Abstract

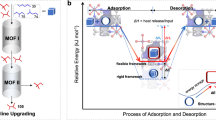

The thermal distillation of crude oil mixtures is an energy-intensive process, accounting for nearly 1% of global energy consumption. Membrane-based separations are an appealing alternative or tandem process to distillation due to intrinsic energy efficiency advantages. We developed a family of spirocyclic polytriazoles from structurally diverse monomers for membrane applications. The resulting polymers were prepared by a convenient step-growth method using copper-catalysed azide–alkyne cycloaddition, providing very fast reaction rates, high molecular weights and solubilities in common organic solvents and non-interconnected microporosity. Fractionation of whole Arabian light crude oil and atmospheric tower bottom feeds using these materials enriched the low-boiling-point components and removed trace heteroatom and metal impurities (comparable performance with the lighter feed as the commercial polyimide, Matrimid), demonstrating opportunities to reduce the energy cost of crude oil distillation with tandem membrane processes. Membrane-based molecular separation under these demanding conditions is made possible by high thermal stability and a moderate level of dynamic chain mobility, leading to transient interconnections between micropores, as revealed by the calculations of static and swollen pore structures.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The experimental data supporting the findings of this study are available within the Article and its Supplementary Information. Source data are provided with this paper.

Code availability

The code used to build the polymer models (Polymatic) is available as open-source software at https://nanohub.org/resources/17278. The complete polymer models are available via GitHub at https://github.com/Ibechis/polymer_models.

References

International Energy Agency. World Balance IEA Sankey Diagram (2018).

Sholl, D. S. & Lively, R. P. Seven chemical separations to change the world. Nature 532, 435–437 (2016).

Marchetti, P., Peeva, L. & Livingston, A. The selectivity challenge in organic solvent nanofiltration: membrane and process solutions. Annu. Rev. Chem. Biomol. Eng. 8, 473–497 (2017).

Bye, K. P. et al. Pure and mixed fluid sorption and transport in Celazole® polybenzimidazole: effect of plasticization. J. Membr. Sci. 580, 235–247 (2019).

McKeown, N. B. & Budd, P. M. Polymers of intrinsic microporosity (PIMs): organic materials for membrane separations, heterogeneous catalysis and hydrogen storage. Chem. Soc. Rev. 35, 675–683 (2006).

Cook, M., Gaffney, P. R. J., Peeva, L. G. & Livingston, A. G. Roll-to-roll dip coating of three different PIMs for organic solvent nanofiltration. J. Membr. Sci. 558, 52–63 (2018).

Jue, M. L., McKay, C. S., McCool, B. A., Finn, M. G. & Lively, R. P. Effect of nonsolvent treatments on the microstructure of PIM-1. Macromolecules 48, 5780–5790 (2015).

Thompson, K. A. et al. N-Aryl-linked spirocyclic polymers for membrane separations of complex hydrocarbon mixtures. Science 369, 310–315 (2020).

Chisca, S. et al. Polytriazole membranes with ultrathin tunable selective layer for crude oil fractionation. Science 376, 1105–1110 (2020).

Li, S. Y. et al. Hydrophobic polyamide nanofilms provide rapid transport for crude oil separation. Science 377, 1555–1561 (2022).

Kolb, H. C., Finn, M. G. & Sharpless, K. B. Click chemistry: diverse chemical function from a few good reactions. Angew. Chem. Int. Ed. 40, 2004–2021 (2001).

Hawker, C. J., Fokin, V. V., Finn, M. G. & Sharpless, K. B. Bringing efficiency to materials synthesis: the philosophy of click chemistry. Aust. J. Chem. 60, 381–383 (2007).

Kantaria, T. et al. New 1,2,3-triazole containing polyesters via click step-growth polymerization and nanoparticles made of them. Int. J. Polym. Sci. 2018, 6798258 (2018).

Zhou, X. et al. Synthesis and characterization of novel polytriazoleimides by CuAAC step-growth polymerization. Polym. J. 42, 216–222 (2010).

