Abstract

MXenes are an emerging class of 2D materials of interest in applications ranging from energy storage to electromagnetic shielding. MXenes are synthesized by selective etching of layered bulk MAX phases into sheets of 2D MXenes. Their chemical tunability has been significantly expanded with the successful synthesis of double transition metal MXenes. While knowledge of the structure and energetics of double transition metal MAX phases is critical to designing and optimizing new MXenes, only a small subset of these materials been explored. We present a comprehensive dataset of key properties of MAX phases obtained using density functional theory within the generalized gradient approximation exchange-correlation functionals. Energetics and structure of 8,712 MAX phases have been calculated and stored in a queryable, open database hosted at nanoHUB.

Similar content being viewed by others

Background & Summary

The recent emergence of atomically-thin materials within the last two decades has precipitated a multitude of families of 2D materials, each offering complementary properties, including remarkable mechanical, optical, and electronic properties1,2. One class of 2D materials with a recent rise in interest is MXenes, a family of layered transition metal carbides and nitrides first discovered in 20113.

The synthesis of MXenes is accomplished by preferential etching of layered MAX phases. These MAX phases consist of M, A, and X-type atoms, where M denotes an early transition metal, A denotes a group 13–16 element, and X denotes carbon or nitrogen. The M, A, and X atoms crystallize into a layered structure of composition Mn+1AXn, where n = 1, 2, 3 and n corresponds to the number of X layers in the MXene flake. This layered structure forms the basis for 2D MXene sheets. Figure 1 shows the three crystal structures observed in MAX phases. From the MAX phase precursor, the comparatively weaker M-A bonds can be etched away, resulting in single- or multi-layered MXenes. This unique top-down synthesis approach gives MXenes more scalability than other families of 2D materials. Beyond their synthesis route, MXenes are desirable for applications in energy storage, catalysis, and electronic sensors due to their metallic conductivity and 2D structure4. For these reasons, MXenes have a large potential in both existing and future applications.

A recently emerging sub-class of MXenes known as double transition metal (DTM) MXenes contain two different transitional metal elements5. These DTM MXenes retain the layered structure of mono-M MXenes, with M′ and M″ atoms occupying the M sites. These MAX phases are further subdivided into in-plane ordered (i-MAX), out-of-plane ordered (o-MAX), and solid-solution (ss-MAX) phases, depending on the distribution of the M′ and M″ atoms6. The o-MAX phases are defined by compositions of M′M″AX, M′2M″AX2, and M′2M″2AX3 for n = 1, 2, 3, respectively.

Out of the 8712 possible o-DTM-MAX materials, only a few have been etched into MXenes. Thus, to guide future experimental efforts, we introduce a comprehensive dataset of density functional theory (DFT) results for all possible o-MAX phases, including energetics and structural information.

The multivariate composition of DTM MXenes and their precursor MAX phases offer a high-dimensional domain of exploration well-suited for high-throughput density functional theory. Existing databases of DFT calculations, such as Materials Project7, only contain a small fraction of all possible MAX phases. For example, querying Materials Project’s API for all MAX-formulae with space group P63/mmc reveals only 75 MAX phases, none of which are DTM MAX structures.

Several other studies have reported DFT investigations of DTM MAX structures, but none present a complete view of the entire DTM MAX domain of compositions. Exhaustive computational investigations of mono-M MAX phases and their MXenes have been performed8, but this has not been extended to DTM MAX phases. Several studies have characterized DTM MXenes using DFT, but each was limited in domain to <100 compositions9,10,11. A database of 23,870 DTM MXene phases has previously been established; however, this database contains no precursor MAX phases, and 70% of the MXene properties in the database are machine learning generated12.

This paper aims to fill this gap by establishing a complete database of bulk DTM o-MAX structures, which can accelerate the development of new DTM MXenes. Electronic structure calculations using DFT predict several of the properties of interest in MXene applications and help guide the design of new 2D materials of this family. The composition domain of this database is defined below in Fig. 2, where M′, M″ = Hf, Mn, Cr, Mo, Nb, Sc, Ti, V, Zr, and Ta, and W; A = Cd, Pb, P, S, Tl, As, Al, Si, Ge, Ga, In, and S; and X = C or N, with n = 1, 2, and 3 layers. This database includes 8712 potential MAX phases.

Methods

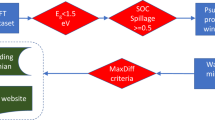

Workflow overview

The data and simulations workflow used to characterize and obtain features for all 8712 candidate MAX phases consists of three main steps, see Fig. 3: i) initial structure generation, ii) DFT calculations, and postprocessing/indexing of results into a queryable database. The following subsections describe each step in detail.

Initial structure generation

The unit cell for each MAX structure is first estimated starting with the Ti3 AlC2 MAX structure obtained from the Materials Project7. From each MAX composition, the selected elements are mapped using pymatgen, and the lattice vectors are adjusted based on the atomic radii of the elements involved, using geometric insight on MAX phases to serve as a starting estimate for the DFT calculations13. The expressions used to calculate the a and c lattice parameters for each of the three crystal structures are listed in Table 1.

