Abstract

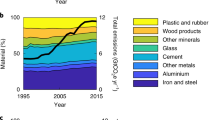

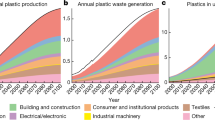

China, as the largest global producer of bulk materials, confronts formidable challenges in mitigating greenhouse gas emissions arising from their production. Yet the emission savings resulting from circular economy strategies, such as improved scrap recovery, more intensive use and lifetime extension, remain underexplored. Here we show that, by 2060, China could source most of its required bulk materials through recycling, partially attributable to a declining population. Province-level results show that, while economic development initially drives up material demand, it also enables closed loops as demand approaches saturation levels. Between now and 2060, improved scrap recovery cumulatively reduces greenhouse gas emissions by 10%, while more intensive use, resulting in reduced material demand, reduces emissions by 21%. Lifetime extension offers a modest benefit, leading to a 3% reduction in emissions. Alongside the large potential for recycling, our findings highlight the importance of demand reduction in meeting global climate targets.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$209.00 per year

only $17.42 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Data used for populating the model are available from https://doi.org/10.6084/m9.figshare.21837195 (ref. 43). Source data are provided with this paper.

Code availability

Codes used for simulating material flows and stocks and GHG emissions are available via https://doi.org/10.6084/m9.figshare.21837195 (ref. 43).

Change history

25 October 2023

A Correction to this paper has been published: https://doi.org/10.1038/s41558-023-01866-3

References

Graedel, T. E., Harper, E. M., Nassar, N. T. & Reck, B. K. On the materials basis of modern society. Proc. Natl Acad. Sci. USA 112, 6295–6300 (2015).

Net Zero by 2050: A Roadmap for the Global Energy Sector (IEA, 2021); https://www.iea.org/reports/net-zero-by-2050

Global Resources Outlook 2019: Natural Resources for the Future we Want (UNEP, 2019); https://wedocs.unep.org/handle/20.500.11822/27517

Cao, Z. et al. The sponge effect and carbon emission mitigation potentials of the global cement cycle. Nat. Commun. 11, 3777 (2020).

Creutzig, F. et al. Demand-side solutions to climate change mitigation consistent with high levels of well-being. Nat. Clim. Change 12, 36–46 (2022).

Adoption of the Paris Agreement by the President: Paris Climate Change Conference (UNFCCC, 2019); http://unfccc.int/resource/docs/2015/cop21/eng/l09r01.pdf

Rogelj, J. et al. Energy system transformations for limiting end-of-century warming to below 1.5 °C. Nat. Clim. Change 5, 519–527 (2015).

Grubler, A. et al. A low energy demand scenario for meeting the 1.5 °C target and sustainable development goals without negative emission technologies. Nat. Energy 3, 515–527 (2018).

IPCC. Special Report on Renewable Energy Sources and Climate Change Mitigation (eds Edenhofer, O. et al.) (Cambridge Univ. Press, 2011).

Habert, G. et al. Environmental impacts and decarbonization strategies in the cement and concrete industries. Nat. Rev. Earth Environ. 1, 559–573 (2020).

Watari, T., Cao, Z., Hata, S. & Nansai, K. Efficient use of cement and concrete to reduce reliance on supply-side technologies for net-zero emissions. Nat. Commun. 13, 4158 (2022).

Habert, G., Billard, C., Rossi, P., Chen, C. & Roussel, N. Cement production technology improvement compared to factor 4 objectives. Cem. Concr. Res. 40, 820–826 (2010).

Tong, D. et al. Committed emissions from existing energy infrastructure jeopardize 1.5 °C climate target. Nature 572, 373–377 (2019).

Pauliuk, S. et al. Global scenarios of resource and emission savings from material efficiency in residential buildings and cars. Nat. Commun. 12, 5097 (2021).

Allwood, J. M. Unrealistic techno-optimisim is holding back progress on resource efficiency. Nat. Mater. 17, 1050–1053 (2018).

Watari, T., Hata, S., Nakajima, K. & Nansai, K. Limited quantity and quality of steel supply in a zero-emission future. Nat. Sustain. 6, 336–343 (2023).

