Abstract

Lithium phosphorus oxynitride (LiPON) is an amorphous solid electrolyte that has been extensively studied over the last three decades. Despite the promise of pairing it with various electrode materials, LiPON’s rigidity and air sensitivity set limitations to understanding its intrinsic properties. Here we report a methodology to synthesize LiPON in a free-standing form that manifests remarkable flexibility and a Young’s modulus of ∼33 GPa. We use solid-state nuclear magnetic resonance and differential scanning calorimetry to quantitatively reveal the chemistry of the Li/LiPON interface and the presence of a well-defined LiPON glass-transition temperature of 207 °C. Combining interfacial stress and a gold seeding layer, our free-standing LiPON shows a uniformly dense deposition of lithium metal without the aid of external pressure. This free-standing LiPON film offers opportunities to study fundamental properties of LiPON for interface engineering for solid-state batteries.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Additional data related to this paper are available from the corresponding authors upon reasonable request. Source data are provided with this paper.

References

Yu, X., Bates, J. B., Jellison, G. E. & Hart, F. X. A stable thin-film lithium electrolyte: lithium phosphorus oxynitride. J. Electrochem. Soc. 144, 524 (1997).

Bates, J. B. et al. Electrical properties of amorphous lithium electrolyte thin films. Solid State Ion. 29, 42–44 (1992).

Lacivita, V. et al. Resolving the amorphous structure of lithium phosphorus oxynitride (Lipon). J. Am. Chem. Soc. 140, 11029–11038 (2018).

Santhanagopalan, D. et al. Interface limited lithium transport in solid-state batteries. J. Phys. Chem. Lett. 5, 298–303 (2014).

Wang, Z. et al. In situ STEM-EELS observation of nanoscale interfacial phenomena in all-solid-state batteries. Nano Lett. 16, 3760–3767 (2016).

Wang, Z. et al. Effects of cathode electrolyte interfacial (CEI) layer on long term cycling of all-solid-state thin-film batteries. J. Power Sources 324, 342–348 (2016).

Cheng, D. et al. Unveiling the stable nature of the solid electrolyte interphase between lithium metal and lipon via cryogenic electron microscopy. Joule 4, 2484–2500 (2020).

Hood, Z. D. et al. Elucidating interfacial stability between lithium metal anode and Li phosphorus oxynitride via in situ electron microscopy. Nano Lett. 21, 151–157 (2021).

Lewis, J. A., Tippens, J., Cortes, F. J. Q. & McDowell, M. T. Chemo-mechanical challenges in solid-state batteries. Trends Chem. https://doi.org/10.1016/j.trechm.2019.06.013 (2019).

Herbert, E. G., Tenhaeff, W. E., Dudney, N. J. & Pharr, G. M. Mechanical characterization of LiPON films using nanoindentation. Thin Solid Films 520, 413–418 (2011).

Xu, F. et al. Complete elastic characterization of lithium phosphorous oxynitride films using picosecond ultrasonics. Thin Solid Films 548, 366–370 (2013).

Zhao, S., Fu, Z. & Qin, Q. A solid-state electrolyte lithium phosphorus oxynitride film prepared by pulsed laser deposition. Thin Solid Films 415, 108–113 (2002).

Kozen, A. C., Pearse, A. J., Lin, C. F., Noked, M. & Rubloff, G. W. Atomic layer deposition of the solid electrolyte LiPON. Chem. Mater. 27, 5324–5331 (2015).

Liu, W. Y., Fu, Z. W., Li, C. L. & Qin, Q. Z. Lithium phosphorus oxynitride thin film fabricated by a nitrogen plasma-assisted deposition of E-beam reaction evaporation. Electrochem. Solid-State Lett. 7, 36–41 (2004).

Nowak, S., Berkemeier, F. & Schmitz, G. Ultra-thin LiPON films—fundamental properties and application in solid state thin film model batteries. J. Power Sources 275, 144–150 (2015).

Kim, H. T., Mun, T., Park, C., Jin, S. W. & Park, H. Y. Characteristics of lithium phosphorous oxynitride thin films deposited by metal–organic chemical vapor deposition technique. J. Power Sources 244, 641–645 (2013).

Muñoz, F. et al. Increased electrical conductivity of LiPON glasses produced by ammonolysis. Solid State Ion. 179, 574–579 (2008).

Westover, A. S. et al. Plasma synthesis of spherical crystalline and amorphous electrolyte nanopowders for solid-state batteries. ACS Appl. Mater. Interfaces 12, 11570–11578 (2020).

López-Aranguren, P. et al. Crystalline LiPON as a bulk-type solid electrolyte. ACS Energy Lett. https://doi.org/10.1021/acsenergylett.0c02336 (2021).

