Abstract

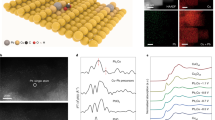

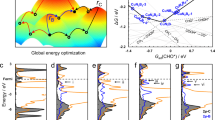

The electrochemical reduction of CO2 to multi-carbon products has attracted much attention because it provides an avenue to the synthesis of value-added carbon-based fuels and feedstocks using renewable electricity. Unfortunately, the efficiency of CO2 conversion to C2 products remains below that necessary for its implementation at scale. Modifying the local electronic structure of copper with positive valence sites has been predicted to boost conversion to C2 products. Here, we use boron to tune the ratio of Cuδ+ to Cu0 active sites and improve both stability and C2-product generation. Simulations show that the ability to tune the average oxidation state of copper enables control over CO adsorption and dimerization, and makes it possible to implement a preference for the electrosynthesis of C2 products. We report experimentally a C2 Faradaic efficiency of 79 ± 2% on boron-doped copper catalysts and further show that boron doping leads to catalysts that are stable for in excess of ~40 hours while electrochemically reducing CO2 to multi-carbon hydrocarbons.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Change history

29 October 2019

An amendment to this paper has been published and can be accessed via a link at the top of the paper.

References

Farrell, A. E. et al. Ethanol can contribute to energy and environmental goals. Science 311, 506–508 (2006).

Hill, J., Nelson, E., Tilman, D., Polasky, S. & Tiffany, D. Environmental, economic, and energetic costs and benefits of biodiesel and ethanol biofuels. Proc. Natl Acad. Sci. USA 103, 11206–11210 (2006).

Bushuyev, O. S. et al. What should we make with CO2 and how can we make it?. Joule 5, 825–832 (2017).

Loiudice, et al. Tailoring copper nanocrystals towards C2 products in electrochemical CO2 reduction. Angew. Chem. Int. Ed. 55, 5789–5792 (2016).

Mistry, H. et al. Highly selective plasma-activated copper catalysts for carbon dioxide reduction to ethylene. Nat. Commun. 7, 12123 (2016).

Yano, H., Tanaka, T., Nakayama, M. & Ogura, K. Selective electrochemical reduction of CO2 to ethylene at a three-phase interface on copper(I) halide-confined Cu-mesh electrodes in acidic solutions of potassium halides. J. Electroanal. Chem. 565, 287–293 (2004).

Kuhl, K. P., Cave, E. R., Abram, D. N. & Jaramillo, T. F. New insights into the electrochemical reduction of carbon dioxide on metallic copper surfaces. Energy Environ. Sci. 5, 7050 (2012).

Xiao, H., Goddard, W. A. 3rd, Cheng, T. & Liu, Y. Cu metal embedded in oxidized matrix catalyst to promote CO2 activation and CO dimerization for electrochemical reduction of CO2. Proc. Natl Acad. Sci. USA 114, 6685–6688 (2017).

Allen, J. & Bard, L. R. F. Electrochemical Methods: Fundamentals and Applications (Wiley, New York, NY, 2000).

De Luna, P. et al. Catalyst electro-redeposition controls morphology and oxidation state for selective carbon dioxide reduction. Nat. Catal. 1, 103–110 (2018).

Ren, D. et al. Selective electrochemical reduction of carbon dioxide to ethylene and ethanol on copper(I) oxide catalysts. ACS Catal. 5, 2814–2821 (2015).

Lee, S. & Lee, J. Electrode build-up of reducible metal composites toward achievable electrochemical conversion of carbon dioxide. ChemSusChem 9, 333–344 (2016).

Eilert, A., Roberts, F. S., Friebel, D. & Nilsson, A. Formation of copper catalysts for CO2 reduction with high ethylene/methane product ratio investigated with in situ X-ray absorption spectroscopy. J. Phys. Chem. Lett. 7, 1466–1470 (2016).

Li, C. W. & Kanan, M. W. CO2 reduction at low overpotential on Cu electrodes resulting from the reduction of thick Cu2O films. J. Am. Chem. Soc. 134, 7231–7234 (2012).

