Abstract

The properties of two-dimensional (2D) van der Waals materials can be tuned through nanostructuring or controlled layer stacking, where interlayer hybridization induces exotic electronic states and transport phenomena. Here we describe a viable approach and underlying mechanism for the assisted self-assembly of twisted layer graphene. The process, which can be implemented in standard chemical vapour deposition growth, is best described by analogy to origami and kirigami with paper. It involves the controlled induction of wrinkle formation in single-layer graphene with subsequent wrinkle folding, tearing and re-growth. Inherent to the process is the formation of intertwined graphene spirals and conversion of the chiral angle of 1D wrinkles into a 2D twist angle of a 3D superlattice. The approach can be extended to other foldable 2D materials and facilitates the production of miniaturized electronic components, including capacitors, resistors, inductors and superconductors.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Source data are provided with this paper. All other data that support the findings of this study are available within the Article and the Supplementary Information.

References

Xu, X. et al. Ultrafast epitaxial growth of metre-sized single-crystal graphene on industrial Cu foil. Sci. Bull. 62, 1074–1080 (2017).

Wang, L. et al. Epitaxial growth of a 100-square-centimetre single-crystal hexagonal boron nitride monolayer on copper. Nature 570, 91–95 (2019).

Trambly de Laissardière, G., Mayou, D. & Magaud, L. Localization of Dirac electrons in rotated graphene bilayers. Nano Lett. 10, 804–808 (2010).

Suárez Morell, E., Correa, J. D., Vargas, P., Pacheco, M. & Barticevic, Z. Flat bands in slightly twisted bilayer graphene: tight-binding calculations. Phys. Rev. B 82, 121407 (2010).

Kim, K. et al. Tunable moiré bands and strong correlations in small-twist-angle bilayer graphene. Proc. Natl Acad. Sci. USA 114, 3364–3369 (2017).

Cao, Y. et al. Unconventional superconductivity in magic-angle graphene superlattices. Nature 556, 43–50 (2018).

Hennig, G. R. Screw dislocations in graphite. Science 147, 733–734 (1965).

Xu, F., Yu, H., Sadrzadeh, A. & Yakobson, B. I. Riemann surfaces of carbon as graphene nanosolenoids. Nano Lett. 16, 34–39 (2016).

Patel, A. R. & Bahl, O. P. Evidence of screw dislocations in graphite. Br. J. Appl. Phys. 16, 169–171 (1965).

Sun, Y. Q., Alemany, L. B., Billups, W. E., Lu, J. X. & Yakobson, B. I. Structural dislocations in anthracite. J. Phys. Chem. Lett. 2, 2521–2524 (2011).

Allen, M. J. et al. Chemically induced folding of single and bilayer graphene. Chem. Commun. 6285–6287 (2009).

Mu, J. K. et al. Origami-inspired active graphene-based paper for programmable instant self-folding walking devices. Sci. Adv. 1, e1500533 (2015).

Ebbesen, T. W. & Hiura, H. Graphene in 3-dimensions: towards graphite origami. Adv. Mater. 7, 582–586 (1995).

Blees, M. K. et al. Graphene kirigami. Nature 524, 204–207 (2015).

Miskin, M. Z. et al. Graphene-based bimorphs for micron-sized, autonomous origami machines. Proc. Natl Acad. Sci. USA 115, 466–470 (2018).

Wang, Z.-J. et al. Direct observation of graphene growth and associated copper substrate dynamics by in situ scanning electron microscopy. ACS Nano 9, 1506–1519 (2015).

Hillert, M. On the theory of normal and abnormal grain growth. Acta Metall. 13, 227–238 (1965).

Wu, M. et al. Seeded growth of large single-crystal copper foils with high-index facets. Nature 581, 406–410 (2020).

Jin, S. et al. Colossal grain growth yields single-crystal metal foils by contact-free annealing. Science 362, 1021–1025 (2018).

Sutter, P. W., Flege, J.-I. & Sutter, E. A. Epitaxial graphene on ruthenium. Nat. Mater. 7, 406–411 (2008).

Zhu, W. et al. Structure and electronic transport in graphene wrinkles. Nano Lett. 12, 3431–3436 (2012).

