Abstract

Polypropylene (PP) has raised severe environmental issues concerning its non-degradability, with a current recycling rate of only 1%. This current study utilises Aspergillus terreus ATCC 20542 and Engyodontium album BRIP 61534a to break down PP while focusing on pre-treatment. Polypropylene granule (GPP), film (FPP) and metallised film (MFPP) are pre-treated by either UV, heat, or Fenton’s reagent. UV and heat-treated MFPP by A. terreus exhibits notable weight loss percentage (25.29% and 22.13%, respectively). Biomass production, reduction rate, Fourier transform infrared (FTIR), and scanning electron microscopy (SEM) analyses further validate the degradation rate. A. terreus incubated with UV-treated MFPP produced a relatively high biomass yield of 1.07 mg/ml. Reduction in carbonyl index and surface morphological changes reveal consistent biodeterioration evidence. This investigation demonstrates that A. terreus and E. album can grow on, change, and utilise PP as a carbon source with pre-treatments’ aid, promoting the biological pathways for plastic waste treatment.

Similar content being viewed by others

Introduction

Increasing plastic production is causing accelerated environmental pollution. With some exceptions, such as polyurethanes, most plastics are very stable and are not readily degraded when they enter the ground as waste. They take decades to biodegrade and therefore are significant pollutants of terrestrial and marine ecosystems1. In 2015, the world produced 68 million tonnes of PP2. Based on this overwhelming number, only 1% of PP was recycled3. As they are assumed to be recalcitrant4, it is essential to discover ways to degrade these difficult to recycle compounds, including understanding the optimal environmental conditions and the possible biological mechanisms involved in their deterioration and degradation5. Here, PP materials employed were in the form of granule (isotactic), film (biaxially oriented) and metallised film (aluminium-coated surface). We select these materials based on their applications and structural variability. Isotactic PP granule is the raw material for automotive, housewares, general moulding products and multi- and monofilament fibre6. The biaxially oriented isotactic PP (BOPP) film is a stretched film in transverse order, producing a stiffer and more rigid molecular chain orientation in two directions7. BOPP is used in food packaging, confectionaries and tobacco packaging7,8. On the other hand, PP metallised film represents a niche application of capacitors. It is composed of polypropylene and aluminium on one side9.

The pre-treatment technique is the preliminary step before contemplating the biological approach. PP underwent various pre-treatments before biodegradation steps in most previous studies, except one study4. The pre-treatment techniques employed varies from UV10,11,12, γ-irradiation13,14 and heat treatment11,15. Pre-treatments are essential to decrease the polymer’s hydrophobicity, making it susceptible to microorganisms’ attacks. Since PP is an inert material, pre-treatments will enhance the degradation process either in vitro (incubation with specific microorganisms) or in vivo (soil burial) conditions. Moreover, the introductions of C = O or –OH to the C-C backbones of PP will result in polymer prone to degradation16. It was reported that UV and thermal treated PP samples are more susceptible to degradation than untreated samples based on the polymer’s weight loss and chemical structure analysis11,17.

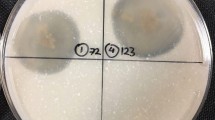

Then, we employ a biological approach by utilising fungi (Fig. 1). Although microbes capable of using neat PP as the sole carbon source is yet to be reported, few studies have been done on PP blends. For example, Actinomycetes sp. and Pseudomonas sp. isolated from soil were found to be able to biodegrade PP treated with UV or nitric acid for one month18. A study conducted by Sheik et al. 13 revealed an enhanced degradation of gamma-treated PP incubated with Lasiodiplodia theobromae and a few other isolated fungi. Presumably, fungi’s mycelium plays a vital role in polymer degradation19,20,21. Some species can produce enzymes capable of degrading specific polymers or utilising the carbon in the polymer chain as their carbon source. Enzymes engaged in polymer degradation are referred to as exo-enzymes have a broad reactivity ranging from oxidative to hydrolytic functionality. The exo-enzymes can degrade complex polymer structures to smaller, simple units that can take in the microbial cell to complete the process of degradation22.

