Abstract

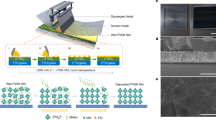

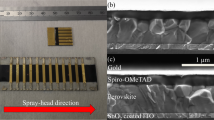

Novel photovoltaic technologies such as perovskites hold the promise of a reduced levelized cost of electricity, but the low-cost potential depends on the ability to scale-up solution-based deposition. So far, complex fluid dynamics have limited the solution deposition of uniform pinhole-free organic–inorganic perovskite thin films over large areas. Here, we show that very small amounts (tens of parts per million) of surfactants (for example, l-α-Phosphatidylcholine) dramatically alter the fluid drying dynamics and increase the adhesion of the perovskite ink to the underlying non-wetting charge transport layer. The additives enable blading of smooth perovskite films at a coating rate of 180 m h–1 with root-mean-square roughness of 14.5 nm over 1 cm. The surfactants also passivate charge traps, resulting in efficiencies over 20% for small-area solar cells. Fast blading in air of perovskite films results in stabilized module efficiencies of 15.3% and 14.6% measured at aperture areas of 33.0 cm2 and 57.2 cm2, respectively.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Yablonovitch, E. Lead halides join the top optoelectronic league. Science 351, 1401 (2016).

Yang, Y. & You, J. Make perovskite solar cells stable. Nature 544, 155–156 (2017).

Li, X. et al. A vacuum flash–assisted solution process for high-efficiency large-area perovskite solar cells. Science 353, 58–62 (2016).

Tan, H. et al. Efficient and stable solution-processed planar perovskite solar cells via contact passivation. Science 355, 722–726 (2017).

Yang, W. S. et al. Iodide management in formamidinium-lead-halide–based perovskite layers for efficient solar cells. Science 356, 1376–1379 (2017).

Son, D.-Y. et al. Self-formed grain boundary healing layer for highly efficient CH3 NH3 PbI3 perovskite solar cells. Nat. Energy 1, 16081 (2016).

Zhao, D. et al. Low-bandgap mixed tin–lead iodide perovskite absorbers with long carrier lifetimes for all-perovskite tandem solar cells. Nat. Energy 2, 17018 (2017).

Eperon, G. E. et al. Perovskite-perovskite tandem photovoltaics with optimized band gaps. Science 354, 861–865 (2016).

Barrows, A. T. et al. Efficient planar heterojunction mixed-halide perovskite solar cells deposited via spray-deposition. Energy Environ. Sci. 7, 2944–2950 (2014).

Bag, S., Deneault, J. R. & Durstock, M. F. Aerosol-jet-assisted thin-film growth of CH3NH3PbI3 perovskites—a means to achieve high quality, defect-free films for efficient solar cells. Adv. Energy Mater. 7, 1701151 (2017).

Kim, J. et al. Overcoming the challenges of large-area high-efficiency perovskite solar cells. ACS Energy Lett. 2, 1978–1984 (2017).

Chen, H., Wei, Z., Zheng, X. & Yang, S. A scalable electrodeposition route to the low-cost, versatile and controllable fabrication of perovskite solar cells. Nano Energy 15, 216–226 (2015).

Ye, F. et al. Soft-cover deposition of scaling-up uniform perovskite thin films for high cost-performance solar cells. Energy Environ. Sci. 9, 2295–2301 (2016).

Chen, H. et al. A solvent-and vacuum-free route to large-area perovskite films for efficient solar modules. Nature 550, 92–95 (2017).

Kim, J. H., Williams, S. T., Cho, N., Chueh, C.-C. & Jen, A. K. Y. Enhanced environmental stability of planar heterojunction perovskite solar cells based on blade-coating. Adv. Energy Mater. 5, 1401229 (2015).

Deng, Y. et al. Scalable fabrication of efficient organolead trihalide perovskite solar cells with doctor-bladed active layers. Energy Environ. Sci. 8, 1544–1550 (2015).

Deng, Y., Dong, Q., Bi, C., Yuan, Y. & Huang, J. Air‐stable, efficient mixed-cation perovskite solar cells with cu electrode by scalable fabrication of active layer. Adv. Energy Mater. 6, 1600372 (2016).

Yang, M. et al. Perovskite ink with wide processing window for scalable high-efficiency solar cells. Nat. Energy 2, 17038 (2017).

He, M. et al. Meniscus-assisted solution printing of large-grained perovskite films for high-efficiency solar cells. Nat. Commun. 8, 16045 (2017).

Hwang, K. et al. Toward large scale roll-to-roll production of fully printed perovskite solar cells. Adv. Mater. 27, 1241–1247 (2015).

Hu, Q. et al. In-situ dynamic observations of perovskite crystallization and microstructure evolution intermediated from [PbI6] 4-cage nanoparticles. Nat. Commun. 8, 15688 (2017).

