Abstract

NbO2 has the potential for a variety of electronic applications due to its electrically induced insulator-to-metal transition (IMT) characteristic. In this study, we find that the IMT behavior of NbO2 follows the field-induced nucleation by investigating the delay time dependency at various voltages and temperatures. Based on the investigation, we reveal that the origin of leakage current in NbOx is partly due to insufficient Schottky barrier height originating from interface defects between the electrodes and NbOx layer. The leakage current problem can be addressed by inserting thin NiOy barrier layers. The NiOy inserted NbOx device is drift-free and exhibits high Ion/Ioff ratio (>5400), fast switching speed (<2 ns), and high operating temperature (>453 K) characteristics which are highly suitable to selector application for x-point memory arrays. We show that NbOx device with NiOx interlayers in series with resistive random access memory (ReRAM) device demonstrates improved readout margin (>29 word lines) suitable for x-point memory array application.

Similar content being viewed by others

Introduction

The transition metal oxide NbO2 has gained significant interest over the years due to its wide range of applications such as optical sensors and various electronic devices due to its insulator-to-metal transition (IMT) characteristics1,2,3,4. Recently, several groups reported that the electrically-driven IMT characteristics of NbO2 as a selector device integrated with resistive switching random access memory (ReRAM) can suppress the leakage current of an x-point memory array5,6,7,8,9,10,11,12.

However, the Ion/Ioff ratio of such selectors is limited. Additionally, the intrinsic electrically-driven IMT mechanism of NbO2 has not yet been fully understood. The most widely used model to explain electrically-driven IMT mechanism of NbO2 is Joule-heating induced temperature driven transition model8. In this model, NbO2 can change to metallic state from insulating state at a certain voltage due to Joule-heating of filamentary activated metallic regions. However, the Joule-heating model conflicts with the fact that transition temperature of NbO2 (1080 K) is much higher than the temperature that can be induced by Joule-heating of the insulating state of NbO2 9. A number of groups have reported that NbOx can change its resistance far below the IMT temperature of NbO2 (1080 K) based on thermal runaway model with Poole-Frenkel simulation13,14,15. However, IMT mechanism of NbOx under electrical field (E-field) is still not well understood. In this paper, we fabricated highly crystalline NbO2 film using molecular beam epitaxy (MBE) method and sputter-deposited NiOy barrier inserted NbOx device to analyze the underlying IMT mechanism of NbO2 film. Based on the electroforming analysis performed in previous research16, we examined the dependence of delay time on various applied voltages and temperatures to study the IMT mechanism of the film. Moreover, by comparing energy barriers for metallic phase nucleation with a calculated minimum energy pathway (MEP) value of the Peierls transition in NbO2 and with energy barriers for oxygen vacancy diffusion driven IMT in NbO2, we found that the IMT proceeds through a Peierls transition. We conclude that the IMT mechanism of NbO2 devices is consistent with a Peierls phase transition and follows the field induced nucleation theory. Although the IMT occurs within NbO2 by Peierls transition, we found that the leakage current of the insulating state is dominated by the interfacial defects between electrode and NbO2. Therefore, interface engineering was necessary to reduce the leakage current of NbO2 to improve its performance as a selector device. We revealed that insufficient Schottky barrier height between electrode and NbO2 formed as a result of interfacial defects, which increased the conductivity of insulating state.

Interface defects were successfully suppressed and a higher Schottky barrier can be formed by inserting a thin NiOy barrier layer between electrode and sputtered-NbOx (W/NiOy/NbOx/NiOy/W). As a result, the leakage current of W/NiOy/NbOx/NiOy/W device was significantly decreased and the device exhibited high Ion/Ioff ratio (>5400). The W/NiOy/NbOx/NiOy/W device exhibits very fast transition speed (<2 ns) and excellent operating thermal stability (>453 K). The W/NiOy/NbOx/NiOy/W device can have very fast delay time (<30 ns) and is drift-free, which are highly suitable attributes for selector application in x-point memory array.

We demonstrated the 1S1R (1 selector – 1 ReRAM) unit cell and showed improved readout margin (>29 word lines) by using W/NiOy/NbOx/NiOy/W device.

