Abstract

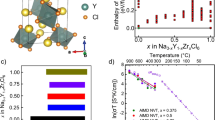

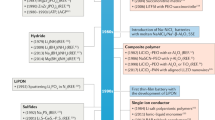

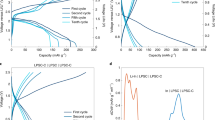

Carefully designed solid-electrolyte interphases are required for stable, reversible and efficient electrochemical energy storage in batteries. We report that hybrid battery anodes created by depositing an electrochemically active metal (for example, Sn, In or Si) on a reactive alkali metal electrode by a facile ion-exchange chemistry lead to very high exchange currents and stable long-term performance of electrochemical cells based on Li and Na electrodes. By means of direct visualization and ex situ electrodeposition studies, Sn–Li anodes are shown to be stable at 3 mA cm−2 and 3 mAh cm−2. Prototype full cells in which the hybrid anodes are paired with high-loading LiNi0.8Co0.15Al0.05O2(NCA) cathodes are also reported. As a second demonstration, we create and study Sn–Na hybrid anodes and show that they can be cycled stably for more than 1,700 hours with minimal voltage divergence. Charge storage at the hybrid anodes is reported to involve a combination of alloying and electrodeposition reactions.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Armand, M. & Tarascon, J. M. Building better batteries. Nature 451, 652–657 (2008).

Goodenough, J. B. & Kim, Y. Challenges for rechargeable Li batteries. Chem. Mater. 22, 587–603 (2009).

Bruce, P. G. Energy storage beyond the horizon: Rechargeable lithium batteries. Solid State Ion. 179, 752–760 (2008).

Whittingham, M. S. Electrical energy storage and intercalation chemistry. Science 192, 1126–1127 (1976).

Xu, W. et al. Lithium metal anodes for rechargeable batteries. Energy Environ. Sci. 7, 513–537 (2014).

Tikekar, M. D., Choudhury, S., Tu, Z. & Archer, L. A. Design principles for electrolytes and interfaces for stable lithium-metal batteries. Nat. Energy 1, 16114 (2016).

Lin, D., Liu, Y. & Cui, Y. Reviving the lithium metal anode for high-energy batteries. Nat. Nanotech. 12, 194–206 (2017).

Tarascon, J. M. & Armand, M. Issues and challenges facing rechargeable lithium batteries. Nature 414, 359–367 (2001).

Aurbach, D., McCloskey, B. D., Nazar, L. F. & Bruce, P. G. Advances in understanding mechanisms underpinning lithium–air batteries. Nat. Energy 1, 16128 (2016).

Ma, L., Hendrickson, K. E., Wei, S. & Archer, L. A. Nanomaterials: science and applications in the lithium–sulfur battery. Nano Today 10, 315–338 (2015).

Li, Y. & Dai, H. Recent advances in zinc–air batteries. Chem. Soc. Rev. 43, 5257–5275 (2014).

Wei, S. et al. A stable room-temperature sodium-sulfur battery. Nat. Commun. 7, 11722 (2016).

Al Sadat, W. I. & Archer, L. A. The O2-assisted Al/CO 2 electrochemical cell: A system for CO2 capture/conversion and electric power generation. Sci. Adv. 2, e1600968 (2016).

Tu, Z., Nath, P., Lu, Y., Tikekar, M. D. & Archer, L. A. Nanostructured electrolytes for stable lithium electrodeposition in secondary batteries. Acc. Chem. Res. 48, 2947–2956 (2015).

Cheng, X. B. et al. A review of solid electrolyte interphases on lithium metal anode. Adv. Sci. 3, 1500213 (2016).

Xu, K. Electrolytes and interphases in Li-ion batteries and beyond. Chem. Rev. 114, 11503–11618 (2014).

Verma, P., Maire, P. & Novák, P. A review of the features and analyses of the solid electrolyte interphase in Li-ion batteries. Electrochim. Acta 55, 6332–6341 (2010).

Ji, L., Lin, Z., Alcoutlabi, M. & Zhang, X. Recent developments in nanostructured anode materials for rechargeable lithium-ion batteries. Energy Environ. Sci. 4, 2682–2699 (2011).

