Abstract

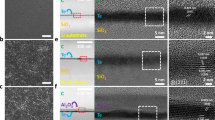

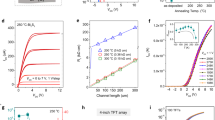

There is an emerging need for semiconductors that can be processed at near ambient temperature with high mobility and device performance. Although multiple n-type options have been identified, the development of their p-type counterparts remains limited. Here, we report the realization of tellurium thin films through thermal evaporation at cryogenic temperatures for fabrication of high-performance wafer-scale p-type field-effect transistors. We achieve an effective hole mobility of ~35 cm2 V−1 s−1, on/off current ratio of ~104 and subthreshold swing of 108 mV dec−1 on an 8-nm-thick film. High-performance tellurium p-type field-effect transistors are fabricated on a wide range of substrates including glass and plastic, further demonstrating the broad applicability of this material. Significantly, three-dimensional circuits are demonstrated by integrating multi-layered transistors on a single chip using sequential lithography, deposition and lift-off processes. Finally, various functional logic gates and circuits are demonstrated.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the plots within this paper and other findings of this study are available from the corresponding author on reasonable request.

References

Nomura, K. et al. Room-temperature fabrication of transparent flexible thin-film transistors using amorphous oxide semiconductors. Nature 432, 488–492 (2004).

Wang, Z., Nayak, P. K., Caraveo-Frescas, J. A. & Alshareef, H. N. Recent developments in p-type oxide semiconductor materials and devices. Adv. Mater. 28, 3831–3892 (2016).

Kim, M.-G., Kanatzidis, M. G., Facchetti, A. & Marks, T. J. Low-temperature fabrication of high-performance metal oxide thin-film electronics via combustion processing. Nat. Mater. 10, 382–388 (2011).

Shulaker, M. M. et al. Three-dimensional integration of nanotechnologies for computing and data storage on a single chip. Nature 547, 74–78 (2017).

Kwon, J. et al. Three-dimensional monolithic integration in flexible printed organic transistors. Nat. Commun. 10, 54 (2019).

Chen, H., Cao, Y., Zhang, J. & Zhou, C. Large-scale complementary macroelectronics using hybrid integration of carbon nanotubes and IGZO thin-film transistors. Nat. Commun. 5, 4097 (2014).

Rembert, T., Battaglia, C., Anders, A. & Javey, A. Room temperature oxide deposition approach to fully transparent, all-oxide thin-film transistors. Adv. Mater. 27, 6090–6095 (2015).

Yeom, H.-I., Ko, J. B., Mun, G. & Park, S.-H. K. High mobility polycrystalline indium oxide thin-film transistors by means of plasma-enhanced atomic layer deposition. J. Mater. Chem. C. 4, 6873–6880 (2016).

Martinez-Landeros, V. H. et al. Low-temperature thin film transistors based on pulsed laser deposited CdS active layers. Semicond. Sci. Tech. 34, 025008(2018).

Stinner, F. S. et al. Flexible, high-speed CdSe nanocrystal integrated circuits. Nano Lett. 15, 7155–7160 (2015).

Sirringhaus, H. 25th Anniversary Article: Organic field-effect transistors: the path beyond amorphous silicon. Adv. Mater. 26, 1319–1335 (2014).

Shahrjerdi, D., Hekmatshoar, B., Mohajerzadeh, S., Khakifirooz, A. & Robertson, M. High mobility poly-Ge thin-film transistors fabricated on flexible plastic substrates at temperatures below 130 °C. J. Electron. Mater. 33, 353–357 (2004).

Fortunato, E., Barquinha, P. & Martins, R. Oxide semiconductor thin-film transistors: a review of recent advances. Adv. Mater. 24, 2945–2986 (2012).

Powell, M. J. The physics of amorphous-silicon thin-film transistors. IEEE Trans. Electron Devices 36, 2753–2763 (1989).

Geier, M. L. et al. Solution-processed carbon nanotube thin-film complementary static random access memory. Nat. Nanotechnol. 10, 944–948 (2015).

Park, H. et al. High-density integration of carbon nanotubes via chemical self-assembly. Nat. Nanotechnol. 7, 787–791 (2012).

Chen, B. et al. Highly uniform carbon nanotube field-effect transistors and medium scale integrated circuits. Nano Lett. 16, 5120–5128 (2016).

Cao, Q. et al. Arrays of single-walled carbon nanotubes with full surface coverage for high-performance electronics. Nat. Nanotechnol. 8, 180–186 (2013).

