Abstract

Successful sucrose replacement in cake systems requires thorough understanding of its functionality. Time-domain 1H NMR showed that water in the viscous aqueous phase isolated from cake batter by ultracentrifugation [i.e. the batter liquor (BL)] exhibits low mobility by its low T2 relaxation time (T2,D RT). This is due to its interactions with sucrose or sucrose replacers. The T2,D RT itself is positively related with the effective volumetric hydrogen bond density of sucrose or sucrose replacers. Sucrose additionally co-determines the quantity and viscosity of cake BL and thereby how much air the batter contains at the end of mixing. Like sucrose, maltitol and oligofructose provide adequate volumes of BL with low water mobility and thus sufficient air in the batter, while the rather insoluble mannitol and inulin do not. Differential scanning calorimetry and rapid viscosity analysis revealed, however, that, in contrast to sucrose and maltitol, oligofructose fails to provide appropriate timings of starch gelatinisation and protein denaturation, resulting in poor cake texture. The shortcomings of mannitol and oligofructose in terms of respectively ensuring appropriate gas content in batter and biopolymer transitions during baking can be overcome by using mixtures thereof. This work shows that successful sucrose substitutes or substitute mixtures must provide sufficient BL with low water mobility and ensure appropriate timings of starch and protein biopolymer transitions during baking.

Similar content being viewed by others

Introduction

The global cake market size was valued at USD 42.94 billion in 2019 and is anticipated to grow at a compound annual growth rate of 3.3% from 2020 to 20271. Cakes are sugar-rich foods which may be categorised as foam-, batter-, or chiffon-type cakes based on their formulation and production methods2,3. Foam-type (e.g. sponge) cakes are made from flour, sucrose, eggs, and leavening agent2. Batter- (or emulsion-) type cream and pound cakes additionally contain an oil or a fat source, respectively3. Chiffon-type cakes are a combination of the two cake types.

In response to dietary guidelines4, the food industry aims to reduce/replace sucrose in food systems. In soft drinks, this is comparatively easier because sugar can be replaced by high-intensity sweeteners5. In cake recipes, it is much more difficult to replace sucrose because of its diverse functionalities in their production, and because high-intensity sweeteners such as rebaudioside A6 and stevioside7 merely provide sweetness.

The cake-making process consists of mixing the ingredients into a batter and a baking phase of the batter. During mixing, air bubbles are incorporated in the batter, lowering batter density (BD)2. The air bubbles need to be sufficiently stable to ensure that the baked product has its desired volume8 and crumb texture9. For pound cake7,10,11 systems, high batter viscosity (ηB) (measured with rotational7 or oscillating rod10,11 viscometers) has been associated with efficient air incorporation. Sucrose increases the viscosity of the aqueous phase of model foam systems, and thereby foam stability8. In sponge cakes, air is incorporated in the batter’s aqueous phase [further referred to as batter liquor (BL)]12. Against this background, we hypothesised that when using sucrose (substitutes), the quantity and quality of sponge cake BL, rather than the ηB, are important determinants of air incorporation and batter stability during batter mixing. We thus examined whether BL fraction (i.e. the sum of water and sucrose divided by total recipe mass), viscosity (ηBL)13, and proton (1H) mobility [analysed by time-domain (TD) NMR]14 are related to the incorporation of air in sponge cake batter and thus BD when using either less sucrose or the sucrose substitutes maltitol, mannitol, oligofructose, or inulin (Fig. 1). They all have lower calorie contents15,16,17 than sucrose, are bulking agents15,16 and, in case of mannitol and maltitol, also provide some sweetness16,17. Polyols such as maltitol may cause digestive issues when consumed in amounts exceeding 40 g/day18. Also, fibers such as oligofructose can induce browning during baking due to an increased amount of reducing oligosaccharides. To examine whether said potential negative effects can be reduced, mixtures of the previously stated sucrose substitutes are also tested.

While obtaining the right viscosity (ηB & ηBL) may be important in cake making, it is not the sole parameter that determines cake quality19. During baking, the cake matrix sets due to wheat starch gelatinisation and protein denaturation20,21,22, the timings of which largely affect cake texture and quality23. Sucrose impacts the temperature at which starch gelatinises24,25,26,27,28,29 and protein denatures30,31. The assumed simultaneous occurrence of both phenomena32 transforms the liquid batter into a solid cake33,34. We here determined the effect of sucrose reduction/substitution on starch gelatinisation and protein denaturation using differential scanning calorimetry (DSC)35. Batter structure setting was studied by rapid viscosity analysis (RVA)36 and cake texture by texture profile analysis37.

We evaluated whether the findings for sponge cakes would also hold for batter-type cream and pound cakes. Based on our results, cake manufacturers are advised to select (mixtures of) sucrose substitutes which generate sufficient BL with low mobility and, in addition, ensure appropriate timings of starch gelatinisation and protein denaturation during baking.

Results

Sponge cake batter (liquor) properties

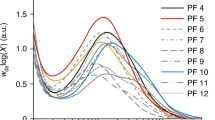

Sponge cake batters were made using different sucrose contents/substitutions (Table 1). The proton distributions of their recovered BLs (Fig. 2, Supplementary Data 1) revealed the effects of the different formulations at the molecular level. Proton populations in the Carr-Purcell-Meiboom-Gill (CPMG) pulse sequence were designated A to D in order of increasing mobility and assigned to dissolved compounds based on earlier work38,39,40,41. Populations A and B represent protons from minor constituents such as soluble starch (0–5% and 2–5% of total protons, respectively)39,40, while proton population C represents non-exchanging (CH) protons from dissolved sucrose38 or sucrose substitutes (2–11% of total protons). The most mobile fraction, proton population D, contained 82–93% of the protons. It mainly represents the hydroxyl group protons of water exchanging with those from sucrose38,41 or dissolved substitutes. Their T2 relaxation times (T2,D RT) are a measure of hydroxyl proton mobility and evidently reflect the interaction of soluble components [mainly sucrose (substitutes)] with water41.

