Abstract

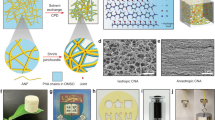

The structure–property paradox of biological tissues, in which water-rich porous structures efficiently transfer mass while remaining highly mechanically stiff, remains unsolved. Although hydrogel/sponge hybridization is the key to understanding this phenomenon, material incompatibility makes this a challenging task. Here we describe hydrogel/sponge hybrids (hydrospongels) that behave as both ultrastiff water-rich gels and reversibly squeezable sponges. The self-organizing network of cyano-p-aramid nanofibres holds approximately 5,000 times more water than its solid content. Hydrospongels, even at a water concentration exceeding 90 wt%, are hard as cartilage with an elastic modulus of 50−80 MPa, and are 10–1,000 times stiffer than typical hydrogels. They endure a compressive strain above 85% through poroelastic relaxation and hydrothermal pressure at 120 °C. This performance is produced by amphiphilic surfaces, high rigidity and an interfibrillar, interaction-driven percolating network of nanofibres. These features can inspire the development of future biofunctional materials.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All relevant data supporting the findings of this study are available within the Article and its Supplementary Information, or from the corresponding authors on reasonable request. Source data are provided with this paper. They are also available via Figshare at https://doi.org/10.6084/m9.figshare.24418129.

References

Annabi, N. et al. 25th anniversary article: rational design and applications of hydrogels in regenerative medicine. Adv. Mater. 26, 85–124 (2014).

Li, J. & Mooney, D. J. Designing hydrogels for controlled drug delivery. Nat. Rev. Mater. 1, 16071 (2016).

Zhang, X. et al. Direction-specific van der Waals attraction between rutile TiO2 nanocrystals. Science 356, 434–437 (2017).

Hua, Y. et al. Ultrafast, tough, and adhesive hydrogel based on hybrid photocrosslinking for articular cartilage repair in water-filled arthroscopy. Sci. Adv. 7, eabg0628 (2021).

Cianchetti, M., Laschi, C., Menciassi, A. & Dario, P. Biomedical applications of soft robotics. Nat. Rev. Mater. 3, 143–153 (2018).

Yang, C. & Suo, Z. Hydrogel ionotronics. Nat. Rev. Mater. 3, 125–142 (2018).

Chen, J., Peng, Q., Thundat, T. & Zeng, H. Stretchable, injectable, and self-healing conductive hydrogel enabled by multiple hydrogen bonding toward wearable electronics. Chem. Mater. 31, 4553–4563 (2019).

Shin, S.-H. et al. Ion-conductive self-healing hydrogels based on an interpenetrating polymer network for a multimodal sensor. Chem. Eng. J. 371, 452–460 (2019).

Lee, Y., Song, W. & Sun, J.-Y. Hydrogel soft robotics. Mater. Today Phys. 15, 100258 (2020).

Ohm, Y. et al. An electrically conductive silver–polyacrylamide–alginate hydrogel composite for soft electronics. Nat. Electron. 4, 185–192 (2021).

Tringides, C. M. et al. Viscoelastic surface electrode arrays to interface with viscoelastic tissues. Nat. Nanotechnol. 16, 1019–1029 (2021).

Balakrishnan, B. & Banerjee, R. Biopolymer-based hydrogels for cartilage tissue engineering. Chem. Rev. 111, 4453–4474 (2011).

Wang, W., Zhang, Y. & Liu, W. Bioinspired fabrication of high strength hydrogels from non-covalent interactions. Prog. Polym. Sci. 71, 1–25 (2017).

Liu, J. et al. Fatigue-resistant adhesion of hydrogels. Nat. Commun. 11, 1071 (2020).

Obeid, E., Adams, M. & Newman, J. Mechanical properties of articular cartilage in knees with unicompartmental osteoarthritis. J. Bone Jt Surg. 76, 315–319 (1994).

Williamson, A. K., Chen, A. C., Masuda, K., Thonar, E. J. M. & Sah, R. L. Tensile mechanical properties of bovine articular cartilage: variations with growth and relationships to collagen network components. J. Orthop. Res. 21, 872–880 (2003).

Nakayama, A. et al. High mechanical strength double‐network hydrogel with bacterial cellulose. Adv. Funct. Mater. 14, 1124–1128 (2004).

