Abstract

The methylotrophic yeast Pichia pastoris is widely used in the manufacture of industrial enzymes and pharmaceuticals. Like most biotechnological production hosts, P. pastoris is heterotrophic and grows on organic feedstocks that have competing uses in the production of food and animal feed. In a step toward more sustainable industrial processes, we describe the conversion of P. pastoris into an autotroph that grows on CO2. By addition of eight heterologous genes and deletion of three native genes, we engineer the peroxisomal methanol-assimilation pathway of P. pastoris into a CO2-fixation pathway resembling the Calvin–Benson–Bassham cycle, the predominant natural CO2-fixation pathway. The resulting strain can grow continuously with CO2 as a sole carbon source at a µmax of 0.008 h−1. The specific growth rate was further improved to 0.018 h−1 by adaptive laboratory evolution. This engineered P. pastoris strain may promote sustainability by sequestering the greenhouse gas CO2, and by avoiding consumption of an organic feedstock with alternative uses in food production.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$209.00 per year

only $17.42 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request. Genome sequencing reads of mutant strains are available at NCBI BioProject PRJNA586834. Sequences of codon-optimized genes are shown in the Supplementary Information. The accession numbers and locus tags of all native and heterologous sequences are shown in Supplementary Table 7 and Supplementary Table 8. Materials will be made available for non-profit research under a material-transfer agreement upon reasonable request to the corresponding author.

Code availability

Mass-spectrometry data were collected using Agilent Technologies MassHunter GCMS Acquisition Software B.07.06 SR1 combined with a post-acquisition application (Agilent SureMass). Theoretical masses were extracted from the SureMass-converted data and analyzed using the Agilent Technologies MassHunter Workstation Quantitative Analysis for TOF Build 10.0.707.0 and the Isotope Correction Toolbox v.0.04. Genome sequence analysis including calling of single-nucleotide polymorphisms was carried out using CLC Genomic Workbench 12.0 (QIAGEN). Microscopy pictures were processed using Zen 2.3 lite (blue edition) software (Carl Zeiss Microscopy). Flow cytometry data were analyzed using CytExpert (v.2.3.0.84) (Beckman Coulter). No custom code was used in this study.

References

Steiger, M. G., Sauer, M. & Mattanovich, D. Microbial organic acid production as carbon dioxide sink. FEMS Microbiol. Lett. 364, fnx212 (2017).

Bassham, J. A. et al. The path of carbon in photosynthesis. XXI. The cyclic regeneration of carbon dioxide acceptor 1. J. Am. Chem. Soc. 76, 1760–1770 (1954).

Berg, I. A. Ecological aspects of the distribution of different autotrophic CO2 fixation pathways. Appl. Environ. Microbiol. 77, 1925–1936 (2011).

Claassens, N. J., Sousa, D. Z., dos Santos, V. A. P. M., de Vos, W. M. & van der Oost, J. Harnessing the power of microbial autotrophy. Nat. Rev. Microbiol. 14, 692–706 (2016).

Erb, T. J. & Zarzycki, J. A short history of RubisCO: the rise and fall of nature’s predominant CO2 fixing enzyme. Curr. Opin. Biotechnol. 49, 100–107 (2018).

Zhuang, Z.-Y. & Li, S.-Y. Rubisco-based engineered Escherichia coli for in situ carbon dioxide recycling. Bioresour. Technol. 150, 79–88 (2013).

Antonovsky, N. et al. Sugar synthesis from CO2 in Escherichia coli. Cell 166, 115–125 (2016).

Herz, E. et al. The genetic basis for the adaptation of E. coli to sugar synthesis from CO2. Nat. Commun. 8, 1705 (2017).

Guadalupe-Medina, V. et al. Carbon dioxide fixation by Calvin-cycle enzymes improves ethanol yield in yeast. Biotechnol. Biofuels 6, 125 (2013).

Li, Y.-J. et al. Engineered yeast with a CO2-fixation pathway to improve the bio-ethanol production from xylose-mixed sugars. Sci. Rep. 7, 43875 (2017).

Xia, P.-F. et al. Recycling carbon dioxide during xylose fermentation by engineered Saccharomyces cerevisiae. ACS Synth. Biol. 6, 276–283 (2017).