Result and Discussions

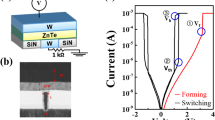

The cross-sectional transmission electron microscopy (TEM) image shows film structure and crystalline state of both MBE and sputter deposited films (Fig. 1). The films were analyzed by in-situ X-ray photoelectron spectroscopy (XPS) to confirm that the correct phase and composition were achieved. Details of the MBE growth and XPS phase identification are found in ref. 17 and XPS results for the sputtered films are shown in Supplementary Fig. S1 18, 19. The MBE NbO2 film was polycrystalline with a lattice constant of 3.4 Å. This corresponds to the d-spacing of the (400) planes of the insulating body-centered tetragonal NbO2 phase20. On the other hand, the sputter-deposited NbOx film was amorphous as-grown.

(a) Overall TEM image of device structure of MBE deposited NbO2 film. Thickness was about 25 nm. (b) HRTEM image and (c) FFT image of MBE deposited NbO2 film which has poly-crystalline state. The lattice constant was about 3.4 Å and it was corresponding with (400) direction of NbO2. (d) HRTEM image and (e) FFT image of sputter deposited NbOx film shows that it has purely amorphous state.

In comparison with the sputter-deposited NbOx film, the electroforming process was mostly eliminated in the MBE-deposited NbO2 film, as shown in Supplementary Fig. S2. In the case of the sputter-deposited film, the pristine state of the film was amorphous. Therefore, electroforming was needed to form crystalline tetragonal NbO2 regions within the amorphous matrix to exhibit IMT16. On the other hand, electroforming was not needed in the case of MBE-deposited NbO2 film because the pristine state of the film was already polycrystalline tetragonal NbO2. The difference in electroforming and IMT process between sputter- and MBE-deposited films is summarized in Supplementary Fig. S3. Because there is no longer any need for electroforming, the IMT process in MBE-deposited NbO2 films can be precisely analyzed.

The mechanism of IMT of NbO2 under E-field was widely interpreted by Joule-heating model, and this model suggests that electrically induced Joule-heating generate the sufficient heat over IMT temperature of NbO2 (1080 K)8, 10. However, the IMT temperature of NbO2 (1080 K) is much higher than the temperature that can achieved by Joule-heating within the insulating state of NbO2 9. Therefore, several researches proposed that the mechanism of IMT under E-field is the result of thermal runaway model13,14,15. These researches simulated the conductivity of NbO2 device as a function of temperature and E-field by fitting the I-V characteristics with Poole-Frenkel model. They showed that IMT can take place far below IMT temperature of NbO2 (1080 K) by thermal runaway, which successfully resolved the main drawback of classical Joule-heating IMT model.

We take a different perspective by using field-induced nucleation theory to explain IMT mechanism in this research. Devices that abruptly change their resistance at a certain electric field, such as phase change random access memory (PRAM) or VO2-based IMT devices, energetically favor metallic nuclei with a cylindrical shape upon nucleation via the applied electric field21,22,23,24,25. Similarly, the field-induced IMT of NbO2 is expected to result of a Peierls transition of conductive NbO2 (metallic, i.e. rutile NbO2) regions formed as cylindrical shape nuclei within an insulating NbO2 matrix (tetragonal, distorted rutile NbO2) under the influence of an electric field21, 22. The formation of nuclei is favorable and forms a conductive path through the insulating host material. The free energy the system ∆G consist of:

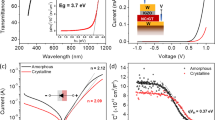

Here, σ and μ are the surface tension and the chemical potential difference between the two NbO2 phases, respectively. The transition energy barrier is lowered by an external electric field (\({{\rm{W}}}_{{\rm{E}}}=\,-\frac{\varepsilon {E}^{2}{\rm{\Omega }}}{8n\pi }\), where ε is the dielectric constant of the host and n is the depolarizing factor (\(n=\frac{1}{3}\) for a sphere)) as shown in Fig. 2(a).

(a) Energy barrier W0 to nucleate without E-field can be lowered by E-field. W(E) is effective barrier energy to nucleate with E-field. (b) Measurement example to detect the delay time predicted by the nucleation theory during IMT. (c) Arrhenius’s plot of delay time versus voltage and temperature of NbO2 film. (d) The schematic diagram of phase transition: the transition is the result of Pielers phase transition.

