Abstract

The quality of palm oil is strongly influenced by the maturity level of the fruit to be processed into palm oil. Many studies have been carried out for detecting and classifying the maturity level of oil palm fruit to improve the quality with the use of computer vision. However, most of these studies use datasets in the form of images of oil palm fresh fruit bunches (FFB) with incomplete categorization according to real conditions in palm oil mills. Therefore, this study introduces a new complete dataset obtained directly from palm oil mills in the form of videos and images with different categories in accordance with the real conditions faced by the grading section of the palm oil mill. The video dataset consists of 45 videos with a single category of FFB videos and 56 videos with a collection of FFB with multiple categories for each video. Videos are collected using a smart phone with a size of 1280 × 720 pixels with .mp4 format. In addition, this dataset has also been annotated and labelled based on the maturity level of oil palm fruit with 6 categories, which are unripe, under-ripe, ripe, overripe, empty bunches and abnormal fruit.

Similar content being viewed by others

Background & Summary

To produce quality palm oil, mature palm fruit is needed. Maturity of Oil Palm Fruit Bunches (FFB) is usually determined by the number of loose fruits falling from the bunch1. Besides, maturity can also be seen from the colour of the fruit from black to orange. Usually, determining the maturity of FFB is done by visual inspection of the fruit colour. Visual inspection of colour ripeness has several disadvantages when the FFB is on a tall tree and it depends on the perception of the observer. Detection of ripeness by waiting for fruit to fall can cause crop losses. Detection of ripeness in tall trees makes it difficult for observers to ascertain ripe fruit due to distance and lighting. Many studies related to the detection of oil palm fruit ripeness have been carried out, either with a computer vision approach2,3,4,5,6,7,8,9,10,11,12 or with a light sensor approach13,14,15,16,17, but they have not obtained satisfactory results because of the complex characteristics of oil palm fruit, such as uneven colour of ripe fruit, oil palm fruit in bunches which looks small, and the different levels of fruit maturity in some varieties. Table 1 shows the results of a study to classify and detect the maturity level of oil palm FFB. The dataset has limitations such as incomplete categorization and a lack of FBB variations, making it substantially different from real-world conditions.

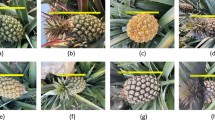

Research using computer vision is usually done based on the input image to detect the colour of the fruit, while research with a light sensor is done by analysing the results of the spectrum of light emitted to the oil palm fruit. Most previous studies used oil palm image input or the colour spectrum of oil palm fruit because with this input the detection process is more efficient. Several previous studies using a computer vision approach with an input image have been carried out by using the SVM method with 3 classes18, namely raw, under-ripe and ripe. Research with deep learning for ripeness detection has been carried out by using EfficientNet3 with single image datasets. Real time oil palm ripeness detection using YOLOv4 with 3 classes dataset has been proposed19 for harvesting system and another research of real time ripeness detection at harvesting process has been proposed using YOLOv320. Based on the results of this literature study, there are no oil palm datasets in the form of images or videos of collections or piles of oil palm fresh fruit bunches with various categories or single categories. This paper provides image and video datasets from collections or piles of oil palm fresh fruit bunches taken directly from palm oil mills in South Kalimantan. In the grading section, smart phones were used with 6 levels of oil palm fruit maturity levels, which are unripe, under-ripe, ripe, overripe, empty bunches and abnormal fruit (Fig. 1). There is research to detect oil palm in real-time using YOLOv4, the data used is fresh fruit bunches of oil palm that are still attached to trees with ripe and unripe classes11. However, this research is not fully applicable because it can only be used on oil palm plantations, whereas to conduct an assessment at a palm oil mill requires more than 2 classes to avoid inappropriate maturity levels.

This dataset is multimodal data in the form of videos and images of oil palm fresh fruit bunches with 6 categories that have been determined and validated by experts in grading the level of maturity of oil palm fruit in palm oil mills. This dataset can be used by many stakeholders such as students and researchers, application developers, machine learning and deep learning engineers, data scientists, agronomists and palm oil mill graders and other researchers. Datasets are very useful for application developers to test data and develop machine learning models that can be used to create smartphone-based applications or applications embedded in robots or other devices. This data is also very useful for data scientists to be able to find the right method for classifying and detecting fruit ripeness. Besides, this data is also very useful for developing deep learning algorithms to classify and detect ripeness as well as fruit counting effectively and efficiently. In the real world application, consistency is required in assessing the maturity level of oil palm so that there are no errors in estimating the maturity level and causing losses to the palm oil processing mill. Some video data properties, such as dynamic luminance, objects partially obscured by other objects, and motion blurs when transitioning between frames, are identical to how the human eye works21 so that the video (or sequential image) will be more applicable in the real world compared to image pieces that have no connection between frames. This dataset is a collection of videos on the maturity level of oil palm fruit with a single category for each video and with multiple categories for each video. An example of a dataset with a single category for each video can be seen in Fig. 2, while an example of data with multiple categories for each image can be seen in Fig. 3. By using a combination of the multiple categories, the dataset can produce machine learning that is in accordance with real conditions in the field so that better model performance can be obtained compared to using datasets with a single category.

