Abstract

We developed an efficient synthesis of aza-chromones from 3-iodo-4-(1H)-pyridones and terminal acetylenes via a cascade carbonylation-Sonogashira-cyclization reaction. By controlling the use of bases, both 6-aza-chromones 5 and 3-(4-oxo-1,4-dihydroquinoline-3-carbonyl)-4H-pyrano[3,2-c]quinolin-4-ones 6 could be selectively obtained in moderate to good yields.

Similar content being viewed by others

Introduction

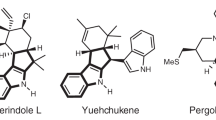

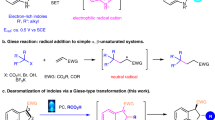

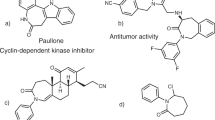

Chromone and chromone derivatives are ubiquitous structures that constitute a variety of naturally occurring and synthetic bioactive compounds1. Among them, 6-aza-chromones are a class of interesting compounds that display various biological activities. For example (Fig. 1), compound I can inhibit bromodomain and extra terminal domain (BET) proteins with the potential as cancer therapeutic agents2; repirinast is an antiallergic drug used for bronchial asthma3; and SB236049 is a metallo-β-lactamase inhibitor that can overcome bacteria resistance to beta-lactam antibiotics4, 5. However, to date only few synthetic routes to this interesting scaffold been reported. These include the condensation of 3-acetyl-quinolinone with benzaldehyde (Fig. 2 and Eq. 1)6, 7, the cyclization of 1-(ortho-hydroxyaryl)-1,3-diketone (Fig. 2 and Eq. 2)8, and the condensation of 3-carbonyl-2-(2-(dimethylamino)vinyl)-4H-pyran-4-one with ammonium acetate (Fig. 2 and Eq. 3)9. The limited number of methodologies restricts the diversification and development of these compounds. In the context of our ongoing efforts to develop new methods for generating these diversified natural-product-like scaffolds10,11,12,13,14, we report herein a new facile synthetic method for 6-azachromone derivatives from 3-iodo-4-(1H)-pyridones and terminal acetylenes via cascade CO insertion, Sonogashira coupling and cyclization.

Recently, palladium catalyzed carbonylative Sonogashira cross-couplings have attracted much attention15,16,17,18,19,20, and have been successfully applied in the synthesis of chromones using o-iodophenols and terminal acetylenes21,22,23,24,25,26,27. We have envisioned that a similar strategy could be applied to 3-iodo-4-(1H)-pyridone substrates to construct diverse 6-aza-chromone derivatives (5) (Fig. 3).

Results and Discussion

Our investigation started with the reaction of 3-iodo-quinolinone (4a) and phenylacetylene (2a). Initially, 4a and 2a were treated with Et2NH (as base and solvent)21 and PdCl2(dppf) (5 mol%) under 1 atm CO at 50 °C, but only a trace amount of product 5a was observed, presumably due to the poor solubility of 4a in Et2NH (Fig. 4, entry 1). In order to improve the solubility, we ran the reaction in DMF with an excess of Et2NH (10 equiv) as base; under these conditions, product 5a could be obtained in 30% isolated yield, together with another unexpected compound 6a in 26% yield. (Fig. 4, entry 2, the structure of 6a was verified by single crystal X-ray diffraction, see Supplementary Information, Fig. 1S). Replacement of PdCl2(dppf) with PdCl2(PPh3)2 led to, allowed full conversion of 4a and the yields of 5a and 6a were improved to 31% and 50%, respectively (Fig. 4, entry 3). Subsequently, different bases, including Et3N, DIPEA, DBU, DABCO, Cs2CO3 and K2CO3 were screened for this reaction. Using 5 equiv of Et3N or DIPEA as base, 4a can be completely consumed and give 6a in good yields (76% and 86%, respectively, Fig. 4, entries 5, 6). However, when DBU, DABCO, Cs2CO3 or K2CO3 was used, 4a reacted partially react and produced 5a and 6a in low to moderate yields (23–42%, Fig. 4, entries 7–10). Reduction of the amount of DIPEA decreased the yield of 6a (Fig. 4, entries 11, 12). Next, the effect of different solvents (DMSO, DMA, CH3CN, THF) was studied. Replacement of DMF with DMSO or DMA only slightly decreased the yield of 6a (Fig. 4, entries 13, 14), while using CH3CN or THF as the solvent greatly lower the yield for both 5a and 6a (Fig. 4, entries 15, 16), probably due to the poor solubility of substrate 4a in these solvents. Further replacement of CO gas (1 atm) with CO donor Mo(CO)6 gave inferior results (Fig. 4, entry 17). In summary, the optimized conditions (Condition B, Fig. 4, entry 6, shown in red) for the selective preparation of 6a are PdCl2(PPh3)2 (5 mol%), DIPEA (5 equiv) in DMF under CO (1 atm) at 50 °C.

