Abstract

This study investigates the application of plasma treatment as a means to enhance biodegradation and modify the structural characteristics of fibrous composites. The methodological component of the study includes the selection of the research object; production of composites; low-temperature plasma treatment, and treatment of biodegradability and mechanical strength of samples. The strengthening of fibers with cellulose leads to a significant improvement in mechanical strength. Such an indicator as mechanical strength increases from 18 to 21 MPa. Treatment of natural fibers with low-temperature plasma led to an increase in mechanical strength from 18 to 25 MPa. Treating reinforced fibers with low-temperature plasma currently results in an even greater enhancement in mechanical strength, increasing from 18 to 29 MPa.The electron microscopy of samples reveals some differences in cell wall microfibrils between plasma-treated and non-treated samples. The non-treated fibres are found to have chips and voids. Meantime, the plasma-treated fibres show structural changes in certain regions which resemble wood charring. Through a comprehensive analysis, this research underscores the substantial impact of plasma treatment on the degradation kinetics and morphological features of cellulose-based composites. The results reveal distinct alterations in the composition and behavior of plasma-treated fibres, signifying a shift towards enhanced biodegradability. The natural fibres examined in this study contained 28–30% lignin, whereas the composites exhibited a lower lignin content of 21–23%. These findings corroborate the inference that plasma treatment induces significant changes in fibre structure, accelerating the biodegradation process by 7 days.

Similar content being viewed by others

Introduction

The lightweight materials industry is a strategically important sector of the economy in many countries. Due to the growing population, the demand for clothing, footwear, and other textile products increases each year. At the same time, lightweight materials industry products must meet strict requirements related to hygiene, durability, and performance properties such as adhesion, water resistance, and so forth. Compliance and product quality largely depend on the methods and technologies used to manufacture and process natural and synthetic materials1,2.

The textile industry makes use of both natural and synthetic materials. Man-made fibers are used to create non-woven and artificial materials or impart specific properties to those materials. Synthetic fibers are superior to some products and inferior to others; hence, the choice of synthetics may be justified. However, polymeric materials do not decompose easily, and represent a serious threat to the environment in countries with intense production. According to recent reports, nearly 30% of polymer waste is subjected to incineration, some 30% is recycled, and the remaining 30% is left undisposed3,4,5.

Scholars are actively engaged in the advancement of synthetic polymers designed for degradation by bacteria and other microorganisms within the natural ecological milieu6,7,8. These polymers can be useful in many industries, including packaging, the textile industry, medical equipment, the automotive industry, and so forth9,10,11,12. Recent studies have also investigated the use of plasma for processing synthetic polymers to increase their biodegradation. Plasma treatment can change the surface structure of the polymer, thereby providing a more efficient decomposition of the synthetic material by biological processes13,14,15.

The study of biodegradation of synthetic polymers exhibits certain gaps. Unexplored areas encompass the pathways of biodegradation for various polymer types, factors influencing biodegradation, resultant products, and biodegradation methods16. Some researchers posit that successful biodegradation of the synthetic component within a natural-synthetic blend occurs when the natural polymer is chemically attached (grafted) to the synthetic polymer. Bacterial activity initiates the degradation of the natural polymer chain, which subsequently extends into the synthetic segment17,18,19.

The work20 uses epoxy as a matrix material, and polymer composites with reinforcement from untreated and alkali-treated Zanthoxylum acanthopodium bark fibers (5–25 wt.%). Hand lay-up was used in the development of the epoxy composites. The mechanical characteristics and water absorption rates of the produced epoxy composites were evaluated following ASTM standards. Epoxy composites containing 20 wt.% of alkali-treated Zanthoxylum acanthopodium bark fibers had excellent mechanical qualities, including an ultimate tensile strength of 47.3 MPa, according to the test findings. However, there was a positive correlation between fiber loading and water absorption. The fiber bonding and void characteristics of the analyzed composites were observed using a scanning electron microscope.

In the work21, Vachellia farnesiana fibers were selected and extracted by the manual retting process. The obtained Vachellia farnesiana fibers were chemically treated with hydrochloric acid (HCl) and sodium hydroxide (NaOH) solutions. The chemically treated and untreated Vachellia farnesiana fibers were characterized for physical, chemical, tensile, morphological, and thermal properties. Test results showed that the cellulose content was 47.8 ± 0.697 wt % for NaOH-treated Vachellia farnesiana fibers with reduced moisture and amorphous contents. HCl-treated Vachellia farnesiana fiber showed more cellulose content removal, which resulted in the degradation of its properties due to the acidic nature of HCl.

