Abstract

Fragmentation of macromolecular solutes in rapid flows is of considerable fundamental and practical importance. The sequence of molecular events preceding chain fracture is poorly understood, because such events cannot be visualized directly but must be inferred from changes in the bulk composition of the flowing solution. Here we describe how analysis of same-chain competition between fracture of a polystyrene chain and isomerization of a chromophore embedded in its backbone yields detailed characterization of the distribution of molecular geometries of mechanochemically reacting chains in sonicated solutions. In our experiments the overstretched (mechanically loaded) chain segment grew and drifted along the backbone on the same timescale as, and in competition with, the mechanochemical reactions. Consequently, only <30% of the backbone of a fragmenting chain is overstretched, with both the maximum force and the maximum reaction probabilities located away from the chain centre. We argue that quantifying intrachain competition is likely to be mechanistically informative for any flow fast enough to fracture polymer chains.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data discussed in the main text and Supplementary Information are tabulated in the Supplementary Data file suppdata.mat.

Code availability

This work used a simplified version of the previously reported MATLAB code for simulating the composition of a sonicated solution, provided in Supplementary Information along with the instructions for use. The full code with examples of input/output datasets is available at https://datacat.liverpool.ac.uk/1697/.

References

Rubinstein, M. & Colby, R. H. Polymer Physics (Oxford Univ. Press, 2007).

Boger, D. V. Viscoelastic flows through contractions. Annu. Rev. Fluid Mech. 19, 157–182 (1987).

Graham, M. D. Fluid dynamics of dissolved polymer molecules in confined geometries. Annu. Rev. Fluid Mech. 43, 273–298 (2011).

Price, G. J. The use of ultrasound for the controlled degradation of polymer solutions. Adv. Sonochem. 1, 231–287 (1990).

Akbulatov, S. & Boulatov, R. Experimental polymer mechanochemistry and its interpretational frameworks. ChemPhysChem 18, 1422–1450 (2017).

Boulatov, R. Topics in Current Chemistry (Springer Cham, 2015).

Larson, R. G. The rheology of dilute solutions of flexible polymers: progress and problems. J. Rheol. 49, 1–70 (2005).

Schroeder, C. M. Single polymer dynamics for molecular rheology. J. Rheol. 62, 371–403 (2018).

Kausch, H. H. Polymer Fracture (Mir, 1981).

Rognin, E., Willis-Fox, N., Aljohani, T. A. & Daly, R. A multiscale model for the rupture of linear polymers in strong flows. J. Fluid Mech. 848, 722–742 (2018).

Rognin, E., Willis-Fox, N., Zhao, T. Z., Aljohani, T. A. & Daly, R. Laminar flow-induced scission kinetics of polymers in dilute solutions. J. Fluid Mech. 924 https://doi.org/10.1017/jfm.2021.646 (2021).

Garrepally, S., Jouenne, S., Olmsted, P. D. & Lequeux, F. Scission of flexible polymers in contraction flow: predicting the effects of multiple passages. J. Rheol. 64, 601–614 (2020).

Ayer, M. A. et al. Modeling ultrasound-induced molecular weight decrease of polymers with multiple scissile azo-mechanophores. Polym. Chem-UK 12, 4093–4103 (2021).

Nguyen, T. Q. & Kausch, H. H. Chain scission in transient extensional flow kinetics and molecular-weight dependence. J. Nonnewton. Fluid Mech. 30, 125–140 (1988).

Haward, S. J., Oliveira, M. S. N., Alves, M. A. & McKinley, G. H. Optimized cross-slot flow geometry for microfluidic extensional rheometry. Phys. Rev. Lett. 109, 128301 (2012).

Boulatov, R. The challenges and opportunities of contemporary polymer mechanochemistry. ChemPhysChem 18, 1419–1421 (2017).

Hsieh, C.-C., Park, S. J. & Larson, R. G. Brownian dynamics modeling of flow-induced birefringence and chain scission in dilute polymer solutions in a planar cross-slot flow. Macromolecules 38, 1456–1468 (2005).

Stauch, T. & Dreuw, A. Advances in quantum mechanochemistry: electronic structure methods and force analysis. Chem. Rev. 116, 14137–14180 (2016).

Kochhar, G. S., Heverly-Coulson, G. S. & Mosey, N. J. Theoretical approaches for understanding the interplay between stress and chemical reactivity. Top. Curr. Chem. 369, 37–96 (2015).

Kucharski, T. J. & Boulatov, R. The physical chemistry of mechanoresponsive polymers. J. Mater. Chem. 21, 8237–8255 (2011).