Optimization of the reaction conditions for the selective synthesis of 5a or 6a. aReaction condition (unless otherwise noted): 4a (0.2 mmol), 2a (0.36 mmol), catalyst (5 mol%), Solvent (1 mL), base, CO (1 atm), stirred at 50 °C for about 14 h. bisolated yield. cUsing 1 atm N2 and Mo(CO)6 instead of 1 atm CO.

Following optimization of reaction conditions for the preparation of 6a, we began searching for the optimal conditions for the preparation of 5. It could be noted that when excessive amount of Cs2CO3 was used as a base only 5a was selectively obtained in 37% yield, albeit 35% of 4a was recovered (Fig. 4, entry 9). Our previous result indicated that DIPEA can promote the full conversion of 4a, therefore we envisioned that the addition of DIPEA and Cs2CO3 together might achieve better yield of 5a. Indeed, when DIPEA was used together with Cs2CO3 both the yield for 5a (58%) and the conversion rate of 4a were improved (Fig. 4, entry 18). When 4 equiv of DIPEA and 2 equiv of Cs2CO3 were used as bases, 4a was completely consumed and 5a was obtained in a yield of 74%. (Fig. 4, entry 19, condition A, shown in red).

Based on the above results, a reaction mechanism has been proposed (Fig. 5). Iodoquinoline substrate 4 first undergoes a consecutive oxidative addition and CO insertion to give Pd(II) complex A. Sonogashira coupling of A with terminal alkyne can generate intermediate propynone B. Deprotonation of B and the subsequent rearrangement can provide C, which undergoes 6-endo-dig cyclization to give product 5 (Path A). Intermediate B can also coordinate with another molecule of Pd(II) complex A to form Pd(II) complex D; Cyclization of D can afford intermediate E, which is followed by reductive elimination to give product 6 (Path B).

An interesting phenomenon about this reaction is that the use of different base leads to the production of compound 5 or 6 selectively, we speculate that DIEPA might facilitate a carbonylative Sonogashira coupling process to generate intermediate B, but have less effect on the deprotonation of B to C. While Cs2CO3 is not an optimum base for the carbonylative Sonogashira coupling, it is a stronger base, which promotes the deprotonation of B to generate phenoxide anion intermediate C, thus favors the self-cyclization to afford product 5.

With the optimized reaction conditions for path B in hand, the substrate scope of alkynes 2 was investigated. As shown in Fig. 6, both electron-donating and electron-withdrawing groups and substituted phenyl acetylenes can afford the desired products in good yields (72–87%, 6b–6e), while hexyne only gave 6f in moderate yield (49%), indicating the aromatic alkynes are more favorable substrates than aliphatic alkynes for this reaction. Subsequently, phenylacetylene 2a was reacted with different substituted iodoquinolines (4g–4i) to explore the effect of substituents on the iodoquinoline ring. These reactions proceed smoothly with moderate to good yields (57%–85%), indicating the good tolerance of different substituents on iodoquinoline. In addition, using 4j or 4k as substrate also produces the corresponding product 6j or 6k with the yields of 48% and 60%, respectively, indicating the wide substrate scope of this reaction.

In a similar manner, we applied the optimized reaction conditions for path A to synthesize compound 5b–5k (Fig. 7). All the reactions proceeded to give the corresponding products in moderate to good yields (30%–75%) except compound 5i. The inferior yield of 5c (30%) in comparison with 5d (63%) suggests that an electron donating group on phenylacetylene is unfavourable for the production of compound 5. Failure of the synthesis of compound 5i is likely due to the strong electron withdrawing effect of CF3, which decreases the stability of 5i. Mono heterocycle substrates 3-iodo-4-(1H)-pyridone and 5-iodopyrimidin-4(1 H)-one also gave corresponding products 5j and 5k in good yields (72%, 75%), indicating the good tolerance of various substrates in this transformation.

Conclusions

In summary, we have developed an efficient method for the synthesis of 6-aza-chromone derivatives through cascade Carbonylation-Sonogashira-Cyclization reactions. Using different bases, both 6-aza-chromone derivatives 5 and 6 can be synthesized selectively in good yields. Further applications of these methods and the biological activities of these compounds are under investigation.