Papapetridis, I. et al. Optimizing anaerobic growth rate and fermentation kinetics in Saccharomyces cerevisiae strains expressing Calvin-cycle enzymes for improved ethanol yield. Biotechnol. Biofuels 11, 17 (2018).

Schada von Borzyskowski, L. et al. An engineered Calvin–Benson–Bassham cycle for carbon dioxide fixation in Methylobacterium extorquens AM1. Metab. Eng. 47, 423–433 (2018).

Phaff, H. J., Miller, M. W. & Shifrine, M. The taxonomy of yeasts isolated from Drosophila in the Yosemite region of California. Antonie Van Leeuwenhoek 22, 145–161 (1956).

Kurtzman, C. P. Description of Komagataella phaffii sp. nov. and the transfer of Pichia pseudopastoris to the methylotrophic yeast genus Komagataella. Int. J. Syst. Evol. Microbiol. 55, 973–976 (2005).

Gasser, B. et al. Pichia pastoris: protein production host and model organism for biomedical research. Future Microbiol. 8, 191–208 (2013).

Liu, L. et al. How to achieve high-level expression of microbial enzymes. Bioengineered 4, 212–223 (2013).

Peña, D. A., Gasser, B., Zanghellini, J., Steiger, M. G. & Mattanovich, D. Metabolic engineering of Pichia pastoris. Metab. Eng. 50, 2–15 (2018).

Agrawal, G., Shang, H. H., Xia, Z.-J. & Subramani, S. Functional regions of the peroxin Pex19 necessary for peroxisome biogenesis. J. Biol. Chem. 292, 11547–11560 (2017).

Ma, C., Agrawal, G. & Subramani, S. Peroxisome assembly: matrix and membrane protein biogenesis. J. Cell Biol. 193, 7–16 (2011).

Rußmayer, H. et al. Systems-level organization of yeast methylotrophic lifestyle. BMC Biol. 13, 80 (2015).

Weninger, A., Hatzl, A.-M., Schmid, C., Vogl, T. & Glieder, A. Combinatorial optimization of CRISPR/Cas9 expression enables precision genome engineering in the methylotrophic yeast Pichia pastoris. J. Biotechnol. 235, 139–149 (2016).

Prielhofer, R. et al. GoldenPiCS: a Golden Gate-derived modular cloning system for applied synthetic biology in the yeast Pichia pastoris. BMC Syst. Biol. 11, 123 (2017).

Gassler, T., Heistinger, L., Mattanovich, D., Gasser, B. & Prielhofer, R. CRISPR/Cas9-mediated homology-directed genome editing in Pichia pastoris. Methods Mol. Biol. 1923, 211–225 (2019).

Lee, P. C. Peroxisome targeting of lycopene pathway enzymes in Pichia pastoris. Methods Mol. Biol. 898, 161–169 (2012).

Raines, C. A., Lloyd, J. C. & Dyer, T. A. New insights into the structure and function of sedoheptulose-1,7-bisphosphatase; an important but neglected Calvin cycle enzyme. J. Exp. Bot. 50, 1–8 (1999).

Waites, M. J. & Quayle, D. J. R. Dihydroxyacetone synthase: a special transketolase for formaldehyde fixation from the methylotrophic yeast Candida boidinii CBS 5777. J. Gen. Microbiol. 129, 935–944 (1983).

Visser, W. F., van Roermund, C. W. T., Ijlst, L., Waterham, H. R. & Wanders, R. J. A. Metabolite transport across the peroxisomal membrane. Biochem. J. 401, 365–375 (2007).

de Koning, W., Gleeson, M. A. G., Harder, W. & Dijkhuizen, L. Regulation of methanol metabolism in the yeast Hansenula polymorpha. Arch. Microbiol. 147, 375–382 (1987).

Siu, K.-H. et al. Synthetic scaffolds for pathway enhancement. Curr. Opin. Biotechnol. 36, 98–106 (2015).

Hammer, S. K. & Avalos, J. L. Harnessing yeast organelles for metabolic engineering. Nat. Chem. Biol. 13, 823–832 (2017).

Bar-Even, A., Noor, E., Lewis, N. E. & Milo, R. Design and analysis of synthetic carbon fixation pathways. Proc. Natl Acad. Sci. USA 107, 8889–8894 (2010).