Lenhardt, J. M., Ramirez, A. L. B., Lee, B., Kouznetsova, T. B. & Craig, S. L. Mechanistic insights into the sonochemical activation of multimechanophore cyclopropanated polybutadiene polymers. Macromolecules 48, 6396–6403 (2015).

Lenhardt, J. M. et al. Trapping a diradical transition state by mechanochemical polymer extension. Science 329, 1057–1060 (2010).

Tian, Y. et al. A polymer with mechanochemically active hidden length. J. Am. Chem. Soc. 142, 18687–18697 (2020).

Zhang, H. et al. Multi-modal mechanophores based on cinnamate dimers. Nat. Commun. 8, 1147 (2017).

O’Neill, R. T. & Boulatov, R. The contributions of model studies for fundamental understanding of polymer mechanochemistry. Synlett 33, 851–862 (2022).

O’Neill, R. T. & Boulatov, R. in Molecular Photoswitches Vol. 2 (ed. Pianowski, Z. L.) Ch. 12, 253–281 (Wiley, 2022).

O’Neill, R. T. & Boulatov, R. The many flavours of mechanochemistry and its plausible conceptual underpinnings. Nat. Rev. Chem. 5, 148–167 (2021).

Akbulatov, S. et al. Experimentally realized mechanochemistry distinct from force-accelerated scission of loaded bonds. Science 357 https://doi.org/10.1126/science.aan1026 (2017).

Akbulatov, S., Tian, Y. & Boulatov, R. Force-reactivity property of a single monomer is sufficient to predict the micromechanical behavior of its polymer. J. Am. Chem. Soc. 134, 7620–7623 (2012).

Huang, Z. et al. Method to derive restoring forces of strained molecules from kinetic measurements. J. Am. Chem. Soc. 131, 1407–1409 (2009).

Wang, C. et al. The molecular mechanism of constructive remodeling of a mechanically-loaded polymer. Nat. Commun. 13, 3154 (2022).

Nguyen, T. Q., Liang, O. Z. & Kausch, H. H. Kinetics of ultrasonic and transient elongational flow degradation: a comparative study. Polymer 38, 3783–3793 (1997).

Vanapalli, S. A., Ceccio, S. L. & Solomon, M. J. Universal scaling for polymer chain scission in turbulence. Proc. Natl Acad. Sci. USA 103, 16660–16665 (2006).

Okkuama, M. & Hirose, T. Mechanics of ultrasonic degradation of linear high polymer and ultrasonic cavitation. J. Appl. Polym. Sci. 7, 591–602 (1963).

Ryskin, G. Calculation of the effect of polymer additive in a converging flow. J. Fluid Mech. 178, 423–440 (1987).

Lorenzo, T. & Marco, L. Brownian dynamics simulations of cavitation-induced polymer chain scission. Ind. Eng. Chem. Res. 60, 10539–10550 (2021).

Sim, H. G., Khomami, B. & Sureshkumar, R. Flow-induced chain scission in dilute polymer solutions: algorithm development and results for scission dynamics in elongational flow. J. Rheol. 51, 1223–1251 (2007).

Hsieh, C.-C. & Larson, R. G. Modeling hydrodynamic interaction in Brownian dynamics: simulations of extensional and shear flows of dilute solutions of high molecular weight polystyrene. J. Rheol. 48, 995–1021 (2004).

Lauterborn, W. & Kurz, T. Physics of bubble oscillations. Rep. Prog. Phys. 73, 106501 (2010).

Hermes, M. & Boulatov, R. The entropic and enthalpic contributions to force-dependent dissociation kinetics of the pyrophosphate bond. J. Am. Chem. Soc. 133, 20044–20047 (2011).

Huang, Z. & Boulatov, R. Chemomechanics: chemical kinetics for multiscale phenomena. Chem. Soc. Rev. 40, 2359–2384 (2011).

Huo, S. et al. Mechanochemical bond scission for the activation of drugs. Nat. Chem. 13, 131–139 (2021).

Kean, Z. S., Gossweiler, G. R., Kouznetsova, T. B., Hewage, G. B. & Craig, S. L. A coumarin dimer probe of mechanochemical scission efficiency in the sonochemical activation of chain-centered mechanophore polymers. Chem. Commun. 51, 9157–9160 (2015).

Chen, Y., Mellot, G., van Luijk, D., Creton, C. & Sijbesma, R. P. Mechanochemical tools for polymer materials. Chem. Soc. Rev. 50, 4100–4140 (2021).

Nixon, R. & De Bo, G. Isotope effect in the activation of a mechanophore. J. Am. Chem. Soc. 143, 3033–3036 (2021).