If we assume that spherical nuclei exist in zero-field (WE = 0), then the surface area and volume of the nuclei can be defined as A = 4πR2 and Ω = 4πR3/3, respectively. By using the differential form of the free energy at zero-field (\({\rm{\Delta }}{\rm{G}}=4{{\rm{\pi }}{\rm{R}}}^{2}{\rm{\sigma }}-4{{\rm{\pi }}{\rm{R}}}^{3}{\rm{\mu }}/3\)), we can define the energy barrier at zero-field (\({{\rm{W}}}_{0}=16\pi {{\rm{\sigma }}}^{3}/3{{\rm{\mu }}}^{2}\)) and the equivalent radius of the nuclei (R0 = 2σ/μ). However, because the nuclei with cylindrical shape are energetically more favorable than spherical ones when an E-field is applied22, it is preferable to modify Equation (1) as follows:

with R being the cylinder radius and h its height. Following from Eq. (2), the reduced barrier energy W(E) under E-field is given by:

Here, E0 is the voltage acceleration factor of the first order, independent of the external voltage or temperature, and its conventional value is 1 MV/cm22, d is the thickness of film; and α is geometric factor of cylinder radius compared with equivalent radius of the nuclei at zero-field (R = αR0) where 0.1 ≤ α < 0.5. We assume α = 0.5 because this value corresponds to the maximum barrier23.

The theory predicts the delay time between application of the field and the switching event expressed as24:

The value of τd for the film was measured by using rising ramp pulses that can minimize RC delay effect and can reveal the delay time with various voltages (VA) and temperatures26. τd is defined as the point where ID (VD/50 Ω) suddenly increases, as shown in Fig. 2(b). Here, τd decreases exponentially with VA and temperature. Figure 2(c) shows that the relation between temperature/VA and τd can be described by an Arrhenius plot, which follows Equation (4).

We found that the experimentally determined value of the zero field barrier W0, which is 47–63 meV, agrees well with the calculated minimum energy pathway (MEP) found between rutile and tetragonal NbO2 during the Peierls transition, which is 43 meV27. The alternative mechanism of diffusion or electromigration of oxygen (vacancies) has also been discussed in terms of the IMT in niobium oxides11, 28, 29. The values of the diffusion barrier height of roughly 290–550 meV deduced from the diffusion studies in Nb2O5 reported in ref. 30. Also, the observed oxygen diffusion coefficient in NbO2 is lower than that of the pentoxide (indicating a higher diffusion barrier for NbO2 than for Nb2O5). Therefore, we can conclude that oxygen diffusion is energetically less favorable than Peierls phase transition due to the high barrier for oxygen diffusion. Furthermore, the diffusion barrier at zero field is estimated to be reduced by only ~10 meV under electric field application considering the electric potential drop along a typical diffusion length of ~1 Å. Therefore, IMT of NbO2 is likely due to a Peierls phase transition through field induced nucleation rather than oxygen electromigration. The events that occur during IMT are illustrated in Fig. 2(d).

The expected transition speed of NbO2 film is quite fast because only short-range atomic arrangement is needed for the transition (Peierls transition). Therefore, NbO2 based IMT device is well suited for selector device in x-point memory array. However, sufficiently high resistivity in the insulating state of NbOx film has not yet been obtained. Moreover, the off-current of NbO2 film can be suppressed under 1 nA at 1 V (Area = 50 × 50 nm2, Thickness = 25 nm) because insulating state of NbO2 conductivity is about 10−4 S/cm31. Likely, the relatively high conductivity of the insulating state of NbOx originates from interface defects between electrode and NbOx layer. In fact, many defects (Grain boundary, dislocation, and point defects) are observed between electrode and MBE-deposited NbO2 film by TEM image (Supplementary Fig. S4). Additionally, these interface defects were observed in sputter-deposited NbOx device from our previous research32.

