Abstract

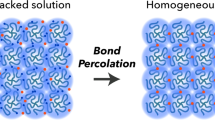

Cosmic large-scale structures, animal flocks and living tissues can be considered non-equilibrium organized systems created by dissipative processes. Replicating such properties in artificial systems is still difficult. Herein we report a dissipative network formation process in a dilute polymer–water mixture that leads to percolation-induced gel–gel phase separation. The dilute system, which forms a monophase structure at the percolation threshold, spontaneously separates into two co-continuous gel phases with a submillimetre scale (a dilute-percolated gel) during the deswelling process after the completion of the gelation reaction. The dilute-percolated gel, which contains 99% water, exhibits unexpected hydrophobicity and induces the development of adipose-like tissues in subcutaneous tissues. These findings support the development of dissipative structures with advanced functionalities for distinct applications, ranging from physical chemistry to tissue engineering.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Data generated or analysed during this study are included in the main and Supplementary Information files. Further data are available from the corresponding authors upon request. Source data are provided with this paper.

References

Riback, J. A. et al. Composition-dependent thermodynamics of intracellular phase separation. Nature 581, 209–214 (2020).

Chen, H. et al. Liquid–liquid phase separation by SARS-CoV-2 nucleocapsid protein and RNA. Cell Res. 30, 1143–1145 (2020).

Flory, P. J. Principles of Polymer Chemistry (Cornell Univ. Press, 1953).

Bischofberger, I. & Trappe, V. New aspects in the phase behaviour of poly-N-isopropyl acrylamide: systematic temperature dependent shrinking of PNiPAM assemblies well beyond the LCST. Sci. Rep. 5, 15520 (2015).

Liow, S. S. et al. Thermogels: in situ gelling biomaterial. ACS Biomater. Sci. Eng. 2, 295–316 (2016).

Van Vlierberghe, S., Dubruel, P. & Schacht, E. Biopolymer-based hydrogels as scaffolds for tissue engineering applications: a review. Biomacromolecules 12, 1387–1408 (2011).

Cobo, I., Li, M., Sumerlin, B. S. & Perrier, S. Smart hybrid materials by conjugation of responsive polymers to biomacromolecules. Nat. Mater. 14, 143–159 (2015).

D’Souza, A. A. & Shegokar, R. Polyethylene glycol (PEG): a versatile polymer for pharmaceutical applications. Expert Opin. Drug Deliv. 13, 1257–1275 (2016).

Kolate, A. et al. PEG — a versatile conjugating ligand for drugs and drug delivery systems. J. Control. Release 192, 67–81 (2014).

Akagi, Y., Matsunaga, T., Shibayama, M., Chung, U. I. & Sakai, T. Evaluation of topological defects in tetra-PEG gels. Macromolecules 43, 488–493 (2010).

Akagi, Y. et al. Examination of the theories of rubber elasticity using an ideal polymer network. Macromolecules 44, 5817–5821 (2011).

Sakai, T. et al. Design and fabrication of a high-strength hydrogel with ideally homogeneous network structure from tetrahedron-like macromonomers. Macromolecules 41, 5379–5384 (2008).

Hayashi, K. et al. Fast-forming hydrogel with ultralow polymeric content as an artificial vitreous body. Nat. Biomed. Eng. 1, 0044 (2017).

Sakai, T. (ed.) Physics of Polymer Gels (Wiley-VCH Verlag, 2020).

Matsunaga, T., Sakai, T., Akagi, Y., Chung, U. I. & Shibayama, M. Structure characterization of tetra-PEG gel by small-angle neutron scattering. Macromolecules 42, 1344–1351 (2009).

Matsunaga, T., Sakai, T., Akagi, Y., Chung, U. I. & Shibayama, M. SANS and SLS studies on tetra-arm PEG gels in as-prepared and swollen states. Macromolecules 42, 6245–6252 (2009).

Matsunaga, T. et al. SANS studies on tetra-PEG gel under uniaxial deformation. Macromolecules 44, 1203–1210 (2011).