Roberts, F. S., Kuhl, K. P. & Nilsson, A. High selectivity for ethylene from carbon dioxide reduction over copper nanocube electrocatalysts. Angew. Chem. Int. Ed. 127, 5268–5271 (2015).

Gao, D. et al. Plasma-activated copper nanocube catalysts for efficient carbon dioxide electroreduction to hydrocarbons and alcohols. ACS Nano 11, 4825–4831 (2017).

Favaro, M. et al. Subsurface oxide plays a critical role in CO2 activation by Cu(111) surfaces to form chemisorbed CO2, the first step in reduction of CO2. Proc. Natl Acad. Sci. USA 114, 6706–6711 (2017).

Lee, S., Kim, D. & Lee, J. Electrocatalytic production of C3-C4 compounds by conversion of CO2 on a chloride-induced bi-phasic Cu2O–Cu catalyst. Angew. Chem. Int. Ed. 54, 14701–14705 (2015).

Larrazabal, G. O., Martin, A. J., Krumeich, F., Hauert, R. & Perez-Ramirez, J. Solvothermally-prepared Cu2O electrocatalysts for CO2 reduction with tunable selectivity by the introduction of p-block elements. ChemSusChem 10, 1255–1265 (2017).

Grace, A. N. et al. Electrochemical reduction of carbon dioxide at low overpotential on a polyaniline/Cu2O nanocomposite based electrode. Appl. Energy 120, 85–94, (2014).

Trinh, Q. T., Banerjee, A., Yang, Y. H. & Mushrif, S. H. Sub-surface boron-doped copper for methane activation and coupling: first-principles investigation of the structure, activity, and selectivity of the catalyst. J. Phys. Chem. C 121, 1099–1112 (2017).

Soon, A., Todorova, M., Delley, B., & Stampfl, C. Oxygen adsorption and stability of surface oxides on Cu(111): a first-principles investigation. Phys. Rev. B 73, 165424 (2006).

Goodpaster, J. D., Bell, A. T. & Head-Gordon, M. Identification of possible pathways for C–C bond formation during electrochemical reduction of CO2: new theoretical insights from an improved electrochemical model. J. Phys. Chem. Lett. 7, 1471–1477 (2016).

Montoya, J. H., Peterson, A. A. & Nørskov, J. K. Insights into C–C coupling in CO2 electroreduction on copper electrodes. ChemCatChem 5, 737–742 (2013).

Cheng, T., Xiao, H. & Goddard, W. A. III Free-energy barriers and reaction mechanisms for the electrochemical reduction of CO on the Cu(100) surface, including multiple layers of explicit solvent at pH 0. J. Phys. Chem. Lett. 6, 4767–4773 (2015).

Filhol, J. S. & Neurock, M. Elucidation of the electrochemical activation of water over Pd by first principles. Angew. Chem. Int. Ed. 45, 402–406 (2006).

Neugebauer, J. & Scheffler, M. Adsorbate–substrate and adsorbate–adsorbate interactions of Na and K adlayers on Al(111). Phys. Rev. B 46, 16067–16080 (1992).

Gawande, M. B. et al. Cu and Cu-based nanoparticles: synthesis and applications in catalysis. Chem. Rev. 116, 3722–3811 (2016).

Kresse, G. & Hafner, J. Ab initio molecular dynamics for liquid metals. Phys. Rev. B 47, 558–561 (1993).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mat. Sci. 6, 15–50 (1996).

Massalski, T. B., Okamoto, H., Subramanian, P. R. & Kacprzak, L. Binary Alloy Phase Diagrams 2nd edn (ASM International, OH, 1990).

Carenco, S., Portehault, D., Boissiere, C., Mezailles, N. & Sanchez, C. Nanoscaled metal borides and phosphides: recent developments and perspectives. Chem. Rev. 113, 7981–8065 (2013).

