Abstract

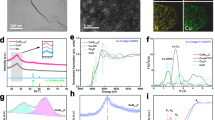

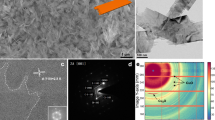

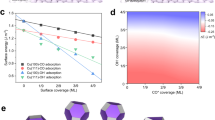

Carbon dioxide electroreduction facilitates the sustainable synthesis of fuels and chemicals1. Although Cu enables CO2-to-multicarbon product (C2+) conversion, the nature of the active sites under operating conditions remains elusive2. Importantly, identifying active sites of high-performance Cu nanocatalysts necessitates nanoscale, time-resolved operando techniques3,4,5. Here, we present a comprehensive investigation of the structural dynamics during the life cycle of Cu nanocatalysts. A 7 nm Cu nanoparticle ensemble evolves into metallic Cu nanograins during electrolysis before complete oxidation to single-crystal Cu2O nanocubes following post-electrolysis air exposure. Operando analytical and four-dimensional electrochemical liquid-cell scanning transmission electron microscopy shows the presence of metallic Cu nanograins under CO2 reduction conditions. Correlated high-energy-resolution time-resolved X-ray spectroscopy suggests that metallic Cu, rich in nanograin boundaries, supports undercoordinated active sites for C–C coupling. Quantitative structure–activity correlation shows that a higher fraction of metallic Cu nanograins leads to higher C2+ selectivity. A 7 nm Cu nanoparticle ensemble, with a unity fraction of active Cu nanograins, exhibits sixfold higher C2+ selectivity than the 18 nm counterpart with one-third of active Cu nanograins. The correlation of multimodal operando techniques serves as a powerful platform to advance our fundamental understanding of the complex structural evolution of nanocatalysts under electrochemical conditions.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All relevant data are available from the corresponding author on request.

References

Ross, M. B. et al. Designing materials for electrochemical carbon dioxide recycling. Nat. Catal. 2, 648–658 (2019).

Birdja, Y. Y. et al. Advances and challenges in understanding the electrocatalytic conversion of carbon dioxide to fuels. Nat. Energy 4, 732–745 (2017).

Yang, Y. et al. Operando methods in electrocatalysis. ACS Catal. 11, 1136–1178 (2021).

Mefford, J. T. et al. Correlative operando microscopy of oxygen evolution electrocatalysts. Nature 593, 67–73 (2021).

Vavra, J., Shen, T. H., Stoian, D., Tileli, V. & Buonsanti, R. Real-time monitoring reveals dissolution/redeposition mechanism in copper nanocatalysts during the initial stages of the CO2 reduction reaction. Angew. Chem. Int. Ed. Engl. 60, 1347–1354 (2021).

Hahn, C. et al. Engineering Cu surfaces for the electrocatalytic conversion of CO2: controlling selectivity toward oxygenates and hydrocarbons. Proc. Natl Acad. Sci. USA 114, 5918–5923 (2017).

Li, C. W., Ciston, J. & Kanan, M. W. Electroreduction of carbon monoxide to liquid fuel on oxide-derived nanocrystalline copper. Nature 508, 504–507 (2014).

Arán-Ais, R. M., Scholten, F., Kunze, S., Rizo, R. & Roldan Cuenya, B. The role of in situ generated morphological motifs and Cu(i) species in C2+ product selectivity during CO2 pulsed electroreduction. Nat. Energy 5, 317–325 (2020).

Eilert, A. et al. Subsurface oxygen in oxide-derived copper electrocatalysts for carbon dioxide reduction. J. Phys. Chem. Lett. 8, 285–290 (2017).

Chang, C.-J. et al. Dynamic reoxidation/reduction-driven atomic interdiffusion for highly selective CO2 reduction toward methane. J. Am. Chem. Soc. 142, 12119–12132 (2020).

Kimura, K. W. et al. Selective electrochemical CO2 reduction during pulsed potential stems from dynamic interface. ACS Catal. 10, 8632–8639 (2020).

Li, J. et al. Copper adparticle enabled selective electrosynthesis of n-propanol. Nat. Commun. 9, 4614 (2018).

Lum, Y. & Ager, J. W. Stability of residual oxides in oxide‐derived copper catalysts for electrochemical CO2 reduction investigated with 18O labeling. Angew. Chem. Int. Ed. Engl. 57, 551–554 (2018).

Fields, M., Hong, X., Nørskov, J. K. & Chan, K. Role of subsurface oxygen on Cu surfaces for CO2 electrochemical reduction. J. Phys. Chem. C 122, 16209–16215 (2018).

Garza, A. J., Bell, A. T. & Head-Gordon, M. Is subsurface oxygen necessary for the electrochemical reduction of CO2 on copper? J. Phys. Chem. Lett. 9, 601–606 (2018).

Feng, X., Jiang, K., Fan, S. & Kanan, M. W. A direct grain-boundary-activity correlation for CO electroreduction on Cu nanoparticles. ACS Cent. Sci. 2, 169–174 (2016).

