Abstract

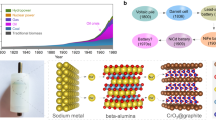

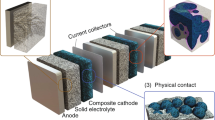

Solid-state batteries (SSBs) are expected to provide higher energy densities, faster charging performance and greater safety than lithium-ion batteries (LIBs). Introducing a solid electrolyte (SE) results in changes in materials, manufacturing processes and cell characteristics. Compared to LIBs, however, there is a limited understanding of the recyclability of SSBs. Here we review the present strategies for indirect recycling of various SSBs, such as resynthesis, and direct recycling, such as reconditioning, focusing on promising SEs including oxides, sulfides/thiophosphates/halides and polymers. We consider the recycling routes adapted to different SEs, consisting of pretreatment as well as mechanical and metallurgical processes. Future recycling solutions will need to meet the demands for robust, energy-efficient methods with minimal environmental impact, while delivering high recycling rates and good secondary material quality.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Bai, Y. et al. Energy and environmental aspects in recycling lithium-ion batteries: concept of battery identity global passport. Mater. Today 41, 304–315 (2020).

Larouche, F. et al. Progress and status of hydrometallurgical and direct recycling of Li-ion batteries and beyond. Materials (Basel) 13, 801 (2020).

Doose, S., Mayer, J. K., Michalowski, P. & Kwade, A. Challenges in ecofriendly battery recycling and closed material cycles: a perspective on future lithium battery generations. Metals 11, 291 (2021).

Kwade, A. et al. Resource-Efficient Battery Life Cycles—Driving Electric Mobility with the Circular Economy (Circular Economy Initiative, 2020).

Xu, P. et al. Efficient direct recycling of lithium-ion battery cathodes by targeted healing. Joule 4, 2609–2626 (2020).

Brückner, L., Frank, J. & Elwert, T. Industrial recycling of lithium-ion batteries—a critical review of metallurgical process routes. Metals 10, 1107 (2020).

Duffner, F. et al. Post-lithium-ion battery cell production and its compatibility with lithium-ion cell production infrastructure. Nat. Energy 6, 123–134 (2021).

Lee, Y.-G. et al. High-energy long-cycling all-solid-state lithium metal batteries enabled by silver–carbon composite anodes. Nat. Energy 5, 299–308 (2020).

Yu, S. et al. Insights into a layered hybrid solid electrolyte and its application in long lifespan high-voltage all-solid-state lithium batteries. J. Mater. Chem. A 7, 3882–3894 (2019).

Jeon, E. J., Jean-Fulcrand, A., Kwade, A. & Garnweitner, G. A room-temperature high performance all-solid-state lithium-sulfur battery enabled by a cross-linked copolymer@ceramic hybrid solid electrolyte. Nano Energy 104, 107912 (2022).

Zhao, Q., Stalin, S., Zhao, C.-Z. & Archer, L. A. Designing solid-state electrolytes for safe, energy-dense batteries. Nat. Rev. Mater. 5, 229–252 (2020).

Marchiori, C. F. N., Carvalho, R. P., Ebadi, M., Brandell, D. & Araujo, C. M. Understanding the electrochemical stability window of polymer electrolytes in solid-state batteries from atomic-scale modeling: the role of Li-ion salts. Chem. Mater. 32, 7237–7246 (2020).

Janek, J. & Zeier, W. G. Challenges in speeding up solid-state battery development. Nat. Energy 8, 230–240 (2023). This review outlines the current challenges facing SSB technology prior to market breakthrough and possible solutions.

Zhang, Z. et al. New horizons for inorganic solid state ion conductors. Energy Environ. Sci. 11, 1945–1976 (2018).

Umeshbabu, E., Zheng, B. & Yang, Y. Recent progress in all-solid-state lithium-sulfur batteries using high Li-ion conductive solid electrolytes. Electrochem. Energ. Rev. 2, 199–230 (2019).