The process begins with the selection of PP samples. These samples were further pre-treated by UV, heat and Fenton’s chemical before feeding it to the fungi and incubating for 90 days. Post-incubation, PP residues were tested to confirm their degradation by GC-MS, FTIR, TGA and SEM. GC-MS and FTIR confirm the chemical changes, TGA determines its thermal stability, while SEM elucidates the morphological changes.

Even though the work carried out in this area is scarce, a few promising fungi stand above the rest. Past results utilised several Aspergillus species ranging from unspecified Aspergillus sp., Aspergillus niger and Aspergillus terreus. Aspergillus sp. can form biofilms, which can organise themselves in a communal structure and by secreting extracellular enzymes, they can stick to inert surfaces23,24. The pure culture of A. terreus has never been assessed for PP degradation. However, a study conducted by Strömberg and Karlsson25 utilised a consortium of fungi and algae, including A. terreus to test the biodegradation effect on PP’s surface and bulk property changes. Additionally, we selected Engyodontium album based on previous research by Jeyakumar et al. 11. In their study, the E. album MTP09 isolated from a plastic dumping site were exposed to pre-treated PP and 18.8% weight loss was observed for the UV-treated metal-ion PP. Thus, in current research, Aspergillus terreus and Engyodontium album fungi were selected as PP degraders. As these fungi contain rich sources of degrading enzymes and the ability to survive in harsh environments under low nutrient and moisture conditions, they were considered highly potential organisms. Pre-treatments will enhance fungal degradation; thus, making the overall biodegradation process efficient.

Results and discussion

The gravimetric weight loss of PP

To quantify the degradation efficiency of PP, we measured the weight loss of the GPP, FPP, and MFPP after 30, 60, and 90 days of incubation. We observed the gravimetric weight loss of pre-treated PP samples to be higher than the control after 30, 60, and 90 days of incubation for both A. terreus and E. album. Figure 2a showed that the highest PP weight loss incubated with A. terreus was observed for UV-treated MFPP (25.29%) after 90 days while highest for heat-treated MFPP in E. album (27.08%) after 90 days. The weight loss decreases in the order of MFPP, followed by FPP and GPP in almost all pre-treatment strategies incubated in both fungi. Hypothetically, the gravimetric weight loss trend will increase proportionally to incubation days26. For example, UV-treated MFPP, FPP and GPP incubated with A. terreus, and heat-treated GPP and FPP incubated with E. album demonstrated increasing gravimetric weight loss percentage trend to incubation days. However, few PP samples such as heat-treated MFPP in A. terreus and E. album indicated different weight loss trends compared to the others. Gravimetric weight loss percentage of heat-treated MFPP in A. terreus was 21.07%, increased to 22.92% and dropped slightly to 22.07% after 30, 60, and 90 days, respectively.

a Percentage gravimetric weight loss of the pre-treated and untreated GPP, FPP, and MFPP incubated with A. terreus and E. album at the end of 30, 60, and 90 days. The error bars represent the standard error of mean (sem) of the triplicate reading for the gravimetric weight loss percentage. b, c Heat map of the mass reduction efficiency of A. terreus and E. album in GPP, FPP, MFPP and controls-infused mineral salt media (details in Supplementary Table 2). d Biomass production of 30, 60, and 90 days inoculation of A. terreus and E. album with pre-treated GPP, FPP, and MFPP and biotic control (MSM + A. terreus or E. album). GPP PP granule; FPP PP film, MFPP PP metallised film, GPP PP granule, FPP PP film, MFPP PP metallized film, WP Control without pre-treatment control, UV UV treatment, H heat treatment, FR Fenton reagent treatment. Within each box, horizontal black lines denote median values; the boundary of the box closest to 0 indicates the 25th percentile while the value farthest from 0 indicates the 75th percentile; whiskers extending from top to bottom of the box indicate the 10th and 90th percentiles; the top end of the whiskers indicate the maximum value while the lowest end indicates the minimum value of the biomass.

