in combinations Gl/C. vulgaris, which is 17.7% higher than Gl/S. capricornutum (the lowest). Sun et al.35 measured TP removal efficiencies of co-cultivation of C. vulgaris, S. obliquus, and N. oleoabundans with activated sludge with different CO2 concentrations, respectively and reported the TP removal efficiency in the range of 57.92 and 74.11%, which are in keeping with our results. As a result, C. vulgaris achieved a significantly higher (P < 0.05) TP removal efficiency in the selected five strains, and cultures 2 showed a significantly higher (P < 0.05) TP removal efficiency among the three cultivation treatments. The high TP removals of cocultivation of fungi with microalgae (culture 2) is associated with carbohydrate content in microalgae, the high COD reduction accelerate the TP migration36. It will result in higher microalgal-bacterial activity and higher TP removals mainly on account of the low dissolved oxygen in the biogas slurry, thus a higher CO2 are available for photosynthesis37.

Biogas upgrading

The CH4 concentration represented the biogas upgrade level, the higher CH4 concentration, the higher biogas upgrade level. According to Tables 2 and 3, in cultures 2 and cultures 3, CO2 could be significantly removed from biogas (P < 0.05). The P-values for the CH4 parameter in Table 3 show that the interaction of the three different cultivation treatments and microalgae strains significantly influenced CH4 concentrations (P < 0.05), while there were no significant effect of microalgae strains on CH4 concentration (P > 0.05). In the present study, the combination Gl/S. obliquus had the highest CH4 concentration (90.35 ± 3.77%), which was significantly higher than other treatments (P < 0.05). The high CO2 reduction using C. vulgaris lead to the CH4 enrichment because of the photosynthesis of microalgae. Therefore, cultures 2 seemed to be the optimal treatment for biogas upgrading. Moreover, high mean daily productivity (g L−1 d−1) of microalgae and nutrient removal efficiency showed that C. vulgaris can effectively be used in biogas purification, followed by S. obliquus. In cultures 2 and cultures 3, most of the fungal-microalgal pellets could efficiently remove CO2 from biogas and reach the efficient combustion standard when the CH4 concentration > 90% (v/v)8, with the exception of using A. spiroides and S. capricornutum. The microalgal strains can change their metabolic pathway based on the amounts of organic substrates, such as organic acids and glucose, suggesting that they can grow by heterotrophic way in addition to common autotrophic growth and use CO2 as the sole carbon source30.

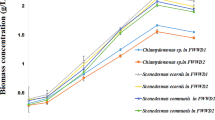

Microalgae-fungal strain growth at various mixed LED light wavelength treatments

Table 4 presents the daily productivity of Gl/C. vulgaris, Gl/S. obliquus, and Gl/N. palea over a period of 10 days under various mixed LED light wavelength treatments. Gl/S. obliquus has the maximal mean daily productivity of 0.353 ± 0.019 under the mixed LED light wavelength ratio of red: blue = 5:5. In all treatments, the mean daily productivity of mixed LED light wavelength ratio red: blue = 5:5 was the highest. The microalgae grown better under mixed LED light wavelength treatments than the white LED light wavelength when compared with the results showed in Table 1. The results are in agreement with the findings of Yan et al.38, who compared the effects of three mixed and white LED light wavelength treatments on growth of Chlorella sp. When fungi were cultured with microalgae in biogas slurry, the fungal were pelletized through bioflocculation and non-bioflocculation. The cocultivation way resulted in the large specific surface area of algae-fungi symbionts and the nutrient intake capacity39.

Nutrient removal efficiencies at various mixed LED light wavelength treatments

COD removal efficiency in various ratios of mixed red and blue LED light wavelengths during a 10-day culture are shown in Fig. 1. The combinations Gl/C. vulgaris, Gl/S. obliquus, and Gl/N. palea showed similar trend of COD removal efficiencies (Fig. 1a–c) under different mixed light wavelength ratio of red: blue. It was increased dramatically in the first six days, and then slightly increased in the following days. The combinations Gl/C. vulgaris, Gl/S. obliquus, and Gl/N. palea showed the highest COD removal efficiency (more than 90%) at the 7th, 9th, and 8th day, respectively. The removal efficiency finally decreased until the 10th day under the mixed LED light wavelength ratio of red: blue = 5:5. The COD removal efficiency achieved by Gl/S. obliquus in red: blue = 5:5 was significantly higher than those of the other treatments (p < 0.05). Research has shown that fungi can consume carbohydrates and other nutrients produced during the photosynthesis of microalgae. The fungi will also capture the minerals and other nutrients because of its water-retaining property40. Therefore, red: blue = 5:5 was considered as the optimal mixed light wavelength ratio of red: blue for COD removal using Gl/S. obliquus treatment (Table 4).