Gao, R. et al. A highly homogeneous polymer composed of tetrahedron-like monomers for high-isotropy expansion microscopy. Nat. Nanotechnol. 16, 698–707 (2021).

Fujinaga, I. et al. Cluster growth from a dilute system in a percolation process. Polym. J. 52, 289–297 (2020).

Saeki, S., Kuwahara, N., Nakata, M. & Kaneko, M. Upper and lower critical solution temperatures in poly (ethylene glycol) solutions. Polymer 17, 685–689 (1976).

Yasuda, T., Sakumichi, N., Chung, U. I. & Sakai, T. Universal equation of state describes osmotic pressure throughout gelation process. Phys. Rev. Lett. 125, 267801 (2020).

Tanaka, T. & Fillmore, D. J. Kinetics of swelling of gels. J. Chem. Phys. 70, 1214–1218 (1979).

Kjellander, R. & Florin, E. Water structure and changes in thermal stability of the system poly(ethylene oxide)–water. J. Chem. Soc. Faraday Trans. 1 77, 2053–2077 (1981).

Bae, Y. C., Shim, J. J., Soane, D. S. & Prausnitz, J. M. Representation of vapor–liquid and liquid–liquid equilibria for binary systems containing polymers: applicability of an extended Flory–Huggins equation. J. Appl. Polym. Sci. 47, 1193–1206 (1993).

Yoshikawa, Y., Sakumichi, N., Chung, U. I. & Sakai, T. Connectivity dependence of gelation and elasticity in AB-type polymerization: an experimental comparison of the dynamic process and stoichiometrically imbalanced mixing. Soft Matter 15, 5017–5025 (2019).

Bastide, J. & Leibler, L. Large-scale heterogeneities in randomly cross-linked networks. Macromolecules 21, 2647–2649 (1988).

Shibayama, M., Shirotani, Y. & Shiwa, Y. Static inhomogeneities and dynamics of swollen and reactor-batch polymer gels. J. Chem. Phys. 112, 442–449 (2000).

Schmidt, H. R. in Protein Functionality in Foods, ACS Symposium Series Vol. 147 (ed. Cherry, J. P.) Ch. 7 131–147 (2009).

de Gennes, P. Scaling Concepts in Polymer Physics (Cornell Univ. Press, 1979).

Li, X., Nakagawa, S., Tsuji, Y., Watanabe, N. & Shibayama, M. Polymer gel with a flexible and highly ordered three-dimensional network synthesized via bond percolation. Sci. Adv. 5, eaax8647 (2019).

Yao, Y., Sakai, T., Steinhart, M., Butt, H. J. & Floudas, G. Effect of poly(ethylene oxide) architecture on the bulk and confined crystallization within nanoporous alumina. Macromolecules 49, 5945–5954 (2016).

Li, X., Watanabe, N., Sakai, T. & Shibayama, M. Probe diffusion of sol–gel transition in an isorefractive polymer solution. Macromolecules 50, 2916–2922 (2017).

Chen, Q., Huang, C., Weiss, R. A. & Colby, R. H. Viscoelasticity of reversible gelation for ionomers. Macromolecules 48, 1221–1230 (2015).

Semenov, A. N. & Rubinstein, M. Thermoreversible gelation in solutions of associative polymers. 1. Statics. Macromolecules 31, 1373–1385 (1998).

Stauffer, D., Coniglio, A. & Adam, M. Gelation and critical phenomena. Adv. Polym. Sci. 44, 103–158 (1982).

Frantz, C., Stewart, K. M. & Weaver, V. M. The extracellular matrix at a glance. J. Cell Sci. 123, 4195–4200 (2010).

Antmen, E., Vrana, N. E. & Hasirci, V. The role of biomaterials and scaffolds in immune responses in regenerative medicine: macrophage phenotype modulation by biomaterial properties and scaffold architectures. Biomater. Sci. 9, 8090–8110 (2021).

Lynn, A. D., Kyriakides, T. R. & Bryant, S. J. Characterization of the in vitro macrophage response and in vivo host response to poly(ethylene glycol)-based hydrogels. J. Biomed. Mater. Res. A 93, 941–953 (2010).