Supplementary Table 1 shows the p-value of PP samples incubated with both fungi, compared to untreated and treated controls. We observed that UV and heat-treated MFPP established significant differences of percentage weight loss with untreated and treated controls, especially for heat-treated samples (p < 0.0001) after 30, 60, and 90 days of incubation with A. terreus. In contrast, heat and Fenton-treated MFPP incubated in E. album showed a significant difference in weight loss percentage compared to controls. This finding implied the ability of both A. terreus and E. album to utilise the carbon source or excrete specific enzymes that can degrade and putatively attack heat-treated MFPP more effectively than others and consequently cause partial PP degradation27. The results also depicted a considerable difference in PP samples incubated with both fungi. Different PP demonstrated distinct effects of pre-treatments employed. GPP, FPP, and MFPP differ in their molecular properties and additive, though they originated from the same fundamental (C3H6)n structure11. We observed that MFPP established the highest gravimetric weight loss than GPP and FPP. Therefore, it suggested that heat treatment and metal additives have the most significant influence on the biodegradation of PP for both E. album and A. terreus11. Moreover, a higher gravimetric weight loss percentage of MFPP incubated with A. terreus showed that it could degrade and putatively attack MFPP more effectively than others and consequently cause partial PP degradation27. The production of specific enzymes such as laccase possibly contributes to the degradability of A. terreus28.

A. terreus and E. album may have catalysed metabolic reactions that contributed to PP’s adsorption, desorption, and breakdown27. A previous study of fungi degradation on different types of PP films recorded a weight loss of 18.8% in UV treated catalyst-blended PP with E. album after 12 months of incubation11. Their findings indicated that UV pre-treatment and metal ion additives in PP film influenced the biodeterioration and biodegradation of PP. In a more recent study, a 6.4% weight loss percentage was observed in the degradation of PP granule by Rhodococcus sp. strain 36. This study was conducted on PP microplastic and pre-treated by UV27 (specific parameters such as wavelength and treatment duration were undisclosed). The current study showed the highest weight loss in heat-treated samples, followed by UV and Fenton treatment. Degradation differs from one to another due to different PP characteristics27,29. Very low weight loss percentages of GPP, FPP, and MFPP were observed in the control flask (without pre-treatment), with no significant difference with UV, heat, and Fenton-treated control. Fungi activity results in the weight loss of PP, which hint at its ability for physical breakdown and degradation of PP30.

The reduction rate of PP

This study also established the removal rate constant (K) of PP samples per day by A. terreus and E. album using first-order kinetics and half-life (t1/2). We calculated the half-life to determine the time taken for half of PP samples to be reduced or degraded. Figure 2b, c show the overall values of reduction rate and half-life of all samples. Supplementary Table 2 depicted detailed information of weight, K, half-life, and p-values of both fungi on GPP, FPP, and MFPP after 90 days of incubation. We adopted this model as it gives a constant fraction per unit of time removed within the polymer.

Figure 2b demonstrated the removal constant rate (K), while Fig. 2c shows the half-life (days) of PP samples. The figure shows that heat-treated MFPP incubated in E. album after 30 days indicated the highest mass reduction efficiency of 0.0167 day−1 and a half-life of approximately 41 days. After 90 days of incubation, E. album recorded a higher PP uptake rate of 0.0035 day−1 and a shorter life span of approximately 197 days for the heat-treated MFPP, compared to the heat-treated MFPP by A. terreus. In contrast, UV-treated MFPP incubated in A. terreus showed a higher PP uptake of 0.0032 day−1 than MFPP incubated with E. album in the same condition. Overall, GPP, FPP, and MFPP incubated in Fenton reagent demonstrated a much lower reduction rate and higher half-life than heat-treated PP samples. The higher uptake rate by E. album and A. terreus on heat-treated MFPP was due to the genetic make-up of the fungi where they can utilise the carbon source27 and its greater tolerance towards the heat-treated PP samples, especially MFPP. The rate constants (K) and subsequent half-lives supported the degree of degradation activities within the PP samples infused with the fungi.