Figures 2 and 3 shows the TN and TP removal efficiency in various mixed red and blue LED light wavelengths ratios during a 10-day culture, respectively. The combinations Gl/C. vulgaris, Gl/S. obliquus, and Gl/N. palea pellets of TN and TP removal efficiency under different light qualities (Figs 2 and 3) increased dramatically within 7 and 5 days. Gl/S. obliquus has the highest TN removal efficiency on the 9th day, while the combinations Gl/C. vulgaris and Gl/N. palea achieved relatively high TP removal efficiencies on the 7th and 8th day, respectively. As seen in Table 4, the maximum mean TN removal was also found when using Gl/S. obliquus under the wavelength ratio of red: blue = 5:5. To be different, Gl/S. obliquus (92.34%) showed the highest TP removal efficiency in the 9th day under red: blue light wavelength ratio of 7:3. The maximal mean TP removal efficiency (84.26%) of Gl/S. obliquus was found under the wavelength ratio red: blue of 5:5. These findings revealed that the selected mixed wavelength light for microalgal growth improved the photosynthetic efficiency. The adequate ratio of mixed red and blue light source is good for nitrogen and phosphorus capturing from biogas slurry. It is an efficient alternative way to increase nitrogen and phosphorus removal rates41. Predilection of red or blue light in the mix leads to a negative effect on phosphorus removal. As a result, the appropriate mixed LED light wavelength ratio of red: blue for TN removal using Gl/S. obliquus is 5:5 when in view of the COD and TN removal efficiency.

Biogas upgrading at various mixed LED light wavelength treatments

Gl/C. vulgaris, Gl/S. obliquus, and Gl/N. palea were used for CO2 removal in a 10-day culture (Fig. 4a–c; Table 4). The CH4 content first increased dramatically, and then slightly increased in the following days. However, the CO2 removal efficiency of Gl/N. palea almost increased throughout the 10 days. All three strains under the three different mixed LED light wavelength treatments resulted in more than 90% of CH4 in biogas, which were equivalent to those of natural gas. The CH4 amount under mixed LED light wavelength ratio red: blue of 7:3 was higher than those of 5:5 and 3:7, respectively. However, Yan et al. found that Chlorella sp. increased microalgal growth and achieved the highest CO2 removal efficiency under the mixed LED light wavelength ratio red: blue of 5:513, 38. Therefore, red and blue light with the wavelength of 620–750 nm and 476–495 nm are beneficial to the photosynthesis of microalgae, the suitable mix ratio are better for the growth of microalgae than providing a single wavelength38. The microalgal reproduction is largely dependent on the utilizable light wavelengths. With the optimal mixed LED light wavelength ratio red: blue of 7:3 cause an efficient CO2 removal efficiency. This phenomenon was different from the results of Yan and Zheng mainly because of the different microalgal strains42. So, Gl/N. palea could achieve the highest CO2 removal efficiency under the mixed LED light wavelength ratio red: blue of 7:3.

Conclusions

Co-cultivation of microalgae with fungi or activated sludge showed higher growth rates and mean daily productivity when compared to mono-cultivation. Among the five strains, C. vulgaris, S. obliquus, and N. palea achieved the nearly high COD, TN, TP, and CO2 removal efficiency in cultures 2. Biomass growth was not always directly related to nutrient and CO2 removal. Although S. obliquus demonstrated the highest growth efficiency in the three treatments, it was not the best for TP and CO2 removal efficiencies. Based on our results, the mixed LED light wavelength ratio red: blue of 5:5 for nutrients removal using Gl/S. obliquus was recommended as the optimum. Meanwhile, the mixed LED light wavelength ratio red: blue of 7:3 using Gl/N. palea yielded optimal results in terms of CO2 removal. Thus, the microalgae-based photo-bioreactor used in this study can effectively upgrade biogas and reduce nutrients simultaneously.