Bates, J. B. et al. Fabrication and characterization of amorphous lithium electrolyte thin films and rechargeable thin-film batteries. J. Power Sources 43, 103–110 (1993).

Schwöbel, A., Hausbrand, R. & Jaegermann, W. Interface reactions between LiPON and lithium studied by in-situ X-ray photoemission. Solid State Ion. 273, 51–54 (2015).

Le Van-Jodin, L., Ducroquet, F., Sabary, F. & Chevalier, I. Dielectric properties, conductivity and Li+ ion motion in LiPON thin films. Solid State Ion. 253, 151–156 (2013).

Li, J., Ma, C., Chi, M., Liang, C. & Dudney, N. J. Solid electrolyte: the key for high-voltage lithium batteries. Adv. Energy Mater. 5, 1401408 (2015).

Marple, M. A. T. et al. Local structure of glassy lithium phosphorus oxynitride thin films: a combined experimental and ab initio approach. Angew. Chem. Int. Ed. 59, 22185–22193 (2020).

Köcher, S. S. et al. Chemical shift reference scale for Li solid state NMR derived by first-principles DFT calculations. J. Magn. Reson. 297, 33–41 (2018).

Vieira, E. et al. Flexible solid-state Ge–LiCoO2 battery: from materials to device application. Adv. Mater. Lett. 8, 820–829 (2017).

Sepúlveda, A., Criscuolo, F., Put, B. & Vereecken, P. M. Effect of high temperature LiPON electrolyte in all solid state batteries. Solid State Ion. 337, 24–32 (2019).

Kalnaus, S., Westover, A. S., Kornbluth, M., Herbert, E. & Dudney, N. J. Resistance to fracture in the glassy solid electrolyte Lipon. J. Mater. Res. https://doi.org/10.1557/s43578-020-00098-x (2021).

Ma, D., Chung, W. O., Liu, J. & He, J. Determination of Young’s modulus by nanoindentation. Sci. China E 47, 398–408 (2004).

Abadias, G. & Daniel, R. in Handbook of Modern Coating Technologies (eds Aliofkhazraei, M. et al.) 359–436 (Elsevier, 2021).

Swadener, J. G., Taljat, B. & Pharr, G. M. Measurement of residual stress by load and depth sensing indentation with spherical indenters. J. Mater. Res. 16, 2091–2102 (2001).

Lee, J. Z. et al. Cryogenic focused ion beam characterization of lithium metal anodes. ACS Energy Lett. 4, 489–493 (2019).

Wang, M. J., Carmona, E., Gupta, A., Albertus, P. & Sakamoto, J. Enabling ‘lithium-free’ manufacturing of pure lithium metal solid-state batteries through in situ plating. Nat. Commun. 11, 5201 (2020).

Lee, Y. G. et al. High-energy long-cycling all-solid-state lithium metal batteries enabled by silver–carbon composite anodes. Nat. Energy 5, 299–308 (2020).

Motoyama, M., Ejiri, M. & Iriyama, Y. Modeling the nucleation and growth of Li at metal current collector/LiPON interfaces. J. Electrochem. Soc. 162, A7067–A7071 (2015).

Yan, K. et al. Selective deposition and stable encapsulation of lithium through heterogeneous seeded growth. Nat. Energy 1, 16010 (2016).

Lee, K., Kazyak, E., Wang, M. J., Dasgupta, N. P. & Sakamoto, J. Analyzing void formation and rewetting of thin in situ-formed Li anodes on LLZO. Joule 6, 2547–2565 (2022).

Kasemchainan, J. et al. Critical stripping current leads to dendrite formation on plating in lithium anode solid electrolyte cells. Nat. Mater. 18, 1105–1111 (2019).

Acknowledgements

We gratefully acknowledge funding support from the US Department of Energy, Office of Basic Energy Sciences, under award number DE-SC0002357. The FIB/SEM in this work was performed in part at the San Diego Nanotechnology Infrastructure (SDNI) of the University of California San Diego, a member of the National Nanotechnology Coordinated Infrastructure, which is supported by the National Science Foundation (grant ECCS-2025752). NMR was performed under the auspices of the US Department of Energy by Lawrence Livermore National Laboratory under contract number DE-AC52-07NA27344. XPS and DSC were performed at the UC Irvine Materials Research Institute (IMRI) using instrumentation funded in part by the National Science Foundation Major Research Instrumentation Program under grant numbers CHE-1338173 and DMR-2011967.