Horn, A. F. Midpoint scission of macromolecules in dilute-solution in turbulent-flow. Nature 312, 140–141 (1984).

Bowser, B. H. & Craig, S. L. Empowering mechanochemistry with multi-mechanophore polymer architectures. Polym. Chem-UK 9, 3583–3593 (2018).

Lee, B., Niu, Z. B., Wang, J. P., Slebodnick, C. & Craig, S. L. Relative mechanical strengths of weak bonds in sonochemical polymer mechanochemistry. J. Am. Chem. Soc. 137, 10826–10832 (2015).

Wang, J. P., Kouznetsova, T. B., Boulatov, R. & Craig, S. L. Mechanical gating of a mechanochemical reaction cascade. Nat. Commun. https://doi.org/10.1038/ncomms13433 (2016).

Peterson, G. I., Lee, J. & Choi, T.-L. Multimechanophore graft polymers: mechanochemical reactions at backbone–arm junctions. Macromolecules 52, 9561–9568 (2019).

Izak-Nau, E., Campagna, D., Baumann, C. & Göstl, R. Polymer mechanochemistry-enabled pericyclic reactions. Polym. Chem-UK 11, 2274–2299 (2020).

Pan, Y. et al. A mechanochemical reaction cascade for controlling load-strengthening of a mechanochromic polymer. Angew. Chem. Int. Ed. 49, 21980–21985 (2020).

Yang, J. et al. Bicyclohexene-peri-naphthalenes: scalable synthesis, diverse functionalization, efficient polymerization, and facile mechanoactivation of their polymers. J. Am. Chem. Soc. 142, 14619–14626 (2020).

Zhang, H. & Diesendruck, C. Off-center mechanophore activation in block copolymers. Angew. Chem. Int. Ed. Engl. https://doi.org/10.1002/anie.202213980 (2022).

Willis-Fox, N., Rognin, E., Aljohani, T. A. & Daly, R. Polymer mechanochemistry: manufacturing is now a force to be reckoned with. Chem 4, 2499–2537 (2018).

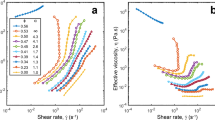

Willis-Fox, N. et al. Going with the flow: tunable flow-induced polymer mechanochemistry. Adv. Funct. Mater. 30, 2002372 (2020).

Poole, R. J. Editorial for the special issue on ‘Polymer degradation in turbulent drag reduction’. J. Nonnewton. Fluid Mech. https://doi.org/10.1016/j.jnnfm.2020.104283 (2020).

Larson, R. G. & Desai, P. S. Modeling the rheology of polymer melts and solutions. Annu. Rev. Fluid Mech. 47, 47–65 (2015).

Klok, H.-A., Herrmann, A. & Göstl, R. Force ahead: emerging applications and opportunities of polymer mechanochemistry. ACS Polym. Au 2, 208–212 (2022).

Lloyd, E. M., Vakil, J. R., Yao, Y., Sottos, N. R. & Craig, S. L. Covalent mechanochemistry and contemporary polymer network chemistry: a marriage in the making. J. Am. Chem. Soc. 145, 751–768 (2023).

Tian, Y. & Boulatov, R. Quantum-chemical validation of the local assumption of chemomechanics for a unimolecular reaction. ChemPhysChem 13, 2277–2281 (2012).

Akbulatov, S., Tian, Y., Kapustin, E. & Boulatov, R. Model studies of the kinetics of ester hydrolysis under stretching force. Angew. Chem. Int. Ed. 52, 6992–6995 (2013).

Cramer, C. J. Essentials of Computational Chemistry 2nd edn (Wiley, 2004).

Ochterski, J. W. Vibrational analysis in Gaussian. Gaussian http://gaussian.com/vib/ (1999).

Boulatov, R., Supplementary data file for NCOMMS-22-00503A. University of Liverpool https://doi.org/10.17638/datacat.liverpool.ac.uk%2F1697, (2022).

Acknowledgements

The work was funded by the Engineering and Physical Sciences Research Council under grant EP/L000075/1; R.T.O. received support from the University of Liverpool. We thank S. Akbulatov and L. Anderson for preliminary studies that enabled the design of this project and Waters Corporation for the gift of Acquity ultraperformance liquid chromatography system and the technical help in converting it to SEC.

Author information

Authors and Affiliations

Contributions

R.T.O. performed all experiments and contributed to data analysis and writing. R.B. designed the study, developed the model and wrote the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Chemistry thanks the anonymous reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

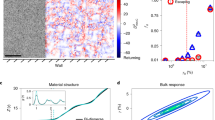

Extended Data Fig. 1 Summary of the UVvis absorption properties.