Methods and Materials

Collection of algal and fungi strains and culturing conditions

We selected five microalgae strains, Chlorella vulgaris (C. vulgaris; FACHB-31), Scenedesmus obliquus (S. obliquus; FACHB-416), Selenastrum capricornutum (S. capricornutum; FACHB-271), Nitzschia palea (N. palea; FACHB-211), and Anabaena spiroides (A. spiroides; FACHB-498). All strains were obtained from the Institute of Hydrobiology at the Chinese Academy of Sciences. The strains C. vulgaris, S. obliquus, and A. spiroides were preserved in standard BG11 medium, while N. palea was preserved in CSI medium and S. capricornutum in SE medium. The culturing conditions were as follows: white LED light with an intensity of 200 μmolm−2 s−1, 25 ± 0.5 °C, light: dark = 14 h: 10 h, and artificial intermittent shaking four times a day.

A strain of the fungus Ganoderma lucidum (G. lucidum; 5.765) was obtained from the China General Microbiological Culture Collection Center. After a three-day pre-cultivation, the G. lucidum spores were washed from the potato dextrose agar (PDA) medium with sterile water and transferred into 1 L potato dextrose broth (PDB) medium. The spore solution was then cultivated at 28 ± 0.5 °C. To obtain pellets, spore solutions were cultivated at 28 ± 0.5 °C for 72 h in a 1 L synthetic medium (glucose, 10 g·L−1; NH4NO3, 2.0 g·L−1; K2HPO4, 1.0 g·L−1; NaH2PO4·H2O, 0.4 g·L−1; MgSO4·7H2O, 0.5 g·L−1; and yeast extract, 2.0 g·L−1; pH 6.5). Algal cultures were concentrated, washed and resuspended to achieve a final concentration of 103.26 ± 7.39 mg L−1 before being added to the collected fungus for pelletization. The fungal-algal mixtures were shaken at 160 rpm for 48 h under constant light (200 μmol·m−2 s−1) and kept under a light-dark cycle of 14 h: 10 h at 25 ± 0.5 °C.

The five selected algae strains were cultivated in biogas slurry, which was inoculated with 1 L of a 0.75 g total suspended solid (TSS) L−1 and 200 mL of a 4.14 g TSS L−1 nitrifying-denitrifying activated sludge from a wastewater treatment plant in Shanghai, China. The initial concentration of TSS in the cultivation biogas slurry was about 0.06 g·L−1.

Photobioreactor (PBR)

The PBR was formed by two interconnected and individual 16.8 L glass cylinder blocks (Fig. 5). The two cylinder blocks had a total height of 0.6 m and a diameter of 0.2 m. The PBR were hermetically sealed with rubber stoppers. The biogas slurry was filtered using a glass microfiber filter (GF/C; Whatman, USA) to remove large particles before being sterilized with an ultraviolet sterilizer (SKW-UVU01; SKYUV Water Treatment Co. Ltd, China) for 2 min, and then pumped into the right tank. Biogas slurry (2.8 L) was pumped from the right to the left cylinder block of the PBR. Raw biogas (14 L) was injected into the left reactor. The mono-cultured microalgae, fungal-microalgal pellets and microalgae assisted with activated sludge were added to the left reactor before being illuminated by LED lights at 200 μmol m−2 s−1 arranging in a circular configuration (20 W, 110 V). The carbon, nitrogen and phosphorus in biogas slurry will provide the nutrient for microalgae growth. The CO2 in biogas and light will provide raw materials for photosynthesis of microalgae. The biogas in PBR was sampled from the upside of PBR for gas component analysis every 24 h after the PBR started. The biogas slurry was sampled from the downside of the PBR for analysis of COD, TN and TP.

Table 5 shows the characteristics of the biogas slurry and crude biogas for the three treatment technologies in this work. Crude biogas was fed via PBR headspace. We determined the effects of the appropriate technology under different mixed LED light wavelength treatments on the growth rate, mean daily productivity, nutrient removal efficiency, and biogas purification. The culture conditions were similar to algal and fungi strains and culturing conditions. The microalgae were cultured for 10 days.