Plasma treatment is recognized as a dry and clean process. The utilization of low-pressure cold plasma for the pre-treatment of natural fibers is becoming increasingly prevalent as a method for surface modification22. This approach offers advantages compared to traditional chemical treatment, as it does not require water or chemicals, rendering it environmentally friendly and cost-effective. Plasma modification substantially reduces the number of chemical pollutants. It etches the fiber surface, enhancing the action of the binding agent for improved adhesion23. It can also render the surface rough through material ablation, enhancing adhesion. Moreover, it introduces free radicals and can alter the chemical structure. Low-pressure cold plasma modifies the fiber surface without changing the material volume. Additionally, it eliminates the need for chemical solvents and reduces process time24.

Existing studies lack a comprehensive examination of the biodegradability of plasma-modified fibers. This article investigates the influence of low-temperature plasma treatment on the biodegradation of cellulose and its composite. The results provide insights into assessing the biodegradability of other materials. The study underscores the potential of plasma treatment in enhancing the quality of natural and synthetic fibers. Low-temperature plasma treatment of cellulose-based materials is employed for this purpose.

Most studies note that low-temperature plasma treatment is a progressive and rather effective method since it can change the chemical composition of the fiber surface and the physical structure of molecules while maintaining the bulk material properties. Utilizing low-temperature and low-pressure plasma treatment demands a lesser amount of gasoline when contrasted with alternative techniques, leading to a near-total mitigation of waste generation. However, there are limited data on the biodegradability of plasma-treated fibers. The empirical evidence that fiber materials can partially or completely decompose after plasma treatment and that it affects the rate of biodegradation can serve as justification for the use of plasma treatment with a wider range of natural and synthetic fibers.

This study aims to measure the biodegradability of plasma-treated wood fiber-reinforced polypropylene composites to determine whether plasma modification alters the rate of biodegradation. The secondary objectives of the study are (1) to examine the low molecular weight components of wood fiber-reinforced polypropylene composites during biodegradation, and (2) to explore the composition and properties of substances isolated from the plasma-treated samples. Finally, the study attempts to experimentally substantiate the mechanism behind the plasma-induced decomposition of cellulose.

Results and discussion

Mechanical strength of fibers

The results of determining the mechanical strength of the obtained fibers are given in Table 1.

Analyzing the data presented, we can conclude that strengthening fibers with cellulose leads to a significant improvement in mechanical strength. In particular, such an indicator as mechanical strength increased from 18 to 21 MPa, or by 16.7%. Treatment of natural fibers with low-temperature plasma led to an increase in mechanical strength from 18 to 25 MPa, or by 33.3%. Treatment of reinforced fibers with low-temperature plasma led to an even greater increase in mechanical strength, from 18 to 29 MPa or by 50%.

The electron microscopy of cellulose samples revealed some differences in cell wall microfibrils between plasma-treated and non-treated samples (Fig. 1). The non-treated fibers were found to have chips and voids. Meantime, the plasma-treated fibers show structural changes in certain regions that resemble wood charring.

Interestingly, following plasma treatment, certain segments of the cellulose fiber exhibited a hollowed morphology. In contrast, the control sample displayed increased fragility due to the presence of voids and ruptures in the cell walls. This implies that plasma treatment influenced the microfibril structure of cellulose. Typically, reinforcing elements of microfibrils were diminished as a result of plasma treatment, enhancing flexibility and disrupting structural integrity.

When investigating the composite of polypropylene fibers reinforced with cellulose (Fig. 2), a distinct behavior was observed following plasma treatment. The fibers of the treated composite exhibited fewer visible defects and were predominantly embedded within the polypropylene matrix. Importantly, no slip lines or voids were evident on the fracture surface. Instead, the images displayed polymer adhesion to the fibers at multiple points, indicating a noteworthy transformation of material composition and interactions.

