Abstract

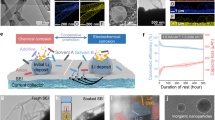

The rechargeable lithium metal battery has attracted wide attention as a next-generation energy storage technology. However, simultaneously achieving high cell-level energy density and long cycle life in realistic batteries is still a great challenge. Here we investigate the degradation mechanisms of Li || LiNi0.6Mn0.2Co0.2O2 pouch cells and present fundamental linkages among Li thickness, electrolyte depletion and the structure evolution of solid–electrolyte interphase layers. Different cell failure processes are discovered when tuning the anode to cathode capacity ratio in compatible electrolytes. An optimal anode to cathode capacity ratio of 1:1 emerges because it balances well the rates of Li consumption, electrolyte depletion and solid–electrolyte interphase construction, thus decelerating the increase of cell polarization and extending cycle life. Contrary to conventional wisdom, long cycle life is observed by using ultra-thin Li (20 µm) in balanced cells. A prototype 350 Wh kg−1 pouch cell (2.0 Ah) achieves over 600 long stable cycles with 76% capacity retention without a sudden cell death.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data generated this study are included in the published article and its Supplementary Information.

References

Liu, J. et al. Pathways for practical high-energy long-cycling lithium metal batteries. Nat. Energy 4, 180–186 (2019).

Whittingham, M. S. Ultimate limits to intercalation reactions for lithium batteries. Chem. Rev. 114, 11414–11443 (2014).

Whittingham, M. S. Lithium batteries and cathode materials. Chem. Rev. 104, 4271–4302 (2004).

Xiao, J. How lithium dendrites form in liquid batteries. Science 366, 426–427 (2019).

Xu, W. et al. Lithium metal anodes for rechargeable batteries. Energy Environ. Sci. 7, 513–537 (2014).

Jiao, S. et al. Behavior of lithium metal anodes under various capacity utilization and high current density in lithium metal batteries. Joule 2, 110–124 (2018).

Wu, B., Lochala, J., Taverne, T. & Xiao, J. The interplay between solid electrolyte interface (SEI) and dendritic lithium growth. Nano Energy 40, 34–41 (2017).

Chen, S. et al. Critical parameters for evaluating coin cells and pouch cells of rechargeable Li-metal batteries. Joule 3, 1094–1105 (2019).

Cao, X. et al. Monolithic solid–electrolyte interphases formed in fluorinated orthoformate-based electrolytes minimize Li depletion and pulverization. Nat. Energy 4, 796–805 (2019).

Ren, X. et al. High-concentration ether electrolytes for stable high-voltage lithium metal batteries. ACS Energy Lett. 4, 896–902 (2019).

Fang, C. et al. Quantifying inactive lithium in lithium metal batteries. Nature 572, 511–515 (2019).

Yamada, Y., Wang, J., Ko, S., Watanabe, E. & Yamada, A. Advances and issues in developing salt-concentrated battery electrolytes. Nat. Energy 4, 269–280 (2019).

Fan, X. et al. Non-flammable electrolyte enables Li-metal batteries with aggressive cathode chemistries. Nat. Nanotechnol. 13, 715–722 (2018).

Shen, L. et al. Progress on lithium dendrite suppression strategies from the interior to exterior by hierarchical structure designs. Small 27, 2000699 (2020).

Zhang, Y. et al. Towards better Li metal anodes: challenges and strategies. Mater. Today 33, 56–74 (2020).

Lin, D., Liu, Y. & Cui, Y. Reviving the lithium metal anode for high-energy batteries. Nat. Nanotechnol. 12, 194–206 (2017).

Niu, C. et al. Self-smoothing anode for achieving high-energy lithium metal batteries under realistic conditions. Nat. Nanotechnol. 14, 594–601 (2019).

Kang, N. et al. Cathode porosity is a missing key parameter to optimize lithium-sulfur battery energy density. Nat. Commun. 10, 4597 (2019).

Hwang, J. et al. Customizing a Li–metal battery that survives practical operating conditions for electric vehicle applications. Energy Environ. Sci. 12, 2174–2184 (2019).

Ue, M., Sakaushi, K. & Uosaki, K. Basic knowledge in battery research bridging the gap between academia and industry. Mater. Horiz. 7, 1937–1954 (2020).

Shi, P. et al. Electrochemical diagram of an ultrathin lithium metal anode in pouch cells. Adv. Mater. 31, 1902785 (2019).

Palanisamy, M., Parikh, V. P., Parekh, M. H. & Pol, V. G. Lithium metal battery pouch cell assembly and prototype demonstration using tailored polypropylene separator. Energy Technol. 8, 2000094 (2020).

Zhang, X. et al. Rethinking how external pressure can suppress dendrites in lithium metal batteries. J. Electrochem. Soc. 166, A3639–A3652 (2019).