Binauld, S. et al. Kinetic study of copper(i)‐catalyzed click chemistry step‐growth polymerization. J. Polym. Sci. A Polym. Chem. 46, 5506–5517 (2008).

Huang, D., Liu, Y., Qin, A. & Tang, B. Z. Structure–property relationship of regioregular polytriazoles produced by ligand-controlled regiodivergent Ru(ii)-catalyzed azide–alkyne click polymerization. Macromolecules 52, 1985–1992 (2019).

Gonda, Z. & Novák, Z. Highly active copper-catalysts for azide-alkyne cycloaddition. Dalton Trans. 39, 726–729 (2010).

Kislukhin, A. A., Hong, V. P., Breitenkamp, K. E. & Finn, M. G. Relative performance of alkynes in copper-catalyzed azide-alkyne cycloaddition. Bioconjug. Chem. 24, 684–689 (2013).

Rodionov, V. O., Presolski, S. I., Gardinier, S., Lim, Y. H. & Finn, M. G. Benzimidazole and related ligands for Cu-catalyzed azide-alkyne cycloaddition. J. Am. Chem. Soc. 129, 12696–12704 (2007).

McCool, B. A., Joshi, Y. V., Bhandari, D. A., Garcia, R. & Partridge, R. D. Methods for separating wax products from hydrocarbon feedstreams. US patent 11,186,788 (2019).

Villalanti, D. C., Fuchs, K. A. & Dowling, D. C. in Encyclopedia of Analytical Chemistry: Applications, Theory and Instrumentation (John Wiley & Sons, 2018).

Prado, G. H. C., Rao, Y. & de Klerk, A. Nitrogen removal from oil: a review. Energy Fuels 31, 14–36 (2016).

Javadli, R. & de Klerk, A. Desulfurization of heavy oil. Appl. Petrochem. Res. 1, 3–19 (2012).

Ali, M. F. & Abbas, S. A review of methods for the demetallization of residual fuel oils. Fuel Process. Technol. 87, 573–584 (2006).

McCool, B. A., Bhandari, D. A. & Joshi, Y. V. Boiling free fractionation of hydrocarbon steams utilizing a membrane cascade. US patent 11,084,985 (2019).

Hart, K. E., Springmeier, J. M., McKeown, N. B. & Colina, C. M. Simulated swelling during low-temperature N2 adsorption in polymers of intrinsic microporosity. Phys. Chem. Chem. Phys. 15, 20161–20169 (2013).

Abbott, L. J., Hart, K. E. & Colina, C. M. Polymatic: a generalized simulated polymerization algorithm for amorphous polymers. Theor. Chem. Acc. 132, 1334 (2013).

Sun, H. Force field for computation of conformational energies, structures, and vibrational frequencies of aromatic polyesters. J. Comput. Chem. 15, 752–768 (1994).

Thompson, A. P. et al. LAMMPS—a flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales. Comput. Phys. Commun. 271, 108171 (2022).

Willems, T. F., Rycroft, C. H., Kazi, M., Meza, J. C. & Haranczyk, M. Algorithms and tools for high-throughput geometry-based analysis of crystalline porous materials. Microporous Mesoporous Mater. 149, 134–141 (2012).

Acknowledgements

This work was supported by ExxonMobil Research and Engineering. We thank A. Livingston (Queen Mary University of London) for generously providing the crosslinked Ultem supports, Y. Feliachi for assistance with DUCKY-9 oligostyrene rejection measurements, A. Roy for assistance with CO2 physisorption measurements and M. Rivera and Y. J. Lee for the scanning electron microscopy images. K.E.J. acknowledges the Royal Society University Research Fellowship and a 2018 Enhancement Grant and the European Research Council (ERC) under FP7 (CoMMaD, ERC grant no. 758370).