Albertus, P. et al. Challenges for and pathways toward Li-metal-based all-solid-state batteries. ACS Energy Lett 6, 1399–1404 (2021).

Diekmann, J. et al. Ecological recycling of lithium-ion batteries from electric vehicles with focus on mechanical processes. J. Electrochem. Soc. 164, A6184–A6191 (2017).

Sojka, R. et al. (eds) in Recycling und Sekundärrohstoffe, Band 13 506–523 (Thomé-Kozmiensky, 2020).

Harper, G. et al. Recycling lithium-ion batteries from electric vehicles. Nature 575, 75–86 (2019).

Sommerville, R., Shaw-Stewart, J., Goodship, V., Rowson, N. & Kendrick, E. A review of physical processes used in the safe recycling of lithium ion batteries. Sustain. Mater. Technol. 25, e00197 (2020).

Fan, E. et al. Sustainable recycling technology for Li-ion batteries and beyond: challenges and future prospects. Chem. Rev. 120, 7020–7063 (2020).

Georgi-Maschler, T., Friedrich, B., Weyhe, R., Heegn, H. & Rutz, M. Development of a recycling process for Li-ion batteries. J. Power Sources 207, 173–182 (2012).

Chagnes, A. & Pospiech, B. A brief review on hydrometallurgical technologies for recycling spent lithium-ion batteries. J. Chem. Technol. Biotechnol. 88, 1191–1199 (2013).

Werner, D., Peuker, U. A. & Mütze, T. Recycling chain for spent lithium-ion batteries. Metals 10, 316 (2020).

Gaines, L., Dai, Q., Vaughey, J. T. & Gillard, S. Direct recycling R&D at the ReCell Center. Recycling 6, 31 (2021).

Wu, N., Wu, H., Kim, J.-K., Liu, X. & Zhang, Y. Restoration of degraded nickel-rich cathode materials for long-life lithium-ion batteries. ChemElectroChem 5, 78–83 (2018).

Chen, J. et al. Environmentally friendly recycling and effective repairing of cathode powders from spent LiFePO4 batteries. Green Chem. 18, 2500–2506 (2016).

Gupta, V. Scalable direct recycling of cathode black mass from spent lithium-ion batteries. Adv. Energy Mater 13, 2203093 (2023).

Wu, J. et al. Direct recovery: a sustainable recycling technology for spent lithium-ion battery. Energy Storage Mater. 54, 120–134 (2023).

Li, L. et al. Sustainable recovery of cathode materials from spent lithium-ion batteries using lactic acid leaching system. ACS Sustain. Chem. Eng. 5, 5224–5233 (2017).

Or, T., Gourley, S. W. D., Kaliyappan, K., Yu, A. & Chen, Z. Recycling of mixed cathode lithium‐ion batteries for electric vehicles: current status and future outlook. Carbon Energy 2, 6–43 (2020).

Zheng, X. et al. A mini-review on metal recycling from spent lithium ion batteries. Engineering 4, 361–370 (2018).

Cardarelli, F. & Dube, J. Method for recycling spent lithium metal polymer rechargeable batteries and related materials. US patent 7192564B2 (2004).

Huang, W.-Z. et al. Anode‐free solid‐state lithium batteries: a review. Adv. Energy Mater. 12, 2201044 (2022).

Jung, K.-N., Shin, H.-S., Park, M.-S. & Lee, J.-W. Solid‐state lithium batteries: bipolar design, fabrication and electrochemistry. ChemElectroChem 6, 3842–3859 (2019).

Culver, S. P., Koerver, R., Zeier, W. G. & Janek, J. On the functionality of coatings for cathode active materials in thiophosphate‐based all‐solid‐state batteries. Adv. Energy Mater. 9, 1900626 (2019).

Velázquez-Martínez, V., Santasalo-Aarnio, R. & Serna-Guerrero A critical review of lithium-ion battery recycling processes from a circular economy perspective. Batteries 5, 68 (2019).