Recipe numbers are those of the different batters listed in Table 1. The proton populations are described by letters A–D, in order of increasing mobility. The amplitudes are provided in arbitrary units (au).

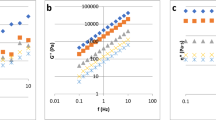

When reducing the sucrose content from 100% (control, recipe 1) to 70% (recipe 2), the batter contained less soluble material. The BL fraction indeed decreased from 62.1% to 56.8%. The mobility of the BL population D protons was slightly higher as evidenced by the higher T2,D RT and lower ηBL (Fig. 3A) resulting from less strong water-sucrose interactions. Sucrose reduction also caused BD to increase (Table 2, Supplementary Data 2), but did not affect ηB (Table 1). This showed that the latter is a poor predictor of air incorporation during batter mixing.

Relation between (A) T2,D relaxation time (RT) and BL viscosity (ηBL) and (B) batter density (BD) and ηBL. Recipe numbers are those of the different batters listed in Table 1. Error bars show the standard deviations from the means of three analytical replicates.

Maltitol (recipe 3), like sucrose, completely dissolved in the BL (solubility ~200 g/100 ml), resulting in similar BL quantities and properties [i.e. T2,D, ηBL, BD (Fig. 3, Supplementary Data 3), and ηB (Table 1)] to the control recipe. Mannitol (recipe 4) did not completely dissolve (solubility ~21.6 g/100 ml) resulting in less BL (estimated to be 43.2%) and lower ηBL (Fig. 3B). Accordingly, its T2,D RT was substantially higher and the relaxation peak broader in shape than that of the control (Fig. 2), likely due to its poor solubility and the consequent heterogeneity in its interaction with water. The BD (Table 2) was significantly higher, and thus worse than noted for the control. When sucrose was replaced by oligofructose (recipe 5), DSC analyses (results not shown) indicated that it completely dissolved during batter mixing (as also observed earlier15), resulting in a BL fraction equal to that of recipe 1 (62.1%) and a high ηBL (Fig. 3B). In this BL, the T2,D RT was slightly lower than that of the control (Fig. 3A). The distribution of proton population D was broader (Fig. 2) because oligofructose is a heterogeneous mixture of different components. In these samples, for reasons not understood at present, the largest proportion of population C protons (about 10%) among all samples was noted. BD was low (Table 2) indicating high air incorporation in the batter.

Next, the impact of replacing mannitol (recipe 4) by oligofructose or inulin in increments of 25% (Table 1) was tested. Replacing 25% mannitol by oligofructose (recipe 6) led to improved air incorporation (reflected in the BD) and lower T2,D RT (Fig. 3A). When 50% (recipe 7) or 75% oligofructose (recipe 8) were used with the corresponding mannitol complements, the mobility of water in the BL decreased even more, as reflected by their lower T2,D RTs (Fig. 3A). The T2,D RT of recipe 8 and the control BL were very similar, as were their ηBL and BD (Table 2). When replacing 25% mannitol by inulin (recipe 9), DSC tests showed that, unlike oligofructose, it did not completely dissolve during batter mixing. While its BL and batter properties improved [lower T2,D RT and higher ηBL (Fig. 3)] or remained comparable [ηB (Table 1)] to recipe 4, the BD remained inferior to recipe 1 (Table 2). Inspection by the naked eye revealed that replacing more than 25% mannitol by inulin resulted in batters and cakes of exceedingly lower quality [i.e. BD, cake density (CD), and crumb firmness were high] and thus were not further considered.

This study shows that there are high correlations between ηBL and either T2,D RT (R2 = 0.93) or BD (R2 = 0.84) (Fig. 3) and that there are no such correlations between either ηB and BD or T2,D RT (results not shown).

Biopolymer transitions during sponge cake baking

At high temperatures, a cake batter loses its fluidity and the cake structure starts setting as a result of starch gelatinisation and protein denaturation33.

During regular cake baking, both thermal events overlap2,32. The impact of sucrose (substitutes) on these endothermic transitions was examined, both separately and in batter, by DSC analysis. In the former case, the starch or egg white transitions were determined in excess water (recipe 0) and in media simulating the different BLs. In the latter case, the batters themselves were analysed. The resultant peak temperatures for wheat starch gelatinisation (Tp,starch), egg white protein denaturation (Tp1,EW and Tp2,EW), and the endothermic batter transition (Tp,batter) are listed in Table 3 (Supplementary Data 4).

Compared to the water medium (recipe 0), biopolymer transitions occurred at increasingly higher temperatures in the sucrose-reduced (recipe 2) and sucrose-rich medium (recipe 1). No differences in the transition temperatures were noted between the sucrose-rich and maltitol-rich (recipe 3) media. The oligofructose-rich medium (recipe 5) caused egg white protein to denature at the same temperature as the sucrose-rich medium, while starch gelatinisation was delayed significantly (Table 3). This explains the significantly higher Tp,batter noted for recipe 5 batter. The biopolymer transition temperatures of the 25% mannitol and 75% oligofructose batter (recipe 8) were most similar to those of the control batter (Table 3), indicating that a combination of the two substitutes can provide appropriate cake structure setting.