Methods

The dataset was collected from some palm oil mills in the section on grading the maturity level of oil palm fruit in South Kalimantan, Indonesia. Oil palm fresh fruit bunches with various levels of maturity were collected and recorded using a smartphone on the concrete cement floor background at factory backyard. The recording strategy uses rotating the camera 360° around the pile of palm oil FFB to capture the most of the FFB positions. A variation of the position of the FFB can be obtained by rotating 360° and can represent the whole condition of the oil palm’s maturity level, an example of the position variation in the FFB can be seen in Fig. 4. The video was captured throughout the day, between 12.00 and 13.00 p.m., in sunny weather conditions. Due to weather issues that are not always sunny, the total time required to gather the dataset is estimated to be two months. So, there are several different variations of oil palm FFB obtained.

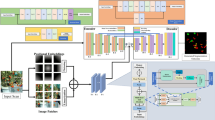

Figure 5 is a pre-processing flow that is carried out to process raw data into ready-to-use data. The raw data used is in mp4 format with a resolution of 1280 × 720 and taken using a smartphone. All types of object classes have been determined and evaluated by palm oil experts at the palm oil grading site. The data that can be used to conduct training on the deep learning model is in the form of images. Therefore, we extracted the frames on the video into sequential images. Frame extraction was carried out with the VLC Media Player22 application with a recording ratio configuration of 30. It aims to extract 1 frame every 1 second so that the possibility of image redundancy is very small21. The resulting output resolution is 416 × 416.

Sequential images with a resolution of 416 × 416 successfully extracted from the video were given a bounding box. The process of giving bounding boxes was done using DarkLabel23. DarkLabel is a tool for annotating object detection, annotation formats available in DarkLabel are Pascal VOC, YOLO, and Multiple Object Tracking (MOT). In pre-processing stage, bounding boxes were assigned manually to each image to ensure the density between the box and the object, the illustration of bounding box annotator can be seen in Fig. 6. The annotation format is stored in the form of a YOLO annotation (.txt) consisting of [class id, x, y, w, h] where x and y are the coordinates of the box, w is the width, and h is the height. The results of each class that has been given a bounding box are stored in a different file. Bounding box is given by making a box-shaped barrier. The box shape is rearranged so that the boundary surrounds the object you want to detect Annotation file has the same name as the annotated image name and placed in the same folder.

Data Records

Based on Fig. 6, data was recorded in two modals namely videos dataset and image dataset. Video datasets contain 45 file of single category and 56 file of multi categories oil palm FFB. Image datasets have been annotated using Roboflow24 software than can be used as input data for ripeness detection and classification using YOLO model. The datasets is available at Science Data Bank25. The video data criteria used were: (1) recordings with 360° rotation of oil palm FFB and (2) video duration of approximately 10 to 15 seconds. Then based on the video criteria used, 1 frame is extracted for every second. Based on Table 2, the total extracted images from video of oil palm FFB file are 4160 files with 14559 objects and 7171 image. The total files of images of each maturity category of oil palm FFB were different from the sum of images, because each image file has more than one object class in the piles of oil palm FFB. The datasets have been split into data training, validation, and testing using composition 70:20:10 with the total images are 2908 for training, 835 for validation and 417 for testing. The detail of image and object for each category can be seen in Table 2.

Technical Validation

For data validation, it was tested using the YOLOv4 models22 with hyper-parameters as shown in Table 3. To suit the dataset, hyper-parameter values such as width, height, max batches, and steps are modified. This change was implemented in accordance to recommendations from the initial YOLOv4 research26. Figure 7 shows a graph of the model’s performance during training and validation. Based on the graph indicates the performance of validation loss was convergence to zero and based on the value of mAP that closed to 1 indicates that the models have good performance. Table 4 presents the test result of each YOLO model used. Figure 8 shows testing result of the of the model with input video of palm oil FFB with multi category of ripeness. The data utilized for training, validation, and testing is composed of consecutive images successfully retrieved from video, making them more applicable to real-world applications. The sequential image structure also enables the model to determine the FFB’s development level from multiple perspectives.