High interfacial shear strength and, consequently, a stronger interaction between fibers and matrices can significantly decelerate the biodegradation of composite materials. Plasma changes the structure of cellulose, with the latter completely dissolved in a solution of sodium hydroxide and simply in water. Low molecular weight components occur during depolymerization. Nearly 50 products were generated through the plasma-chemical decomposition of fibers; some (19%) are listed in Table 2. By comparing the quantitative composition of components in the table, significant differences between the degradation products of plasma-treated and untreated fibers can be identified. Specifically, several compounds exhibit changes in molecular mass and percentage yield as a result of plasma treatment. For instance, compounds such as C6H10O5, 3-deoxyglucofuranose, and C6H6O3 display altered molecular masses and percentage yields following plasma treatment, indicating the influence of plasma on the degradation process. These variations underscore that plasma treatment affects the molecular structure, which, in turn, may impact the biodegradation of composites.

The yield of levoglucosan (C6H10O5) was 7.92%, suggesting the achievement of stability after plasma treatment. A rather large amount (10.1%) of 3-dioxyglucosenone is released with a molecular weight of 144 g·mol−1 during cellulose dehydration. The concentration of methyl maltol is lower (6.12%) but its molar mass is almost the same as that of 3-dioxyglucosenone. Two substances with the same molar mass of 126 g·mol−1, pyrogallol and anhydrosucrose, account for 4.56 and 20.1% of the yield, respectively. A furan aldehyde called furforol (C5H6O2) is released in the amount of 5.11%; part of furfural can be released with the participation of xylane. All molecules with a mass below 90 Da are marked as decay products of O2 and CO2.

Plasma does not affect sulfate lignin. The plasma-treated natural fibers were 21% lignin, whereas the composites had a lignin content of 18%. The study results show that the dehydration and decomposition velocities of non-composites are almost 2 times lower as compared to composites. In natural conditions, lignin is strongly influenced by filamentous fungi, which have the power to cause the degradation of complex polymers by enzymes; in these conditions, materials decompose faster.

Judging by data concerning the degradation products of plasma-treated fibers, the chemical processes associated with the biodegradation of natural cellulose are similar to those occurring in untreated samples. The structural changes to microfibrils, however, caused the biodegradation time of plasma-treated cellulose to accelerate.

In the case of plasma-treated specimens, biodegradation commenced on the 12th day of the experiment, while for untreated specimens, it occurred a week later, specifically after 19 days. The buried plasma-treated material changed and became brittle and thinner than the control. At the end of the 30-day biodegradation test, prominent changes were detected in the samples.

The biodegradation of natural fiber-reinforced composites can occur through a variety of mechanisms; the choice depends on the type of natural filler used, its quality, and its chemical composition. The plasma-treated cellulose-reinforced polypropylene composites exhibit clear signs of decomposition. This finding coincides with previous research. It also suggests that plasma-treated fiber materials can decompose, partially or completely, and that plasma treatment can alter the rate of biodegradation.

Plasma modification of the fiber surface is one of the most elaborated methods for improving the quality characteristics of materials. Plasma treatment can affect the surface properties of materials, such as the ability to bond dissimilar fibers. The adhesion of materials is often used to metalize, paint, or glue surfaces to obtain composites. This method also makes it possible to develop a range of properties less typical for unprocessed natural fabrics, such as hydrophilicity, dirt and dust repellency, antistatic properties, and so forth. In addition, plasma removes fat and other organics from fur and wool. It improves the absorption of dye pigments25,26.

The essence of the plasma treatment method is to treat a material with a plasma medium (ionized gas) at low or atmospheric pressure. This causes surface reactions and modifications up to a change in the functional groups of molecules and a change in surface energy. Plasma is an ionized gas, in which free electrons and ions coexist. Plasma is produced by heating a gas to extremely high temperatures or by subjecting it to strong electromagnetic fields. Both of these processes may result in the release of electrons from atoms and molecules. The electrons have enough kinetic energy to remove additional electrons in case of a collision with other molecules27. These collisions induce cascade ionization. A release of ions and electrons occurs, balanced by the recombination of material molecules until plasma reaches equilibrium.

The results obtained by Hamad28 show that plasma treatment of keratin-containing materials, such as wool and fur, at reduced pressure, opens the fiber cuticle, caused by the mutual repulsion of multiple charged jets. This allows the effective removal of organic compounds from the Merino wool fibers, without changing the fiber structure and physical properties29,30. Zille31 evaluated the effects of plasma surface treatment of flax, cotton, and animal-based fibers (wool, pile) on the tensile load resistance. Plasma treatment activates the surface of various synthetic materials, such as ultra-high modulus polyethylene, thereby improving their ability to absorb or completely repel moisture. This occurs due to the increase in surface tension of the fibers immersed in various gaseous media13,15,17.