Unfortunately, the media simulating BLs containing more than 25% mannitol or inulin (recipes 4, 6, 7, 9; Table 1) could not be tested because their endothermic dissolution during heating interfered with the starch gelatinisation and egg protein denaturation endotherms.

Sponge cake characteristics

Cross-sections of sponge cakes from selected recipes are shown in Fig. 4A. The cakes made from control batter (recipe 1) had low CD and thus high volume with their texture properties taken as the benchmark for sponge cake (Table 2). When sucrose-content was reduced (recipe 2), the temperature of viscosity increase (Tη↑, determined by RVA) was shown to decrease relative to the control batter and cakes were denser. Crumb cohesiveness and softness were negatively affected by sucrose reduction, while crumb springiness and resilience were not.

Cakes made with maltitol (recipe 3) displayed similar Tη↑ and CD compared to control cakes (recipe 1, Table 2). Substitution with maltitol resulted in a similar cake crumb resilience and softness as determined for the control, and a lower crumb springiness and cohesiveness. Using mannitol (recipe 4), which minimally affects starch gelatinisation due to its low solubility42, resulted in poor cake quality as revealed by the significantly higher CD and poor cake crumb texture, even if the Tη↑ was similar to that of the control (recipe 1). The use of 100% oligofructose (recipe 5) led to a higher Tη↑ and thus delayed structure setting during baking (Table 2). While the CD was optimal, the crumb texture was suboptimal probably due to the significantly higher Tp,batter43 than noted for the control and because starch gelatinisation and protein denaturation did not fully overlap (Table 3).

When mannitol was replaced by oligofructose in increments of 25% (recipes 6 to 8), CD and crumb softness were significantly better (Table 2). Other crumb characteristics also improved, however, even with 75% replacement of mannitol by oligofructose (recipe 8), they remained slightly inferior to those of the control cakes, in spite of their similar BL and batter properties (Fig. 3, Table 2).

Use of 25% inulin and 75% mannitol (recipe 9) resulted in a Tη↑ comparable to that of the control and the 100% mannitol recipe (recipe 4). However, CD, crumb springiness, cohesiveness and resilience were not better than those of recipe 4 cakes (Table 2). The slightly better gas cell incorporation during mixing led to average-wise thinner cell walls, and resulted in slightly softer crumb.

Cream and pound cake making

To evaluate whether the present findings for foam-type cakes would also hold for batter-type cakes, cream (Fig. 4B) and pound (Fig. 4C) cakes were produced from recipes containing either sucrose, maltitol, a mixture of 25% mannitol and 75% oligofructose, or mannitol.

Replacing sucrose (recipe a) by maltitol (recipe b) in cream cake resulted in marginally better BD (Table 2). While the Tp,batter and CD of maltitol cream cakes did not differ from the control, their texture was inferior. Mannitol (recipe c) usage resulted in similar but less pronounced trends as observed for sponge cake (slightly worse BD and CD, significantly worse cake texture). Use of 25% mannitol and 75% oligofructose (recipe d) resulted in a BD and CD similar to those of the control, however, structure setting occurred slightly later.

In pound cake making, replacing sucrose (recipe α) by maltitol (recipe β) brought about similar BD and CD values (Table 2). While the biopolymer phase transitions of the batters were highly comparable, maltitol once again detrimentally affected cake texture. When sucrose was substituted by mannitol (recipe γ), BD did not differ. For reasons not understood at present, CD was better, however, as also noted for sponge and cream cakes, there was a significant negative effect on crumb texture. The use of 25% mannitol and 75% oligofructose (recipe δ) resulted in a slightly better BD and a similar CD as noted for the control. Structure setting was once again slightly delayed due to oligofructose use.

The observations for cream and pound cake thus aligned well with those for sponge cake.

Discussion

Solubility of sucrose (substitutes) in the batter’s aqueous phase significantly affects the BL quantity, proton mobility in the BL, and ηBL. Batters from recipes containing high amounts of sucrose (recipe 1) or soluble sucrose substitutes maltitol or oligofructose (recipes 3, 5, and 8) have high BL quantities and evidently contain high amounts of air. At the same time, the mobility of their BL population D protons is low, ηBL is high (Fig. 3A), and the air is well retained in the foam/batter. Their resulting BDs are low. When the batters contain less sucrose (i.e. recipe 2), insoluble, or only partly soluble sucrose substitutes (i.e. recipes 4, 6, 7, 9), BL quantities and viscosities are lower, proton mobility in BL is higher, and batters are more dense. The T2,D RT values are related to the volumetric density of hydrogen bonds in the aqueous phase (nOH,eff) (Fig. 5, Supplementary Data 5). As a result, nOH,eff may be indirectly related to the ηBL. The nOH,eff parameter is important for explaining starch gelatinization and protein denaturation44,45,46,47 behaviour regarding the substitution of sucrose in cake systems. The high correlation between nOH,eff and T2,D RT (Fig. 5) underline how important it is to examine the intrinsic properties of the aqueous phase (i.e. ηBL, T2,D RT) when optimising sucrose substitution.

Recipe numbers are those of the different batters listed in Table 1. Error bars show the standard deviations from the means of three analytical replicates of T2,D RT.

Importantly, the polynomial relation in Fig. 3B shows that a minimum ηBL of ±60–80 mPa.s is necessary to provide an appropriate BD. No such relation was found between ηB (Table 1) and BD. These results thus demonstrate that, to ensure sufficient gas cell incorporation and gas cell stability during batter mixing, BL quantity, ηBL, and proton mobility – and not ηB – should be considered when replacing sucrose in sponge cake recipes.