Author information

Authors and Affiliations

Contributions

Monomer and polymer synthesis, GPC, spectroscopic characterization and differential scanning calorimetry were conducted by N.C.B. Polymer model generation and analyses were carried out by I.B., A.T. and K.E.J. Blade coating, thermogravimetric analysis, gas physisorption and physisorption model fitting were conducted by R.M. Oligostyrene rejections were conducted by R.M., G.Z. and Y.-H.A. Dilute mixture separations were conducted by R.M. and N.C.B. Eleven-component mixture permeation tests in DUCKY versus Matrimid membranes and solubility tests of standard solutes in the polymers were carried out by Y.J.L. Whole-crude separations were suggested and conducted by N.D.R., B.A.M. and J.R.J. GCxGC analysis was conducted by S.H. The research was conceived by R.L. and M.G.F. N.C.B. prepared the manuscript with input from all of the authors.

Corresponding authors

Ethics declarations

Competing interests

N.C.B., R.M., B.A.M., R.L. and M.G.F. are inventors on patent applications (WO2021041162A1, US20190275469 and US20190390126; filed in Taiwan, Mexico, Canada, Russia, Korea, Brazil, Japan, Australia, China, South Africa, Singapore, United States and the International Bureau of the World Intellectual Property Organization) submitted by Georgia Tech Research Corporation and ExxonMobil Research and Engineering that covers the DUCKY polymers, membrane fabrications and crude oil fractionation applications. All the other authors declare no competing interests.

Peer review

Peer review information

Nature Materials thanks the anonymous reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1

Chemical structures of DUCKY and BP polymer repeat units.

Extended Data Fig. 2 Physical characterizaton of DUCKY polymers.

(a) Differential scanning calorimetry (DSC) of DUCKY polymers. (b) Thermogravimetric analysis (TGA) of DUCKY polymers normalized to starting sample weight. (c) Uptake of N2 (77 K) by DUCKY polymers and PIM-1. (d) CO2 physadsorption of DUCKY polymers and SBAD-1.

Extended Data Fig. 3 Scanning electron microscopy (SEM) images of thin film membrane composites.

Dense DUCKY polymer layers were coated on porous, cross-linked polyether imide Ultem.

Extended Data Fig. 4 Molecular separations performance of DUCKY membranes.

(a,b) Polystyrene rejections of DUCKY polymers in ethanol (a) and (b) toluene, compared to those of PIM-1 in (a) methanol (ref. 6) and (b) toluene (ref. 8). (c) Hydrocarbon molecular weight cutoff curve (~415 g/mol) for DUCKY-9 from an 11-component mixture using 1 mol% of each solute in toluene. Error bars represent one standard deviation from the mean of three independent runs with different membranes. The MWCO was determined by fitting all rejections above 60% to a logarithmic curve (y = 44.319ln(x) - 177.18) and interpolating to 90%.

Extended Data Fig. 5 Comparison of DUCKY-9 and Matrimid® membranes.

Rejection curves based on (a) molecular weights and (b) boiling points of molecules in a 11-component hydrocarbon mixture (the same as in Extended Data Fig. 4c, but omitting pyrene).

Extended Data Fig. 6 Crude oil fractionation with DUCKY-9 membranes.

(a,b) High stage cut fractionation of Arabian light crude at 130 °C, 55 bar. (a) Boiling point distribution of feed, 10% stage cut, 20% stage cut, 30% stage cut and retentate from Arabian light crude oil fractionated with DUCKY-9 membrane (inset from left to right: 10% stage cut sample, 20% stage cut sample, 30% stage cut sample). (b) SEM image of thinner DUCKY-9 membrane used for fractionation (~100 nm). Note that though both low and high stage cut experiments used Arabian light crude oil as the feed, the two crudes were sourced from different wells and thus the feed boiling point distributions are slightly different in panel a here and in Fig. 4a. (c,d) Fractionation of atmospheric tower bottoms with a DUCKY-9 thin film composite at 140 °C, 55 bar (panels c and d show separate independent runs). Modest enrichment was observed at a 10% stage cut with no enrichment from the feed observed at higher stage cuts; the average permeance was 0.0145 L • m−2 • h−1 • bar−1.