Mariano, R. G., McKelvey, K., White, H. S. & Kanan, M. W. Selective increase in CO2 electroreduction activity at grain-boundary surface terminations. Science 358, 1187–1192 (2017).

Mariano, R. G. et al. Microstructural origin of locally enhanced CO2 electroreduction activity on gold. Nat. Mater. 20, 1000–1006 (2021).

Yang, Y. et al. Electrocatalysis in alkaline media and alkaline membrane-based energy technologies. Chem. Rev. 122, 6117–6321 (2022).

Hung, L., Tsung, C.-K., Huang, W. & Yang, P. Room-temperature formation of hollow Cu2O nanoparticles. Adv. Mater. 22, 1910–1914 (2010).

Kim, D., Kley, C. S., Li, Y. & Yang, P. Copper nanoparticle ensembles for selective electroreduction of CO2 to C2–C3 products. Proc. Natl Acad. Sci. USA 114, 10560–10565 (2017).

Li, Y. et al. Electrochemically scrambled nanocrystals are catalytically active for CO2-tomulticarbons. Proc. Natl Acad. Sci. USA 117, 9194–9201 (2020).

Holtz, M. E. et al. Nanoscale imaging of lithium ion distribution during in situ operation of battery electrode and electrolyte. Nano Lett. 14, 1453–1459 (2014).

Yang, Y., Shao, Y.-T., Lu, X., Abruña, H. D. & Muller, D. A. Metal monolayers on command: underpotential deposition at nanocrystal surfaces: a quantitative operando electrochemical transmission electron microscopy study. ACS Energy Lett. 7, 1292–1297 (2022).

Williamson, M., Tromp, R., Vereecken, P., Hull, R. & Ross, F. Dynamic microscopy of nanoscale cluster growth at the solid–liquid interface. Nat. Mater. 2, 532–536 (2003).

Holtz, M. E., Yu, Y., Gao, J., Abruña, H. D. & Muller, D. A. In situ electron energy-loss spectroscopy in liquids. Microsc. Microanal. 19, 1027–1035 (2013).

Yang, Y., Shao, Y.-T., Lu, X., Abruña, H. D. & Muller, D. A. Elucidating cathodic corrosion mechanisms with operando electrochemical transmission electron microscopy. J. Am. Chem. Soc. 144, 15698–15708 (2022).

Serra-Maia, R. et al. Nanoscale chemical and structural analysis during in situ scanning/transmission electron microscopy in liquids. ACS Nano 15, 10228–10240 (2021).

Chen, Z. et al. Electron ptychorgraphy achieves atomic-resolution limits set by lattice vibrations. Science 372, 826–831 (2021).

Tate, M. W. et al. High dynamic range pixel array detector for scanning transmission electron microscopy. Microsc. Microanal. 22, 237–249 (2016).

Ophus, C. Four-dimensional scanning transmission electron microscopy (4D-STEM): from scanning nanodiffraction to ptychography and beyond. Micro. Microanal. 25, 563–582 (2020).

Zuo, J. M. & Tao, J. in Scanning Transmission Electron Microscopy (eds Pennycook, S. & Nellist, P.) Ch. 9 (Springer, 2011).

Yu, S. et al. Nanoparticle assembly induced ligand interactions for enhanced electrocatalytic CO2 conversion. J. Am. Chem. Soc. 143, 19919–19927 (2021).

Yang, Y. et al. Operando resonant soft X-ray scattering studies of chemical environment and interparticle dynamics of Cu nanocatalysts for CO2 electroreduction. J. Am. Chem. Soc. 144, 8927–8931 (2022).

Glatzel, P. & Bergmann, U. High resolution 1s core hole X-ray spectroscopy in 3D transition metal complexes-electronic and structural information. Coord. Chem. Rev. 249, 65–95 (2005).

Yang, Y. et al. In situ X-ray absorption spectroscopy of a synergistic Co-Mn oxide catalyst for the oxygen reduction reaction. J. Am. Chem. Soc. 141, 1463–1466 (2019).

Reske, R., Mistry, H., Behafarid, F., Roldan Cuenya, B. & Strasser, P. Particle size effects in the catalytic electroreduction of CO2 on Cu nanoparticles. J. Am. Chem. Soc. 136, 6978–6986 (2018).

Zeng, R. et al. Methanol oxidation using ternary ordered intermetallic electrocatalysts: a DEMS study. ACS Catal. 10, 770–776 (2020).

Cao, L. et al. Mechanistic insights for low-overpotential electroreduction of CO2 to CO on copper nanowires. ACS Catal. 7, 8578–8587 (2017).

Jeong, H. M. et al. Atomic-scale spacing between copper facets for the electrochemical reduction of carbon dioxide. Adv. Energy Mater. 10, 1903423 (2020).

Mantella, V. et al. Polymer lamellae as reaction intermediates in the formation of copper nanospheres as evidenced by in situ X-ray studies. Angew. Int. Chem. Ed. Engl. 59, 11627–11633 (2020).

Kim, D. et al. Selective CO2 electrocatalysis at the pseudocapacitive nanoparticle/ordered-ligand interlayer. Nat. Energy 5, 1032–1042 (2020).