In the control batter (recipe 1), starch gelatinisation and protein denaturation (Table 3) occur within a similar temperature range. When sucrose content is reduced (recipe 2), starch gelatinisation and protein denaturation occur at lower temperatures (Table 3) and batter leavening during baking is reduced, leading to cakes with higher CD and thicker gas cell walls48. Along with extensive amylose crystallisation49 after structure setting (due to more amylose leaching50), this causes cake crumb to be firmer (Table 2).

Sucrose and maltitol (recipe 3) have similar effects on the ηB, starch gelatinisation51, and protein denaturation. The resultant cakes have comparable CDs and only a slightly different texture. Using mannitol (recipe 4) instead of sucrose leads to lower BL quantities, less gas cell incorporation during mixing, and detrimental effects on CD and cake crumb texture. Due to its poor solubility, mannitol does not delay starch gelatinisation and/or protein denaturation to a similar degree as sucrose. This explains its negative effect on cake quality. While using 100% oligofructose (recipe 5) has a positive effect on CD, starch gelatinisation is excessively delayed (Table 3)43, resulting in incomplete cake structure setting. The structural collapse and suboptimal crumb texture of these cakes likely results from starch gelatinisation and protein denaturation occurring at different moments during baking.

Step-wise replacement of mannitol (recipe 4) by oligofructose (i.e. recipes 6, 7, 8) positively affects CD and crumb texture (Table 2) due to the increased number of gas cells (with thinner gas cell walls) in the batter. When 75% of mannitol is replaced by oligofructose (recipe 8), the resultant BD is similar to that of the control (Table 2). However, the temperature of starch gelatinisation is slightly elevated compared to the control. The resultant cakes have an optimal CD and a similar crumb texture, except for a slightly reduced springiness and cohesiveness, the latter presumably due to the different timings of starch gelatinisation and protein denaturation. We conclude that the functionality of a mixture of oligofructose and mannitol in sponge cake making is similar to that of sucrose. Replacing 25% mannitol by inulin (recipe 9) marginally improves batter and cake quality (Table 2), and higher inulin concentrations result in significantly lower quality (data not shown).

When sucrose (recipe A, Table 4) is replaced by maltitol (recipe B) in cream cake, an almost identical effect as in sponge cake is observed regarding BD, CD, structure setting, and texture. In contrast to what is the case for sponge cake, mannitol has a limited effect on BD and CD in cream (recipe C) cake. In emulsion-type cake systems, gas cells are stabilised not solely in the aqueous phase, but also in the lipid phase3. Therefore, the effect of substitute solubility and ηBL on gas cell stability and BD is more limited, translating to mannitol-containing cakes having a similar CD as the control. Nonetheless, mannitol has a negative impact on cake texture, likely due to the altered phase transition temperatures of starch and protein compared to sucrose. Oligofructose (recipe D) positively impacts BD and CD, as also observed in sponge cake making.

When sucrose (recipe α, Table 4) is replaced by maltitol (recipe β), mannitol (recipe γ), or oligofructose (recipe δ) in pound cake (an emulsion-type cake), similar effects as those described for sponge cake are detected. Still, as noted above, mannitol has a different effect on CD in pound cake.

Thus, while the batter and BL properties of sponge cake (a foam-type cake) differ from those of emulsion-type cake systems in terms of gas cell stabilisation, the phenomena occurring during sponge cake baking and their impact on cake texture can be extended to cream and pound cake baking. This implies that both maltitol and mixtures of mannitol and oligofructose can be effective sucrose replacers in different cake systems.

The present findings regarding the intrinsic properties of the aqueous batter phase (i.e. ηBL, T2,D RT) and the biopolymer transitions and cake characteristics, along with the outcome of earlier research47, can serve as a basis for optimizing cake recipes, making sucrose replacement in these systems a bit more “a piece of cake”.

Methods

Materials

Wheat flour [moisture content, 14.0%; protein content, 11.6% (dry basis, N x 5.7)], maltitol, mannitol, leavening agent [sodium bicarbonate (NaHCO3) and sodium acid pyrophosphate (SAPP15)], and a monoacylglycerol and diacylglycerol based emulsifier were provided by Puratos (Groot-Bijgaarden, Belgium). SAPP15 releases 15% of the maximum amount of carbon dioxide (CO2) resulting from its reaction with NaHCO3 during the cake batter mixing phase52. Oligofructose [Orafti®P95, degree of polymerisation (DP) = 2–9] and inulin (Orafti®HP, DP ≥ 23) were provided by Beneo (Wijgmaal, Belgium). Wheat starch (moisture content 12.3%) was from Cargill (Sas van Gent, The Netherlands). Ultra-fine sugar, rapeseed oil, margarine, and hen eggs were obtained from a local supermarket. For some experiments, egg white was flash frozen with liquid nitrogen and freeze-dried. Freeze-dried egg white had a moisture content of 7.1%.