Experimental Section

General procedure A (Condition A): Synthesis of 5

A test tube equipped with a magnetic stir bar and fitted with a septum, was charged with 3-iodo substrates (0.2 mmol), Cs2CO3 (2.0 equiv), DIPEA (4.0 equiv), PdCl2(PPh3)2 (5 mol%). The test tube was evacuated and backfilled with CO (repeated 3 times) and then the alkyne (0.36 mmol) was added via syringe. The reaction mixture was heated to 50 °C until the starting material was completely consumed as monitored by TLC (typically 14 h). The reaction mixture was then cooled to room temperature, diluted with ethyl acetate, washed with water, concentrated under reduced pressure and purified by column chromatography (silica gel) to afford the corresponding compound 5.

General procedure B (Condition B): Synthesis of 6

A test tube equipped with a magnetic stir bar and fitted with a septum, was charged with 3-iodo substrates (0.2 mmol), DIPEA (5.0 equiv), PdCl2(PPh3)2 (5 mol%). The test tube was evacuated and backfilled with CO (repeated 3 times) and then the alkyne (0.36 mmol) was added via syringe. The reaction mixture was heated to 50 °C until the starting material was completely consumed as monitored by TLC (typically 14 h). The reaction mixture was then cooled down to room temperature, diluted with ethyl acetate, washed with water, concentrated under reduced pressure and purified by column chromatography (silica gel) to afford the corresponding compounds 6.

References

Gaspar, A., Matos, M. J., Garrido, J., Uriarte, E. & Borges, F. Chromone: A Valid Scaffold in Medicinal Chemistry. Chem. Rev. 114, 4960–4992 (2014).

McLure, K. G. & Young, P. R. Treatment of diseases by epigenetic regulation. U.S. Pat. Appl. Publ., US 20130281396 A1 (2013).

Morinaka, Y., Takahashi, K., Hata, S. & Yamada, S. Antiallergic agents. I. Pyranoquinoline derivatives. Eur. J. Med. Chem. 16, 251–256 (1981).

Gan, M. et al. Polyketides with New Delhi Metallo-β-lactamase 1 Inhibitory Activity from Penicillium sp. J. Nat. Prod. 76, 1535–1540 (2013).

Payne, D. J., Hueso-Rodríguez, J. A., Boyd, H., Concha, N. O. & Rivera-Sagredo, A. Identification of a Series of Tricyclic Natural Products as Potent Broad-Spectrum Inhibitors of Metallo-β-Lactamases. Antimicrob. Agents Chemother. 46, 1880–1886 (2002).

Liu, Z., Huang, J. & Cai, M. Synthesis of α-Aryl-4-oxo-4H-pyrano[3,2-c]-9-bromoquinolines. Youji Huaxue 11, 191–195 (1991).

Ghorab, M. M., Abdel-Hamide, S. G. & Farrag, H. A. Synthesis of novel quinolines, pyranoquinolines, furoquinolines, thienoquinoline and their effect on the ultrastructure of some pathogenic microorganisms. Acta. pol. Pharm. 58, 175–184 (2001).

Khlebnikov, V. et al. Synthesis of 2-Aryl-4H-pyrano[2,3-b]pyridin-4-ones by a one-pot deprotection–cyclization reaction. Tetrahedron 65, 6932–6940 (2009).

Zupancic, S., Svete, J. & Stanovnik, B. Transformation of 1, 5-diphenylpentane-1, 3, 5-trione. The synthesis of substituted (4H)-pyranones, pyridin-4(1H)-ones and 4H-pyrano[3,2-c]pyridin-4-ones. Heterocycles 75, 899–909 (2008).

Huang, L., Hu, F., Ma, Q. & Hu, Y. CuBr-catalyzed cascade reaction of 2-substituted-3-(1-alkynyl) chromones to synthesize functionalized 3-acylfurans. Tetrahedron Lett. 54, 3410–3414 (2013).

Huang, L., Liu, Y., Xie, F. & Hu, Y. An Organic Molecule Modulated Chemoselective Cyclization of Alkynyl Nitriles Tethered to 2-Alkyl Substituted Chromones with Multireactive Sites. Org. Lett. 14, 6122–6125 (2012).

Zhao, L., Xie, F., Cheng, G. & Hu, Y. A base-promoted tandem reaction of 3-(1-alkynyl)chromones with 1,3-dicarbonyl compounds: an efficient approach to functional xanthones. Angew. Chem. Int. Ed. 48, 6520–6523 (2009).