Khurana, R., Schaefer, J. L., Archer, L. A. & Coates, G. W. Suppression of lithium dendrite growth using cross-linked polyethylene/poly(ethylene oxide) electrolytes: a new approach for practical lithium-metal polymer batteries. J. Am. Chem. Soc. 136, 7395–7402 (2014).

Tung, S.-O., Ho, S., Yang, M., Zhang, R. & Kotov, N. A. A dendrite-suppressing composite ion conductor from aramid nanofibres. Nat. Commun. 6, 6152 (2015).

Fergus, J. W. Ceramic and polymeric solid electrolytes for lithium-ion batteries. J. Power Sources 195, 4554–4569 (2010).

Lu, Y., Korf, K., Kambe, Y., Tu, Z. & Archer, L. A. Ionic-liquid-nanoparticle hybrid electrolytes: applications in lithium metal batteries. Angew. Chem. Int. Ed. 53, 488–492 (2014).

Villaluenga, I. et al. Compliant glass–polymer hybrid single ion-conducting electrolytes for lithium batteries. Proc. Natl Acad. Sci. USA 113, 52–57 (2016).

Tu, Z., Lu, Y. & Archer, L. A Dendrite‐free lithium metal battery model based on nanoporous polymer/ceramic composite electrolytes and high‐energy electrodes. Small 11, 2631–2635 (2015).

Tu, Z. et al. Nanoporous hybrid electrolytes for high‐energy batteries based on reactive metal anodes. Adv. Energy Mater. 7 7, 1602367 (2017).

Monroe, C. & Newman, J. The impact of elastic deformation on deposition kinetics at lithium/polymer interfaces. J. Electrochem. Soc. 152, A396–A404 (2005).

Bouchet, R. et al. Single-ion BAB triblock copolymers as highly efficient electrolytes for lithium-metal batteries. Nat. Mater. 12, 452–457 (2013).

Ma, Q. et al. Single lithium‐ion conducting polymer electrolytes based on a super‐delocalized polyanion. Angew. Chem. Int. Ed. 55, 2521–2525 (2016).

Lu, Y. et al. Stable cycling of lithium metal batteries using high transference number electrolytes. Adv. Energy Mater. 5, 1402073 (2015).

Wei, S. et al. Highly stable sodium batteries enabled by functional ionic polymer membranes. Adv. Mater. 29, 1605512 (2017).

Lee, Y. M. et al. Effects of triacetoxyvinylsilane as SEI layer additive on electrochemical performance of lithium metal secondary battery. Electrochem. Solid-State Lett. 10, A216–A219 (2007).

Zhang, X. Q., Cheng, X. B., Chen, X., Yan, C. & Zhang, Q. Fluoroethylene carbonate additives to render uniform Li deposits in lithium metal batteries. Adv. Funct. Mater. 27, 1605989 (2017).

Zheng, G. et al. High-performance lithium metal negative electrode with a soft and flowable polymer coating. ACS Energy Lett. 1, 1247–1255 (2016).

Ma, L., Kim, M. S. & Archer, L. A. Stable artificial solid electrolyte interphases for lithium batteries. Chem. Mater. 29, 4181–4189 (2017).

Liu, Y. et al. An artificial solid electrolyte interphase with high Li‐ion conductivity, mechanical strength, and flexibility for stable lithium metal anodes. Adv. Mater. 29, 1605531 (2017).

Li, J., Dudney, N. J., Nanda, J. & Liang, C. Artificial solid electrolyte interphase to address the electrochemical degradation of silicon electrodes. ACS Appl. Mater. Interfaces 6, 10083–10088 (2014).

Choudhury, S., Agrawal, A., Wei, S., Jeng, E. & Archer, L. A. Hybrid hairy nanoparticle electrolytes stabilizing lithium metal batteries. Chem. Mater. 28, 2147–2157 (2016).

Kim, M. S., Ma, L., Choudhury, S. & Archer, L. A. Multifunctional separator coatings for high‐performance lithium. Adv. Mater. Interfaces 3, 1600450 (2016).

Han, X. et al. Negating interfacial impedance in garnet-based solid-state Li metal batteries. Nat. Mater. 16, 572–579 (2017).

Lin, D. et al. Layered reduced graphene oxide with nanoscale interlayer gaps as a stable host for lithium metal anodes. Nat. Nanotech. 11, 626–632 (2016).