Biogas slurry and biogas

Biogas was obtained from a farm biogas plant in JiaYuan Green Meadow. Prior to the experiments, biogas was desulfurized in chemical absorption reactors to reduce H2S concentration to value below 100 ppm.

Experimental procedure

Experiment 1

Mono-cultivation of microalgae (cultures 1): Microalgal suspensions (100 mL; 119.72 ± 8.13 mg·L−1 dry weight) of C. vulgaris, S. obliquus, S. capricornutum, N. palea, and A. spiroides were prepared.

Co-cultivation of microalgae with fungi (cultures 2): Microalgal suspensions (100 mL; 115.63 ± 7.39 mg·L−1 dry weight) of C. vulgaris, S. obliquus, S. capricornutum, N. palea, and A. spiroides were prepared, and each suspension was mixed with 5 mL of G. lucidum pellet suspension (78.34 ± 6.05 mg·L−1 dry weight). The initial density of the microalgae co-cultivated with fungal cells was maintained constant at 117.47 ± 5.98 mg·L−1.

Co-cultivation of microalgae with activated sludge (cultures 3): The biogas slurry was inoculated with 1 L of a 1.50 g TSS L−1 for each microalgal strain culture and with 200 mL of an 8.39 g TSS L−1 nitrifying-denitrifying activated sludge from a wastewater treatment plant in Shanghai, China. Initial TSS concentration in the cultivation broth of the biogas slurry was 121.06 ± 6.36 mg·L−1. The amount of bacteria inoculated in the biogas slurry was twice as high as that of the microalgae to ensure a rapid biodegradation start-up.

Initial dry weight of mono-cultivation of microalgae, co-cultivation of microalgae with fungi, and co-cultivation of microalgae with activated sludge before being injected the PBR was about 120 mg·L−1. The experiment was conducted 25.0 ± 0.5 °C with the light intensity of 200 μmol m−2 s−1 and a white light-dark cycle of 14: 10 h (light was provided only from 8:00 am. to 10:00 pm.) for 10 d (240 h).

Experiment 2

The optimal ratios of mixed LED light wavelengths for efficient nutrient removal of biogas slurry and biogas purification under the selected cultivation treatment were studied at various light wavelength ratios of red: blue (3:7, 5:5, and 7:3) at constant light intensity of 200 μmol m−2 s−1 for the left-cylinder block over 10 days. In this experiment, the PBR was also filled with 14 L of raw biogas and 2.8 L of biogas slurry. All treatments were performed at a temperature of 25.0 ± 0.5 °C and a light: dark cycle of 14: 10 h.

The effects of different treatments on biogas upgrading and biogas slurry purification as well as on microalgal growth were evaluated in two steps. The first step was to select three dominant microalgal strains under the irradiation of the same white light. In the second step, the optimization of biogas slurry purification and biogas upgrading technology using the selected three strains in the first step based on different mixed light wavelength control strategy.

Sampling and analyses

All treatments in all PBRs were sampled daily from the beginning of the inoculation. The dry weight was measured as follows: Culture suspensions of 100 mL were filtered using a glass microfiber filter (GF/C, Whatman, USA). The microalgae were then attached to the filter, which was subsequently dried at 100 °C for 24 h and then cooled to room temperature in a desiccator. Finally, dry weight was calculated from the difference between the filter weights before and after filtration. Concentrations of CH4, and CO2 (v/v) in the biogas were analyzed by a gas analyzer (GA94, ONUEE Co., Ltd., China)13. The culture filtrates were analyzed for COD, TN, and TP concentrations by using standard methods43.Biomass productivity (P, g L−1 d−1) was calculated using Eq. (1):

Specific growth rate (µ) was calculated using Eq. (2)44:

where D i is the biomass concentration (g L−1) at time t i (d) and D 0 is the initial biomass concentration (g L−1) at t0 (d).Biogas CO2 or nutrient removal efficiency (R, %) was calculated using Eq. (3):

where C i is the biogas CO2 content (%, v/v) or nutrient concentration (g L−1) in the filtrates of the cultures at time t i and C 0 is the initial biogas CO2 content (%, v/v) or nutrient concentration (g L−1) at t 0 (day).