Unfortunately, the open datasets used in the current study on oil palm ripeness are not available. Comparatively, the current research’s typical dataset attempts to increase the grade and output of refined palm oil2,3,4,5,6,8,10,11,13,15. The video dataset employed in this study, however, is concentrated on offering an assessment of the oil palm FFB maturity level, especially in oil palm processing facilities. Video can be used as a dataset since it closely reflects real-time situations, which makes it more appropriate for real-time grading procedures. The use of a video dataset and a real-time object detection algorithm can improve the speed of determining the oil palm FFB’s maturity level. However, using video datasets presents several challenges. Compared to using non-sequential photos, pre-processing will be more difficult. Then the data used in carrying out the training process will become more numerous so that it can make the model training time longer. In addition, the background contained in this dataset is the backyard of the place for grading the level of maturity of the oil palm so that the results of direct detection on oil palm plantations may experience a decrease in performance because the background on the oil palm plantation is more complex than the background from the factory backyard where the FFB of palm oil ripeness is graded.

Usage Notes

The existing dataset has some limitations as follows:

-

1.

The dataset consists of image classes that are not balanced for each category due to the availability of data in the grading process to obtain abnormal data and empty bunches are difficult to obtain from shipping to palm oil mills.

-

2.

The dataset has not been augmented so that to get better performance in the model development, it is necessary to do data augmentation in order to increase the dataset.

Code availability

The software used to process the dataset consists of software for converting video data into a collection of images using VLC (https://www.videolan.org/index.id.html).

Software used for labelling and making image bounding boxes using Darklabel is provided by https://github.com/darkpgmr/DarkLabel.

Software used for converting labelled data into data that is ready for input in processed modelling with a deep learning is the Roboflow (https://roboflow.com/) and the software used for data validation is the Python program.

References

Chew, C. L. et al. Exogenous ethylene application on postharvest oil palm fruit bunches improves crude palm oil quality. Food Sci. Nutr. 9 (2021).

Septiarini, A., Hamdani, H., Hatta, H. R. & Anwar, K. Automatic image segmentation of oil palm fruits by applying the contour-based approach. Sci. Hortic. (Amsterdam). 261 (2020).

Suharjito, Elwirehardja, G. N. & Prayoga, J. S. Oil palm fresh fruit bunch ripeness classification on mobile devices using deep learning approaches. Comput. Electron. Agric. 188, 106359 (2021).

Fadilah, N., Mohamad-Saleh, J., Halim, Z. A., Ibrahim, H. & Ali, S. S. S. Intelligent color vision system for ripeness classification of oil palm fresh fruit bunch. Sensors (Switzerland) 12 (2012).

Sabri, N., Ibrahim, Z., Syahlan, S., Jamil, N. & Mangshor, N. N. A. Palm oil fresh fruit bunch ripeness grading identification using color features. J. Fundam. Appl. Sci. 9 (2018).

Pamornnak, B., Limsiroratana, S. & Chongcheawchamnan, M. Oil content determination scheme of postharvest oil palm for mobile devices. Biosyst. Eng. 134 (2015).

Herman, H., Susanto, A., Cenggoro, T. W., Suharjito, S. & Pardamean, B. Oil Palm Fruit Image Ripeness Classification with Computer Vision using Deep Learning and Visual Attention. Journal of Telecommunication, Electronic and Computer Engineering (JTEC) vol. 12 (2020).

Ibrahim, Z., Sabri, N. & Isa, D. Palm oil fresh fruit bunch ripeness grading recognition using convolutional neural network. J. Telecommun. Electron. Comput. Eng. 10 (2018).

Ishak, W. I. W. & Hudzari, R. M. Image based modeling for oil palm fruit maturity prediction. J. Food, Agric. Environ. 8 (2010).

Zolfagharnassab, S., Shariff, A. R. B. M., Ehsani, R., Jaafar, H. Z. & Aris, I. Bin. Classification of Oil Palm Fresh Fruit Bunches Based on Their Maturity Using Thermal Imaging Technique. Agriculture 12, 1779 (2022).

Lai, J. W., Ramli, H. R., Ismail, L. I. & Hasan, W. Z. W. Real-Time Detection of Ripe Oil Palm Fresh Fruit Bunch Based on YOLOv4. IEEE Access 10, 95763–95770 (2022).

Ghazali, S. A., Selamat, H., Omar, Z. & Yusof, R. Image Analysis Techniques for Ripeness Detection of Palm Oil Fresh Fruit Bunches. Elektr. J. Electr. Eng. 18 (2019).