It is worth mentioning that some scientists31,32,33,34 agree that plasma treatment reduces the total energy consumption associated with the production of synthetic fibers by 25% as compared to other treatment methods. Research demonstrates that the modification of natural fibers requires 14–50% less energy than the production of synthetic fibers. The real value in this broad range depends on a myriad of plant growth factors and plasma processing parameters.

This study aligns with previous research emphasizing the significance of incorporating environmentally degradable components into composite materials35. Earlier investigations examined fiber degradation alongside polylactic acid and clay silicates, revealing that the quantity and nature of natural constituents influence composite biodegradation35. Correspondingly, analogous burial-based studies36,37,38 echo our findings, showcasing the accelerated degradation of triple compositions compared to double ones due to increased biodegradable content. Moreover, experts in plasma treatment advocate its efficacy in preserving textile properties and enhancing mechanical attributes of biodegradable composites, considering it more sustainable than chemical methods39,40,41,42,43.

The choice between plasma and chemical treatment hinges on material requisites41,42,43. Plasma treatment surpasses chemical counterparts in efficacy, transforming material surfaces, enhancing adhesion, and durability44,45,46. This approach is particularly useful for biodegrading recalcitrant materials by promoting microbial interaction47,48,49. Similarly, studies focusing on fiber-modified bioplastics suggest enhanced fiber-matrix adhesion41,42. Cold plasma emerges as an efficient, eco-friendly alternative40,41,42,43, fostering sustainable composite markets.

This holistic exploration of plasma-treated materials showcases their potential in renewable and biodegradable materials research47,50,51. Industrial use of plasma-modified materials necessitates eco-conscious biodegradability. Consequently, leveraging natural fibers for polymer matrix composites aligns with environmental awareness and promotes renewable resources35,52,53. Such studies aid in curbing waste and toxic releases, ensuring safer decompositions and material cycles. This research contributes to reducing environmental impact while bolstering sustainable material applications.

The study utilized scanning electron microscopy (SEM) to show that plasma treatment significantly affects both the biodegradation process and the material’s structure. SEM enabled a comprehensive examination of the process phases, particularly focusing on the interaction between electrons and the specimen. The study’s methodology involved selecting the research subject, creating composites, applying low-temperature plasma treatment, and assessing the biodegradability and mechanical strength of the samples. The addition of cellulose fibers leads to a significant improvement in mechanical strength. More precisely, the measure of mechanical strength increased from 18 to 21 MPa, indicating a growth of 16.7%. The utilization of low-temperature plasma on natural fibers led to a significant 33.3% improvement in mechanical strength, elevating it from 18 to 25 MPa. The mechanical strength of reinforced fibers was significantly enhanced with low-temperature plasma treatment, resulting in a rise from 18 to 29 MPa, or a 50% improvement. The electron microscopy study revealed notable differences in cell wall microfibrils between the samples that underwent plasma treatment and those that did not. Unprocessed fibers exhibited the presence of chips and cavities. Concurrently, the fibers that have been subjected to plasma treatment display distinct changes in their structure in certain regions, like the charring process observed in wood. The cellulose cell walls of both treated and untreated samples exhibited disparities in the microfibrils, including alterations in structure after plasma treatment. In addition, changes were noted in composites composed of polypropylene fiber and cellulose. The fibers that received plasma treatment exhibited enhanced integration, as shown by the absence of slip lines on the fracture surface. The quantitative measurement table of biodegradation products reveals significant differences in composition between the treated and untreated fibers. These alterations illustrate the influence of plasma on chemical processes and biodegradation. Plasma treatment can accelerate the biodegradation process and modify the characteristics of materials. This can generate composites that possess enhanced durability and resilience, a crucial factor in the manufacturing of ecologically friendly products and the effective utilization of waste.

Methods

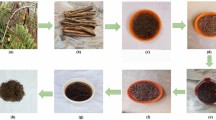

The flowchart of the experimental part is shown in Fig. 3.

The production of wood fiber-reinforced polypropylene composites

This study addresses natural fibers of the finest coniferous wood species and cellulose-containing materials as experimental objects. Those were unbleached softwood sulfate pulp and softwood sulfate lignin. The sample of natural wood fibers was analyzed using a scanning electron microscope. The SEM analysis method included the following steps: sample preparation, sample loading, vacuum chamber, and electron beam directed at the sample. The latter interacted with the sample, causing electron emission from the sample surface. Electron detection: a detector located in the SEM chamber identified electrons emitted by the sample. These signals were then processed and used to create an image of the sample’s surface topography and morphology.