Kononova, N., Blömeke, S., Cerdas, F., Zellmer, S. & Herrmann, C. Identification of target materials for the recycling of solid-state batteries from environmental and economic perspective using information theory entropy. In Proc. CIRP (eds Mpofu, K. & Sacks, N.) Vol. 116, 185–190 (Elsevier, 2023).

Blengini, G. A. et al. Study on the EU’s List of Critical Raw Materials (2020). Final Report (Publications Office of the European Union, 2020).

Kim, S. Y. et al. Lithium ytterbium-based halide solid electrolytes for high voltage all-solid-state batteries. ACS Mater. Lett. 3, 930–938 (2021).

Schmaltz, T. et al. Solid-State Battery Roadmap 2035+ (Fraunhofer, 2022); https://doi.org/10.24406/publica-68

Asp, L. E., Johansson, M., Lindbergh, G., Xu, J. & Zenkert, D. Structural battery composites: a review. Funct. Compos. Struct. 1, 42001 (2019).

Helmers, L. et al. Sustainable solvent‐free production and resulting performance of polymer electrolyte‐based all‐solid‐state battery electrodes. Energy Technol. 9, 2000923 (2021).

Sharanappa, C., Raghu, S. & Devendrappa, H. Enhanced electrochemical, structural, optical, thermal stability and ionic conductivity of (PEO/PVP) polymer blend electrolyte for electrochemical applications. Ionics 22, 803–814 (2016).

Xiao, W. et al. Preparation of core-shell structural single ionic conductor SiO2@Li+ and its application in PVDF-HFP-based composite polymer electrolyte. Electrochim. Acta 85, 612–621 (2012).

Surianarayanan, M., Vijayaraghavan, R. & Raghavan, K. V. Spectroscopic investigations of polyacrylonitrile thermal degradation. J. Polym. Sci. A Polym. Chem. 36, 2503–2512 (1998).

Ali, U., Karim, K. J. B. A. & Buang, N. A. A review of the properties and applications of poly(methyl methacrylate) (PMMA). Polym. Rev. 55, 678–705 (2015).

Kerner, M., Plylahan, N., Scheers, J. & Johansson, P. Thermal stability and decomposition of lithium bis(fluorosulfonyl)imide (LiFSI) salts. RSC Adv. 6, 23327–23334 (2016).

Capiglia, C. et al. DSC study on the thermal stability of solid polymer electrolyte cells. J. Power Sources 119–121, 826–832 (2003).

Azhari, L., Bong, S., Ma, X. & Wang, Y. Recycling for all solid-state lithium-ion batteries. Matter 3, 1845–1861 (2020). A Perspective, which evaluates the recyclability of different electrolyte classes and the application of conventional recycling processes to SSBs, and proposes a single process for recycling all types of SSB.

Tan, D. H. S. et al. Sustainable design of fully recyclable all solid-state batteries. MRS Energy Sustain. 7, 23 (2020). A study that focuses on the design for recycling solid-state batteries and evaluates the direct regeneration of the (sulfide) solid electrolyte and CAM.

Wang, Y.-Y., Diao, W.-Y., Fan, C.-Y., Wu, X.-L. & Zhang, J.-P. Benign recycling of spent batteries towards all-solid-state lithium batteries. Chemistry 25, 8975–8981 (2019).

Ajith, K. et al. in Solid State Batteries (eds Palaniyandy, N. et al.) 245–274 (Springer, 2022).

Tran, H. K. et al. Composite polymer electrolytes based on PVA/PAN for all-solid-state lithium metal batteries operated at room temperature. ACS Appl. Energy Mater. 3, 11024–11035 (2020).

Pal, P. & Ghosh, A. Investigation of ionic conductivity and relaxation in plasticized PMMA-LiClO4 solid polymer electrolytes. Solid State Ion. 319, 117–124 (2018).

Jie, J. et al. High-performance PVDF-HFP based gel polymer electrolyte with a safe solvent in Li metal polymer battery. J. Energy Chem. 49, 80–88 (2020).