Density functional theory calculations were performed on each structure using the Vienna Ab initio Simulation Package (VASP)14,15. These simulations utilized Perdew−Burke−Ernzerhof (PBE) exchange-correlation functional and projector-augmented wave (PAW) pseudopotentials16,17. The calculations include collinear spin-polarization with magnetic moments for each ion initialized to one. Starting with the initial structures described above, a fixed-cell ionic relaxation via energy minimization is performed. This is followed by a cell relaxation to relax the stress tensor and a single-point energy calculation on this optimized structure to obtain energetic properties. Ionic relaxations use the conjugate gradient algorithm with 10−5 eV stopping criteria and the cell relaxation uses conjugate gradient algorithm and 10−6 eV threshold. To ensure numerical convergence of the runs, a kinetic energy cutoff of 550 eV and a k-point grid of 18x18x3 was chosen. This was determined to be a sufficient cutoff by ensuring a variability of less than 1% of the total a and c lattice parameter values.

Simulation results postprocessing and indexing into a queryable database

The raw VASP outputs are processed to extract the structural and energetics of interest using the following procedure. The first step is to parse the VASP output using the VaspDrone function of atomate218 to convert it into a structured JSON document. Atomate2 is an open-source set of computational materials science workflows designed for high-throughput automation. To extract the desired quantities of interest and make the data Findable, Accessible, Interoperable, and Reusable (FAIR)19, we use nanoHUB’s20 Sim2Ls21. Sim2Ls are online, end-to-end, and queryable workflows with formally declared inputs and outputs. They are implemented as Jupyter notebooks and can be executed from nanoHUB or using an API. The open source VASPINGESTOR Sim2L ingests JSON files produced by atomate2 and extracts the desired structural and energetic information22. Importantly, all the inputs and outputs, including the JSON file and auxiliary quantities of interest, are automatically indexed into nanoHUB’s results database (resultsDB) where they can be accessed through a web interface or queried using an API. The Section Data Records describes the properties extracted from the JSON file with the raw results and stored in the ResultsDB. We note that the VASPINGESTOR tool is open and available online, it can be used by any researcher using VASP to make their data FAIR.

Data Records

The dataset is available on Zenodo, an open data repository23. In addition, the dataset is available on nanoHUB.org as both a database24 and an interactive tool22 with a GNU GPL license. As described above, we use nanoHUB’s Sim2Ls to make both the postprocessing workflow and the data FAIR21. All the inputs and the outputs of the vaspingestor Sim2L are indexed in the ResultsDB, they are listed in Tables 2, 3 with an (I) or (O) following their names, respectively. The features extracted from the 8712 DFT simulations can be grouped into two categories, the first being those directly extracted from the VASP output, such as energies, stresses, and structures. These results are listed in Table 2.

From the DFT results, additional quantities of interest useful as descriptors for machine learning applications are extracted, these are provided in Table 3. These quantities are categorized separately as they either require additional DFT calculations, such as formation and cohesive energy, or they are MAX-specific, such as the selected bond lengths and interlayer distances.

The bond lengths and interlayer distances listed in Table 3 are illustrated in Fig. 4.

Formation energies are calculated using:

This equation takes the difference of the obtained MAX phase energy \({E}_{bulk}^{MAX}\) and the constituent elements i in their respective standard states, \({e}_{i}^{0}\), which represent the energy per atom in the standard state and Ni the number of atoms of type i in the MAX structure. These equilibrium states are the lowest energy configurations of each element; for example, the equilibrium state of carbon would be the graphite structure. This provides a metric of the relative stability of the MAX phase over the stability of the individual components.

Finally, cohesive energies were calculated using Eq. 2.

This equation takes the difference of the obtained MAX phase energy \({E}_{bulk}^{MAX}\) and the constituent elements i as single atoms in vacuum. This provides an additional metric of stability as the difference between a bonded and dissociated structure.

The interactive tool is implemented as a Jupyter notebook, it queries the database and provides several ways of visualizing the data. These include scatter and violin plots of formation energy as a function of M′, A, X, and n, in addition to heatmaps of each M′/M″/A combination for both carbides and nitrides. It also shows an example of the use of the Sim2L inputs to reproduce a VASP calculation, and a visualization of the ternary and quaternary convex hulls.

Technical Validation

Comparison to Frey et al

The largest existing database of MAX phases, published by Frey et al.8, contains 792 MAX phases with single-M structures. This work reported lattice a lattice parameters, formation energies, and cohesive energies for all calculated MAX phases. A comparison between their MAX phase results and this work is provided in Fig. 5 as parity plots of formation and cohesive energies as well as a lattice parameters. Values are generally in agreement for the formation and cohesive energies, with RMSE values of 0.13 and 0.25 eV/atom, respectively. As shown in Fig. 5, the major outliers are limited to Sc-A-C type MAX phases, where A is any of the 12 possible A-group elements. We independently confirmed our calculations and we compared them with the Sc-containing MAX phases in the Materials Project. Both these tests indicate our results to be correct. A possible origin of this discrepancy is differences in the spin state of the systems. Comparisons of lattice parameters indicate an RMSE of 0.12 Å with 76% of the structures showing discrepancies less than 2%. 10% of the structures show differences of over 5% which could not be explained by differences in the methods used. This comparison and analysis highlight the importance of making research data FAIR, as Frey et al. did.