The results demonstrated that the average length of wood fibers was 190 µm (range, 100–400 µm; standard deviation: 63 µm) and that the average width was 50 µm (range, 20–100 µm; standard deviation: 19 µm).

Table 3 shows the approximate composition of fiber samples54.

The production of polypropylene/cellulose composites requires using a solid-state shear pulverization. The sheared polymer method helped to reduce the particle size of cellulose materials. The cellulose fibers were mixed with a polypropylene matrix in a plastic mixer (Haake Rheocord 9000, Germany) with a rotor velocity of 60 rpm at 185 °C for 8 min. The resulting blend underwent compression molding at 185 °C at a pressure of 10 MPa for 15 min. Before being used, the samples rested at room temperature for 5 days.

Figure 4 shows the scheme of the reactor.

The plasma reactor consists of a solenoid or radio-frequency induction coil (A) wound around a borosilicate glass tube (B). There will be a supply of gas (C) in the vacuum, and a vacuum pump valve (D) will keep the gas inside. The induction coil is to store energy within a magnetic field, which is numerically equal to that produced by the source to induce a current in the winding, generating a magnetic field of the solenoid. Inside the external glass tube, there is a partially open glass tube (E). It contains fibers that a stepper motor rotates (F) throughout the entire plasma treatment process.

Low-pressure and low-power plasma does not cause excessive surface heating, and the glass tube is warm to the touch. Therefore, there is no excessive thermal exposure, thermal degradation of the fibers, or their incineration to be expected.

The parameters of low-temperature plasma are as follows: I = 4.8–5.2 mA; U = 25–28 kW; gas medium: sulfur hexafluoride (SF6); additional medium – water (Н2О); exposure time = 10−30 min; Р = 102 Pa.

The plasma treatment procedure is described below

1) The glass tube and the sample holder are cleaned with an air gun and disinfected with isopropyl alcohol to eliminate any contamination of the vacuum and plasma. All individuals involved in the experiment are required to wear nitrile gloves to prevent contamination.

2) A 5-g sample of investigated fibers is weighed and placed on the sample holder (internal glass tube (E) as shown in Fig. 2). The tube is inserted into the reactor and attached to the axis of the stepper motor for further rotation of the sample.

3) Once the reactor is closed, the air is evacuated by a vacuum pump. The pump must be connected to the reactor through a chamber equipped with a diaphragm valve. The latter opens slowly at the evacuation starts to prevent fibers from being absorbed in.

4) As soon as the pressure falls below 10 Pa (10−1 mbar), the stepper motor rotates, causing the sample holder to rotate and the fibers to mix. A short-term increase in pressure occurs due to the release of accumulated gas.

5) The selected process gas (partially or fully ionized; without signs of being polymerized) is introduced into the chamber using a needle valve or mass flow controller. During pumping, the pressure increases to almost 102 Pa (1 mbar) for 2 min, and then the gas supply is over. The procedure is repeated after 2–5 min of further pumping. This ensures a faster decrease in pressure as moisture transport occurs and guarantees enough gas in the tube.

6) Finally, the system is pumped down to an atmospheric pressure of about 10−1 Pa (10−3 mbar). Because fluorocarbon bonds are sensitive to X-ray, the following sequence was followed: initial phase: 250–350 eV; final phase: 0-1,150 eV; high-resolution oxygen spectrum, binding energy: 526–540 eV.

The equipment used here includes a gas chromatograph СhroZen UHPLC, a gas chromatograph-mass spectrometer GCMSQP2010 Plus, a thermal desorber TD-20, an ATR-8200HA attachment (Pike Tech), a scanning electron microscope (SEM) Sigma VP ZEISS, and a probe microscope MultiMode 8. The chemical analysis was compliant with GOST55. Results were analyzed by gas chromatography using gas chromatograph Agilent 7820.

Mechanical testing

Tensile testing (ISO 527) was carried out using a universal testing machine (UTM) with a gauge length of 6 cm and a speed of 5 mm/min. All the mechanical results were obtained with an average of 10 samples.

Biodegradability testing

The biodegradability test assessed the resulting cellulose composite’s ability to decompose under the influence of microorganisms within certain environmental conditions. The samples were buried in the soil for 30 days. This method is widely used for assessing the ability to decompose since it provides a simulated environment similar to natural decomposition.