(a) Wavelength-dependent extinction coefficients of polystyrene and the two isomers of stiff stilbene, SS, in THF at 30 °C and ~1500 psi (the pressure of the PDA detector). (b) An example of deconvolution of the absorption spectrum of 1c to PS, Z-SS and E-SS contributions using the reference spectra in (a). The plotted data is tabulated in the supplementary data file, suppdata.mat.

Extended Data Fig. 2 The calculated contributions of different backbone bonds to chain fracture.

(a) Calculated force-dependent activation free energies, ΔG≠ for homolysis of the color-matching bonds in the inset structure. ΔG≠ for the C-C bonds of the PS backbone is black. (b) The calculated fraction of mechanochemical fractures of the polymer shown in the inset (n = 125, m = 124) by homolysis of the C-C bond of the PS backbone as a function of fmax of a parabolic force distribution in a macromolecular ensemble with the SS(OCH2CO2(CH2)3O2C)2 moiety distributed as in 1c. The calculations are at uBMK/6-31 + G(d) level in the gas phase. Homolysis of the endocyclic bond of cyclopentane of SS (dark purple line in a) doesn’t fracture the chain but probably destroys SS. Undetectable bleaching of SS in sonicated solutions suggests that this reaction is negligible in our polymers. The plotted data is tabulated in the supplementary data file, suppdata.mat.

Extended Data Fig. 3 An illustrative summary of the capacity of different models to reproduce observed mechanochemistry of 4o.

(a, b) measured MMDs and \({\chi }_{{Z}}\); (c, d) dynamic model; (e, f) overstretched-chain model; (g, h) overstretched segment model. The legend in (a) applies to all panels. The plotted data is tabulated in the supplementary data file, suppdata.mat.

Extended Data Fig. 4 The chain-size-dependent distributions of molecular parameters responsible for observed mechanochemistry from the dynamic model.

(a) the time a chain remains loaded to fmax ≥ 2.5 nN, Δtstretch; (b) fmax at chain fracture; (c, d) the overstretched backbone fraction, λos, at fmax = 2.5 (c) and at chain fracture; (e, f) the backbone fraction between the middle of the overstretched segment and the closest chain terminus, δ, at fmax = 2.5 nN (e) and at chain fracture (f). In all distributions the listed x value correspond to the center of each bin of width 0.3 μs (a), 50 pN (b) and 0.05 (c–f). The legend in (a) applies to all panels. The plotted data is tabulated in the supplementary data file, suppdata.mat.

Extended Data Fig. 5 Calculated discrete distributions of the fitted parameters of the dynamic model.

(a) ks; (b) kd; (c–f) 0th and 1st order Taylor expansion coefficients (α and β) of the coupling between fmax and the squared fractional length of the overstretched segment, λos2. These distributions apply only to chains with fmax ≥ 2.5 nN: the available data do not allow parameterization of the model at lower forces, because the underlying mechanochemical reactions are too slow to affect the bulk compositions. The distributions of ks, kd and α/β pairs are cross-correlated so that the probability of a mechanochemically-reactive chain to experience a specific combination of the 4 model parameters does not equal the product of the fractions of chains experiencing the same parameter values individually. The bin size of each distribution was selected to eliminate artifactually non-monotonic variations in each parameter due to this cross-correlation. The plotted data is tabulated in the supplementary data file, suppdata.mat.

Extended Data Fig. 6 The calculated localization of mechanochemical reactivity at chain center.

(a) fraction of PS chains fragmenting by dissociation of a backbone C-C bond within the central portion of the backbone of increasing fractional width; (b) fraction of Z-SS moieties that are calculated to isomerize before fracture of a hypothetical poly(Z-SS) chain of the same number of monomers as in (a). The plotted data is tabulated in the supplementary data file, suppdata.mat.

Supplementary information

Supplementary Information

Supplementary Figs. 1–29, discussion, Tables 1–3 and equations (S1)–(S12).

Supplementary Data

All data underlying the results in the paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

O’Neill, R.T., Boulatov, R. Experimental quantitation of molecular conditions responsible for flow-induced polymer mechanochemistry. Nat. Chem. 15, 1214–1223 (2023). https://doi.org/10.1038/s41557-023-01266-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41557-023-01266-2

This article is cited by

-

Allosteric control of olefin isomerization kinetics via remote metal binding and its mechanochemical analysis

Nature Communications (2023)

-

How polymers dance to the pulses of ultrasound

Nature Chemistry (2023)