Wang, Z.-J. et al. Stacking sequence and interlayer coupling in few-layer graphene revealed by in situ imaging. Nat. Commun. 7, 13256 (2016).

Yang, R. et al. An anisotropic etching effect in the graphene basal plane. Adv. Mater. 22, 4014–4019 (2010).

Chen, H. et al. Atomically precise, custom-design origami graphene nanostructures. Science 365, 1036–1040 (2019).

Zhao, Y. et al. Supertwisted spirals of layered materials enabled by growth on non-Euclidean surfaces. Science 370, 442–445 (2020).

Zhang, K. & Arroyo, M. Understanding and strain-engineering wrinkle networks in supported graphene through simulations. J. Mech. Phys. Solids 72, 61–74 (2014).

Pereira, V. M., Castro Neto, A. H., Liang, H. Y. & Mahadevan, L. Geometry, mechanics, and electronics of singular structures and wrinkles in graphene. Phys. Rev. Lett. 105, 156603 (2010).

Tay, R. Y. et al. Concentric and spiral few-layer graphene: growth driven by interfacial nucleation vs screw dislocation. Chem. Mater. 30, 6858–6866 (2018).

Rakovan, J. & Jaszczak, J. A. Multiple length scale growth spirals on metamorphic graphite {001} surfaces studied by atomic force microscopy. Am. Mineral. 87, 17–24 (2002).

Frank, F. C. & Read, W. T. Multiplication processes for slow moving dislocations. Phys. Rev. 79, 722–723 (1950).

Wang, Z. J. et al. The coalescence behavior of two-dimensional materials revealed by multiscale in situ imaging during chemical vapor deposition growth. ACS Nano 14, 1902–1918 (2020).

Nabarro, F. R. N. The force between two screw dislocations. Philos. Mag. A 54, 577–582 (1986).

Karamat, S. et al. Coalescence of few layer graphene grains grown by chemical vapor deposition and their stacking sequence. J. Mater. Res. 31, 46–54 (2016).

Sun, J. et al. Growth mechanism of graphene on platinum: surface catalysis and carbon segregation. Appl. Phys. Lett. 104, 152107 (2014).

Liu, Y. et al. Helical van der Waals crystals with discretized Eshelby twist. Nature 570, 358–362 (2019).

Sutter, P., Wimer, S. & Sutter, E. Chiral twisted van der Waals nanowires. Nature 570, 354–357 (2019).

Guo, W. et al. Governing rule for dynamic formation of grain boundaries in grown graphene. ACS Nano 9, 5792–5798 (2015).

Niyogi, S. et al. Covalent chemistry for graphene electronics. J. Phys. Chem. Lett. 2, 2487–2498 (2011).

Schweizer, P. et al. Mechanical cleaning of graphene using in situ electron microscopy. Nat. Commun. 11, 1743 (2020).

Rogge, P. C. et al. Real-time observation of epitaxial graphene domain reorientation. Nat. Commun. 6, 6880 (2015).

Tyurnina, A. V., Okuno, H., Pochet, P. & Dijon, J. CVD graphene recrystallization as a new route to tune graphene structure and properties. Carbon 102, 499–505 (2016).

Wang, Z. J. et al. Formation mechanism, growth kinetics, and stability limits of graphene adlayers in metal‐catalyzed CVD growth. Adv. Mater. Interfaces 5, 1800255 (2018).

Zhu, Y. et al. Unravelling surface and interfacial structures of a metal–organic framework by transmission electron microscopy. Nat. Mater. 16, 532–536 (2017).

Pirart, J. et al. Reversed size-dependent stabilization of ordered nanophases. Nat. Commun. 10, 1982 (2019).

Duerrschnabel, M. et al. Atomic structure and domain wall pinning in samarium-cobalt-based permanent magnets. Nat. Commun. 8, 54 (2017).