Simha, N., Carlson, C. & Lewis, J. Evaluation of fracture toughness of cartilage by micropenetration. J. Mater. Sci. Mater. Med. 15, 631–639 (2004).

Sun, J.-Y. et al. Highly stretchable and tough hydrogels. Nature 489, 133–136 (2012).

Yao, W., Geng, C., Han, D., Chen, F. & Fu, Q. Strong and conductive double-network graphene/PVA gel. RSC Adv. 4, 39588–39595 (2014).

Zhuang, Y. et al. Alginate/graphene double-network nanocomposite hydrogel beads with low-swelling, enhanced mechanical properties, and enhanced adsorption capacity. J. Mater. Chem. A 4, 10885–10892 (2016).

Li, X. et al. Strong, tough and mechanically self-recoverable poly (vinyl alcohol)/alginate dual-physical double-network hydrogels with large cross-link density contrast. RSC Adv. 8, 16674–16689 (2018).

Xu, L., Zhao, X., Xu, C. & Kotov, N. A. Water‐rich biomimetic composites with abiotic self‐organizing nanofiber network. Adv. Mater. 30, 1703343 (2018).

Zhu, J. et al. Branched aramid nanofibers. Angew. Chem. Int. Ed. 56, 11744–11748 (2017).

Zhao, Y., Li, X., Shen, J., Gao, C. & Van der Bruggen, B. The potential of Kevlar aramid nanofiber composite membranes. J. Mater. Chem. A 8, 7548–7568 (2020).

Xie, C., Guo, Z. X., Qiu, T. & Tuo, X. Construction of aramid engineering materials via polymerization‐induced para‐aramid nanofiber hydrogel. Adv. Mater. 33, 2101280 (2021).

Hu, Y. & Suo, Z. Viscoelasticity and poroelasticity in elastomeric gels. Acta Mech. Solida Sin. 25, 441–458 (2012).

Xu, Q., Wilen, L. A., Jensen, K. E., Style, R. W. & Dufresne, E. R. Viscoelastic and poroelastic relaxations of soft solid surfaces. Phys. Rev. Lett. 125, 238002 (2020).

Koo, J. M. et al. Nonstop monomer-to-aramid nanofiber synthesis with remarkable reinforcement ability. Macromolecules 52, 923–934 (2019).

Park, S.-A. et al. Aramid nanofiber templated in situ SNAr polymerization for maximizing the performance of all-organic nanocomposites. ACS Macro Lett. 9, 558–564 (2020).

Hanif, Z. et al. Butanol-mediated oven-drying of nanocellulose with enhanced dehydration rate and aqueous re-dispersion. J. Polym. Res. 25, 191 (2018).

Kim, H.-J., Roy, S. & Rhim, J.-W. Effects of various types of cellulose nanofibers on the physical properties of the CNF-based films. J. Environ. Chem. Eng. 9, 106043 (2021).

Shin, S. H. et al. Malleable hydrogel embedded with micellar cargo‐expellers as a prompt transdermal patch. Adv. Healthc. Mater. 9, 2000876 (2020).

Lin, S., Sangaj, N., Razafiarison, T., Zhang, C. & Varghese, S. Influence of physical properties of biomaterials on cellular behavior. Pharm. Res. 28, 1422–1430 (2011).

Mori, Y. et al. Usefulness of agarose mold as a storage container for three-dimensional tissue-engineered cartilage. Mater. Sci. Appl. 4, 73–78 (2013).

Yang, C. H. et al. Strengthening alginate/polyacrylamide hydrogels using various multivalent cations. ACS Appl. Mater. Interfaces 5, 10418–10422 (2013).

Yang, X., Abe, K., Biswas, S. K. & Yano, H. Extremely stiff and strong nanocomposite hydrogels with stretchable cellulose nanofiber/poly (vinyl alcohol) networks. Cellulose 25, 6571–6580 (2018).

Vecchio, D. A., Mahler, S. H., Hammig, M. D. & Kotov, N. A. Structural analysis of nanoscale network materials using graph theory. ACS Nano 15, 12847–12859 (2021).

Vecchio, D. A. et al. Spanning network gels from nanoparticles and graph theoretical analysis of their structure and properties. Adv. Mater. 34, e2201313 (2022).

Kamata, H., Akagi, Y., Kayasuga-Kariya, Y., Chung, U.-I. & Sakai, T. “Nonswellable” hydrogel without mechanical hysteresis. Science 343, 873–875 (2014).