Biomass production of A. terreus and E. album

The fungal biomass production further verified PP’s weight loss and reduction rate. We calculated fungal biomass to measure the growth of the strains in the medium and contain live and dead cells11. After 30, 60, and 90 days of incubation, biomass collected was highest in different pre-treated PP for both fungi. Based on Fig. 2d, we observed that biomass in the supernatant of heat-treated MFPP with A. terreus after 90 days was highest (1.073 mg/ml) compared to FPP, GPP and PP incubated with E. album. However, E. album’s biomass production was slightly higher in Fenton-treated MFPP (0.81 mg/ml) than other PP samples and pre-treatments after 90 days.

The highest biomass produced by A. terreus in heat-treated MFPP showed a significant difference with its control (p < 0.0001), Fenton-treated (p < 0.0001) and UV-treated MFPP (p = 0.0008). The biomass produced was also significantly higher than E. album in the same condition (p < 0.0001). Overall, both fungi biomass productions were higher than the control. Supplementary Table 3 showed that biomass produced by both A. terreus and E. album differ from their respective controls. Overall, we observe that A. terreus incubated with UV-treated PP (GPP, FPP, and MFPP) produce significantly higher biomass than E. album after 30, 60, and 90 days. The biomass of A. terreus in heat-treated PP samples was also higher than E. album. However, E. album exhibited significantly higher biomass production than A. terreus in Fenton-treated PP samples after 90 days (p = 0.0186). Generally, biomass produced by A. terreus was consistently higher in UV and heat-treated PP samples as the substrate. We also observed that MFPP showed the highest biomass production in both A. terreus and E. album’s pre-treated samples. However, some exhibited no significant differences with its control.

Pre-treatment strategies have significantly influenced the biomass produced by fungi11. Thus, it showed that UV, heat, and Fenton treatment could be utilised as a strategy before subjecting PP to biodegradation. The results concurred with Jeyakumar et al. 11, where they discovered that additives such as starch or metal have a significant effect on the oxidation process. Therefore, the biomass content was higher in the pre-treated PP samples than in the control. While the biomass produced was high in UV and heat-treated PP samples, A. terreus showed notably low biomass produced in Fenton-treated PP. There was no significant difference between the biomass produced with PP samples and control, except for incubation with FPP and MFPP after 60 and 90 days. As for E. album, although the biomass produced was higher than the control, there were no significant differences observed between most of the UV, heat and Fenton-treated GPP and FPP samples and control, except for MFPP after 90 days. The insignificance has resulted from the limited ability of this fungus to completely adapt to the culture conditions due to limited growth duration or the PP samples conditions that were unfavourable for the fungi growth. Production of metabolites may also render the culture media hostile for fungi’s growth27. Thus, these findings indicated that A. terreus and E. album responded differently with different pre-treated PP samples compared to the control. A. terreus adapted to the culture condition with GPP, FPP and MFPP better than E. album and possibly utilised PP samples as a carbon source for its growth.

Correlation between gravimetric weight loss of PP and biomass production of A. terreus and E. album

Based on the prior results, we then observed the correlations between weight loss, biomass, and reduction rate. In Fig. 3a–d, the multiple variables plot of biomass vs gravimetric weight loss plots elucidate the influence and relationship between weight loss and the amount of biomass produced regarding PP materials, pre-treatments applied and incubation days. It indicated different responses of both fungi on the substrate applied. As previously discussed, the substrate consumed influences the fungi’ biomass, which implies the growth of the strains in the medium11.

a, b Biomass vs gravimetric weight loss of A. terreus a and E. album b PP samples and pre-treatment as factors. c, d Biomass vs gravimetric weight loss of A. terreus c and E. album d PP samples and incubation days as factors. e–g S (gravimetric weight loss)/X (∆ biomass) of A. terreus and E. album vs pre-treatments e, vs incubation days f and vs PP materials g. GPP PP granule, FPP PP film, MFPP PP metallised film, UV UV treatment, H heat treatment, FR Fenton reagent treatment.