Acknowledgements

This work was mainly supported by the National Natural Science Foundation of China under grant no. 12027804. We acknowledge the Center for High-Resolution Electron Microscopy of ShanghaiTech University for use of the electron microscope. W.J. thanks the National Natural Science Foundation (grant no. 11974422) and the Strategic Priority Research Program of the Chinese Academy of Sciences (grant no. XDB30000000). Y. Huang thanks the National Key Research and Development Program of China (grant no. 2019YFA0308000). H.-J.G. thanks the National Key Research & Development Projects of China (grant no. 2022YFA1204100) and the National Natural Science Foundation of China (grant no. 61888102). L.B. and H.Y. thank the Strategic Priority Research Program of the Chinese Academy of Sciences (XDB30000000) and the National Key Research & Development Projects of China (grant no. 2022YFA1204100). H.C. thanks the National Natural Science Foundation of China (grant no. 52022105).

Author information

Authors and Affiliations

Contributions

Z.-J.W. conceived this project and supervised the research. Z.-J.W. modified the ESEM, planned and conducted the in situ growth experiments and did most of the ESEM data analysis. Z.-J.W., K.C., Y. Huang, P.B., M.K., Y. Hu, J.C., Z.C. and L.W. performed the TEM and AFM measurements. Theoretical simulations and implementation of the obtained results were carried out by X.K., K.L, W.J., Q.Z. and F.D. STM measurements were performed by Y. Cui, H.C., Zhongkai Liu, Zhi Liu, Y. Chen, H.-J.G. and X.B. Transport measurements were performed by L.B., Y.W., Y.Z., F.P., H.Y. and J.L. Important contributions to the interpretation of the results, conception and writing of the manuscript were made by Z.-J.W., F.D. and M.-G.W. All authors participated in the scientific discussion.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Materials thanks Peter Ercius and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1 Graphene-induced a variety of surface reconstruction on different Pt grain.

(a) In situ ESEM images recorded the folded-over graphene wrinkle on Pt polycrystal surface at 1400 °C, 25 Pa. (b) Zoom-out SEM image showing wide-angle view of Pt substrate. (c–e) AFM images recorded from the same Pt grains imaged in (a). The graphene covered surfaces are characterized by graphene-induced Pt step bunching and surface reconstructions. (f) Global SEM image showing the overview morphology of Pt substrate. (g) Schematic of typical EBSD data collection showing the orientation of the crystal reference frame, from rolling (RD), transverse (TD) and normal (ND) orthogonal directions. The EBSD map recorded from a region in (f) is shown in (h) from ND, and in (i) from RD respectively. The different orientations of the cubic model represent the local orientation of Pt surface gains.

Extended Data Fig. 2 Tubular edge structure.

(a) Atomically resolved the curvature of tubular edge. (b) The height profile of the green line in (a). (c) Analogy with paper model for demonstration folded-over graphene wrinkle. (d) Schematic view showing folded-over graphene wrinkle. The cracking tubular edge energy profile as a function of the number of carbon atoms cracking is shown in (e). (f) The corresponding atomistic models used to calculate energies of the tubular edge cracking along zigzag direction (for details of the calculation, refer to the Methods section). Note: The DFT calculations were carried out to model the graphene cracking step on the basis of experimentally obtained values for the curvature of the tubular edge (a, b). (f) shows the modelled hydrogen etching process, in which an H2 molecule was attached at the point of the highest curvature; this attachment ultimately results in graphene cracking. The total energies of representative steps in the etching process (e) indicates the cracking is energetically favourable and further verifies the proposed graphene cracking mechanism.

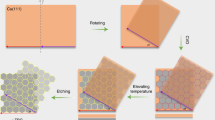

Extended Data Fig. 3 Magnified region of yellow square in main text Fig. 1d in situ showing the formation of sawtooth graphene edges.

(a) The folded-over graphene wrinkle. The purple lines highlight the tubular edges of folding-over wrinkle. (b–f) shape evolution of the etching along the tubular edge creates two new growth fronts that will relatively fast re-establish the typical zigzag growth fronts. This will lead to the formation of sawtooth graphene edges unless the crack in the tubular edge is parallel to a zigzag edge. As shown in (f) the second layer and the third layer is finally terminated by zigzag edges with 120° corner. The corresponding formation steps (graphene wrinkling, folding over, cracking and regrowth) are demonstrated in the schematics of (g) using origami-like paper folding. Green and light-green lines highlight the zigzag direction of the odd and even layer, respectively. Yellow line indicates wrinkle axis of wrinkle.