Allwood, J. M. in Handbook of Recycling (eds Worrell, E. & Reuter, M. A.) 445–477 (Elsevier, 2014).

Material Efficiency in Clean Energy Transitions (IEA, 2019); https://www.iea.org/reports/material-efficiency-in-clean-energy-transitions

Cao, Z., Masanet, E., Tiwari, A. & Akolawala, S. Decarbonizing Concrete: Deep Decarbonization Pathways for the Cement and Concrete Cycle in the United States, India and China (Industrial Sustainability Analysis Laboratory, 2021).

Wang, P. et al. Efficiency stagnation in global steel production urges joint supply-and-demand-side mitigation efforts. Nat. Commun. 12, 2066 (2021).

Zhong, X. et al. Global greenhouse gas emissions from residential and commercial building materials and mitigation strategies to 2060. Nat. Commun. 12, 6126 (2021).

Creutzig, F. et al. in Climate Change 2022: Mitigation of Climate Change (eds Shukla, P. R. et al.) 752–943 (Cambridge Univ. Press, 2022).

Cement Statistics and Information (USGS, 2021); https://www.usgs.gov/centers/national-minerals-information-center/cement-statistics-and-information

Primary Aluminium Production (International Aluminium Institute, 2022); https://international-aluminium.org/statistics/primary-aluminium-production

World Steel in Figures 2022 (World Steel Association, 2022); https://worldsteel.org/steel-topics/statistics/world-steel-in-figures-2022

Plastics—the Facts 2021. An Analysis of European Plastics Production, Demand and Waste Data (PlasticsEurope, 2022); https://plasticseurope.org/knowledge-hub/plastics-the-facts-2021

An Energy Sector Roadmap to Carbon Neutrality in China (IEA, 2021); https://www.iea.org/events/an-energy-sector-roadmap-to-carbon-neutrality-in-china

Pauliuk, S., Wang, T. & Müller, D. B. Steel all over the world: estimating in-use stocks of iron for 200 countries. Resour. Conserv. Recycl. 71, 22–30 (2013).

Song, L. et al. Mapping provincial steel stocks and flows in China: 1978–2050. J. Clean. Prod. 262, 121393 (2020).

Song, L. et al. China material stocks and flows account for 1978–2018. Sci. Data 8, 303 (2021).

Energy Technology Perspectives 2017: Catalysing Energy Technology Transformations (IEA, 2017); https://www.iea.org/reports/energy-technology-perspectives-2017

Morseletto, P. Targets for a circular economy. Resour. Conserv. Recycl. 153, 104553 (2020).

van Ewijk, S. et al. Ten Insights From Industrial Ecology for the Circular Economy (ISIE, 2023).

Global Material Resources Outlook to 2060: Economic Drivers and Environmental Consequences (OECD, 2019); https://doi.org/10.1787/9789264307452-en

Bleischwitz, R., Nechifor, V., Winning, M., Huang, B. & Geng, Y. Extrapolation or saturation—revisiting growth patterns, development stages and decoupling. Glob. Environ. Change 48, 86–96 (2018).

Building a Greener Future: How China can Reach its Dual Climate Goals (Boston Consulting Group, 2021); https://web-assets.bcg.com/ff/a6/c514e7314190b5cb27b1383fae1b/bcg-x-cdrf-how-china-can-reach-its-dual-climate-goals-mar-2021-en.pdf

Corvellec, H., Stowell, A. F. & Johansson, N. Critiques of the circular economy. J. Ind. Ecol. 26, 421–432 (2021).

Reuter, M. A., van Schaik, A., Gutzmer, J., Bartie, N. & Abadías-Llamas, A. Challenges of the circular economy: a material, metallurgical and product design perspective. Annu. Rev. Mater. Res. 49, 253–274 (2019).

van Ewijk, S., Stegemann, J. A. & Ekins, P. Limited climate benefits of global recycling of pulp and paper. Nat. Sustain. 4, 180–187 (2021).

Westbroek, C. D., Bitting, J., Craglia, M., Azevedo, J. M. & Cullen, J. M. Global material flow analysis of glass: from raw materials to end of life. J. Ind. Ecol. 25, 333–343 (2021).

