Abstract

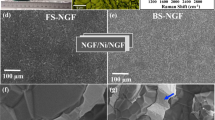

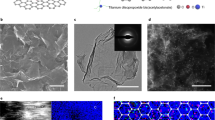

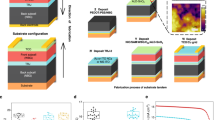

The instability of rear electrodes undermines the long-term operational durability of efficient perovskite solar cells. Here, a composite electrode of copper–nickel (Cu–Ni) alloy stabilized by in situ grown bifacial graphene is designed. The alloying makes the work function of Cu suitable for regular perovskite solar cells. Cu–Ni is the ideal substrate for preparing high-quality graphene via chemical vapour deposition, which simultaneously protects the device from oxygen, water and reactions between internal components. To rivet the composite electrode with the semi-device, a thermoplastic copolymer is applied as an adhesive layer through hot pressing. The resulting devices achieve power conversion efficiencies of 24.34% and 20.76% (certified 20.86%) with aperture areas of 0.09 and 1.02 cm2, respectively. The devices show improved stability: 97% of their initial efficiency is retained after 1,440 hours of a damp-heat test at 85 °C with a relative humidity of 85%; 95% of their initial efficiency is retained after 5,000 hours at maximum power point tracking under continuous 1 sun illumination.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Source data are provided with this paper. All data generated or analysed during this study are included in the published article and its Supplementary Information and Source Data files.

References

Kojima, A., Teshima, K., Shirai, Y. & Miyasaka, T. Organometal halide perovskites as visible-light sensitizers for photovoltaic cells. J. Am. Chem. Soc. 131, 6050–6051 (2009).

Kim, H. S. et al. Lead iodide perovskite sensitized all-solid-state submicron thin film mesoscopic solar cell with efficiency exceeding 9%. Sci. Rep. 2, 591 (2012).

Jeon, N. J. et al. Compositional engineering of perovskite materials for high-performance solar cells. Nature 517, 476–480 (2015).

Li, J. et al. Highly efficient thermally co-evaporated perovskite solar cells and mini-modules. Joule 4, 1035–1053 (2020).

Yoo, J. J. et al. Efficient perovskite solar cells via improved carrier management. Nature 590, 587–593 (2021).

Cai, M. et al. Cost-performance analysis of perovskite solar modules. Adv. Sci. 4, 1600269 (2017).

Boyd, C. C., Cheacharoen, R., Leijtens, T. & McGehee, M. D. Understanding degradation mechanisms and improving stability of perovskite photovoltaics. Chem. Rev. 119, 3418–3451 (2019).

Wang, Q., Phung, N., Di Girolamo, D., Vivo, P. & Abate, A. Enhancement in lifespan of halide perovskite solar cells. Energy Environ. Sci. 12, 865–886 (2019).

Bai, S. et al. Planar perovskite solar cells with long-term stability using ionic liquid additives. Nature 571, 245–250 (2019).

Kong, J. et al. CO2 doping of organic interlayers for perovskite solar cells. Nature 594, 51–56 (2021).

Wang, Y. B. et al. Stabilizing heterostructures of soft perovskite semiconductors. Science 365, 687–691 (2019).

Yang, S. et al. Stabilizing halide perovskite surfaces for solar cell operation with wide-bandgap lead oxysalts. Science 365, 473–478 (2019).

Xiao, J.-W. et al. Contact engineering: electrode materials for highly efficient and stable perovskite solar cells. Sol. RRL 1, 1700082 (2017).

Li, J. W., Dong, Q. S., Li, N. & Wang, L. D. Direct evidence of ion diffusion for the silver-electrode-induced thermal degradation of inverted perovskite solar cells. Adv. Energy Mater. 7, 1602922 (2017).

Kato, Y. et al. Silver iodide formation in methyl ammonium lead iodide perovskite solar cells with silver top electrodes. Adv. Mater. Interfaces 2, 1500195 (2019).

Xiong, J. et al. Interface degradation of perovskite solar cells and its modification using an annealing-free TiO2 NPs layer. Org. Electron. 30, 30–35 (2016).

Lin, X. S. et al. Efficiency progress of inverted perovskite solar cells. Energy Environ. Sci. 13, 3823–3847 (2020).

Domanski, K. et al. Not all that glitters is gold: metal-migration-induced degradation in perovskite solar cells. ACS Nano 10, 6306–6314 (2016).