Di Giacomo, F. et al. Up-scalable sheet-to-sheet production of high efficiency perovskite module and solar cells on 6-in. substrate using slot die coating. Solar Energy Mater. Solar Cells (in the press).

Tang, S. et al. Composition engineering in doctor-blading of perovskite solar cells. Adv. Energy Mater. 7, 1700302 (2017).

Ye, F. et al. Low-temperature soft-cover deposition of uniform large‐scale perovskite films for high-performance solar cells. Adv. Mater. 29, 1701440 (2017).

Li, Y. et al. In situ observation of crystallization of methylammonium lead iodide perovskite from microdroplets. Small 13, 1604125 (2017).

Le Berre, M., Chen, Y. & Baigl, D. From convective assembly to Landau−Levich deposition of multilayered phospholipid films of controlled thickness. Langmuir 25, 2554–2557 (2009).

Kim, H. et al. Controlled uniform coating from the interplay of Marangoni flows and surface-adsorbed macromolecules. Phys. Rev. Lett. 116, 124501 (2016).

Zheng, X. et al. Defect passivation in hybrid perovskite solar cells using quaternary ammonium halide anions and cations. Nat. Energy 2, 17102 (2017).

Fang, Y. & Huang, J. Resolving weak light of sub-picowatt per square centimeter by hybrid perovskite photodetectors enabled by noise reduction. Adv. Mater. 27, 2804–2810 (2015).

Bi, C. et al. Non-wetting surface-driven high-aspect-ratio crystalline grain growth for efficient hybrid perovskite solar cells. Nat. Commun. 6, 7747 (2015).

McLauchlin, M. L. et al. Evaporative properties and pinning strength of laser-ablated, hydrophilic sites on lotus-leaf-like, nanostructured surfaces. Langmuir 23, 4871–4877 (2007).

Milne, A. J. SpringerAmpamp; Amirfazli, A. Autophilic effect: wetting of hydrophobic surfaces by surfactant solutions. Langmuir 26, 4668–4674 (2009).

Stoebe, T., Lin, Z., Hill, R. M., Ward, M. D. & Davis, H. T. Surfactant-enhanced spreading. Langmuir 12, 337–344 (1996).

Rakocevic, L. et al. Interconnection optimization for highly efficient perovskite modules. IEEE J. Photovolt. 7, 404–408 (2017).

Palma, A. L. et al. Laser-patterning engineering for perovskite solar modules with 95% aperture ratio. IEEE J. Photovolt. 7, 1674–1680 (2017).

Moon, S.-J. et al. Laser-scribing patterning for the production of organometallic halide perovskite solar modules. IEEE J. Photovolt. 5, 1087–1092 (2015).

Acknowledgements

We thank the financial support from Office of Naval Research under award N00014-15-1-2713 and N00014-17-1-2619, and UNC Research Opportunities Initiative. This work was performed in part at the Chapel Hill Analytical and Nanofabrication Laboratory, CHANL, a member of the North Carolina Research Triangle Nanotechnology Network, RTNN, which is supported by the National Science Foundation, grant ECCS-1542015, as part of the National Nanotechnology Coordinated Infrastructure, NNCI. We thank Z. Yu and Z. Holman at Arizona State University for their independent measurements of the fabricated perovskite solar modules.

Author information

Authors and Affiliations

Contributions

J.H. and Y.D. conceived the idea and designed the experiments. Y.D. fabricated the perovskite thin films and devices and conducted the characterization. Y.B. and X.Z. synthesized and prepared the raw chemicals for perovskite thin film deposition. Y.D. and Q.W. conducted the perovskite solution droplet experiment. J.Z. helped with the laser ablation process for module fabrication. J.H. and Y.D. wrote the paper, and all authors reviewed the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Tables 1–2, Supplementary Figures 1–12

Supplementary Video 1

Drying of the perovskite solution without surfactant observed by microscopy

Supplementary Video 2

Drying of the perovskite solution with LP surfactant observed by microscopy

Rights and permissions

About this article

Cite this article

Deng, Y., Zheng, X., Bai, Y. et al. Surfactant-controlled ink drying enables high-speed deposition of perovskite films for efficient photovoltaic modules. Nat Energy 3, 560–566 (2018). https://doi.org/10.1038/s41560-018-0153-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-018-0153-9

This article is cited by

-

Manipulating solvent fluidic dynamics for large-area perovskite film-formation and white light-emitting diodes

Nature Communications (2024)

-

Bridging buried interface enable 24.67%-efficiency doctor-bladed perovskite solar cells in ambient condition

Nano Research (2024)

-

Recent progress of eco-friendly manufacturing process of efficient perovskite solar cells

Nano Convergence (2023)

-

Dissolved-Cl2 triggered redox reaction enables high-performance perovskite solar cells

Nature Communications (2023)

-

Design optimization of bifacial perovskite minimodules for improved efficiency and stability

Nature Energy (2023)