These defects can pin the Fermi level between electrode and NbOx layer. As a result, the device does not have a sufficiently high Schottky barrier. These defects can be eliminated and a high Schottky barrier can be obtained by inserting a NiOy layer, which consists of NiO and Ni2O3 phases (Supplementary Fig. S1), between electrode and NbOx layer (W/NiOy/NbOx/NiOy/W) as shown in Supplementary Fig. S5 33. Based on DC I-V characteristics at various temperatures for both devices, current-temperature dependencies at low field (V = 0.1 V, saturation region) for both devices follow the Richardson relation (Eq. (5)) and the effective Schottky barrier can be obtained using the slope of the Richardson plot (Supplementary Fig. S5). W/NiOy/NbOx/NiOy/W devices have higher Schottky barrier height (φB ~ 0.25 eV) than W/NbOx/W devices (φB ~ 0.15 eV).

(J0 = Current density at saturation region, A* = Richardson constant, T = temperature, k = Boltzmann constant, q = electronic charge, φBp = effective schottky barrier energy).

Before comparing the device performance of W/NiOy/NbOx/NiOy/W device with W/NbOx/W device, we analyzed the delay time of the W/NiOy/NbOx/NiOy/W. Interestingly, the zero field barrier W0 of W/NiOy/NbOx/NiOy/W device (42–70 meV), which was extracted from delay time Arrhenius plot, also corresponds well to the calculated minimum energy pathway (MEP) found between rutile and tetragonal NbO2 during the Peierls transition, which is 43 meV. This value is the same as that obtained from MBE film analysis (Fig. 2(c)). These results inferred that the barrier layers were not affected by transition mechanism of NbOx. Meanwhile, interface structure of NbOx device can control the conductivity of insulating state of the device. Therefore, we can suppress the high conductivity of NbOx film by simply inserting NiOy barrier layer without compromising fast transition characteristics of NbOx IMT layer.

Figure 3(a) shows IMT characteristics after electroforming both W/NbOx/W and W/NiOy/NbOx/NiOy/W devices. Compared with the W/NbOx/W device, the W/NiOy/NbOx/NiOy/W device exhibited decreased conductivity in the insulating state. The Ion/Ioff ratio of W/NiOy/NbOx/NiOy/W device improved to >5400 from >480, which is the Ion/Ioff ratio of the W/NbOx/W device. Both devices have superior endurance that persisted over 108 AC cycles as shown in Fig. 3(b). The W/NiOy/NbOx/NiOy/W device has very uniform device-to-device and cycle-to-cycle stability during several DC I-V sweeps (Supplementary Fig. S6).

Moreover, we measured the transition time and delay time of W/NiOy/NbOx/NiOy/W device to investigate the temporal characteristics of the device. The device has a transition time under 2 ns and a delay time down to 30 ns for variable voltage ramps (Supplementary Fig. S7). We expect that the delay time of W/NiOy/NbOx/NiOy/W can be even shorter for square pulses.

Since IMT mechanism of NbOx is a second-order structural transition of the Peierls type and involves only very short range atomic displacements, the drift-free characteristic is available in NbOx based device. As a matter of fact, Fig. 4(a) shows that W/NiOy/NbOx/NiOy/W device can recover its insulating state under less than 10 ns. Figure 4(b) illustrates the drift-free operation of the W/NiOy/NbOx/NiOy/W device when Vth does not change at different time intervals34. These results indicate that the W/NiOy/NbOx/NiOy/W device can be used for fast operating applications.

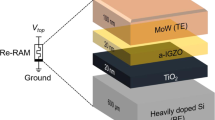

We also evaluated the feasibility of x-point memory array using a novel W/NiOy/NbOx/NiOy/W device. The W/NiOy/NbOx/NiOy/W device was connected in series with a TiN/Ti/HfOx/TiN ReRAM device (ReRAM, 1 R) which has DC I-V characteristic shown in Fig. 5(a). Set voltage (Vset) and reset voltage (Vreset) of ReRAM is about 0.6 V and −1.2 V, respectively. To prevent the hard breakdown of 1 R, we set the compliance current to 500 μA during operation. Figure 5(b) shows DC I-V characteristics of 1S-1R device with superior DC endurance (>300 cycles). The Vset and Vreset of 1S-1R was about 1.8 V and −2 V, respectively. The state of the device is determined by applying a read voltage (Vread) of 1.4 V.