Statistical analyses

One-way analysis of variance (ANOVA) was used to test the statistical difference of the related parameters of the five algae strains using the same light treatment technology. Duncan’s multiple range tests were used to further assess differences among those algae strains that were significant in ANOVA. Two-way ANOVA was used to test for differences between the effects of treatment technology, algae strains, and to detect possible interactions between any two of these factors and their impacts on treatment performance. P = 0.05 and P = 0.01 were used as thresholds for statistical significance. All analyses were performed using SPSS (V19.0).

References

Brennan, L. & Owende, P. Biofuels from microalgae—A review of technologies for production, processing, and extractions of biofuels and co-products. Renewable and Sustainable Energy Reviews 14, 557–577, doi:10.1016/j.rser.2009.10.009 (2010).

Fatih Demirbas, M., Balat, M. & Balat, H. Biowastes-to-biofuels. Energy Conversion and Management 52, 1815–1828, doi:10.1016/j.enconman.2010.10.041 (2011).

Yadvika, S., Sreekrishnan, T. R., Kohli, S. & Rana, V. Enhancement of biogas production from solid substrates using different techniques—a review. Bioresource Technology 95, 1–10, doi:10.1016/j.biortech.2004.02.010 (2004).

Holm-Nielsen, J. B., Al Seadi, T. & Oleskowicz-Popiel, P. The future of anaerobic digestion and biogas utilization. Bioresource Technology 100, 5478–5484, doi:10.1016/j.biortech.2008.12.046 (2009).

Xia, Z.-M. et al. Hydrate-based CO2 capture and CH4 purification from simulated biogas with synergic additives based on gas solvent. Applied Energy 162, 1153–1159, doi:10.1016/j.apenergy.2015.02.016 (2016).

Abdeshahian, P., Lim, J. S., Ho, W. S., Hashim, H. & Lee, C. T. Potential of biogas production from farm animal waste in Malaysia. Renewable and Sustainable Energy Reviews 60, 714–723, doi:10.1016/j.rser.2016.01.117 (2016).

Sun, Q. et al. Selection of appropriate biogas upgrading technology-a review of biogas cleaning, upgrading and utilisation. Renewable and Sustainable Energy Reviews 51, 521–532, doi:10.1016/j.rser.2015.06.029 (2015).

Ryckebosch, E., Drouillon, M. & Vervaeren, H. Techniques for transformation of biogas to biomethane. Biomass and Bioenergy 35, 1633–1645, doi:10.1016/j.biombioe.2011.02.033 (2011).

Tippayawong, N. & Thanompongchart, P. Biogas quality upgrade by simultaneous removal of CO2 and H2S in a packed column reactor. Energy 35, 4531–4535, doi:10.1016/j.energy.2010.04.014 (2010).

Xia, A. & Murphy, J. D. Microalgal Cultivation in Treating Liquid Digestate from Biogas Systems. Trends in Biotechnology 34, 264–275, doi:10.1016/j.tibtech.2015.12.010 (2016).

Zhao, Y. et al. Performance of three microalgal strains in biogas slurry purification and biogas upgrade in response to various mixed light-emitting diode light wavelengths. Bioresource Technology 187, 338–345, doi:10.1016/j.biortech.2015.03.130 (2015).

Bhatnagar, A., Bhatnagar, M., Chinnasamy, S. & Das, K. C. Chlorella minutissima—A Promising Fuel Alga for Cultivation in Municipal Wastewaters. Applied Biochemistry and Biotechnology 161, 523–536, doi:10.1007/s12010-009-8771-0 (2010).

Yan, C. & Zheng, Z. Performance of photoperiod and light intensity on biogas upgrade and biogas effluent nutrient reduction by the microalgae Chlorella sp. Bioresource Technology 139, 292–299, doi:10.1016/j.biortech.2013.04.054 (2013).

Schenk, P. M. et al. Second Generation Biofuels: High-Efficiency Microalgae for Biodiesel Production. BioEnergy Research 1, 20–43, doi:10.1007/s12155-008-9008-8 (2008).

Zhou, W. et al. Novel Fungal Pelletization-Assisted Technology for Algae Harvesting and Wastewater Treatment. Applied Biochemistry and Biotechnology 167, 214–228, doi:10.1007/s12010-012-9667-y (2012).

Wrede, D. et al. Co-cultivation of fungal and microalgal cells as an efficient system for harvesting microalgal cells, lipid production and wastewater treatment. PLoS One 9, e113497 (2014).