Sponge cake batter making

The sugar (substitute) composition of the sponge cake batter are listed in Table 1. The recipes per 100.0 g flour further contained egg white (62.0 g), egg yolk (22.5 g), emulsifier (16.5 g), sodium bicarbonate (NaHCO3, 1.7 g), sodium acid pyrophosphate (SAPP15, 2.3 g), and water (35.2 g). The quantity of water per 100.0 g flour for the 70% sucrose sample (recipe 2) was 20.8 g so that all batters contained 35.5% water. Triplicate batters were made from 281.0 g wheat flour. Egg white and egg yolk were separated and weighed before use to allow accurate dosing. Wheat flour, sucrose or sucrose substitute, NaHCO3, SAPP15, and emulsifier were first manually blended in the mixing bowl of a Hobart N-50 5-Quart Mixer (Troy, OH, USA) until a homogenous dry mix was obtained. Water, egg white, and egg yolk were then manually folded into the dry component mix with a spatula to obtain a homogenous wet blend which was then mixed (300 s, 255 rpm, wire whip) to form aerated batter.

Cream cake batter making

The sugar (substitute) composition of the cream cake batters are listed in Table 4. The recipes per 100.0 g flour further contained rapeseed oil (58.1 g), egg white (43.1 g), egg yolk (24.7 g), emulsifier (1.9 g), sodium bicarbonate (NaHCO3, 1.1 g), sodium acid pyrophosphate (SAPP28, 1.5 g), and water (43.7 g). Triplicate batters were made from 465.0 g wheat flour. Wheat flour, sucrose or sucrose substitute, NaHCO3, SAPP15, and emulsifier were first blended as above. Water, egg white and egg yolk, and rapeseed oil were then manually folded into the dry component mix with a spatula to obtain a homogenous wet blend. The blend was mixed (Hobart mixer) with a flat beater (120 s at 60 rpm; then 120 s at 124 rpm).

Pound cake batter making

The sugar (substitute) composition of the pound cake batters are listed in Table 4. The recipes per 100.0 g flour further contained margarine (100.0 g), egg white (66.6 g), egg yolk (33.3 g), sodium bicarbonate (NaHCO3, 1.1 g), and sodium acid pyrophosphate (SAPP28, 1.5 g). Triplicate batters were made from 450.0 g wheat flour. First, the margarine and sucrose or sucrose substitute were blended (Hobart mixer, flat beater, 180 s at 255 rpm, i.e. the creaming step), after which the egg white and egg yolk were mixed in (30 s at 124 rpm). Finally, the wheat flour, NaHCO3, and SAPP15, were added and the blend was mixed (120 s at 124 rpm) to form batter.

Determination of batter density

Batter densities (BDs) were calculated from the weights of 100 ml of two samples of each individual cake batter in tared plastic cylinders53. Averages of the six BD measurements are reported per batter.

Isolation of sponge cake batter liquor and analysis of its viscosity

From each of the three individual sponge cake batters, six samples (20.0–30.0 g) in 38 mL thick polycarbonate tubes (Beckman Coulter, Brea, CA, USA) were centrifuged at 165,000 g (25 °C, 65 min) in a Beckman Coulter L7-65 Ultracentrifuge. From top to bottom, three phases were distinguished; a lipid, an aqueous, and a solid phase. The upper lipid phase was gently removed, and the aqueous phase was carefully decanted. The combined aqueous phase of each of the six samples per batter is further referred to as the BL.

The ηBL of each individual batter was determined in duplicate at 25 °C with a Brookfield Engineering (Middleboro, MA, USA) DV-III Ultra rheometer equipped with a cylindrical SC4-18 spindle (diameter 17.48 mm, length 31.72 mm). The cylindrical spindle was fully immersed in a BL aliquot (6.7 ml) in a SC4-13R sample chamber (diameter 19.05 mm) and then rotated at 10 rotations/min for 150 s. From 60 s onwards, the viscosity was recorded every 15 s for 90 s resulting in seven ηBL measurements per individual batter. The 14 readings of the ηBL of each tested batter were averaged.

TD 1H NMR analysis of sponge cake BL

TD 1H NMR was used to study molecular mobility in the BLs. BL samples were accurately weighed (± 0.1 g) in NMR tubes (internal diameter 7.0 mm) and sealed to prevent moisture loss during analysis. The measurements were carried out with a Minispec mq 20 TD NMR spectrometer (Bruker, Rheinstetten, Germany) with 20 MHz operating resonance frequency for 1H (magnetic field strength of 0.47 T). The probe head temperature was 25 ± 1 °C. Because BL is an aqueous phase, relaxation curves were obtained using the CPMG pulse (90°, 180°) sequence. The lengths of the 90° and 180° pulses were 3.10 and 6.38 µs, respectively, with a pulse separation of 0.1 ms and 2,500 acquired data points. To obtain good signal-to-noise ratios, 32 scans were executed with a recycle delay of 4.0 s between consecutive scans. The signal decays were transformed to continuous distributions of T2 relaxation times with the CONTIN algorithm from Provencher54 (Bruker software) based on the inverse Laplace transformation.

The obtained proton populations were labelled in order of increasing mobility with alphabetic characters A to D and the assignment of proton populations was based on previous work from Luyts et al. (2013)38 and Pycarelle et al. (2020)40 on pound and sponge cake batter systems, respectively. The primary focus of the discussion was on CPMG proton population D (containing the exchanging protons of water and sucrose or sucrose substitutes) since it represented the largest fraction of protons in the proton distribution.

The weights of the BL samples were used for further calculations. For each proton population, the area and T2 relaxation time is reported, representing the relative amounts and mobility of protons in the corresponding population, respectively. The proton population areas are expressed in A.U. per g of BL. Analysis was performed on three subsamples from each sample, of which measurements were performed in triplicate.

Effective volumetric hydrogen bond density calculation

Calculations of effective volumetric hydrogen bond density (nOH,eff) were done as in van der Sman & Mauer (2019)44. Molar mass (M), density (ρ), and hydrogen groups available for bonding (NOH) values were taken from van der Sman & Mauer (2019) and van der Sman et al (2022)44,55.