We observed that the pre-treatment strategies, types of materials used, and incubation days have a substantially different effect on both A. terreus and E. album. GPP treated in UV, heat, and Fenton incubated in both fungi exhibited the lowest biomass production and low gravimetric weight loss than FPP and MFPP (Fig. 3a, b). We observed that fungi incubated with MFPP generally produced the highest biomass and indicated the highest gravimetric weight loss compared to other PP samples. It was also noteworthy to mention that heat pre-treatment contributed to this effect. However, few MFPP and FPP’s weight loss and biomass produced by both fungi were not proportional to the incubation days (Fig. 3c, d). Nevertheless, most MFPP indicated high weight loss attributed to the biomass produced after 90 days of incubation in E. album.

On the other hand, Fig. 3e–g elucidate trends of substrate and biomass over each factor investigated in this research. In these figures, substrate (S = gravimetric weight remains of PP materials) over biomass (∆X) were plotted against pre-treatments (a), incubation days (b), and PP materials (c). Since we considered many factors to illustrate the effect of PP degradation, these figures represent a detailed illustration of the S/X ratio. Most studies measured increased fungal biomass and weight loss monitoring as conclusive evidence of carbon utilisation from plastics31. However, the ideal ratio will consist of lower PP’s weight remains and higher biomass produced by fungi. The lower ratio displayed will imply the ability of higher fungal biomass’ volume to degrade PP materials better. The S/X ratio on pre-treatments in Fig. 3e indicated that the UV and heat-treated PP samples exhibited the lowest ratio values compared to the Fenton treatment. UV-treated PP in A. terreus showed the lowest ratio compared to other pre-treatments employed.

Based on incubation days (Fig. 3f), the S/X ratio displayed a reducing trend from 30 to 90 days with both fungi. We observed a similar trend in the S/X ratio of PP materials (Fig. 3g). From these values, we deduced that UV and heat pre-treatment after 90 days of incubation with A. terreus is the ideal condition for PP degradation. MFPP was evidently the highly degradable form of PP when treated with UV and heat, and incubated with A. terreus after 90 days. The lowest ratio value acquired indicated that the relatively high fungal biomass conclusively contributes to high gravimetric weight loss.

The analysis matrix of A. terreus and E. album showed a strong correlation between gravimetric weight loss and reduction rate. The correlation coefficient between gravimetric weight loss and reduction rate are 0.79 and 0.83, respectively for A. terreus and E. album. However, biomass production and gravimetric weight loss of A. terreus depicted a relatively lower correlation coefficient value of 0.46, whereas E. album showed a slightly higher value of 0.48. We developed two multiple linear regression models as per equations below relating to gravimetric weight loss with biomass produced and reduction rate.

General equation: Gravimetric Weight Loss (%) ~ Intercept + Reduction Rate (K) + Biomass (mg/ml), where;

with R2 = 0.7853, adjusted R2 = 0.7798, F = 142.6, P < 0.0001

with R2 = 0.8394, adjusted R2 = 0.8352, F = 203.8, P < 0.0001

Statistical parameters represent the goodness of fit data. Supplementary Fig. 1 shows the correlation matrix for both fungi. All data lie within a 95% confidence interval.

Fourier transform infrared spectroscopy (FTIR) analysis

Exposure of PP samples to oxygen, particularly at high temperatures in the presence of UV and chemical oxidiser, leads to its oxidation and changes in the polymer’s structure27,32. The oxidation process occurs through abiotic elements are regarded as auto-oxidation. In this research, abiotic factors in the form of pre-treatments results in the reduction of polymer’s hydrophobicity and introduction of carbonyl or hydroxyl groups (C = O or –OH)33. Thermo or photo-oxidative factors caused by pre-treatments undergoes free radical chain reaction34. The reaction produces carbon-carbon and carbon-hydrogen homolytic cleavage of their covalent bond in the PP chain. Consequently, the Norrish type II reaction occurs, which causes the β-scission of the polymer chain. The scission results in the formation of methyl ketone and a polymer fragment with a vinyl-end (double bond) group (Fig. 4). Hence, it is essential to determine the formation of carbonyl groups as it is dependable on many factors and additives present in PP.