During testing, the samples were buried to a depth of 10–15 cm and covered with soil. The monitoring of soil humidity and temperature ensured that they remained within a certain range for microbial activity (25–75% and 15–25 °C, respectively). After 30 days, samples were excavated from the soil and analyzed for the presence and amount of material residues. The degradation degree was then identified by measuring mass loss.

Statistics analysis

Statistical analysis was performed using a One-way Analysis of Variance, with significance reported at p ≤ 0.05. All findings were presented as means ± standard deviations of at least five experiments.

Data availability

All materials were developed by the authors. All data are presented in the article.

References

Ameer, M. H. et al. Interdependence of moisture, mechanical properties, and hydrophobic treatment of jute fibre-reinforced composite materials. J. Text. Inst. 108, 1768–1776 (2017).

Nawab, Y. et al. Development & characterization of green composites using nNovel 3D woven preforms. Appl. Compos. Mater. 25, 747–759 (2018).

Cordeiro, R. C. Plasma Treatment of Natural Fibers to Improve Fiber-matrix Compatibility (UFRJ/COPPE, 2016).

Ershov, I. P., Sergeeva, E. A., Zenitova, L. A. & Abdullin, I. S. Modification of synthetic fibers and threads. Overview. Bull. Kazan. Technol. Univ. 15, 136–143 (2012).

Islam, M. D., Mohammad Ziaul Hyder, M. K., Masudur Rhaman, M. & Mir, S. H. Application of Lignin-Based Biomaterials in Textile Wastewater. In Textile Wastewater Treatment. Sustainable Textiles: Production, Processing, Manufacturing & Chemistry. 75–99 (Springer, 2022).

Miroshnichenko, D. et al. Study of hybrid modification with humic acids of environmentally safe biodegradable hydrogel films based on hydroxypropyl methylcellulose. C 8, 71 (2022).

Lebedev, V., Miroshnichenko, D., Bilets, D. & Mysiak, V. Investigation of hybrid modification of eco-friendly polymers by humic substances. Solid State Phenom. 334, 154–161 (2022).

Meydanju, N., Pirsa, S. & Farzi, J. Biodegradable film based on lemon peel powder containing xanthan gum and TiO2-Ag nanoparticles: Investigation on physiochemical and antibacterial properties. Polym. Test. 106, 107445 (2022).

Karimi Sani, I. et al. Value-added utilization of fruit and vegetable processing by-products for the manufacture of biodegradable food packaging films. Food Chem. 405, 134964 (2023).

Pirsa, S. & Asadi, S. Innovative smart and biodegradable packaging for margarine based on a nano composite polyactic acid/lycopene film. Food Addit. Contam. Part A 38, 856–869 (2021).

Pirsa, S. & Hafezi, K. Hydrocolloids: Structure, preparation method, and application in food industry. Food Chem. 399, 133967 (2023).

Pirsa, S. Nanocomposite base on carboxymethylcellulose hydrogel: Simultaneous absorbent of ethylene and humidity to increase the shelf life of banana fruit. Int. J. Biol. Macromolecules 193, 300–310 (2021).

Pirsa, S. & Mohammadi, B. Conducting/biodegradable chitosan-polyaniline film; Antioxidant, color, solubility and water vapor permeability properties. Main. Group Chem. 20, 133–147 (2021).

Hosseini, N., Pirsa, S. & Farzia, J. Biodegradable nano composite film based on modified starch-albumin/MgO; antibacterial, antioxidant and structural properties. Polym. Test. 97, 107182 (2021).

Yorghanlu, R., Hemmati, Н, Pirsa, S. & Makhani, A. Production of biodegradable sodium caseinate film containing titanium oxide nanoparticles and grape seed essence and investigation of physicochemical properties. Polym. Bull. 79, 8217–8240 (2022).

Shaker, K., Nawab, Y. & Jabbar, M. Bio-Composites: Eco-Friendly Substitute of Glass Fibre Composites. In Handbook of Nanomaterials and Nanocomposites for Energy and Environmental Applications. 1–25 (Springer, 2020).

Jabraili, А, Pirsa, S., Pirouzifard, M. K. & Amiri, S. Biodegradable nanocomposite film based on gluten/silica/calcium chloride: Physicochemical properties and bioactive compounds extraction capacity. J. Polym. Environ. 29, 2557–2571 (2021).