Differential scanning calorimetry measurements

The effect of sucrose and its substitutes on gelatinisation of wheat starch and denaturation of egg white was studied in triplicate with differential scanning calorimetry (DSC) with a TA Instruments (New Castle, DE, USA) DSC Q2000. Wheat starch or freeze-dried egg white samples (2.5–3.0 mg) were accurately weighed in coated aluminium pans (Perkin Elmer, Waltham, MA, USA), after which water or water-containing media were added to obtain a wheat starch or freeze-dried egg white dry matter content of 25% (wdm/wtotal). Their composition was based on those of the BLs of recipes 1, 2, 3, 5, and 8 (cfr. Table 1) and thus contained 42.8% sucrose (wsucrose/wtotal), 36.3% sucrose, 42.8% maltitol, 42.8% oligofructose, and 42.8% (mannitol+oligofructose) respectively. The batters of said recipes were tested as well, by accurately weighing 6.5 – 8.5 mg of batter in coated aluminium pans. The pans were hermetically sealed, equilibrated at 0 °C, and then heated from 0 to 130 °C at 4 °C/min. A reference pan was heated simultaneously. The calibration was done with indium. Data were processed with TA Universal Analysis software. Unfortunately, the effect on starch gelatinisation, protein denaturation, and the batter could not be tested with DSC for samples containing more than 25% mannitol or inulin (i.e. recipes 4, 6, 7, and 9), due to overlap of their dissolution peak with those of starch gelatinisation and egg white denaturation.

Rapid viscosity analysis of sponge cake batter

Viscosity development during batter heating was analysed in duplicate with an RVA Super 4 (Perten, Hägersten, Sweden). The spindle was fully submerged in RVA cups filled with batter up to a height of 80 mm. Batter was then heated from 23 °C to 98 °C at 7.5 °C/min for 10 mins and further kept at that temperature for an additional 20 min. This heating profile was based on that in the centre of sponge cake batter when baked in a plate oven, as measured with a type T thermocouple (DataPaq, Cambridge, UK). The ηB was calculated from the current required to mix the batter with a paddle rotating at 75 rpm, as mentioned in Deleu et al. (2019)56. The temperature associated with a viscosity increase of more than 10% over the span of three consecutive 8 s intervals, i.e. Tη↑, is here considered to be that at which structure setting started.

Cake baking

Of each batter, 100.0 g (sponge cake) or 220.0 g (cream or pound cake) was added to three aluminium baking tins (lengthxwidthxheight, 170 × 75 x 50 mm) (Gents Bakkershuis, Ghent, Belgium). Batters were baked for 30 (sponge cake), 40 (cream cake), or 55 min (pound cake) in a plate oven (Hein Condilux, Hein, Strassen, Luxembourg) preheated to top and bottom temperatures of 180 °C and 160 °C (sponge and pound cake) or 180 °C and 180 °C (cream cake), respectively.

Analysis of cakes

Baked cakes were cooled for 120 min at 23 °C and weighed prior to determining their volume with a VolScan Profiler (Stable Micro Systems, Godalming, UK). CDs of cakes were determined from their weights and volumes. Texture profile analysis53,57 was performed on the four most central 25 mm thick crumb slices of three cakes made from each batter. Cylindrical (30 mm diameter) crumb samples cut from the centre of these slices were compressed to 50% of their original height at 2 mm/s with an Instron (Norwood, MA, USA) 3342 Texture Analyser equipped with a cylindrical probe (diameter 75 mm) and a 50 N load cell, after which the samples were decompressed. The compression-decompression cycle was then repeated after a rest (3s). Crumb springiness, cohesiveness, resilience, and firmness were determined as in Godefroidt et al. (2021)36. The 12 measurements of each tested batter were averaged.

Statistical analysis

The Tukey method (P < 0.05) was applied to detect differences in BD, CD, textural properties, and cake volume data using JMP Pro 16 (SAS Institute, Cary, NC, USA). The polynomial correlation was made using Microsoft Excel (Redmont, WA, USA).

Reporting summary

Further information on research design is available in the Nature Research Reporting Summary linked to this article.

Data availability

All relevant data are included in the paper. All raw data are available from the authors upon request. Source data are provided with this paper.

References

https://www.grandviewresearch.com/industry-analysis/cakes-market#Cake Market Size, Share & Trends Analysis Report by Product (Cupcakes, Dessert Cakes, Sponge Cakes), by Distribution Channel, by Region, and Segment Forecasts, 2020-2027.

Godefroidt, T., Ooms, N., Pareyt, B., Brijs, K. & Delcour, J. A. Ingredient functionality during foam‐type cake making: A review. Compr. Rev. Food Sci. Food Saf. 18, 1550–1562 (2019).

Wilderjans, E., Luyts, A., Brijs, K. & Delcour, J. A. Ingredient functionality in batter type cake making. Trends Food Sci. Technol. 30, 6–15 (2013).

Luo, X., Arcot, J., Gill, T., Louie, J. C. Y. & Rangan, A. A review of food reformulation of baked products to reduce added sugar intake. Trends Food Sci. Technol. 86, 412–425 (2019).

Agulló, V., García-Viguera, C. & Domínguez-Perles, R. The use of alternative sweeteners (sucralose and stevia) in healthy soft-drink beverages, enhances the bioavailability of polyphenols relative to the classical caloric sucrose. Food Chem. 370, 131051 (2022).