Saeed, O. M. B. et al. Classification of oil palm fresh fruit bunches based on their maturity using portable four-band sensor system. Comput. Electron. Agric. 82 (2012).

Huddin, A. A Rapid and Non-Destructive Technique in Determining The Ripeness of Oil Palm Fresh Fruit Bunch (FFB). J. Kejuruter. 30, 93–101 (2018).

Makky, M. A Portable Low-cost Non-destructive Ripeness Inspection for Oil Palm FFB. Agric. Agric. Sci. Procedia 9 (2016).

Makky, M. & Soni, P. In situ quality assessment of intact oil palm fresh fruit bunches using rapid portable non-contact and non-destructive approach. J. Food Eng. 120 (2014).

Makky, M., Soni, P. & Salokhe, V. M. Automatic non-destructive quality inspection system for oil palm fruits. Int. Agrophysics 28 (2014).

Septiarini, A., Hamdani, H., Hatta, H. R. & Kasim, A. A. Image-based processing for ripeness classification of oil palm fruit. Proceeding - 2019 5th Int. Conf. Sci. Inf. Technol. Embrac. Ind. 4.0 Towar. Innov. Cyber Phys. Syst. ICSITech 2019 23–26, https://doi.org/10.1109/ICSITech46713.2019.8987575 (2019).

Junos, M. H., Mohd Khairuddin, A. S., Thannirmalai, S. & Dahari, M. An optimized YOLO-based object detection model for crop harvesting system. IET Image Process. 15, 2112–2125 (2021).

Mohd Basir Selvam, N. A., Ahmad, Z. & Mohtar, I. A. Real Time Ripe Palm Oil Bunch Detection using YOLO V3 Algorithm. In 19th IEEE Student Conference on Research and Development: Sustainable Engineering and Technology towards Industry Revolution, SCOReD 2021, https://doi.org/10.1109/SCOReD53546.2021.9652752 (2021).

Wang, J., Zhang, T., Cheng, Y. & Al-Nabhan, N. New Generation Deep learning for Video Object Detection: A survey. Comput. Syst. Sci. Eng. 38, 165–182 (2021).

Parico, A. I. B. & Ahamed, T. Real Time Pear Fruit Detection and Counting Using YOLOv4 Models and Deep SORT. Sensors (Switzerland) 21, 1–32 (2021).

Habtemariam, L. W., Zewde, E. T. & Simegn, G. L. Cervix Type and Cervical Cancer Classification System Using Deep Learning Techniques. Med. Devices Evid. Res. 15, 163–176 (2022).

Syaefudin, A., Setiawan, W., Widiatmoko, F., Sofyan, E. & Restu, R. N. Computer Vision with Deep Convolutional Neural Network Approach for Cold-Flow Casting Defect Detection. In Conference on Management and Engineering in Industry (CMEI) 31–36, https://doi.org/10.33555/cmei.v3i5.111 (2021).

Suharjito & Junior, F. A. Annotated Video Dataset of Oil Palm Fruit Bunch Piles for Ripeness Grading[DS/OL]. Science Data Bank https://doi.org/10.57760/sciencedb.j00001.00713 (2022).

Bochkovskiy, A., Wang, C.-Y. & Liao, H.-Y. M. YOLOv4: Optimal Speed and Accuracy of Object Detection. (2020).

Acknowledgements

The authors would like to express their gratitude to BINUS University for the support and the oil palm mill for supporting the data preparation. This research receives grant from the Directorate General of Higher Education Ministry of Education, Culture, Research, and Technology with contract number: 410/LL3/AK.04/2022, 126/VR.RTT/VI/2022.

Author information

Authors and Affiliations

Contributions

Suharjito: Design Research, Investigation, funding acquisition, data collection, data preparation, wrote manuscript draft; Franz Adeta Junior: Data curation, wrote first draft, software development and validation dataset; Yosua Putra Koeswandy: software development, data labelling and validation dataset; Debi: data labelling and validation dataset; Pratiwi Wahyu Nurhayati: data labelling and validation dataset; Muhammad Asrol: writing—review and editing; Marimin: Data curation & validation.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests or personal relationships that could have influenced the work reported in this paper.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Suharjito, Junior, F.A., Koeswandy, Y.P. et al. Annotated Datasets of Oil Palm Fruit Bunch Piles for Ripeness Grading Using Deep Learning. Sci Data 10, 72 (2023). https://doi.org/10.1038/s41597-023-01958-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41597-023-01958-x

This article is cited by

-

DOES - A multimodal dataset for supervised and unsupervised analysis of steel scrap

Scientific Data (2023)