Wang, J. Z., You, M. L., Ding, Z. Q. & Ye, W. B. A review of emerging bone tissue engineering via PEG conjugated biodegradable amphiphilic copolymers. Mater. Sci. Eng. C 97, 1021–1035 (2019).

Acknowledgements

This study was supported by the Japan Society for the Promotion of Science (JSPS) through Grants-in-Aid for JSPS Research Fellows grant number 20J01344 to S.I., Early Career Scientists grant number 19K14672 to N.S., Scientific Research (B) grant numbers 22H01187 to N.S. and 22H02135 to X.L., Scientific Research (A) grant numbers 21H04688 to T.Sakai. and 21H04952 to U.C., Innovative Areas grant numbers 19H05794 and 19H05795 to Y.O. and Transformative Research Areas grant number 20H05733 to T.Sakai. This study was also supported by the Japan Science and Technology Agency (JST) PRESTO grant number JPMJPR1992 to T.U., FOREST JPMJFR201Z to X.L., JPMJFR225N to H.H., CREST grant number JPMJCR1992 to T.Sakai., JPMJCR1852 and JPMJCR20E2 to Y.O., Moon-shot R&D grant number 1125941 to T.Sakai., JPMJMS2025-14 to Y.O. and Data Creation and Utilization-Type Material Research and Development Project (JPMXP1122714694) to T.Sakai.

Author information

Authors and Affiliations

Contributions

All authors contributed to writing the paper and discussing the results. Experiments were planned, conducted and analysed by S.I., Y.I., T.U., X.L. and I.F. Discussions regarding the mechanism of GGPS involved S.I., N.S., T.K. and T.Sakai. CLSM observation was performed by S.I. and Y.O. Animal experiments were performed by S.I. and Y.I.; N.S. and T.Sakai. conceived the idea and supervised the project.

Corresponding authors

Ethics declarations

Competing interests

T.S. is an inventor on a patent application (WO2020027016) that describes the use of this hydrogel with GGPS.

Peer review

Peer review information

Nature Materials thanks Jens-Uwe Sommer and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–10.

Supplementary Video 1

Inner structure of dilute-percolated gel. 1.7 mm x 2 mm x 0.1 mm volume is shown with a grid size of 200 µm for x and y.

Supplementary Video 2

Three-dimensional phase-separated structure of dilute-percolated gel. Same view as Fig 1c. 400 µm x 400 µm x 200 µm volume is shown with a grid size of 50 µm.

Supplementary Video 3

Inner structure of c* gel. 1.7 mm x 2 mm x 0.1 mm volume is shown with a grid size of 200 µm for x and y.

Supplementary Video 4

Three-dimensional structure of dilute-percolated gel. Same view as Fig 1c. 400 µm x 400 µm x 200 µm volume is shown with a grid size of 50 µm.

Supplementary Video 5

Formation of phase-separated structure.

Supplementary Video 6

Formation of phase-separated structure during cooling process. Shown with pseudo-color to visualize density changes better. Scales are shown in the movie.

Supplementary Video 7

Dilute-percolated gel implanted subcutaneously in rats.

Supplementary Video 8

The c* gel implanted subcutaneously in rats.

Source Data Supplementary Fig. 1

Statistical source data for Supplementary Fig. 1.

Source Data Supplementary Fig. 3

Statistical source data for Supplementary Fig. 3.

Source Data Supplementary Fig. 5

Statistical source data for Supplementary Fig. 5.

Source Data Supplementary Fig. 6

Statistical source data for Supplementary Fig. 6.

Source Data Supplementary Fig. 7

Statistical source data for Supplementary Fig. 7.

Source data

Source Data Fig. 2

Statistical source data.

Source Data Fig. 3

Statistical source data.

Source Data Fig. 4

Statistical source data.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ishikawa, S., Iwanaga, Y., Uneyama, T. et al. Percolation-induced gel–gel phase separation in a dilute polymer network. Nat. Mater. 22, 1564–1570 (2023). https://doi.org/10.1038/s41563-023-01712-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-023-01712-z