Liang, Z. et al. Composite lithium metal anode by melt infusion of lithium into a 3D conducting scaffold with lithiophilic coating. Proc. Natl Acad. Sci. USA 113, 2862–2867 (2016).

Tu, Z., Choudhury, S., Wei, S. & Archer, L. Surface Protected Active Metal Electrodes for Rechargeable Batteries. PCT/US2017/067358 (2017).

Lou, X. W., Wang, Y., Yuan, C., Lee, J. Y. & Archer, L. A. Template‐free synthesis of SnO2 hollow nanostructures with high lithium storage capacity. Adv. Mater. 18, 2325–2329 (2006).

Winter, M. & Besenhard, J. O. Electrochemical lithiation of tin and tin-based intermetallics and composites. Electrochim. Acta 45, 31–50 (1999).

Choi, Y.-S., Byeon, Y.-W., Ahn, J.-P. & Lee, J.-C. Formation of Zintl ions and their configurational change during sodiation in Na–Sn battery. Nano Lett. 17, 679–686 (2017).

Nesper, R. Structure and chemical bonding in Zintl-phases containing lithium. Prog. Solid State Chem. 20, 1–45 (1990).

Li, J.-T. et al. XPS and ToF-SIMS study of Sn–Co alloy thin films as anode for lithium ion battery. J. Power Sources 195, 8251–8257 (2010).

Munichandraiah, N., Scanlon, L. & Marsh, R. Surface films of lithium: an overview of electrochemical studies. J. Power Sources 72, 203–210 (1998).

Zhang, W. M. et al. Tin‐nanoparticles encapsulated in elastic hollow carbon spheres for high‐performance anode material in lithium‐Ion batteries. Adv. Mater. 20, 1160–1165 (2008).

Wang, L. et al. A superior low‐cost cathode for a Na‐ion battery. Angew. Chem. Int. Ed. 52, 1964–1967 (2013).

Acknowledgements

This work was supported by the Department of Energy (DOE), Advanced Research Projects Agency - Energy (ARPA-E) through award no. DE-AR0000750. M.J.Z. and L.F.K. acknowledge support by the NSF (DMR-1654596). The work made use of electrochemical characterization facilities in the KAUST-CU Centre for Energy and Sustainability, supported by the King Abdullah University of Science and Technology (KAUST) through award no. KUS-C1-018-02. Electron microscopy facilities at the Cornell Centre for Materials Research (CCMR), an NSF-supported MRSEC through Grant DMR-1120296, were also used for the study. Additional support for the FIB/SEM cryo-stage and transfer system was provided by the Kavli Institute at Cornell and the Energy Materials Centre at Cornell, DOE EFRC BES (DE-SC0001086). Z.T. thanks B. Polzin for kindly providing NCA cathode materials from the Cell Analysis, Modeling, and Prototyping (CAMP) Facility at Argonne National Laboratories.

Author information

Authors and Affiliations

Contributions

Z.T. and L.A.A. conceptualized the project. Z.T., S.C., M.J.Z., L.F.K. and L.A.A. developed the methodology. Z.T., S.C., M.J.Z. and S.W. conducted all experiments reported in the paper. Z.T. and L.A.A. wrote the original draft. Z.T., S.C., M.J.Z., L.F.K. and L.A.A. further wrote and revised the manuscript. L.F.K. and L.A.A. acquired funding for the work and supervised the research reported in the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figures 1–22.

Rights and permissions

About this article

Cite this article

Tu, Z., Choudhury, S., Zachman, M.J. et al. Fast ion transport at solid–solid interfaces in hybrid battery anodes. Nat Energy 3, 310–316 (2018). https://doi.org/10.1038/s41560-018-0096-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-018-0096-1

This article is cited by

-

Hierarchical Li electrochemistry using alloy-type anode for high-energy-density Li metal batteries

Nature Communications (2024)

-

Achieving high-performance sodium metal anodes: From structural design to reaction kinetic improvement

Nano Research (2024)

-

Naked metallic skin for homo-epitaxial deposition in lithium metal batteries

Nature Communications (2023)

-

A Review of Solid Electrolyte Interphase (SEI) and Dendrite Formation in Lithium Batteries

Electrochemical Energy Reviews (2023)

-

In-situ constructed polymer/alloy composite with high ionic conductivity as an artificial solid electrolyte interphase to stabilize lithium metal anode

Nano Research (2023)