Tian, K. & Bilal, M. Research Progress of Biodegradable Materials in Reducing Environmental Pollution. In Abatement of Environmental Pollutants. 313–330 (Elsevier, 2020).

Kalimullina, G. R., Kulevtsov, G. N. & Mingaliev, R. R. Influence of plasma modification on the creation of a hydrophobic surface of the skin. Bull. Kazan. Technol. Univ. 14, 48–50 (2012).

Raghunathan, V. et al. Influence of alkali-treated and raw Zanthoxylum acanthopodium fibres on the mechanical, water resistance, and morphological behavior of polymeric composites for lightweight applications. In Biomass Conversion and Biorefinery (Springer Nature, 2023).

Raghunathan, V. et al. Influence of chemical treatment on the physico-mechanical characteristics of natural fibres extracted from the barks of vachellia farnesiana. J. Nat. Fibers 19, 5065–5075 (2022).

Armandei, M., Darwish, I. F. & Ghavami, K. Experimental study on variation of mechanical properties of a cantilever beam of bamboo. Constr. Build. Mater. 101, 784–790 (2015).

Zhang, H., Ma, D., Qiu, R., Tang, Y. & Du, C. Non-thermal plasma technology for organic contaminated soil remediation: A review. Chem. Eng. J. 313, 157–170 (2017).

Zanini, S., Grimoldi, E., Citterio, A. & Riccardi, C. Characterization of atmospheric pressure plasma treated pure cashmere and wool/cashmere textiles: Treatment in air/water vapor mixture. Appl. Surf. Sci. 349, 235–240 (2015).

Peran, J. & Ražić, S. E. Application of atmospheric pressure plasma technology for textile surface modification. Text. Res. J. 90, 1174–1197 (2020).

Ngo, H.-T., Vu Thi Hong, K. & Nguyen, T.-B. Surface modification by the DBD plasma to improve the flame-retardant treatment for dyed polyester fabric. Polymers 13, 3011 (2021).

Von Keudell, A. & Schulz-Von Der Gathen, V. Foundations of low-temperature plasma physics—An introduction. Plasma Sources Sci. Technol. 26, 113001 (2017).

Hamad, S. F. Nanoscale Surface Modification of Ramie Fibres by Plasma Treatment for Polymer Composite Applications (Univ. Sheffield, 2019).

Aghbolagh, K. & Pirsa, S. Biodegradable film of black mulberry pulp pectin/chlorophyll of black mulberry leaf encapsulated with carboxymethylcellulose/silica nanoparticles: Investigation of physicochemical and antimicrobial properties. Mater. Chem. Phys. 267, 124580 (2021).

Zille, A. Plasma Technology in Fashion and Textiles. In Sustainable Technologies for Fashion and Textiles. 117–142 (Woodhead Publishing, 2020).

Hamad, S. F., Stehling, N., Hayes, S. A., Foreman, J. P. & Rodenburg, C. Exploiting plasma exposed, natural surface nanostructures in ramie fibers for polymer composite applications. Materials 12, 1631 (2019).

Zhang, C., Zhao, M., Wang, L., Qu, L. & Men, Y. Surface modification of polyester fabrics by atmospheric-pressure air/He plasma for color strength and adhesion enhancement. Appl. Surf. Sci. 400, 304–311 (2017).

Abdullin, I. S. et al. Gas-discharge modification of textiles, threads and fabrics. Bull. Kazan. Stat. Univ. Archit. Civ. Eng. 4, 238–240 (2011).

Nguyen Thi, H., Vu Thi Hong, K., Ngo Ha, T. & Phan, D. N. Application of plasma activation in flame-retardant treatment for cotton fabric. Polymers 12, 1575 (2020).

Kundu, C. K., Li, Z., Song, L. & Hu, Y. An overview of fire retardant treatments for synthetic textiles: From traditional approaches to recent applications. Eur. Polym. J. 137, 109911 (2020).

Cools, P., Morent, R. & De Geyter, N. Plasma Modified Textiles for Biomedical Applications. In Advances in Bioengineering. 1–10 (InTechOpen, 2014).

Jelil, R. A. A review of low-temperature plasma treatment of textile materials. J. Mater. Sci. 50, 5913–5943 (2015).

Gibeop, N. et al. Effect of plasma treatment on mechanical properties of jute fiber/poly (lactic acid) biodegradable composites. Adv. Compost. Mater. 22, 389–399 (2013).