Schulz, P. et al. Interface energetics in organo-metal halide perovskite-based photovoltaic cells. Energy Environ. Sci. 7, 1377–1381 (2014).

Arora, N. et al. Perovskite solar cells with CuSCN hole extraction layers yield stabilized efficiencies greater than 20%. Science 358, 768–771 (2017).

Peng, J. et al. Nanoscale localized contacts for high fill factors in polymer-passivated perovskite solar cells. Science 371, 390–395 (2021).

Zhao, J. J. et al. Is Cu a stable electrode material in hybrid perovskite solar cells for a 30-year lifetime? Energy Environ. Sci. 9, 3650–3656 (2016).

Calio, L., Kazim, S., Graetzel, M. & Ahmad, S. Hole-transport materials for perovskite solar cells. Angew. Chem. Int. Ed. 55, 14522–14545 (2016).

Li, X. D. et al. Chemical anti-corrosion strategy for stable inverted perovskite solar cells. Sci. Adv. 6, eabd1580 (2020).

Mei, A. Y. et al. Stabilizing perovskite solar cells to IEC61215:2016 standards with over 9,000-h operational tracking. Joule 4, 2646–2660 (2020).

Bogachuk, D. et al. Low-temperature carbon-based electrodes in perovskite solar cells. Energy Environ. Sci. 13, 3880–3916 (2020).

Su, H. Z. et al. The application of graphene derivatives in perovskite solar cells. Small Methods 4, 2000507 (2020).

Nguyen, V. L. et al. Layer-controlled single-crystalline graphene film with stacking order via Cu–Si alloy formation. Nat. Nanotech. 15, 861–867 (2020).

Huang, Z. Q. et al. Water-resistant and flexible perovskite solar cells via a glued interfacial layer. Adv. Funct. Mater. 29, 1902629 (2019).

Naito, M. & Takanashi, Y. Back surface protection sheet used for manufacturing solar cell module, comprises base material sheet, sealing material containing ethylene-vinyl acetate copolymer and fluororesin layer comprising compound comprising acryloyl groups. JP2015185802-A. (2015).

Tanabe, J., Tanaka, A. & Kawasaki, M. Sealing film for forming solar cell module, is obtained by carrying out thermal reaction of ethylene-vinyl acetate copolymer, organic peroxide, crosslinking adjuvant as crosslinking agent and additive with self-polymerization property. JP2016092353-A. (2016).

Malinauskas, T. et al. Enhancing thermal stability and lifetime of solid-state dye-sensitized solar cells via molecular engineering of the hole-transporting material spiro-OMeTAD. ACS Appl. Mater. Interfaces 7, 11107–11116 (2015).

Li, M. H. et al. Performance improvement of perovskite solar cells via spiro-OMeTAD pre-crystallization. J. Mater. Sci. 55, 12264–12273 (2020).

Lin, D. X. et al. Construction of an iodine diffusion barrier using network structure silicone resin for stable perovskite solar cells. ACS Appl. Mater. Interfaces 13, 8138–8146 (2021).

Chen, C. L. et al. Effect of BCP buffer layer on eliminating charge accumulation for high performance of inverted perovskite solar cells. RSC Adv. 7, 35819–35826 (2017).

Wu, C. et al. Highly conductive nanocomposites with three-dimensional, compactly interconnected graphene networks via a self-assembly process. Adv. Funct. Mater. 23, 506–513 (2013).

Li, Y. et al. Multifunctional fullerene derivative for interface engineering in perovskite solar cells. J. Am. Chem. Soc. 137, 15540–15547 (2015).

Uddin, A., Upama, M. B., Yi, H. M. & Duan, L. P. Encapsulation of organic and perovskite solar cells: a review. Coatings 9, 65–81 (2019).

Shi, L. et al. Gas chromatography-mass spectrometry analyses of encapsulated stable perovskite solar cells. Science 368, eaba2412 (2020).

Metikos-Hukovic, M., Babic, R. & Paic, I. Copper corrosion at various pH values with and without the inhibitor. J. Appl. Electrochem. 30, 617–624 (2000).

Shlenskaya, N. N. et al. Light-induced reactivity of gold and hybrid perovskite as a new possible degradation mechanism in perovskite solar cells. J. Mater. Chem. A 6, 1780 (2018).

Cacovich, S. et al. Gold and iodine diffusion in large area perovskite solar cells under illumination. Nanoscale 9, 4700–4706 (2017).