Schwander, T., Schada von Borzyskowski, L., Burgener, S., Cortina, N. S. & Erb, T. J. A synthetic pathway for the fixation of carbon dioxide in vitro. Science 354, 900–904 (2016).

Barenholz, U. et al. Design principles of autocatalytic cycles constrain enzyme kinetics and force low substrate saturation at flux branch points. Elife 6, e20667 (2017).

Anderson, R. M. et al. Manipulation of a nuclear NAD+ salvage pathway delays aging without altering steady-state NAD+ levels. J. Biol. Chem. 277, 18881–18890 (2002).

Rouzeau, C. et al. Adaptive response of yeast cells to triggered toxicity of phosphoribulokinase. Res. Microbiol. 169, 335–342 (2018).

Yang, Z. & Zhang, Z. Engineering strategies for enhanced production of protein and bio-products in Pichia pastoris: a review. Biotechnol. Adv. 36, 182–195 (2018).

Olah, G. A. Towards oil independence through renewable methanol chemistry. Angew. Chem. Int. Ed. 52, 104–107 (2013).

Werpy, T. & Petersen, G. Value Added Chemicals from Biomass: Volume I—Results of Screening for Potential Candidates from Sugars and Synthesis Gas (U.S. Department of Energy, 2004).

Mattanovich, D., Jungo, C., Wenger, J., Dabros, M. & Maurer, M. In Industrial Scale Suspension Culture of Living Cells (eds. Meyer, H.-P. & Schmidhalter D.) 94–129 (Wiley-Blackwell, 2014).

Engler, C., Gruetzner, R., Kandzia, R. & Marillonnet, S. Golden gate shuffling: a one-pot DNA shuffling method based on type IIs restriction enzymes. PLoS One 4, e5553 (2009).

Sarkari, P., Marx, H., Blumhoff, M. L., Mattanovich, D. & Steiger, M. G. An efficient tool for metabolic pathway construction and gene integration for Aspergillus niger. Bioresour. Technol. 245, 1327–1333 (2017).

Gao, Y. & Zhao, Y. Self-processing of ribozyme-flanked RNAs into guide RNAs in vitro and in vivo for CRISPR-mediated genome editing. J. Integr. Plant Biol. 56, 343–349 (2014).

Küberl, A. et al. High-quality genome sequence of Pichia pastoris CBS7435. J. Biotechnol. 154, 312–320 (2011).

Valli, M. et al. Curation of the genome annotation of Pichia pastoris (Komagataella phaffii) CBS7435 from gene level to protein function. FEMS Yeast Res. 16, fow051 (2016).

Cregg, J. M. In Pichia Protocols (ed. Cregg, J. M.) 27–40 (Humana Press, 1998).

Blumhoff, M. L., Steiger, M. G., Mattanovich, D. & Sauer, M. Targeting enzymes to the right compartment: metabolic engineering for itaconic acid production by Aspergillus niger. Metab. Eng. 19, 26–32 (2013).

Rußmayer, H. et al. Metabolomics sampling of Pichia pastoris revisited: rapid filtration prevents metabolite loss during quenching. FEMS Yeast Res. 15, fov049 (2015).

Mairinger, T. et al. Gas chromatography-quadrupole time-of-flight mass spectrometry-based determination of isotopologue and tandem mass isotopomer fractions of primary metabolites for 13C-metabolic flux analysis. Anal. Chem. 87, 11792–11802 (2015).

Zamboni, N., Fendt, S.-M., Rühl, M. & Sauer, U. 13C-based metabolic flux analysis. Nat. Protoc. 4, 878–892 (2009).

Jungreuthmayer, C., Neubauer, S., Mairinger, T., Zanghellini, J. & Hann, S. ICT: isotope correction toolbox. Bioinformatics 32, btv514 (2015).

Acknowledgements

This work has been supported by the Federal Ministry for Digital and Economic Affairs, the Federal Ministry for Transport, Innovation and Technology, the Styrian Business Promotion Agency SFG, the Standortagentur Tirol, the Government of Lower Austria and ZIT - Technology Agency of the City of Vienna through the COMET Funding Program managed by the Austrian Research Promotion Agency FFG (grant to D.M. and M.G.S.). We also thank the Austrian Science Fund for support to D.M. and T.G. (FWF W1224, Doctoral Program on Biomolecular Technology of Proteins (BioToP)). The funding agencies had no influence on the conduct of this research. EQ BOKU VIBT is acknowledged for providing fermentation and mass-spectrometry equipment. We kindly acknowledge technical support from S. Heinzl and P. Tondl. We also kindly thank H. Rußmayer for help during labeling experiments.