Author information

Authors and Affiliations

Contributions

D.C., M.Z. and Y.S.M. conceived the ideas. D.C., T.W., B.L., R.S. and B.S. prepared the thin-film samples. The FS-LiPON Li–Cu cell was designed by D.C. B.H., M.Z. and G.Z., and fabricated by D.C. M.M. performed and analysed ss-NMR measurements. D.C. conducted cryo-FIB/SEM and electrical measurements. D.C. and H.N. collected X-ray diffraction data. D.C., J.B. and P.H. collected and analysed the nanoindentation data. D.C., Y.Y. and W.L. collected XPS data. D.C., M.Z., Y.S.M., T.W., M.M., G.Z. and B.H. co-wrote the paper. All authors discussed the results and commented on the paper. All authors have approved the final paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Nanotechnology thanks the anonymous reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1 Optical appearance of FS-LiPON film.

a, Photo of a piece of transparent and flexible FS-LiPON film. b, FS-LiPON films with different sizes in a glass vial.

Extended Data Fig. 2

Cross-section image of FS-LiPON with EDS mapping overlaid on the left part.

Extended Data Fig. 3 XRD measurement and surface EDS mapping on FS-LiPON film.

a, XRD pattern of FS-LiPON thin film. b, SEM image and EDS mapping on the surface of FS-LiPON.

Extended Data Fig. 4 XPS spectra of O 1s, N 1s, P 2p and Li 1s regions collected on FS-LiPON and sub-LiPON thin film.

Note that the peak located at 403.5 eV in N 1s region of sub-LiPON can be attributed to NO2− species, which is not present in the FS-LiPON.

Extended Data Fig. 5

XPS survey spectra of FS-LiPON and sub-LiPON films.

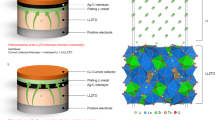

Extended Data Fig. 6 EIS testing for FS-LiPON film.

a, Testing configuration for the EIS measurement. b, EIS result collected on sub-LiPON.

Extended Data Fig. 7 Li7 MAS NMR spectrum of Li/FS-LiPON sample.

The spectrum clearly shows the presence of Li metal in Li/FS-LiPON sample.

Extended Data Fig. 8 Air exposure test on FS-LiPON film.

Photos of the same piece of FS-LiPON film before air exposure (a) and after air exposure (b), showing the film shape change due to stiffening.

Extended Data Fig. 9 Flexibility test on FS-LiPON film.

Time-lapse series of images during the flexibility test on FS-LiPON films with thicknesses of 1.7 μm, 2.6 μm and 3.7 μm, respectively. A flathead tweezer was used to apply force on the FS-LiPON films whilst a video was taken to record the bending and breakage of the film. As the time-lapse series of images show, all the FS-LiPON films exhibit remarkable flexibility upon bending. Right before film breakage, the 1.7-mm-thick film shows a high extent of bending compared with the 3.7-mm-thick film, indicating a higher flexibility.

Supplementary information

Supplementary Information

Supplementary Figs. 1–12 and Discussion.

Supplementary Video 1

A live demonstration of the flexibility and transparency of the FS-LiPON film.

Supplementary Video 2

A live demonstration of the stiffening of the FS-LiPON film after air exposure.

Supplementary Video 3

A live demonstration of the bending test of the FS-LiPON film.

Source data

Source Data Fig. 1

Source data of the XPS plot, EIS and DC polarization result in Fig. 1.

Source Data Fig. 2

Source data of the ss-NMR results, DSC measurement and nanoindentation results in Fig. 2.

Source Data Fig. 3

Source data of the Li plating voltage curve in Fig. 3.

Source Data Fig. 4

Source data of the interfacial stress analysis in Fig. 4.

Source Data Extended Data Fig. 3

Source data of the XRD results in Extended Data Fig. 3.

Source Data Extended Data Fig. 4

Source data of the detailed XPS spectra in Extended Data Fig. 4.

Source Data Extended Data Fig. 5

Source data of the survey XPS spectra in Extended Data Fig. 5.

Source Data Extended Data Fig. 6

Source data of the EIS plot in Extended Data Fig. 6.

Source Data Extended Data Fig. 7

Source data of the 7Li NMR spectrum in Extended Data Fig. 7.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cheng, D., Wynn, T., Lu, B. et al. A free-standing lithium phosphorus oxynitride thin film electrolyte promotes uniformly dense lithium metal deposition with no external pressure. Nat. Nanotechnol. 18, 1448–1455 (2023). https://doi.org/10.1038/s41565-023-01478-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41565-023-01478-0

This article is cited by

-

Li concentration change around Cu/LiPON interface measured by TOF-ERDA

Journal of Solid State Electrochemistry (2024)