We simulated the x-point memory using novel W/NiOy/NbOx/NiOy/W selector based on measurement in Fig. 5(b). Since the leakage current of unselected cell at ½Vread is suppressed to about 300 nA in both LRS and HRS state by adopting the W/NiOy/NbOx/NiOy/W selector, we demonstrate that the readout margin (Eq. (6)) can improve up to 29 vs. 21 word lines (W.L.) as shown in Fig. 5(d) 35, 36.

(# = Number of word line(s))

Conclusion

We have successfully fabricated NbO2 poly-crystalline film using MBE, which does not require an electroforming process. We find that the IMT in NbO2 undergoes the Peierls phase transition through the field-induced nucleation with the formation of a conductive filament of rutile NbO2 in an insulating host matrix of tetragonal NbO2. We also showed that the leakage current of NbO2 IMT device originates from the insufficient Schottky barrier height between electrode and NbOx layer as a result of interfacial defects. Sufficiently high Schottky barrier and improved IMT characteristics can be obtained by introducing a NiOy layer between electrode and NbOx layer. A novel W/NiOy/NbOx/NiOy/W device has high Ion/Ioff ratio (>5400), high operating temperature (>453 K), fast transition speed (<2 ns) and drift-free operation. We employed the W/NiOy/NbOx/NiOy/W device as a selector device on ReRAM memory cell. Due to the excellent selector characteristics of W/NiOy/NbOx/NiOy/W device, we show a significantly improved readout margin (up to 29 word lines) is possible in a large x-point memory array.

Methods

First, to analyze the IMT mechanism under E-field, we fabricated NbOx films using both MBE and RF-sputtering. About 25 nm-thick NbOx film was deposited by MBE and RF-sputtering on a 50 × 50 nm2 TiN bottom electrode (B.E). The MBE-deposited NbO2 film was deposited at 700 °C. Nb metal was evaporated from an electron beam source and molecular oxygen at a pressure of 5 × 10−6 Torr were used. The sputter-deposited NbOx film was deposited at room temperature by RF reactive sputtering with a process gas of Ar/O2 (30 sccm/1.3 sccm), at a working pressure of 5 × 10−3 Torr and forward power of 100 W using a 2-inch Nb metal target. After both of NbOx were deposited, positive photoresist was spincoated at 3000 rpm for 35 s and baked at 100 °C for 90 s. The photoresist were exposed under the lithography mask which has 50 × 50 um2 pattern and removed with developer to deposit contactable top electrode. Afterwards, W top electrode was deposited by RF reactive sputtering at room temperature with a process gas of Ar (30 sccm), at a working pressure of 5 × 10−3 Torr and forward power of 100 W using a 2-inch W metal target.

Secondly, to reduce the leakage current of NbOx film, NiOy barrier layer inserted NbOx structure deposited on a 50 × 50 nm2 W bottom electrode (B.E). About 2-3 nm thick NiOy layer was sputter deposited additionally by RF reactive sputtering with a process gas of Ar/O2 (30 sccm/2.0 sccm), at a working pressure of 5 × 10−3 Torr and forward power of 30 W using a 2-inch Ni metal target as a barrier layer between W electrodes and sputtered NbOx layer. The condition for sputtering NbOx is same with above. As a result, W/NiOy/NbOx/NiOy/W device was fabricated and its electrical characteristics compared to a W/NbOx/W control sample.

References

Arshak, K., Hickey, G., Harris, J. & Ford, E. Ozone sensing properties of NbO2 thin films for health and safety applications. Sensors Applications Symp. 187–192 (2008).

Shin, S. H., Halpern, T. & Raccah, P. M. High-speed high-current field switching of NbO2. J. Appl. Phys. 48.7, 3150–3153 (1977).

Philipp, H. R. & Levinson, L. M. NbO2 devices for subnanosecond transient protection. J. Appl. Phys. 50.7, 4814–4822 (1979).

Lee, J. C. & Durand, W. W. Electrically stimulated optical switching of NbO2 thin films. J. Appl. Phys. 56.11, 3350–3352 (1984).

Cha, E. et al. Nanoscale (~10nm) 3D vertical ReRAM and NbO2 threshold selector with TiN electrode. In IEEE IEDM Tech. Dig. 10.5.1–10.5.4 (2013).