Majzoobi, M., Mohammadi, M., Mesbahi, G. & Farahnaky, A. Feasibility study of sucrose and fat replacement using inulin and rebaudioside A in cake formulations. J. Texture Stud. 49, 468–475 (2018).

Manisha, G., Soumya, C. & Indrani, D. Studies on interaction between stevioside, liquid sorbitol, hydrocolloids and emulsifiers for replacement of sugar in cakes. Food Hydrocoll. 29, 363–373 (2012).

Yang, X. & Foegeding, E. A. Effects of sucrose on egg white protein and whey protein isolate foams: Factors determining properties of wet and dry foams (cakes). Food Hydrocoll. 24, 227–238 (2010).

Hesso, N. et al. Formulation effect study on batter and cake microstructure: Correlation with rheology and texture. Food Struct. 5, 31–41 (2015).

Bath, D. E., Shelke, K. & Hoseney, R. C. Fat replacers in high-ratio layer cakes. Cereal Foods World 37, 495–500 (1992).

Shelke, K., Faubion, J. M. & Hoseney, R. C. The dynamics of cake baking as studied by a combination of viscometry and electrical resistance oven heating. Cereal Chem. 67, 575–580 (1990).

Brooker, B. E. The stabilisation of air in foods containing fat - A review. Food Struct. 12, 115–122 (1993).

Telis, V. R. N., Telis-Romero, J., Mazzotti, H. B. & Gabas, A. L. Viscosity of aqueous carbohydrate solutions at different temperatures and concentrations. Int. J. Food Prop. 10, 185–195 (2007).

Riley, I. M., Nivelle, M. A., Ooms, N. & Delcour, J. A. The use of time domain 1H NMR to study proton dynamics in starch-rich foods: A review. Compr. Rev. Food Sci. Food Saf. 1–38 (2022).

Franck, A. Technological functionality of inulin and oligofructose. Br. J. Nutr. 87, S287–S291 (2002).

Grembecka, M. Sugar alcohols — their role in the modern world of sweeteners: a review. Eur. Food Res. Technol. 241, 1–14 (2015).

Cataldi, T. R. I., Campa, C., Casella, I. G. & Bufo, S. A. Determination of maltitol, isomaltitol, and lactitol by high-pH anion-exchange chromatography with pulsed amperometric detection. J. Agric. Food Chem. 47, 157–163 (1999).

Saraiva, A., Carrascosa, C., Raheem, D., Ramos, F. & Raposo, A. Maltitol: Analytical determination methods, applications in the food industry, metabolism and health impacts. Int. J. Environ. Res. Pub. Health 17, 5227 (2020).

Struck, S., Gundel, L., Zahn, S. & Rohm, H. Fiber enriched reduced sugar muffins made from iso-viscous batters. LWT - Food Sci. Technol. 65, 32–38 (2016).

Donovan, J. W. & Mapes, C. J. A differential scanning calorimetric study of conversion of ovalbumin to S-ovalbumin in eggs. J. Sci. Food Agric. 27, 197–204 (1976).

Donovan, J. W., Mapes, C. J., Davis, J. G. & Garibaldi, J. A. A differential scanning calorimetric study of the stability of egg white to heat denaturation. J. Sci. Food Agric. 26, 73–83 (1975).

Guy, R. C. E. & Pithawala, H. R. Rheological studies of high ratio cake batters to investigate the mechanism of improvement of flours by chlorination or heat treatment. Int. J. Food Sci. Technol. 16, 153–166 (1981).

Struck, S., Jaros, D., Brennan, C. S. & Rohm, H. Sugar replacement in sweetened bakery goods. Int. J. Food Sci. Technol. 49, 1963–1976 (2014).

Beleia, A., Miller, R. A. & Hoseney, R. C. Starch gelatinization in sugar solutions. Starch/Stärke 48, 259–262 (1996).

Kim, C. S. & Walker, C. E. Interactions between starches, sugars, and emulsifiers in high-ratio cake model systems. Cereal Chem. 69, 206–212 (1992).

Kim, C. S. & Walker, C. E. Effects of sugars and emulsifiers on starch gelatinization evaluated by differential scanning calorimetry. Cereal Chem. 69, 212–217 (1992).

Perry, P. A. & Donald, A. M. The effect of sugars on the gelatinisation of starch. Carbohydr. Polym. 49, 155–165 (2002).

Slade, L. & Levine, H. Non-equilibrium behavior of small carbohydrate-water systems. Pure Appl. Chem. 60, 1841–1864 (1988).

Spies, R. D. & Hoseney, R. C. Effect of sugars on starch gelatinization. Cereal Chem. 59, 128–131 (1982).

Donovan, J. W. A study of the baking process by differential scanning calorimetry. J. Sci. Food Agric. 28, 571–578 (1977).

Kaushik, J. K. & Bhat, R. Thermal stability of proteins in aqueous polyol solutions: Role of the surface tension of water in the stabilizing effect of polyols. J. Phys. Chem. B 102, 7058–7066 (1998).

Mizukoshi, M., Maeda, H. & Amano, H. Model studies of cake baking. II. Expansion heat. set. cake batter Bak. Cereal Chem. 57, 352–355 (1980).

Shepherd, I. S. & Yoell, R. W. Cake Emulsions. in Food Emulsions 216–275 (Marcel Dekker, 1976).

Delcour, J. A. & Hoseney, R. C. Principles of Cereal Science and Technology. (AACC International, 2010).

Slade, L., Kweon, M. & Levine, H. Exploration of the functionality of sugars in cake-baking, and effects on cake quality. Crit. Rev. Food Sci. Nutr. 61, 283–311 (2021).