Su, Y. et al. Rational design of a topological polymeric solid electrolyte for high-performance all-solid-state alkali metal batteries. Nat. Commun. 13, 4181 (2022).

Behera, A. in Nanotechnology in Fuel Cells (eds Song, H. et al.) 361–373 (Elsevier, 2022).

Férriz, A. M., Bernad, A., Mori, M. & Fiorot, S. End-of-life of fuel cell and hydrogen products: a state of the art. Int. J. Hydrog. Energy 44, 12872–12879 (2019).

Shieh, P. et al. Cleavable comonomers enable degradable, recyclable thermoset plastics. Nature 583, 542–547 (2020).

Hong, M. & Chen, E. Y.-X. Future directions for sustainable polymers. Trends Chem. 1, 148–151 (2019).

Hong, M. & Chen, E. Y.-X. Completely recyclable biopolymers with linear and cyclic topologies via ring-opening polymerization of γ-butyrolactone. Nat. Chem. 8, 42–49 (2016).

Li, W. et al. Thermally depolymerizable polyether electrolytes for convenient and low-cost recycling of LiTFSI. Angew. Chem. Int. Ed. 61, e202209169 (2022).

Jing, B. B. & Evans, C. M. Catalyst-free dynamic networks for recyclable, self-healing solid polymer electrolytes. J. Am. Chem. Soc. 141, 18932–18937 (2019).

Chen, W.-S. & Ho, H.-J. Recovery of valuable metals from lithium-ion batteries nmc cathode waste materials by hydrometallurgical methods. Metals 8, 321 (2018).

Jiang, Y. et al. Development of the PEO based solid polymer electrolytes for all-solid state lithium ion batteries. Polymers 10, 1237 (2018).

Batzer, M., Heck, C., Michalowski, P. & Kwade, A. Current status of formulations and scalable processes for producing sulfidic solid‐state batteries. Batteries Supercaps 5, e202200328 (2022).

Hayashi, A., Muramatsu, H., Ohtomo, T., Hama, S. & Tatsumisago, M. Improvement of chemical stability of Li3PS4 glass electrolytes by adding MxOy (M = Fe, Zn and Bi) nanoparticles. J. Mater. Chem. A 1, 6320–6326 (2013).

Sakuda, A., Hayashi, A. & Tatsumisago, M. Sulfide solid electrolyte with favorable mechanical property for all-solid-state lithium battery. Sci. Rep. 3, 2261 (2013).

Batzer, M., Voges, K., Wang, W., Michalowski, P. & Kwade, A. Systematic evaluation of materials and recipe for scalable processing of sulfide-based solid-state batteries. Mater. Today Commun. 30, 103189 (2022).

Miura, A. et al. Liquid-phase syntheses of sulfide electrolytes for all-solid-state lithium battery. Nat. Rev. Chem. 3, 189–198 (2019).

Chen, S. et al. Sulfide solid electrolytes for all-solid-state lithium batteries: structure, conductivity, stability and application. Energy Storage Mater. 14, 58–74 (2018).

Tan, D. H. S., Banerjee, A., Chen, Z. & Meng, Y. S. From nanoscale interface characterization to sustainable energy storage using all-solid-state batteries. Nat. Nanotechnol. 15, 170–180 (2020). A review proposing direct regeneration of the particulate components (solid electrolytes and composite cathodes) as part of a sustainable SSB recycling model.

Ghidiu, M., Ruhl, J., Culver, S. P. & Zeier, W. G. Solution-based synthesis of lithium thiophosphate superionic conductors for solid-state batteries: a chemistry perspective. J. Mater. Chem. A 7, 17735–17753 (2019).

Yamamoto, K. et al. Synthesis of sulfide solid electrolytes through the liquid phase: optimization of the preparation conditions. ACS Omega 5, 26287–26294 (2020).

Zheng, C. et al. High-performance all-solid-state lithium-sulfur batteries enabled by slurry-coated Li6PS5Cl/S/C composite electrodes. Front. Energy Res 8, 606494 (2021).