Author information

Authors and Affiliations

Contributions

D.M. conceived and initiated the project. D.M., M.G.S., T.G., M.S. and B.G. designed the experiments. T.G. and M.E. carried out the experiments. S.H., C.T. and T.C. performed mass spectrometry. T.G., M.G.S., M.S. and D.M. analyzed the data. T.G., M.G.S. and D.M. wrote the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

D.M., T.G., M.G.S., M.S. and B.G. are inventors of a patent application (application number PCT/EP2018/064158) that is based on the results reported in this publication.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Integrated supplementary information

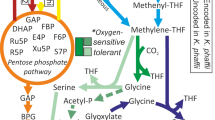

Supplementary Figure 1 Strategy for engineering chemoorganoautotrophy in Pichia pastoris.

(a) Wild type P. pastoris is able to use methanol (MeOH) for biomass in the assimilatory branch of the MeOH utilization by fixation of formaldehyde (FA) to xylulose-5-phosphate (Xu5P) which is regenerated in the xylulose monophosphate (XuMP) cycle (purple pathway) and as an energy source in the dissimilatory branch (pink pathway) by oxidation to carbon dioxide (CO2) under formation of NADH. (b) In an engineered strain MeOH assimilation is blocked by deletion of dihydroxyacetone synthase (DAS1 and DAS2) and a CO2 fixation pathway similar to a Calvin-Benson-Bassham (CBB) cycle is integrated (integration of RuBisCO, PRK, TDH3, PGK1, TKL1, TPI1, groEL and groES). RuBisCO carboxylates ribulose-1,5-bisphosphate which is regenerated in the synthetic CBB cycle; Additionally, the alcohol oxidase 1 gene AOX1 was deleted to avoid accumulation of formaldehyde. The enzymatic steps shown in magenta are present in both pathways (a and b). Abbreviations: alcohol oxidase (Aox), dihydroxyacetone synthase (Das), fructose-1,6-bisphosphate aldolase (Fba1-2), fructose-1,6-bisphosphatase (Fbp1), sedoheptulose-1,7-bisphosphatase (Shb17), ribose-5-phosphate ketol-isomerase (Rki1-2), D-ribulose-5-phosphate 3-epimerase (Rpe1-2), formaldehyde dehydrogenase (Fld1), S-formylglutathione hydrolase (Fgh1), formate dehydrogenase (Fdh1), ribulose-1,5-bisphosphate carboxylase/oxygenase (RuBisCO), dihydroxyacetone (DHA), glyceraldehyde-3-phosphate (GAP), 3-phosphoglycerate (3PGA), glutathione (GSH), ribose-5-phosphate (R5P), ribulose-1,5-bisphosphate (RuBP).

Supplementary Figure 2 Re-integration of AOX1 does not lead to higher growth rates.

CBBp+RuBisCO (black line) and CBBp+RuBisCO (purple line) were cultivated under chemoorganoautotrophic conditions and the mean of at least three biological replicates (independent transformations) with single values (black and purple signs) is shown.

Supplementary Figure 3 Transketolase 1 (Tkl1) does not substitute for dihydroxyacetone synthase (Das1/2).

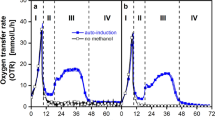

Cells were cultivated in 3 g L-1 glycerol containing minimal medium and then fed with methanol (MeOH) shots as indicated (first shot was for induction while glycerol was still present). Strains: Δaox1 (red dashed line), Δaox1,Δdas1: Δaox1::TDH3p,PGK1p and Δdas1 (yellow line), Δaox1,Δdas1,Δdas2::TKL1p: Δaox1::TDH3p,PGK1p, Δdas1 and Δdas2::TKL1p (dark blue line), Δaox1,Δdas1,Δdas2: Δaox1::TDH3p,PGK1p, Δdas1 and Δdas2 (blue line) and CBBΔRuBisCO: Δaox1::TDH3p,PRKp,PGK1p, Δdas1 and Δdas2::TPI1p,TKL1p, Each clone was cultivated in duplicates (error bars indicate s.e.m.) and the Δaox1 control was cultivated as triplicate (error bars show s.d. of three independent cultivations, n=3).