Van Aarle, W. et al. The ASTRA Toolbox: a platform for advanced algorithm development in electron tomography. Ultramicroscopy 157, 35–47 (2015).

Acknowledgements

This work was supported financially by funding from TOTAL S.A., the Ontario Research Fund: Research Excellence Program, the Natural Sciences and Engineering Research Council of Canada, the CIFAR Bio-Inspired Solar Energy programme, a University of Toronto Connaught grant, the Ministry of Science, Natural Science Foundation of China (21471040, 21271055 and 21501035), the Innovation-Driven Plan in Central South University project (2017CX003), a project from State Key Laboratory of Powder Metallurgy in Central South University, the Thousand Youth Talents Plan of China and Hundred Youth Talents Program of Hunan and the China Scholarship Council programme. This work benefited from the soft X-ray microcharacterization beamline at CLS, sector 20BM at the APS and the Ontario Centre for the Characterisation of Advanced Materials at the University of Toronto. H.Y. acknowledges financial support from the Research Foundation-Flanders (FWO postdoctoral fellowship). C.Z. acknowledges support from the International Academic Exchange Fund for Joint PhD Students from Tianjin University. P.D.L. acknowledges financial support from the Natural Sciences and Engineering Research Council in the form of the Canada Graduate Scholarship—Doctoral award. S.B. and E.B. acknowledge financial support from the European Research Council (ERC Starting Grant #335078-COLOURATOMS). The authors thank B. Zhang, N. Wang, C. T. Dinh, T. Zhuang, J. Li and Y. Zhao for fruitful discussions, as well as Y. Hu and Q. Xiao from CLS, and Z. Finfrock and M. Ward from APS for their help during the course of study. Computations were performed on the SOSCIP Consortium’s Blue Gene/Q computing platform. SOSCIP is funded by the Federal Economic Development Agency of Southern Ontario, the Province of Ontario, IBM Canada, Ontario Centres of Excellence, Mitacs and 15 Ontario academic member institutions.

Author information

Authors and Affiliations

Contributions

E.H.S. and G.C. supervised the project. Y.Z. and M.L. conceived the idea, designed the experiments and analysed the results. Y.Z. synthesized the samples, performed the electrochemical experiments and analysed the results. F.C. carried out the simulations and wrote the corresponding section. M.L., P.C. and P.D.L. conducted the XAS measurements. J.L., Z.W., T.-K.S. and D.S. assisted in analysing the XAS results. C.Z., Y.Z. and Z.L. ran the NMR tests. M.L. and C.Z. carried out the scanning electron microscope measurements. Y.Z. and H.Y. designed the ICP-OES experiments. C.Z. performed the ICP-OES tests. Z.L. ran the X-ray diffractometer tests. R.Q.-B., H.X. and H.L. performed the XPS measurements. E.B. conducted the TEM measurements. E.B., H.Y., S.B. and J.H. assisted in analysing the TEM results. All authors read and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary information

Supplementary computational simulation methods and data, Supplementary Figures 1–42, Supplementary Tables 1–14

Rights and permissions

About this article

Cite this article

Zhou, Y., Che, F., Liu, M. et al. Dopant-induced electron localization drives CO2 reduction to C2 hydrocarbons. Nature Chem 10, 974–980 (2018). https://doi.org/10.1038/s41557-018-0092-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41557-018-0092-x

This article is cited by

-

Ligand-modified nanoparticle surfaces influence CO electroreduction selectivity

Nature Communications (2024)

-

A surface strategy boosting the ethylene selectivity for CO2 reduction and in situ mechanistic insights

Nature Communications (2024)

-

Stability and lifetime of diffusion-trapped oxygen in oxide-derived copper CO2 reduction electrocatalysts

Nature Catalysis (2024)

-

Free-Standing Single-Atom Catalyst-Based Electrodes for CO2 Reduction

Electrochemical Energy Reviews (2024)

-

Nanocavity enriched CuPd alloy with high selectivity for CO2 electroreduction toward C2H4

Rare Metals (2024)