Ko, H. et al. Ultrathin compound semiconductor on insulator layers for high-performance nanoscale transistors. Nature 468, 286–289 (2010).

Ahn, J.-H. et al. Heterogeneous three-dimensional electronics by use of printed semiconductor nanomaterials. Science 314, 1754–1757 (2006).

Wang, Y. et al. Field-effect transistors made from solution-grown two-dimensional tellurene. Nat. Electron. 1, 228–236 (2018).

Zhou, G. et al. High-mobility helical tellurium field-effect transistors enabled by transfer-free, low-temperature direct growth. Adv. Mater. 30, 1803109 (2018).

Dutton, R. W. & Muller, R. S. Electrical properties of tellurium thin films. Proc. IEEE 59, 1511–1517 (1971).

Okuyama, K. & Kumagai, Y. Grain growth of evaporated Te films on a heated and cooled substrate. J. Appl. Phys. 46, 1473–1477 (1975).

Weimer, P. A p-type tellurium thin-film transistor. Proc. IEEE 52, 608–609 (1964).

Okuyama, K., Yamamoto, H. & Kumagai, Y. Effect of Au nucleation centers and deposition rate on crystallinity and electronic properties of evaporated Te films. J. Appl. Phys. 46, 105–111 (1975).

Dutton, R. & Muller, R. Large grain tellurium thin films. Thin Solid Films 11, 229–236 (1972).

Wu, W., Qiu, G., Wang, Y., Wang, R. & Ye, P. Tellurene: its physical properties, scalable nanomanufacturing, and device applications. Chem. Soc. Rev. 47, 7203–7212 (2018).

Chen, J. et al. Ultrathin β-tellurium layers grown on highly oriented pyrolytic graphite by molecular-beam epitaxy. Nanoscale 9, 15945–15948 (2017).

Ellmer, K. & Mientus, R. Carrier transport in polycrystalline ITO and ZnO: Al II: the influence of grain barriers and boundaries. Thin Solid Films 516, 5829–5835 (2008).

Dimitriadis, C. A., Coxon, P. A., Dozsa, L., Papadimitriou, L. & Economou, N. Performance of thin-film transistors on polysilicon films grown by low-pressure chemical vapor deposition at various pressures. IEEE Trans. Electron Devices 39, 598–606 (1992).

Franklin, A. D. Nanomaterials in transistors: from high-performance to thin-film applications. Science 349, aab2750 (2015).

Acknowledgements

Synthesis work was supported by the US Department of Energy, Office of Science, Office of Basic Energy Sciences, Materials Sciences and Engineering Division under contract No. DE-AC02-05CH11231 within the Electronic Materials Program (No. KC1201). Work at the Molecular Foundry was supported by the Office of Science, Office of Basic Energy Sciences, of the US Department of Energy under Contract no. DE-AC02-05CH11231. We thank N. Tamura for help with XRD measurements.

Author information

Authors and Affiliations

Contributions

C.Z., C.T. and A.J. conceived the idea for the project. C.Z. and A.J. designed the experiments. C.Z., M.A. and Z.Y. fabricated the devices. C.Z. performed the device measurements. C.Z., C.T., X.S., D.-H.L., M.H., H.Y.Y.N., L.L. and M.S. performed material characterizations. C.Z. and A.J analysed the data. C.Z., C.T., D.-H.L. and A.J. wrote the manuscript. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Nanotechnology thanks Takhee Lee, SungWoo Nam and the other, anonymous, reviewer(s) for their contribution to the peer review of this work

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–10.

Rights and permissions

About this article

Cite this article

Zhao, C., Tan, C., Lien, DH. et al. Evaporated tellurium thin films for p-type field-effect transistors and circuits. Nat. Nanotechnol. 15, 53–58 (2020). https://doi.org/10.1038/s41565-019-0585-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41565-019-0585-9

This article is cited by

-

Phase-engineered synthesis of atomically thin te single crystals with high on-state currents

Nature Communications (2024)

-

High-performance terahertz modulators induced by substrate field in Te-based all-2D heterojunctions

Light: Science & Applications (2024)

-

Pulse irradiation synthesis of metal chalcogenides on flexible substrates for enhanced photothermoelectric performance

Nature Communications (2024)

-

3D integration of 2D electronics

Nature Reviews Electrical Engineering (2024)

-

Metal oxide ion gated transistors based sensors

Science China Technological Sciences (2024)