Allwood, J. M. et al. Sustainable Materials: With Both Eyes Open (UIT Cambridge, 2012).

The 14th Five-Year Plan for Circular Economy Development (National Development and Reform Commission, 2021); https://www.ndrc.gov.cn/xxgk/zcfb/ghwb/202107/t20210707_1285527.html?code=&state=123

Song, L., Cao, Z. & Chen, W.-Q. Dataset and code for bulk materials flows and GHG emission reduction potential in China. figshare https://doi.org/10.6084/m9.figshare.21837195 (2023).

Fishman, T., Schandl, H. & Tanikawa, H. Stochastic analysis and forecasts of the patterns of speed, acceleration and levels of material stock accumulation in society. Environ. Sci. Technol. 50, 3729–3737 (2016).

Cao, Z., Shen, L., Lovik, A. N., Muller, D. B. & Liu, G. Elaborating the history of our cementing societies: an in-use stock perspective. Environ. Sci. Technol. 51, 11468–11475 (2017).

Chen, Y. et al. Provincial and gridded population projection for China under shared socioeconomic pathways from 2010 to 2100. Sci. Data 7, 83 (2020).

Wiedenhofer, D. et al. Prospects for a saturation of humanity’s resource use? An analysis of material stocks and flows in nine world regions from 1900 to 2035. Glob. Environ. Change 71, 102410 (2021).

Müller, D. B., Wang, T. & Duval, B. Patterns of iron use in societal evolution. Environ. Sci. Technol. 45, 182–188 (2011).

Pauliuk, S., Milford, R. L., Müller, D. B. & Allwood, J. M. The steel scrap age. Environ. Sci. Technol. 47, 3448–3454 (2013).

Wolfram, P., Tu, Q., Heeren, N., Pauliuk, S. & Hertwich, E. G. Material efficiency and climate change mitigation of passenger vehicles. J. Ind. Ecol. 25, 494–510 (2021).

Acknowledgements

This work was supported by the Natural Science Foundation of China (grant nos 71961147003, 52170183 and 52070178 to W.Q.C. and L.L.S.), the National Key Research and Development Program of the Ministry of Science and Technology (grant no. 2017YFC0505703 to W.Q.C. and L.L.S.), the International Partnership Program of the Chinese Academy of Sciences (grant no. 132C35KYSB20200004 to W.Q.C. and L.L.S.), the National Social Science Fund of China (grant no. 21&ZD104 to W.Q.C. and L.L.S.), Special Research Fund (BOF) of the University of Antwerp (grant no. 41-FA100200-FFB200410 to Z.C.) and the Fundamental Research Funds for the Central Universities (grant no. 040-63233060 to Z.C.). E.M., F.M. and J.M.C. acknowledge support from C-THRU: Carbon clarity in the global petrochemical supply chain (www.c-thru.org).

Author information

Authors and Affiliations

Contributions

W.Q.C., L.L.S. and Z.C. conceived and designed the research. W.Q.C. and Z.C. supervised the project. L.L.S. performed the simulations. L.L.S. and Z.C. produced the figures. S.v.E. and E.M. contributed to the scenario design. T.W., F.R.M. and J.M.C. contributed to the result interpretation. L.L.S. and Z.C. prepared the first draft. All authors reviewed and edited the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Climate Change thanks Raimund Bleischwitz, Qingshi Tu and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–18, Methods and Discussion and Tables 1–11.

Source data

Source Data Fig. 2

Future material demand (inflow) and end-of-life material availability (outflow) across China.

Source Data Fig. 3

Material demand, end-of-life material availability, material savings and interprovincial end-of-life material trade in 2060.

Source Data Fig. 4

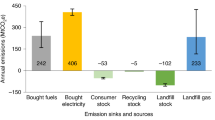

GHG savings by three CE strategies and remaining GHG emissions.

Source Data Fig. 5

GHG savings by three CE strategies and remaining GHG emissions across materials.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Song, L., van Ewijk, S., Masanet, E. et al. China’s bulk material loops can be closed but deep decarbonization requires demand reduction. Nat. Clim. Chang. 13, 1136–1143 (2023). https://doi.org/10.1038/s41558-023-01782-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41558-023-01782-6