Wang, H., Hood, Z. D., Xia, Y. & Liang, C. Fabrication of ultrathin solid electrolyte membranes of β-Li3PS4 nanoflakes by evaporation-induced self-assembly for all-solid-state batteries. J. Mater. Chem. A 4, 8091–8096 (2016).

Zhang, Q. et al. Sulfide-based solid-state electrolytes: synthesis, stability and potential for all-solid-state batteries. Adv. Mater. 31, e1901131 (2019).

Wang, C., Liang, J., Kim, J. T. & Sun, X. Prospects of halide-based all-solid-state batteries: from material design to practical application. Sci. Adv. 8, eadc9516 (2022).

Li, X. et al. Progress and perspectives on halide lithium conductors for all-solid-state lithium batteries. Energy Environ. Sci. 13, 1429–1461 (2020).

Kwak, H. et al. Emerging halide superionic conductors for all-solid-state batteries: design, synthesis and practical applications. ACS Energy Lett. 7, 1776–1805 (2022).

Wang, C. et al. A universal wet-chemistry synthesis of solid-state halide electrolytes for all-solid-state lithium-metal batteries. Sci. Adv. 7, eabh1896 (2021).

Kim, K. J., Balaish, M., Wadaguchi, M., Kong, L. & Rupp, J. L. M. Solid‐state Li-metal batteries: challenges and horizons of oxide and sulfide solid electrolytes and their interfaces. Adv. Energy Mater. 11, 2002689 (2021).

Xia, W. et al. Reaction mechanisms of lithium garnet pellets in ambient air: the effect of humidity and CO2. J. Am. Ceram. Soc. 100, 2832–2839 (2017).

Sharafi, A. et al. Impact of air exposure and surface chemistry on Li-Li7La3Zr2O12 interfacial resistance. J. Mater. Chem. A 5, 13475–13487 (2017).

Schwich, L. et al. Recycling strategies for ceramic all-solid-state batteries—Part I: study on possible treatments in contrast to Li-ion battery recycling. Metals 10, 1523 (2020). This study shows the first possibilities for the recycling of oxide-based solid-state batteries, in particular the hydrometallurgical processing of LLZO.

Ali Nowroozi, M. et al. Towards recycling of LLZO solid electrolyte exemplarily performed on LFP/LLZO/LTO cells. ChemistryOpen 11, e202100274 (2022).

Schneider, K., Kiyek, V., Finsterbusch, M., Yagmurlu, B. & Goldmann, D. Acid leaching of Al- and Ta-substituted Li7La3Zr2O12 (LLZO) solid electrolyte. Metals 13, 834 (2023).

Waidha, A. I. et al. Recycling of all-solid-state Li-ion batteries: a case study of the separation of individual components within a system composed of LTO, LLZTO and NMC. ChemSusChem 16, e202202361 (2022). This study shows the separation of an LTO-LLZO-NMC solid-state battery and the material selective leaching where the pure materials can be reused after further treatment.

Ihrig, M. et al. Thermal recovery of the electrochemically degraded LiCoO2/Li7La3Zr2O12:Al,Ta interface in an all-solid-state lithium battery. ACS Appl. Mater. Interfaces 15, 4101–4112 (2023). This study shows the degradation effects in an LLZO-LCO solid-state battery and uses a thermal recovery (annealing) step to directly recover the materials.

Qin, Z. et al. Recycling garnet-type electrolyte toward superior cycling performance for solid-state lithium batteries. Energy Storage Mater. 49, 360–369 (2022).

Schnell, J. et al. All-solid-state lithium-ion and lithium metal batteries—paving the way to large-scale production. J. Power Sources 382, 160–175 (2018).

Kim, K. M., Shin, D. O. & Lee, Y.-G. Effects of preparation conditions on the ionic conductivity of hydrothermally synthesized Li1 + xAlxTi2 − x(PO4)3 solid electrolytes. Electrochim. Acta 176, 1364–1373 (2015).