Sebastián-Pascual, P. & Escudero-Escribano, M. Surface characterization of copper electrocatalysts by lead underpotential deposition. J. Electroanal. Chem. 896, 115446 (2021).

Förster, S., Apostol, L. & Bras, W. Scatter: software for the analysis of nano- and mesoscale small-angle scattering. J. Appl. Crystallogr. 43, 639–646 (2010).

Acknowledgements

This work was supported by the Director, Office of Science, Office of Basic Energy Sciences, Chemical Sciences, Geosciences, & Biosciences Division of the US Department of Energy under contract nos. DE-AC02-05CH11231 and FWP CH030201 (Catalysis Research Program). Work at Cornell University (in particular, operando EC-STEM) was supported by the Center for Alkaline-Based Energy Solutions, an Energy Frontier Research Center programme supported by the US Department of Energy, under grant no. DE-SC0019445. This work made use of TEM facilities at the CCMR, which are supported through the National Science Foundation Materials Research Science and Engineering Center (NSF MRSEC) programme (no. DMR-1719875). This work also used TEM facilities at the Molecular Foundry, supported by the Office of Science, Office of Basic Energy Sciences of the US Department of Energy under contract no. DE-AC02-05CH11231. This research used resources of the Advanced Light Source, which is a DOE Office of Science User Facility under contract no. DE-AC02-05CH11231. This work is based on research conducted at the Center for High-Energy X-ray Sciences (CHEXS), which is supported by the National Science Foundation under award DMR-1829070. We thank J. Grazul and M. Thomas at Cornell for TEM technical support, and R. Dhall and K. Bustillo at NCEM. We thank H. Celik and UC Berkeley’s NMR facility at the College of Chemistry (CoC-NMR) for spectroscopic assistance. Instruments in the CoC-NMR are supported in part by NIH S10OD024998. We thank Y. Li for the initial discussion on in situ TEM. We thank R. Page and S. McFall for X-ray cell fabrication at the machine shop of Cornell LASSP. Y.Y. acknowledges support from the Miller Research Fellowship. S.Y. acknowledges support from the Samsung Scholarship. J.J. and C.C. acknowledge support from the Suzhou Industrial Park Scholarship.

Author information

Authors and Affiliations

Contributions

Y.Y., S.L. and S.Y. designed the project under the guidance of P.Y. and H.D.A. Y.Y. performed atomic-scale STEM–EELS and operando EC-STEM measurements. Y.Y. performed operando 4D-STEM, with the help of Y.-T.S. and under the guidance of D.A.M. S.L. and I.R. synthesized Cu nanocatalysts and performed CO2RR performance measurements, with the help of M.V.F.G. and J.F. S.Y. performed X-ray diffraction analysis and H-cell measurements. I.R. performed GDE measurements. Y.Y. performed operando HERFD-XAS studies, with help from S.L., S.Y. and X.H. C.J.P. provided generous support for the operando HERFD set-up. Y.Y. performed operando RSoXS studies under the guidance of C.W., with help from J.J. and C.C. H.W. and Y.Y. performed operando DEMS measurements. J.J. and C.C. prepared the scheme. Y.Y., S.L. and S.Y. wrote the manuscript under the supervision of P.Y. All authors revised and approved the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature thanks Dunfeng Gao and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

Extended Data Fig. 1 Atomic-scale microstructures and chemical compositions of a family of Cu NP ensembles (7, 10, 18 nm).

(a–b) HAADF-STEM image and EELS composite map of fresh 7 nm NPs with metallic Cu core (red) and ~2 nm oxide shell (green), which were oxidized to Cu2O NPs after brief air exposure (Supplementary Fig. 3). (c) STEM image of 10 nm Cu@Cu2O NPs with multi-domain Cu core close to the [110] zone axis surrounded by the Cu2O shell with characteristic d-spacings of Cu2O{111} (2.5 Å). (d) STEM-EELS composite map of 10 nm Cu@Cu2O NPs with ~2 nm oxide shell. (e–f) STEM image of 18 nm Cu@Cu2O NPs and EELS composite map showing the ~2 nm oxide shell.

Supplementary information

Supplementary Information

Supplementary text, Figs. 1–57 and legends for Videos 1–7.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, Y., Louisia, S., Yu, S. et al. Operando studies reveal active Cu nanograins for CO2 electroreduction. Nature 614, 262–269 (2023). https://doi.org/10.1038/s41586-022-05540-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-022-05540-0

This article is cited by

-

Superexchange-stabilized long-distance Cu sites in rock-salt-ordered double perovskite oxides for CO2 electromethanation

Nature Communications (2024)

-

Stability and lifetime of diffusion-trapped oxygen in oxide-derived copper CO2 reduction electrocatalysts

Nature Catalysis (2024)

-

Water-assisted oxidative redispersion of Cu particles through formation of Cu hydroxide at room temperature

Nature Communications (2024)

-

Complementary probes for the electrochemical interface

Nature Reviews Chemistry (2024)

-

Solution-based Cu+ transient species mediate the reconstruction of copper electrocatalysts for CO2 reduction

Nature Catalysis (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.