Girijappa, Y. T., Rangappa, S. M. & Siengchin, S. Natural fibers as sustainable and renewable resource for development of eco-friendly composites: A comprehensive review. Front. Mater. 6, 226 (2019).

Vinod, A. et al. Characterization of untreated and alkali treated natural fibers extracted from the stem of Catharanthus roseus. Mater. Res. Express 6, 085406 (2019).

Lahouioui, M., Ben Arfi, R., Fois, M., Ibos, L. & Ghorbal, A. Investigation of fiber surface treatment effect on thermal, mechanical and acoustical properties of date palm fiber-reinforced cementitious composites. Waste Biomass. Valoriz. 11, 4441–4455 (2020).

Sair, S., Mansouri, S., Tanane, O., Abboud, Y. & El Bouari, A. Alfa fiber-polyurethane composite as a thermal and acoustic insulation material for building applications. SN Appl. Sci. 1, 667 (2019).

Sumesh, K. R., Kanthavel, K. & Kavimani, V. Peanut oil cake-derived cellulose fiber: extraction, application of mechanical and thermal properties in pineapple/flax natural fiber composites. Int. J. Biol. Macromol. 150, 775–785 (2020).

Vijay, R. et al. Characterization of raw and alkali treated new natural cellulosic fibers from Tridax procumbens. Int. J. Biol. Macromol. 125, 99–108 (2019).

Ganapathy, T., Sathiskumar, R., Senthamaraikannan, P., Saravanakumar, S. S. & Khan, A. Characterization of raw and alkali treated new natural cellulosic fibres extracted from the aerial roots of banyan tree. Int. J. Biol. Macromol. 138, 573–581 (2019).

Valášek, P., Müller, M. & Šleger, V. Influence of plasma treatment on mechanical properties of cellulose-based fibres and their interfacial interaction in composite systems. BioResources 12, 5449–5461 (2017).

Ojha, A. R. & Biswal, S. K. Thermo physico-mechanical behavior of palm stalk fiber reinforced epoxy composites filled with granite powder. Compos. Commun. 16, 158–161 (2019).

Krishnan, T., Jayabal, S. & Krishna, V. N. Tensile, flexural, impact, and hardness properties of alkaline-treated Sunnhemp fiber reinforced polyester composites. J. Nat. Fibers 17, 326–336 (2020).

Mohana Krishnudu, D., Sreeramulu, D. & Reddy, P. V. Alkali treatment effect: mechanical, thermal, morphological, and spectroscopy studies on Abutilon indicum fiberreinforced composites. J. Nat. Fibers 17, 1775–1784 (2020).

Premnath, A. A. Impact of surface treatment on the mechanical properties of sisal and jute reinforced with epoxy resin natural fiber hybrid composites. J. Nat. Fibers 16, 718–728 (2019).

Saba, N., Alothman, O. Y., Almutairi, Z. & Jawaid, M. Magnesium hydroxide reinforced kenaf fibers/epoxy hybrid composites: mechanical and thermomechanical properties. Constr. Build. Mater. 201, 138–148 (2019).

Artamonov, V., Vorona-Slivinskaya, L. & Medvedeva, A. The algorithm of sustainable development of organizations: A social aspect. Procedia Eng. 165, 1192–1196 (2016).

Voskresenskaya, E., Vorona-Slivinskaya, L. & Achba, L. Digital economy: Theoretical and legal enforcement issues in terms of regional aspect. E3S Web Conf. 164, 09016 (2020).

Elfaleh, I. et al. A comprehensive review of natural fibers and their composites: An eco-friendly alternative to conventional materials. Results Eng. 19, 101271 (2023).

Electronic fund legal and regulatory technical documents. GOST No. 26996-86 https://docs.cntd.ru/document/1200020703 (1988).

Author information

Authors and Affiliations

Contributions

Marzhan Nyssanbek – Conceptualization, Methodology, Validation; Natalya Kuzina –Investigation, Project Administration, Software, Supervision; Valery Kondrashchenko – Formal Analysis, Data Curation, Resources, Writing – Review & Editing; Abdugani Azimov –Funding Acquisition, Resources, Visualization, Writing – Original Draft Preparation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Nyssanbek, M., Kuzina, N., Kondrashchenko, V. et al. Effects of plasma treatment on biodegradation of natural and synthetic fibers. npj Mater Degrad 8, 23 (2024). https://doi.org/10.1038/s41529-024-00437-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41529-024-00437-x