Muradov, N. et al. Fungal-assisted algal flocculation: application in wastewater treatment and biofuel production. Biotechnol Biofuels 8, 24 (2015).

Manheim, D. & Nelson, Y. Settling and bioflocculation of two species of algae used in wastewater treatment and algae biomass production. Environmental Progress & Sustainable Energy 32, 946–954, doi:10.1002/ep.11861 (2013).

Van Den Hende, S., Vervaeren, H., Desmet, S. & Boon, N. Bioflocculation of microalgae and bacteria combined with flue gas to improve sewage treatment. N Biotechnol 29, 23–31, doi:10.1016/j.nbt.2011.04.009 (2011).

Niizawa, I., Heinrich, J. M. & Irazoqui, H. A. Modeling of the influence of light quality on the growth of microalgae in a laboratory scale photo-bio-reactor irradiated by arrangements of blue and red LEDs. Biochemical Engineering Journal 90, 214–223, doi:10.1016/j.bej.2014.05.002 (2014).

Chen, C.-Y., Yeh, K.-L., Aisyah, R., Lee, D.-J. & Chang, J.-S. Cultivation, photobioreactor design and harvesting of microalgae for biodiesel production: A critical review. Bioresource Technology 102, 71–81, doi:10.1016/j.biortech.2010.06.159 (2011).

Das, P., Lei, W., Aziz, S. S. & Obbard, J. P. Enhanced algae growth in both phototrophic and mixotrophic culture under blue light. Bioresource Technology 102, 3883–3887, doi:10.1016/j.biortech.2010.11.102 (2011).

Fakhru’l-Razi, A., Zahangir Alam, M., Idris, A., Abd-Aziz, S. & Molla, A. H. Filamentous fungi in Indah Water Konsortium (IWK) sewage treatment plant for biological treatment of domestic wastewater sludge. Journal of Environmental Science and Health, Part A 37, 309–320, doi:10.1081/ESE-120002830 (2002).

Subramanian, S. B., Yan, S., Tyagi, R. D. & Surampalli, R. Y. A New, Pellet-Forming Fungal Strain: Its Isolation, Molecular Identification, and Performance for Simultaneous Sludge-Solids Reduction, Flocculation, and Dewatering. Water Environment Research 80, 840–852, doi:10.2175/106143008X304703 (2008).

Oh, H.-M. et al. Harvesting of Chlorella vulgaris using a bioflocculant from Paenibacillus sp. AM49. Biotechnology Letters 23, 1229–1234, doi:10.1023/a:1010577319771 (2001).

Lee, J.-S. et al. Effects of SO2 and NO on growth of Chlorella sp. KR-1. Bioresource Technology 82, 1–4, doi:10.1016/S0960-8524(01)00158-4 (2002).

Gultom, S. & Hu, B. Review of Microalgae Harvesting via Co-Pelletization with Filamentous Fungus. Energies 6, 5921–5939, doi:10.3390/en6115921 (2013).

Liao, W., Liu, Y., Frear, C. & Chen, S. A new approach of pellet formation of a filamentous fungus – Rhizopus oryzae. Bioresource Technology 98, 3415–3423, doi:10.1016/j.biortech.2006.10.028 (2007).

Feofilova, E. P. The fungal cell wall: Modern concepts of its composition and biological function. Microbiology 79, 711–720, doi:10.1134/s0026261710060019 (2010).

Tan, X. et al. Chlorella pyrenoidosa cultivation using anaerobic digested starch processing wastewater in an airlift circulation photobioreactor. Bioresource Technology 170, 538–548, doi:10.1016/j.biortech.2014.07.086 (2014).

Serejo, M. L. et al. Influence of biogas flow rate on biomass composition during the optimization of biogas upgrading in microalgal-bacterial processes. Environ Sci Technol 49, 3228–3236, doi:10.1021/es5056116 (2015).

Tan, F. et al. Nitrogen and phosphorus removal coupled with carbohydrate production by five microalgae cultures cultivated in biogas slurry. Bioresource Technology 221, 385–393, doi:10.1016/j.biortech.2016.09.030 (2016).

Kumar, A. et al. Enhanced CO2 fixation and biofuel production via microalgae: recent developments and future directions. Trends in Biotechnology 28, 371–380, doi:10.1016/j.tibtech.2010.04.004 (2010).