Barai, P., Higa, K. & Srinivasan, V. Impact of external pressure and electrolyte transport properties on lithium dendrite growth. J. Electrochem. Soc. 165, A2654–A2666 (2018).

Niu, C. et al. High-energy lithium metal pouch cells with limited anode swelling and long stable cycles. Nat. Energy 4, 551–559 (2019).

Lee, Y. G. et al. High-energy long-cycling all-solid-state lithium metal batteries enabled by silver–carbon composite anodes. Nat. Energy 5, 299–308 (2020).

Weber, R. et al. Long cycle life and dendrite-free lithium morphology in anode-free lithium pouch cells enabled by a dual-salt liquid electrolyte. Nat. Energy 4, 683–689 (2019).

Louli, A. J. et al. Exploring the impact of mechanical pressure on the performance of anode-free lithium metal cells. J. Electrochem. Soc. 166, A1291–A1299 (2019).

Louli, A. J. et al. Diagnosing and correcting anode-free cell failure via electrolyte and morphological analysis. Nat. Energy 5, 693–702 (2020).

Genovese, M. et al. Combinatorial methods for improving lithium metal cycling efficiency. J. Electrochem. Soc. 165, A3000–A3013 (2018).

Xiao, J., Yang, Y., Liu, D. & Deng, Z. D. Li-Batt Design App (Pacific Northwest National Laboratory, 2020).

Wu, B. et al. Good practices for rechargeable lithium metal batteries. J. Electrochem. Soc. 166, A4141–A4149 (2019).

Xiao, J. et al. Understanding and applying coulombic efficiency in lithium metal batteries. Nat. Energy 5, 561–568 (2020).

Zhu, Y. et al. Design principles for self-forming interfaces enabling stable lithium metal anodes. Proc. Natl Acad. Sci. USA 117, 27195–27203 (2020).

Ren, X. et al. Enabling high-voltage lithium-metal batteries under practical conditions. Joule 3, 1662–1676 (2019).

Lu, D. et al. Failure mechanism for fast-charged lithium metal batteries with liquid electrolytes. Adv. Energy Mater. 5, 1400993 (2015).

Goodenough, J. B. & Park, K. S. The Li-ion rechargeable battery: a perspective. J. Am. Chem. Soc. 135, 1167–1176 (2013).

Yang, S., Zavalij, P. Y. & Whittingham, M. S. Anodes for lithium batteries: tin revisited. Electrochem. Commun. 5, 587–590 (2003).

Kim, D. et al. Porosity controlled carbon-based 3D anode for lithium metal batteries by a slurry based process. Chem. Commun. 56, 13040–13043 (2020).

Kim, S. et al. Correlation of electrochemical and mechanical responses: differential analysis of rechargeable lithium metal cells. J. Power Sources 463, 228180 (2020).

Acknowledgements

This research was supported by the Assistant Secretary for Energy Efficiency and Renewable Energy, Office of Vehicle Technologies of the US Department of Energy (DOE) through the Advanced Battery Materials Research Program (Battery500 Consortium). The SEM and TEM were conducted in the William R. Wiley Environmental Molecular Sciences Laboratory, a national scientific user facility sponsored by DOE’s Office of Biological and Environmental Research and located at PNNL. PNNL is operated by Battelle for the DOE under contract DE-AC05-76RLO1830. We thank L. Zou and C. Wang of PNNL for the TEM characterizations. We thank K. Murata of Nippon Shokubai for providing the LiFSI salt.

Author information

Authors and Affiliations

Contributions

J.L. directed and led the research. J.X. led the pouch cell design and fabrication. C.N. assembled the pouch cells, performed the electrochemical measurements and carried out the characterizations. D.L., J.A.L. and C.S.A. participated in discussions. X.C., W.X. and J.-G.Z. provided the electrolyte. M.E.G. helped on cell disassembly and safety protection. M.S.W. provided advice for the research and for the analysis of the electrochemical results. C.N., J.X. and J.L. cowrote the manuscript with input from all authors.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Energy thanks Guohua Chen, Tetsuya Osaka and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–7.

Rights and permissions

About this article

Cite this article

Niu, C., Liu, D., Lochala, J.A. et al. Balancing interfacial reactions to achieve long cycle life in high-energy lithium metal batteries. Nat Energy 6, 723–732 (2021). https://doi.org/10.1038/s41560-021-00852-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-021-00852-3

This article is cited by

-

Controlled large-area lithium deposition to reduce swelling of high-energy lithium metal pouch cells in liquid electrolytes

Nature Energy (2024)

-

Molecular anchoring of free solvents for high-voltage and high-safety lithium metal batteries

Nature Communications (2024)

-

Hierarchical Li electrochemistry using alloy-type anode for high-energy-density Li metal batteries

Nature Communications (2024)

-

Metal electrodes for next-generation rechargeable batteries

Nature Reviews Electrical Engineering (2024)

-

An empirical model for high energy density lithium-(ion) batteries with ultra-thick electrodes

Tungsten (2024)