Sarner, S., Schreiber, A., Menzler, N. H. & Guillon, O. Recycling strategies for solid oxide cells. Adv. Energy Mater. 12, 2201805 (2022).

Liang, J. et al. Recent progress on solid-state hybrid electrolytes for solid-state lithium batteries. Energy Storage Mater. 21, 308–334 (2019).

Wang, M. et al. Challenges in recycling spent lithium-ion batteries: spotlight on polyvinylidene fluoride removal. Glob. Chall. 7, 2200237 (2023).

Asmatulu, E., Twomey, J. & Overcash, M. Recycling of fiber-reinforced composites and direct structural composite recycling concept. J. Composite Mater. 48, 593–608 (2014).

Karuppannan Gopalraj, S. & Kärki, T. A review on the recycling of waste carbon fibre/glass fibre-reinforced composites: fibre recovery, properties and life-cycle analysis. SN Appl. Sci 2, 433 (2020).

Harper, G. D. J. et al. Roadmap for a sustainable circular economy in lithium-ion and future battery technologies. J. Phys. Energy 5, 21501 (2023). A roadmap showing the possible development of each LIB recycling process and adaptations for the next generation of batteries, taking into account life-cycle analysis, legislation and digitalization.

European Comission. Regulation Of The European Parliament and of the Council Concerning Batteries and Waste Batteries, Repealing Directive 2006/66/EC and Amending Regulation (EU) No 2019/1020 (European Commission, 2020).

Interim Measures for the Management of Power Battery Recovery and Utilization of New Energy Vehicles issued (Ministry of Industry and Information Technology, 2018).

Responsible Battery Recycling Act of 2022. State of California—AB 2440 (State of California, 2022).

Nikodimos, Y., Su, W.-N. & Hwang, B. J. Halide solid‐state electrolytes: stability and application for high voltage all‐solid‐state Li batteries. Adv. Energy Mater. 13, 2202854 (2023).

Riegger, L. M., Schlem, R., Sann, J., Zeier, W. G. & Janek, J. Lithium-metal anode instability of the superionic halide solid electrolytes and the implications for solid-state batteries. Angew. Chem. Int. Ed. 60, 6718–6723 (2021).

Chai, J. et al. In situ generation of poly(vinylene carbonate) based solid electrolyte with interfacial stability for LiCoO2 lithium batteries. Adv. Sci. 4, 1600377 (2017).

Porcarelli, L. et al. Single-ion triblock copolymer electrolytes based on poly(ethylene oxide) and methacrylic sulfonamide blocks for lithium metal batteries. J. Power Sources 364, 191–199 (2017).

Wang, H. et al. Reviewing the current status and development of polymer electrolytes for solid-state lithium batteries. Energy Storage Mater. 33, 188–215 (2020).

Golubkov, A. W. et al. Thermal runaway of commercial 18650 Li-ion batteries with LFP and NCA cathodes—impact of state of charge and overcharge. RSC Adv. 5, 57171–57186 (2015).

Yun, L. et al. Metallurgical and mechanical methods for recycling of lithium-ion battery pack for electric vehicles. Resour. Conserv. Recycling 136, 198–208 (2018).

Liu, Y. et al. Composition modulation and structure design of inorganic-in-polymer composite solid electrolytes for advanced lithium batteries. Small 16, e1902813 (2020).

Acknowledgements

This work was supported by the German Ministry of Education and Research (BMBF) through the S²taR (03XP0319A, 03XP0319D) and FB2-Prod (03XP0432A, 03XP0432E) projects. We also acknowledge funding from the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) under Germany´s Excellence Strategy (EXC 2163/1—Sustainable and Energy Efficient Aviation—project ID 390881007).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Energy thanks the anonymous reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ahuis, M., Doose, S., Vogt, D. et al. Recycling of solid-state batteries. Nat Energy 9, 373–385 (2024). https://doi.org/10.1038/s41560-024-01463-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-024-01463-4