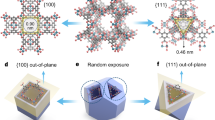

Extended Data Fig. 7 Pore structure modeling.

(a) Definition of Di (diameter of the biggest pore in the systems), Df (the diameter of the biggest sphere that can percolate through the model) and Dif (the biggest pore along Df path) on the left and their values in DUCKY-9 and DUCKY-10 on the right. Values for SBAD-1 and PIM-1 are reported for comparison8. Error bars represent standard deviations across three models. (b) Accessible (plain) and non-accessible (hatched) surface area values for probes with radius of 1.00 Å (light blue) and 1.82 Å (dark blue); error bars represent standard deviations across three models. (c) Accessible (blue) and non-accessible (red) surface area for DUCKY-9, DUCKY-10, SBAD-1 and PIM-1. The accessibility is calculated using a probe of 2.00 Å in diameter.

Extended Data Fig. 8 Polymer structure modeling.

(a,b) One representative model each of the indicated polymer. Carbon is shown in grey, oxygen in red, nitrogen in blue, hydrogen in white. (c,d) Chain distributions in three independent models of each polymer. The chain lengths are determined in the artificial polymerisation steps of the model generation process, where the effects of chain dynamics and packing during those steps are expected to impact the degrees of polymerisation achieved. The formation of longer chains (indicated by more monomer units per chain) in these systems tends to correspond to higher porosity, as was shown for PIM-1 in previous work (ref. 8 in the main text). Here, DUCKY-9 shows a greater distribution of chain lengths longer than 10 monomer units (boxed regions in panels c,d), suggesting greater predicted porosity.

Extended Data Fig. 9 Structure analysis by key dihedral angles.

(a) Definition of the dihedral angles reported in Fig. 5c. (b) Definition and value distributions, in the models, of the dihedral angles highlighted in red. On the left, the dihedral angle involving the spiro-center and on the right, the dihedral angle involving the linkage between the two monomers. Values for SBAD-1 and PIM-1 are reported for comparison.

Extended Data Fig. 10 Computational prediction of swelling behavior.

(a) Df values (b) ΔDf values (c) Dif values and (d) ΔDif values as a function of the percentage of swelling for DUCKY-9, DUCKY-10, SBAD-1 and PIM-1. Δ values are the differences between the swollen and non-swollen state and highlight the tendency of a certain polymer to change its porosity with swelling. The differential increments shown in panels b and d show that the porosity of DUCKY-10 is expected to change faster when swollen than DUCKY-9, especially from 20% swelling onward. Error bars represent standard deviation over the three independent models built for each polymer.

Supplementary information

Supplementary Information

Supplementary Figs. 1–5, Tables 1–12 and Materials and Methods.

Source data

Source Data Fig. 2

Concentration versus time data (Fig. 2b) and CO2 uptake data (Fig. 2c).

Source Data Fig. 3

Hydrocarbon rejection data (Fig. 3a,b).

Source Data Fig. 5

Dihedral angle data (Fig. 5c), swelling data (Fig. 5d) and solvent uptake data (Fig. 5e).

Source Data Extended Data Fig. 2

Differential scanning calorimetry data (Extended Data Fig. 2a), N2 uptake data (Extended Data Fig. 2c) and CO2 uptake data (Extended Data Fig. 2d).

Source Data Extended Data Fig. 4

Polystyrene rejection data (Extended Data Fig. 4).

Source Data Extended Data Fig. 5

Rejection curve data (Extended Data Fig. 5).

Source Data Extended Data Fig. 8

Polymer structure modelling data (Extended Data Fig. 8).

Source Data Extended Data Fig. 9

Dihedral angle data (Extended Data Fig. 9).

Source Data Extended Data Fig. 10

Swelling data (Extended Data Fig. 10).

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bruno, N.C., Mathias, R., Lee, Y.J. et al. Solution-processable polytriazoles from spirocyclic monomers for membrane-based hydrocarbon separations. Nat. Mater. 22, 1540–1547 (2023). https://doi.org/10.1038/s41563-023-01682-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-023-01682-2