Extended Data Fig. 4 Opposite handedness of the adjacent graphene spiral and Burger vector of screw core.

(a–d) The analogy with paper model with two tearing nodal points (red crosses in d) was used to represent graphene origami-kirigami quadruplet (graphene wrinkling, folding, tearing and cracking). The folded wrinkles are easily detected in the ESEM imaging as elongated features of lower brightness, as shown in e (with a grey-level corresponding to 3-layer graphene), each of which contains one exposed layer edge (marked by green lines and arrows) and one buried layer edge (highlighted by light green lines and arrows). (f) Corresponding schematic view representing the contrast variation of SEM observation. (g), Origami-kirigami paper model representing the handedness of GSs at the nodal points of folding of collapsed wrinkle in (e). Note: The handedness of the resulting screw dislocation is defined by the sequence in which the wrinkle parts fold-over to the left or right along folding-axis. The tearing edges at a tearing point always have, as a consequence of the oppositely origami folding of wrinkles, reversed handedness to those at the two nearest adjacent tearing points, as marked by red and green curved arrows in (e–h). In situ ESEM images (h) recorded at 1400 °C, 25 Pa showing the two pair of tearing edges initializing the growth of two intertwined double spirals at the nodal point.

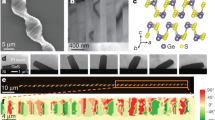

Extended Data Fig. 5 Graphene spiral structure.

(a) Atomic force microscopy imaging of GS structures. (b) The zoom-in of topography over the region indicated by the white square in (a) showing four intertwined spirals structure. (c,d) Schematic representation of initial state and final structure of graphene spiral in (a). Note: as-grown GS is fabricated by in situ observation assisted CVD method (see Methods in main text).

Extended Data Fig. 6 Scanning tunnelling microscopy (STM) imaging of GS structures.

The screw dislocation cores are seen in the STM images (a), and (b) is a zoom-in of local topography over the region indicated by the black window in panel (a). Height profile along the green line in (b) showing the Moiré corrugation. (c) The corresponding atomistic models used to reduce twist angle of top and bottom layers.

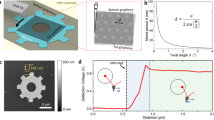

Extended Data Fig. 7 Triggering spiral growth at the endpoints of wrinkle.

(a) Large-area AFM image of CVD grown graphene on Pt substrate showing topography of graphene wrinkles. The apices of wrinkles are marked by light blue arrows. (b) The details of a tail end of wrinkle represent half cone shape, and (c) is a zoom-in of local topography over the region indicated by the white box in panel (b). (d–f) Analogy with paper model for demonstration the cracking of the tubular edge up to the apex of a wrinkle. (g) In situ ESEM images of GSs at 1400 °C showing the GSs morphology at the endpoints of wrinkle and at the middle of wrinkle. The corresponding schematic representation of the formation of GSs at the endpoints of wrinkle and at the middle of wrinkle in in-plane view (h,i) and out-of-plane view (j,k). Note: The two growth fronts formed at the endpoint of cracked tubular edge initialize two spirals growth. The handedness is indicated by the red (right-handedness) and green (left-handedness) curved arrows (the thumb giving the direction of advance along the Z-axis). The tearing nodal points (screw dislocation cores) are highlighted by red ×. The light blue and green arrows in (f,i,k) highlight growth front of GSs at nodal points.

Extended Data Fig. 8 Classifying the shape of twisted few-layer graphene by the orientations of fold-over wrinkles.