Supplementary Figure 4 Engineered CBBp+RuBisCO grow in presence of methanol and CO2.

(a) Engineered CBBp+RuBisCO (a and b) are able to grow in presence of methanol and CO2 while CBBpΔRuBisCO are not. CBS7435 wt cells grow well in presence of both substrates, since methanol can be utilized for biomass and energy generation. Cells were cultivated in batch phase (16.0 g L-1 glycerol) until 10 g L-1 cell dry weight (CDW) and then fed with 0.5 – 1.0% (v/v) methanol pulses and a constant inflow of 5% CO2. CDW values are calculated from OD measurements (correlation: 1 OD600 unit = 0.191 g L-1 CDW) and standard error bars indicate s.e.m.; (b) Methanol consumption. Methanol uptake rates were determined during cultivation (time frame of 24 h indicated by arrows in (a) and showed the highest methanol utilization by CBS7435 wt cells followed by the engineered CBBp+RuBisCO (a and b – experiment repeated twice). The strain lacking RuBisCO (CBBpΔRuBisCO) showed slow methanol utilization.

Supplementary Figure 5 Labeling of engineered P. pastoris cells shows complete biomass formation from 12C carbon dioxide.

(a–c) Bioreactor cultivation of 13C labelled biomass from two CBBp+RuBisCO clones (a, b – individual transformations) and the reinoculated biomass from one clone (c) with 12CO2 as a carbon source. The 13C biomass content of the inoculum was enriched by cultivation on fully labelled 13C glycerol. During cultivation, cells were fed with 5 % 12CO2 and methanol. (d–f) Logarithmic CDW value indicates the specific growth rate for the strains in all three reactors. (g, h) Mean cell size (error bars show cell size s.d. of yeast population – 50000 events recorded) and cell viability (error bars indicate s.e.m.) during the cultivation of CBBp+RuBisCO a and b. (i) Characteristic bright field image from day 1 (upper panel) and day 21 (lower panel) of cultivation (bar = 10µm). (k, l) 13C content of the biomass measured by EA-IRMS for CBBp+RuBisCO a and CBBp+RuBisCO b (k) and its reinoculation (l) empty bars indicate calculated values and full bars show measured values ± s.e.m.

Supplementary Figure 6 Adaptive Laboratory Evolution (ALE) leads to higher growth rates.

Cultivation of strains after ALE in serial batch cultivations for 27 to 29 generations; Cell Dry Weight (CDW) values are calculated from OD600 measurements (correlation: 1 OD600 unit = 0.191 g L-1 CDW, error bars indicate s.e.m.), (a) The pools (full lines) from evolved cells were compared for growth on CO2 and methanol to each parental strain cultivated under the same conditions (dashed lines); (b) from one Pool (CBBp+RuBisCO b) 12 single colonies were further characterized under the same conditions showing better growth for 3 single colonies derived from the evolved population. This experiment was repeated twice with similar results.

Supplementary information

Supplementary Information

Supplementary Figs. 1–6, Supplementary Tables 1–10 and Supplementary Sequences 1–4.

Rights and permissions

About this article

Cite this article

Gassler, T., Sauer, M., Gasser, B. et al. The industrial yeast Pichia pastoris is converted from a heterotroph into an autotroph capable of growth on CO2. Nat Biotechnol 38, 210–216 (2020). https://doi.org/10.1038/s41587-019-0363-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41587-019-0363-0

This article is cited by

-

Physiological versatility of ANME-1 and Bathyarchaeotoa-8 archaea evidenced by inverse stable isotope labeling

Microbiome (2024)

-

Engineering biology and climate change mitigation: Policy considerations

Nature Communications (2024)

-

De novo biosynthesis of 2-hydroxyterephthalic acid, the monomer for high-performance hydroxyl modified PBO fiber, by enzymatic Kolbe–Schmitt reaction with CO2 fixation

Biotechnology for Biofuels and Bioproducts (2023)

-

Efficient production of bacterial antibiotics aminoriboflavin and roseoflavin in eukaryotic microorganisms, yeasts

Microbial Cell Factories (2023)

-

Economical production of Pichia pastoris single cell protein from methanol at industrial pilot scale

Microbial Cell Factories (2023)