Cheng, G. & Hu, Y. Two efficient cascade reactions to synthesize substituted furocoumarins. J. Org. Chem. 73, 4732–4735 (2008).

Cheng, G. & Hu, Y. One-pot synthesis of furocoumarins through cascade addition–cyclization–oxidation. Chem. Commun. 3285–3287 (2007).

Wu, X., Neumann, H. & Beller, M. Synthesis of Heterocycles via Palladium-Catalyzed Carbonylations. Chem. Rev. 113, 1–35 (2013).

Akerbladh, L., Nordeman, P., Wejdemar, M., Odell, L. R. & Larhed, M. Synthesis of 4-quinolones via a carbonylative sonogashira cross-coupling using molybdenum hexacarbonyl as a CO source. J. Org. Chem. 80, 1464–1471 (2015).

Qi, X., Jiang, L., Li, C., Li, R. & Wu, X. Palladium-catalyzed one-pot carbonylative sonogashira reaction employing formic acid as the co source. Chem. Asian J. 10, 1870–1873 (2015).

Sumino, S., Ui, T., Hamada, Y., Fukuyama, T. & Ryu, I. Carbonylative Mizoroki−Heck reaction of alkyl iodides with arylalkenes using a Pd/photoirradiation system. Org. Lett. 17, 4952–4955 (2015).

Liang, B. et al. Pd-catalyzed copper-free carbonylative sonogashira reaction of aryl iodides with alkynes for the synthesis of alkynyl ketones and flavones by using water as a solvent. J. Org. Chem. 70, 6097–6100 (2005).

Miao, H. & Yang, Z. Regiospecific carbonylative annulation of iodophenol acetates and acetylenes to construct the flavones by a new catalyst of palladium−thiourea–dppp complex. Org. Lett. 2, 1765–1768 (2000).

Kalinin, V. N., Shostakovsky, M. V. & Ponomaryo, A. B. Palladium-catalyzed synthesis of flavones and chromones via carbonylative coupling of o-iodophenols with terminal acetylenes. Tetrahedron Lett. 31, 4073–4076 (1990).

Ciattini, P. G., Morera, E., Ortar, G. & Rossi, S. S. Preparative and regiochemical aspects of the palladium-catalyzed carbonylative coupling of 2-hydroxyaryl iodides with ethynylarenes. Tetrahedron 47, 6449–6456 (1991).

Torri, S. O. et al. Syntheses of chromones and quinolones via Pd-catalyzed carbonylation of o-iodophenols and anilines in the presence of acetylenes. Tetrahedron 49, 6773–6794 (1993).

Zhu, F., Li, Y., Wang, Z. & Wu, X. F. Highly efficient synthesis of flavones via Pd/C-catalyzed cyclocarbonylation of 2-iodophenol with terminal acetylenes. Catal. Sci. Technol. 6, 2905 (2016).

Xue, L. et al. Pd–carbene catalyzed carbonylation reactions of aryl iodides. Dalton Trans. 40, 7632–7638 (2011).

Yang, Q. & Alper, H. Synthesis of Chromones via Palladium-Catalyzed Ligand-Free Cyclocarbonylation of o-Iodophenols with Terminal Acetylenes in Phosphonium Salt Ionic Liquids. J. Org. Chem. 75, 948–950 (2010).

Awuah, E. & Capretta, A. Access to Flavones via a Microwave-Assisted, One-Pot Sonogashira-Carbonylation-Annulation Reaction. Org. Lett. 11, 3210–3213 (2009).

Acknowledgements

Financial support of this research provided by National Natural Science Foundation of China (81502916) and Zhejiang Provincial Natural Science Foundation of China (LY16H300002). We thank Mrs. Jianyang Pan (Pharmaceutical Informatics Institute, Zhejiang University) for performing the NMR for structure elucidation.

Author information

Authors and Affiliations

Contributions

G.C., R.S., Y.Z.H., Y.H. designed the work. G.C., Y.Q., X.Z. carried out the experiments, analyzed the data. G.C., R.S., Y.Z.H. wrote the paper. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Cheng, G., Qi, Y., Zhou, X. et al. One-pot Synthesis of 6-Aza-chromone Derivatives Through Cascade Carbonylation-Sonogashira-Cyclization. Sci Rep 7, 4398 (2017). https://doi.org/10.1038/s41598-017-04693-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-04693-7

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.