Perez-Garcia, O., Escalante, F. M. E., de-Bashan, L. E. & Bashan, Y. Heterotrophic cultures of microalgae: Metabolism and potential products. Water Research 45, 11–36, doi:10.1016/j.watres.2010.08.037 (2011).

Sun, S. et al. Performance of CO2 concentrations on nutrient removal and biogas upgrading by integrating microalgal strains cultivation with activated sludge. Energy 97, 229–237, doi:10.1016/j.energy.2015.12.126 (2016).

Markou, G., Chatzipavlidis, I. & Georgakakis, D. Carbohydrates Production and Bio-flocculation Characteristics in Cultures of Arthrospira (Spirulina) platensis: Improvements Through Phosphorus Limitation Process. BioEnergy Research 5, 915–925, doi:10.1007/s12155-012-9205-3 (2012).

Bahr, M., Díaz, I., Dominguez, A., González Sánchez, A. & Muñoz, R. Microalgal-Biotechnology As a Platform for an Integral Biogas Upgrading and Nutrient Removal from Anaerobic Effluents. Environ Sci Technol 48, 573–581, doi:10.1021/es403596m (2014).

Yan, C., Zhu, L. & Wang, Y. Photosynthetic CO2 uptake by microalgae for biogas upgrading and simultaneously biogas slurry decontamination by using of microalgae photobioreactor under various light wavelengths, light intensities, and photoperiods. Applied Energy 178, 9–18, doi:10.1016/j.apenergy.2016.06.012 (2016).

Zhang, J. & Hu, B. A novel method to harvest microalgae via co-culture of filamentous fungi to form cell pellets. Bioresource Technology 114, 529–535, doi:10.1016/j.biortech.2012.03.054 (2012).

Zoller, S. & Lutzoni, F. Slow algae, fast fungi: exceptionally high nucleotide substitution rate differences between lichenized fungi Omphalina and their symbiotic green algae Coccomyxa. Molecular Phylogenetics and Evolution 29, 629–640, doi:10.1016/S1055-7903(03)00215-X (2003).

Kim, T.-H., Lee, Y., Han, S.-H. & Hwang, S.-J. The effects of wavelength and wavelength mixing ratios on microalgae growth and nitrogen, phosphorus removal using Scenedesmus sp. for wastewater treatment. Bioresource Technology 130, 75–80, doi:10.1016/j.biortech.2012.11.134 (2013).

Yan, C. & Zheng, Z. Performance of mixed LED light wavelengths on biogas upgrade and biogas fluid removal by microalga Chlorella sp. Applied Energy 113, 1008–1014, doi:10.1016/j.apenergy.2013.07.012 (2014).

APHA-AWWA-WPCF. (American Public Health Association, Washington, DC, 1995).

Li, Y. et al. Integration of algae cultivation as biodiesel production feedstock with municipal wastewater treatment: Strains screening and significance evaluation of environmental factors. Bioresource Technology 102, 10861–10867, doi:10.1016/j.biortech.2011.09.064 (2011).

Acknowledgements

This study was funded by the National Natural Science Foundation of China (Project no. 31670511 and 31370520), the Zhejiang Provincial Natural Science Foundation (Project no. LY16C030003), and the Science and Technology Department of Zhejiang Province (Project no. 2012C23056).

Author information

Authors and Affiliations

Contributions

Xue Wang and Keting Bao conducted the experiments. Yongjun Zhao and Changwei Hu prepared the figures and wrote the main manuscript. Weixing Cao and Yongjun Zhao polished the article. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, X., Bao, K., Cao, W. et al. Screening of microalgae for integral biogas slurry nutrient removal and biogas upgrading by different microalgae cultivation technology. Sci Rep 7, 5426 (2017). https://doi.org/10.1038/s41598-017-05841-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-05841-9

This article is cited by

-

Assessment of microbial consortiums and their metabolic patterns during the bioconversion of food waste

Biomass Conversion and Biorefinery (2023)

-

A study on biogas production from cassava peel and stem in anaerobic digestion reactor

International Journal of Environmental Science and Technology (2022)

-

Effects of influent C/N ratios and treatment technologies on integral biogas upgrading and pollutants removal from synthetic domestic sewage

Scientific Reports (2017)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.