Kim, S. et al. Ultrathin (<10nm) Nb2O5/NbO2 hybrid memory with both memory and selector characteristics for high density 3D vertically stackable RRAM applications. Symp. on VLSI Tech. Dig. 155–156 (2012).

Liu, X. et al. Diode-less bilayer oxide (WOx–NbOx) device for cross-point resistive memory applications. Nanotechnology 22.47, 475702, doi:10.1088/0957-4484/22/47/475702 (2011).

Pickett, M. D. & Williams, R. S. Sub-100 fJ and sub-nanosecond thermally driven threshold switching in niobium oxide crosspoint nanodevices. Nanotechnology 23.21, 215202, doi:10.1088/0957-4484/23/21/215202 (2012).

Liu, X. et al. Co-Occurrence of Threshold Switching and Memory Switching in Pt/NbOx/Pt Cells for Crosspoint Memory Applications. IEEE Elec. Dev. Lett. 33.2, 236–238 (2012).

Liu, X. et al. Reduced Threshold Current in NbO2 Selector by Engineering Device Structure. IEEE Elec. Dev. Lett. 35.10, 1055–1057 (2014).

Nandi, S. K., Liu, X., Venkatachalam, D. K. & Elliman, R. G. Threshold current reduction for the metal–insulator transition in NbO2− x-selector devices: the effect of ReRAM integration. J. Phys. D. 48.19, 195105, doi:10.1088/0022-3727/48/19/195105 (2015).

Kang, M., Yu, S. & Son, J. Voltage-induced insulator-to-metal transition of hydrogen-treated NbO2 thin films. J. Phys. D: appl. Phys. 48.9, 095301, doi:10.1088/0022-3727/48/9/095301 (2015).

Funck, C. et al. Multidimensional Simulation of Threshold Switching in NbO2 Based on an Electric Field Triggered Thermal Runaway Model. Adv. Elec. Mat. 2.7, 201600169, doi:10.1002/aelm.201600169 (2016).

Slesazeck, S. et al. Physical Model of Threshold Switching in NbO2 Based Memristors. RSC Adv. 5.124, 102318–102322 (2015).

Gibson, G. A. et al. An accurate locally active memristor model for S-type negative differential resistance in NbOx. Appl. Phys. Lett. 108.2, 023505, doi:10.1063/1.4939913 (2016).

Park, J., Cha, E., Karpov, I. V. & Hwang, H. Dynamics of electroforming and electrically driven insulator-metal transition in NbOx selector. Appl. Phys. Lett. 108.23, 232101, doi:10.1063/1.4953323 (2016).

O’Hara, A., Nunley, T. N., Posadas, A. B., Zollner, S. & Demkov, A. A. Electronic and optical properties of NbO2. J. Appl. Phys. 116.21, 213705, doi:10.1063/1.4903067 (2014).

Bharti, D. C. & Rhee, S. W. Dielectric properties and X-ray photoelectron spectroscopic studies of niobium oxide thin films prepared by direct liquid injection chemical vapor deposition method. Thin Solid Films 548, 195–201 (2013).

Chen, Y. S. et al. Microscopic mechanism for unipolar resistive switching behavior of nickel oxides. J. Phys. D. 45.6, 065303, doi:10.1088/0022-3727/45/6/065303 (2012).

Magneli, A., Andersson, G. & Sundkvist, G. Note on the crystal structure of niobium dioxide. Acta Chem. Scand. 9, 1402 (1955).

Chakraverty, B. K. Metal-insulator transition; nucleation of a conducting phase in amorphous semiconductors. J. Non-Crystalline Solids 3.4, 317–326 (1970).

Pevtsov, A. B. et al. Evidence of field-induced nucleation switching in opal: VO2 composites and VO2 films. Phys. Rev. B. 85.2, 024110, doi:10.1103/PhysRevB.85.024110 (2012).

Karpov, I. V. et al. Evidence of field induced nucleation in phase change memory. Appl. Phys. Lett. 92.17, 173501, doi:10.1063/1.2917583 (2008).

Karpov, V. G., Kryukov, Y. A., Karpov, I. V. & Mitra, M. Field-induced nucleation in phase change memory. Phys. Rev. B. 78.5, 052201, doi:10.1103/PhysRevB.78.052201 (2008).