Kamata, H., Kushiro, K., Takai, M., Chung, U. I. & Sakai, T. Non‐osmotic hydrogels: a rational strategy for safely degradable hydrogels. Angew. Chem. Int. Ed. 55, 9282–9286 (2016).

Dong, H., Snyder, J. F., Williams, K. S. & Andzelm, J. W. Cation-induced hydrogels of cellulose nanofibrils with tunable moduli. Biomacromolecules 14, 3338–3345 (2013).

Junchao, H., Yi, Z. & Jie, C. Extremely strong and transparent chitin films: a high‐efficiency, energy‐saving, and “green” route using an aqueous KOH/urea solution. Adv. Funct. Mater. 27, 1701100 (2017).

Caccavo, D., Cascone, S., Lamberti, G. & Barba, A. Hydrogels: experimental characterization and mathematical modelling of their mechanical and diffusive behaviour. Chem. Soc. Rev. 47, 2357–2373 (2018).

Han, G., Hess, C., Eriten, M. & Henak, C. R. Uncoupled poroelastic and intrinsic viscoelastic dissipation in cartilage. J. Mech. Behav. Biomed. Mater. 84, 28–34 (2018).

Kalcioglu, Z. I., Mahmoodian, R., Hu, Y., Suo, Z. & Van Vliet, K. J. From macro-to microscale poroelastic characterization of polymeric hydrogels via indentation. Soft Matter 8, 3393–3398 (2012).

Kim, H. et al. Remarkable elasticity and enzymatic degradation of bio-based poly (butylene adipate-co-furanoate): replacing terephthalate. Green Chem. 22, 7778–7787 (2020).

Noda, I. & Ozaki, Y. Two-Dimensional Correlation Spectroscopy: Applications in Vibrational and Optical Spectroscopy (John Wiley & Sons, 2005).

Eom, Y. et al. Mechano-responsive hydrogen-bonding array of thermoplastic polyurethane elastomer captures both strength and self-healing. Nat. Commun. 12, 621 (2021).

Sun, Q. et al. Covalent organic frameworks as a decorating platform for utilization and affinity enhancement of chelating sites for radionuclide sequestration. Adv. Mater. 30, 1705479 (2018).

Acknowledgements

H.K. acknowledges support from the KRICT Core Project (KS2342-10). D.X.O. acknowledges support from the National Research Foundation of Korea (NRF), funded by the Ministry of Science, ICT & Future Planning (2022R1C1C1003468 and 2022M3H4A1A03076577). J.P. acknowledges support from the NRF, funded by the Ministry of Science, ICT & Future Planning (2022R1C1C1004660, 2015M3D3A1A01064926 and GRDC Cooperative Hub (grant number RS-2023-00259341)). S.Y.H. acknowledges support from the NRF, funded by the Ministry of Science, ICT, & Future Planning (NRF-2022M3J4A1091450 and NRF-2021M3H4A3A02102349).

Author information

Authors and Affiliations

Contributions

M.L., H.K. and Y.E. performed the experiments and analysed the data. M.L., Y.E., H.K., J.P. and D.X.O. prepared the figures and wrote the manuscript. S.-A.P, H.J., J.M.K. and C.C. analysed the materials. M.L. and H.K. performed the hydrogel swelling tests. D.K. performed the experiments on the carbon nanotube/hydrospongel composite. T.S. contributed to conceptualizing the idea and analysis of the non-swelling behaviour. J.P. and D.X.O. conceived and designed the project. S.Y.H. managed the project finances. All authors approved the final version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Materials thanks Xinlin Tuo and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–24, Tables 1–11 and Notes 1–6.

Supplementary Video 1

Dialysis.

Supplementary Video 2

Boiling water.

Supplementary Video 3

Swelling test.

Source data

Source Data Fig. 2

Data underlying Fig. 2.

Source Data Fig. 3

Data underlying Fig. 3.

Source Data Fig. 4

Data underlying Fig. 4.

Source Data Fig. 5

Data underlying Fig. 5.

Source Data Fig. 6

Data underlying Fig. 6.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lee, M., Kwak, H., Eom, Y. et al. Network of cyano-p-aramid nanofibres creates ultrastiff and water-rich hydrospongels. Nat. Mater. 23, 414–423 (2024). https://doi.org/10.1038/s41563-023-01760-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-023-01760-5