Zhang, B. et al. Low-temperature chemical vapor depositon growth of graphene from toluene on electropolished copper foils. ACS Nano 6, 2471–2476 (2012).

Zhang, C. Y. et al. Efficient stable graphene-based perovskite solar cells with high flexibility in device assembling via modular architecture design. Energy Environ. Sci. 12, 3585–3594 (2019).

Boonmongkolras, P. et al. Universal passivation strategy for the hole transport layer/perovskite interface via an alkali treatment for high-efficiency perovskite solar cells. Sol. RRL 5, 2000793 (2021).

Wang, Y. et al. Reliable measurement of perovskite solar cells. Adv. Mater. 31, 1803231 (2019).

Acknowledgements

We thank Z. Bao and Y. Han from the Instrumental Analysis Center of Shanghai Jiao Tong University (China) for assistance with SEM measurements; J. Ding from the Instrumental Analysis Center of Shanghai Jiao Tong University (China) for assistance with time-of-flight secondary ion mass spectroscopy measurements; X. Ding and N. Zhang from the Instrumental Analysis Center of Shanghai Jiao Tong University (China) for assistance with XPS and ultraviolet photoelectron spectroscopy measurements; R. Wang from the Instrumental Analysis Center of Shanghai Jiao Tong University (China) and K. Jiang from the Engineering Research Center for Nanophotonics and Advanced Instrument, Ministry of Education, School of Physics and Electronic Science, East China Normal University (China) for assistance with Raman spectra measurements; X. Liu and Y. Liu from the Instrumental Analysis Center of Shanghai Jiao Tong University (China) for assistance with GC-MS measurements; and Y. Liu and Y. Li from the Instrumental Analysis Center of Shanghai Jiao Tong University (China) for assistance with static contact angle measurements. Funding was provided by the and National Key R&D Program of China grant 2020YFB1506400 (Q.H.), National Natural Science Foundation of China grant 11834011 (L.H.), National Natural Science Foundation of China grant 12074245 (L.H.), National Natural Science Foundation of China grant 52102281 (Y. Wang) and Shanghai Sailing Program grant 21YF1421600 (Y. Wang).

Author information

Authors and Affiliations

Contributions

X.L., Y. Wang and L.H. conceived of the work. X.L. and H. Su fabricated the solar cells. X.L. conducted SEM, AFM, electrochemical impedance spectroscopy and C–V, transient photovoltage, J–V and time-of-flight secondary ion mass spectroscopy measurements. H. Su, S.H. and Y.S. prepared the Cu–Ni alloy and graphene and synthesized the EVA-based adhesive. H. Su, S.H. and Y.S. performed AFM, XPS and ultraviolet photoelectron spectroscopy measurements. X.Y. and Q.H. assisted with the analysis of time-of-flight secondary ion mass spectroscopy and XPS. J.F. assisted with the analysis of the Tafel polarization curves. Z.Q. assisted with measurement of transient photovoltage. Y. Wu assisted with the analysis of GC-MS. X.L. wrote the first draught of the manuscript. X.L., Y.Z., H. Segawa, M.G., Y. Wang and L.H. revised the manuscript. All authors analysed the data and reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Energy thanks Jin-Wook Lee and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–24 and Tables 1–4.

Supplementary Data 1

The individual data behind Supplementary Figs. 11 and 20.

Source data

Source Data Fig. 4

The individual data behind the average values in Fig. 4.

Rights and permissions

About this article

Cite this article

Lin, X., Su, H., He, S. et al. In situ growth of graphene on both sides of a Cu–Ni alloy electrode for perovskite solar cells with improved stability. Nat Energy 7, 520–527 (2022). https://doi.org/10.1038/s41560-022-01038-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-022-01038-1

This article is cited by

-

Defect passivation in methylammonium/bromine free inverted perovskite solar cells using charge-modulated molecular bonding

Nature Communications (2024)

-

Inhibition of defect-induced α-to-δ phase transition for efficient and stable formamidinium perovskite solar cells

Nature Communications (2023)

-

Towards linking lab and field lifetimes of perovskite solar cells

Nature (2023)

-

Stabilization of 3D/2D perovskite heterostructures via inhibition of ion diffusion by cross-linked polymers for solar cells with improved performance

Nature Energy (2023)

-

Stability challenges for the commercialization of perovskite–silicon tandem solar cells

Nature Reviews Materials (2023)