Madan, H., Jerry, M., Pogrebnyakov, A., Mayer, T. & Datta, S. Quantitative Mapping of Phase Coexistence in Mott-Peierls Insulator during Electronic and Thermally Driven Phase Transition. ACS nano 9.2, 2009–2017 (2015).

Kim, B. et al. Temperature dependence of Mott transition in VO2 and programmable critical temperature sensor. Appl. Phys. Lett. 90.2, 023515, doi:10.1063/1.2431456 (2007).

O’Hara, A. & Demkov, A. A. Nature of the metal-insulator transition in NbO2. Phys. Rev. B. 91.9, 094305, doi:10.1103/PhysRevB.91.094305 (2015).

Hanzig, F. et al. Effect of the stoichiometry of niobium oxide on the resistive switching of Nb2O5 based metal–insulator–metal stacks. J. Electron Spectros. Relat. Phenomena 202, 122–127 (2015).

Wang, Y., Comes, R. B., Wolf, S. A. & Lu, J. Threshold Switching Characteristics of Nb/NbO2/TiN Vertical Devices. J. Electron Devices Soc. 4.1, 11–14 (2016).

Oechsner, H., Giber, J., Füßer, H. J. & Darlinski, A. Phase transition and oxide dissolution processes in vacuum-annealed anodic Nb2O5/Nb systems. Thin Solid Films 124.3, 199–210 (1985).

Janninck, R. F. & Whitmore, D. H. Electrical conductivity and thermoelectric power of niobium dioxide. J. Phys. Chem. Solids 27, 1183 (1966).

Park, J. et al. Improved threshold switching characteristics of multi-layer NbOx for 3-D selector application. Microelectronic Engineering 147, 318–320 (2015).

Islam, R., Shine, G. & Saraswat, K. C. Schottky barrier height reduction for holes by Fermi level depinning using metal/nickel oxide/silicon contacts. Applied. Phys. Lett. 105.18, 182103, doi:10.1063/1.4901193 (2014).

Karpov, I. V., Mitra, M., Kau, D. & Spadini, G. Fundamental drift of parameters in chalcogenide phase change memory. J. Appl. Phys. 102.12, 124503, doi:10.1063/1.2825650 (2007).

Linn, E., Rosezin, R., Kügeler, C. & Waser, R. Complementary resistive switches for passive nanocrossbar memories. Nat. Mater. 9.5, 403–406 (2010).

Koo, Y., Baek, K. & Hwang, H. Te-Based Amorphous Binary OTS Device with Excellent Selector Characteristics for X-Point Memory Applications. Symp. on VLSI Tech. Dig. 1–2 (2016).

Acknowledgements

This work was supported by the Semiconductor Research Corporation Program (2525.001) and work at the University of Texas was supported by the Semiconductor Research Corporation under Contract No. 2012-VJ-2299. We appreciate helpful discussions with Dr. Ilya Karpov of Intel Corporation.

Author information

Authors and Affiliations

Contributions

Jaehyuk Park and Hyunsang Hwang wrote the main manuscript text and prepared all figures. Tobias Hadamek, Agham B. Posadas and Alexander A. Demkov deposited the NbO2 film by using molecular beam epitaxial (MBE) and contributed to analyze the mechanism of NbO2 film. Euijun Cha contributed to revise the manuscript. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Park, J., Hadamek, T., Posadas, A.B. et al. Multi-layered NiOy/NbOx/NiOy fast drift-free threshold switch with high Ion/Ioff ratio for selector application. Sci Rep 7, 4068 (2017). https://doi.org/10.1038/s41598-017-04529-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-04529-4

This article is cited by

-

Controllable volatile-to-nonvolatile memristive switching in single-crystal lead-free double perovskite with ultralow switching electric field

Science China Materials (2023)

-

Research on the ability of over current in Ti/NbOx/Pt-based selector

Journal of Materials Science: Materials in Electronics (2021)

-

Filamentary Resistive Switching and Capacitance-Voltage Characteristics of the a-IGZO/TiO2 Memory

Scientific Reports (2020)

-

X-ray reflectivity and X-ray photoelectron spectroscopy studies on reactively sputtered \(\hbox {Nb}_{2}\hbox {O}_{5}\)-based thin-film devices

SN Applied Sciences (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.