Comparison to Materials Project

To further validate our data, a comparison was made to all existing MAX phases in the Materials Project7. The formation energies and a lattice parameters are shown in Fig. 6. In the plot of formation energy, we provided reference lines to account for the disparity in nitrogen reference between datasets. We use nitrogen in its gaseous state as its equilibrium structure, while the Materials Project uses a crystalline form of nitrogen as its reference. When accounting for this difference the formation energies and lattice parameter RMSE values were 0.06 eV/atom and 0.07 Å. The Sc-A-C type MAX phase formation energies have an RMSE of 0.004 eV/atom, showing strong agreement with Materials Project and exhibiting the same deviation from Frey et al. as shown in Fig. 5.

Code availability

The DFT results database, code used to generate figures, and tool for ingesting new data into this database are available at https://nanohub.org/tools/vaspingestor22,23. This code is also available at https://github.com/katnykiel/vasp_ingestor.

References

Mas-Ballesté, R., Gómez-Navarro, C., Gómez-Herrero, J. & Zamora, F. 2D materials: to graphene and beyond. Nanoscale 3, 20–30 (2011).

Akinwande, D. et al. A review on mechanics and mechanical properties of 2D materials—graphene and beyond. Extreme Mechanics Letters 13, 42–77 (2017).

Naguib, M. et al. Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2. Advanced Materials 23, 4248–4253 (2011).

Li, X., Wang, C., Cao, Y. & Wang, G. Functional MXene materials: progress of their applications. Chemistry – An Asian Journal 13, 2742–2757 (2018).

Anasori, B. et al. Two-dimensional, ordered, double transition metals carbides (MXenes). ACS Nano 9, 9507–9516 (2015).

Hong, W., Wyatt, B. C., Nemani, S. K. & Anasori, B. Double transition-metal MXenes: atomistic design of two-dimensional carbides and nitrides. MRS Bull. 45, 850–861 (2020).

Jain, A. et al. Commentary: The materials project: a materials genome approach to accelerating materials innovation. APL Materials 1, 011002 (2013).

Frey, N. C. et al. Prediction of synthesis of 2D metal carbides and nitrides (MXenes) and their precursors with positive and unlabeled machine learning. ACS Nano 13, 3031–3041 (2019).

Sun, W., Xie, Y. & Kent, P. R. C. Double transition metal MXenes with wide band gaps and novel magnetic properties. Nanoscale 10, 11962–11968 (2018).

Zeng, Z. et al. Computational screening study of double transition metal carbonitrides M′2M″CNO2-MXene as catalysts for hydrogen evolution reaction. npj Comput Mater 7, 1–7 (2021).

Zhang, Y. et al. Computational design of double transition metal MXenes with intrinsic magnetic properties. Nanoscale Horiz. 7, 276–287 (2022).

Rajan, A. C. et al. Machine-learning-assisted accurate band gap predictions of functionalized MXene. Chem. Mater. 30, 4031–4038 (2018).

Ong, S. P. et al. Python materials genomics (pymatgen): a robust, open-source python library for materials analysis. Computational Materials Science 68, 314–319 (2013).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab Initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Computational Materials Science 6, 15–50 (1996).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Mathew, K. et al. Atomate: a high-level interface to generate, execute, and analyze computational materials science workflows. Computational Materials Science 139, 140–152 (2017).

Wilkinson, M. D. et al. The FAIR guiding principles for scientific data management and stewardship. Sci Data 3, 160018 (2016).

Strachan, A., Klimeck, G. & Lundstrom, M. cyber-enabled simulations in nanoscale science and engineering. Computing in Science & Engineering 12, 12–17 (2010).

Hunt, M., Clark, S., Mejia, D., Desai, S. & Strachan, A. Sim2Ls: FAIR simulation workflows and data. PLoS ONE 17, e0264492 (2022).

Nykiel, K. & Strachan, A. VASP ingestor. nanoHUB https://doi.org/10.21981/YT8B-E511 (2023).

Nykiel, K. & Strachan, A. High-throughput density functional theory screening of double transition metal MXene precursors. Zenodo https://doi.org/10.5281/zenodo.8400682 (2023).

Nykiel, K. & Strachan, A. VASP ingestor. nanoHUB https://doi.org/10.21981/TDCX-1P76 (2023).

Acknowledgements

We acknowledge support from National Science Foundation, Award 2124241, and nanoHUB.org for storing the data and hosting the tool to access data. Thank you to Robert Appleton for assisting with construction of the convex hull diagrams in nanoHUB.

Author information

Authors and Affiliations

Contributions

Kat Nykiel ran the DFT calculations, build the analysis workflow and developed the nanoHUB tool. Alejandro Strachan guided the workflow, tool, and analysis.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Nykiel, K., Strachan, A. High-throughput density functional theory screening of double transition metal MXene precursors. Sci Data 10, 827 (2023). https://doi.org/10.1038/s41597-023-02755-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41597-023-02755-2