(a) Schematic of the case which has two segments of cracked wrinkle with (10°, 10°) orientation to zigzag direction of basal layer, the radial arrows indicate normal direction of zigzag edge in each layer. The layers with same orientation are labelled by same alphabet (A, B, …). (b–d) the snapshots in growth simulation of graphene corresponding to schematic (a). (e,f) Top view and side view of the final structure corresponding to schematic (a). (g) Schematic of the case which has two segments of wrinkle with (10°, 20°) orientation. (h–j) The snapshots in growth simulation of graphene corresponding to schematic (g); (k,l) top view and side view of the final structure corresponding to schematic (g). (m) Schematic of the case which has three segments of wrinkle with (-5°, 10°, -5°) orientation; (n–p) the snapshots in growth simulation of graphene corresponding to schematic (m); (q,r) top view and side view of the final structure corresponding to schematic (m). (s) Schematic of the case which has three segments of wrinkle with (-5°, 10°, 20°) orientation; (t–v) the snapshots in growth simulation of graphene corresponding to schematic (s); (w,x) Top view and side view of the final structure corresponding to schematic (s).

Extended Data Fig. 9 Reverse inference graphene spiral structure.

The ESEM image (a) shows a complex shaped multi-layer graphene. The brightness in the secondary electron image changes with each additional layer. (b) Reproduced the shape of multi-layer graphene using GSs coalescence, and (c) is a zoom-in of local brightness topography over the region indicated by the yellow window in panel (b). (d) Schematic representation of initial state (c) using origami-kirigami like graphene folds. The number of layers can be abstracted by comparing the contrast in the images with the contrast legend in the (a,b). According layout of graphene folding in (c), the coalescence of GSs are simulated by KMC in (e–h) and represent apparent layer-by-layer growth behaviour.

Extended Data Fig. 10 Characterization of exfoliated graphene on Pt by confocal laser scanning microscopy (CLSM).

(a) CLSM intensity image. (b) CLSM height image.

Supplementary information

Supplementary Information

Supplementary Figs. 1–14, Notes 1 and 2 (size of the as-grown graphene spiral; computational details) and descriptions of Videos 1–4.

Supplementary Video 1

In situ ESEM video showing the graphene origami–kirigami process on the Pt surface under CVD growth conditions from 1,000 °C to 1,400 °C. With increasing temperature, restructuring of the surface and grain growth underneath the growing flakes can be observed. Dark ribbons begin to appear on the surface, which are due to folded-over graphene on the Pt surface. Beyond 1000 °C, the onset of Pt surface grain boundary migration and graphene overlayer origami–kirigami can be detected. The graphene evolution behaviour abstracted from this video is discussed in detail in the main text.

Supplementary Video 2

In the first part of the video, the analogous paper model shows the formation process of wrinkles and subsequent folding as well as the tearing and cracking of single-layer graphene at different growth stages. In the latter part of the video, the KMC simulations reproduce the growth process of the GC.

Supplementary Video 3

The top half of the screen records the evolution of pairwise GSs with opposite handedness, showing the chirality conversion from a 1D wrinkle to a twist angle of 3D stacking layers. The graphene evolution behaviour abstracted from this video is discussed in detail in the main text. The bottom half of the screen shows a KMC simulation of the corresponding coalescence behaviour of the GSs.

Supplementary Video 4

The crystallography of a micrometre-sized Pt grain of the polycrystalline surface pre-characterized via EBSD. Below 1,000 °C, after dosing with a specific amount of C2H4, nucleation events appear first on Pt (14 10 19). With prolonged growth time, the Pt (14 10 19) surface becomes fully covered within 500 s and then the growth front of graphene extends to the adjacent grain (7 7 26). Under the given conditions, no new nucleation event occurs on the grain surface of Pt (7 7 26). All the overlayer that covered the (7 7 26) grain spilled over from the most active grain (14 10 19) in the observation region. After Pt was fully covered by graphene, the temperature was increased from 1,000 °C to 1,400 °C to initialize substrate grain growth. From there on, the sequence of graphene origami–kirigami will proceed as described in Fig. 1 of the main text, with wrinkles forming along the step bunch of the (7 7 26) surface.

Source data

Source Data Fig. 4

Statistical source data.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, ZJ., Kong, X., Huang, Y. et al. Conversion of chirality to twisting via sequential one-dimensional and two-dimensional growth of graphene spirals. Nat. Mater. 23, 331–338 (2024). https://doi.org/10.1038/s41563-023-01632-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-023-01632-y

This article is cited by

-

A double-helix dislocation in graphene

Nature Materials (2024)