Godefroidt, T., Ooms, N., Bosmans, G. M., Brijs, K. & Delcour, J. A. An Ohmic heating study of the functionality of leavening acids in cream cake systems. LWT - Food Sci. Technol. 152, 112277 (2021).

Wilderjans, E., Luyts, A., Goesaert, H., Brijs, K. & Delcour, J. A. A model approach to starch and protein functionality in a pound cake system. Food Chem. 120, 44–51 (2010).

Luyts, A. et al. Low resolution 1H NMR assignment of proton populations in pound cake and its polymeric ingredients. Food Chem. 139, 120–128 (2013).

Le Grand, F., Cambert, M. & Mariette, F. NMR signal analysis to characterize solid, aqueous, and lipid phases in baked cakes. J. Agric. Food Chem. 55, 10947–10952 (2007).

Pycarelle, S. C., Brijs, K. & Delcour, J. A. The role of exogenous lipids in starch and protein mediated sponge cake structure setting during baking. Food Res. Int. 137, 109551 (2020).

Assifaoui, A., Champion, D., Chiotelli, E. & Verel, A. Characterization of water mobility in biscuit dough using a low-field 1H NMR technique. Carbohydr. Polym. 64, 197–204 (2006).

Allan, M. C., Rajwa, B. & Mauer, L. J. Effects of sugars and sugar alcohols on the gelatinization temperature of wheat starch. Food Hydrocoll. 84, 593–607 (2018).

Woodbury, T. J. & Mauer, L. J. Oligosaccharides elevate the gelatinization temperature of wheat starch more than sucrose, paving the way for their use in reduced sugar starch-based formulations. Food Funct. 13, 10248–10264 (2022).

van der Sman, R. G. M. & Mauer, L. J. Starch gelatinization temperature in sugar and polyol solutions explained by hydrogen bond density. Food Hydrocoll. 94, 371–380 (2019).

Renzetti, S., van den Hoek, I. A. F. & van der Sman, R. G. M. Amino acids, polyols and soluble fibres as sugar replacers in bakery applications: Egg white proteins denaturation controlled by hydrogen bond density of solutions. Food Hydrocoll. 108, 106034 (2020).

Renzetti, S., van den Hoek, I. A. F. & van der Sman, R. G. M. Mechanisms controlling wheat starch gelatinization and pasting behaviour in presence of sugars and sugar replacers: Role of hydrogen bonding and plasticizer molar volume. Food Hydrocoll. 119, 106880 (2021).

van der Sman, R. G. M. & Renzetti, S. Understanding functionality of sucrose in cake for reformulation purposes. Crit. Rev. Food Sci. Nutr. 61, 2756–2772 (2021).

Zghal, M. C., Scanlon, M. G. & Sapirstein, H. D. Cellular structure of bread crumb and its influence on mechanical properties. J. Cereal Sci. 36, 167–176 (2002).

Bosmans, G. M., Lagrain, B., Ooms, N., Fierens, E. & Delcour, J. A. Biopolymer interactions, water dynamics, and bread crumb firming. J. Agric. Food Chem. 61, 4646–4654 (2013).

Gunaratne, A., Ranaweera, S. & Corke, H. Thermal, pasting, and gelling properties of wheat and potato starches in the presence of sucrose, glucose, glycerol, and hydroxypropyl β-cyclodextrin. Carbohydr. Polym. 70, 112–122 (2007).

Allan, M. C., Chamberlain, M. & Mauer, L. J. Effects of sugars and sugar alcohols on the gelatinization temperatures of wheat, potato, and corn starches. Foods 9, 1–23 (2020).

Heidolph, B. B. Designing chemical leavening systems. Cereal Foods World 41, 118–126 (1996).

Wilderjans, E., Pareyt, B., Goesaert, H., Brijs, K. & Delcour, J. A. The role of gluten in a pound cake system: A model approach based on gluten-starch blends. Food Chem. 110, 909–915 (2008).

Provencher, S. W. Contin: A general purpose constrainded regularization program for inverting noisy linear algebraic and integral equations. Comput. Phys. Commun. 27, 229–242 (1982).

van der Sman, R. G. M., Jurgens, A., Smith, A. & Renzetti, S. Universal strategy for sugar replacement in foods? Food Hydrocoll. 133, 107966 (2022).

Deleu, L. J. et al. Ohmic versus conventional heating for studying molecular changes during pound cake baking. J. Cereal Sci. 89, 102708 (2019).

Luyts, A. et al. Relative importance of moisture migration and amylopectin retrogradation for pound cake crumb firming. Food Chem. 141, 3960–3966 (2013).

Acknowledgements

The authors acknowledge Ian Van Meel for excellent technical assistance. Bram Pareyt is thanked for helpful discussions. K.B. acknowledges the Industrial Research Fund of KU Leuven for his position as innovation manager.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study design and the discussion and interpretation of the results. The data was collected by T.G. and I.M.R. The manuscript was drafted by T.G. in close collaboration with I.M.R., N.O., K.B., and J.A.D.

Corresponding author

Ethics declarations

Competing interests

The authors declare no Competing Non-Financial Interests but the following Competing Financial Interests: Author G.M.B. works for Puratos, a multinational company active in the area of health and well-being (www.puratos.com).

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Godefroidt, T., Riley, I.M., Ooms, N. et al. Sucrose substitution in cake systems is not a piece of cake. npj Sci Food 7, 52 (2023). https://doi.org/10.1038/s41538-023-00225-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41538-023-00225-y