Current studies revealed that the keto carbonyl index of heat-treated MFPP is very high in A. terreus compared to E. album, except after 60 days of incubation, and lower than the heat-treated control. Moreover, the heat-treated control appears to have a higher carbonyl index than the WPC control. These changes implied new functional groups’ formation, which changed the polymers’ surface energies due to their polar nature35. The carbonyl index of keto carbonyl was very high in heat-treated MFPP samples in 30 and 90 days compared to the WPC control (Fig. 5a). Hypothetically, the treated controls (heat, UV and Fenton) will generate a higher carbonyl index than the WPC control due to new functional groups32. All pre-treated GPP, FPP and MFPP agree with the hypothesis. Subsequently, prolonged exposure of the pre-treated PP to the fungi causes a decrease in carbonyl index from 30 to 90 days. Degradation of GPP and MFPP by A. terreus, and GPP and FPP by E. album leads to the reduction of carbonyl index through the formation of ester32,36. However, few samples such as heat-treated MFPP in E. album exhibited an increase in the carbonyl index after 90 days of incubation. The high carbonyl index observed in these samples suggests a lower biodegradation rate by E. album.

a Keto carbonyl index as a function of time of different PP samples. b Double bond index as a function of pre-treatments of PP samples. c Hydroxyl index as a function of time of different PP samples. GPP: PP granule; FPP: PP film, MFPP PP metallized film, WPC without pre-treatment, UV UV treatment, H heat treatment, FR Fenton reagent treatment. The error bars represent the standard error of mean (sem) of the triplicate reading for the keto and double bond index.

Oxidation due to abiotic factors such as UV, heat, and chemical reagents may lead to the formation of new functional groups such as keto and esters32. The oxidation process caused by abiotic factors is an autocatalytic process called auto-oxidation. In addition, these functional groups reduce hydrophobicity which in turn aid in the biodegradation process37. The introduction of C = O and O-H groups after pre-treatments increased the vulnerability of PP samples to degradation by fungi27. Moreover, the presence of metal ions in PP samples may have assisted the degradation. The metal ions generate free radicals on the surface of PP polymer, hence reacting with oxygen to produce carbonyl groups11. The Norrish type II reaction also elucidated the double bond formation (Fig. 5b). The β-scission in Norrish type II reaction leads to the formation of double bonds in the polyolefin’s polymer chain, making them extremely brittle in a short time38. Figure 5b shows the changes in the double bond index of PP samples in different pre-treatments and fungi incubation. In their findings, Auta et al. 27 concurred that loss and disappearance of peaks corresponding to ester linkages were similarly reported by Russell et al. 38. Other studies depicted the formation of new groups, such as hydroxyl and carbonyl groups in PP biodegradation17,27.

In current research, hydroxyl index depicted in Fig. 5c elucidate the formation of hydroxyl group. Hydroxyl group may form as alcohol, hydroperoxide or carboxylic acids caused predominantly by abiotic factors (pre-treatments). It was observed that significant reduction of the hydroxyl index of the heat-treated MFPP incubated with A. terreus occurs comparably to the reduction in the carbonyl index (Fig. 5a). High hydroxyl index values in the controls illustrated the formation of hydroxyl-related compounds through the Norrish Type I reaction39. Since oxidation decreases the hydrophobicity of PP and other polymers, this action may have facilitated the attachment of fungi on the PP sample surface. Consequently, the combination of both abiotic and biotic factors were observed in the biodeterioration and biodegradation of PP samples by both A. terreus and E. album.

Surface morphological changes

The severity of PP biodeterioration was further validated using scanning electron microscopy (SEM) to observe the surface morphological changes. The WPC controls of GPP, FPP, and MFPP exhibited smooth surfaces in Fig. 6(a, b and c). However, the UV, heat and Fenton-treated PP samples demonstrated various cracks, grooves, and irregularities on its surface (Fig. 6d–f). These formations were results of abiotic pre-treatments employed on PP samples. Hence, it proves that pre-treatment alters the surface morphology while cracks observed indicated that PP samples have become brittle11. GPP, FPP and MFPP’s morphological structure in Fig. 6g–x indicated the appearance of cracks and grooves. These irregularities demonstrated colonisation or attachment of fungal biomass and are prominent on the surface of PP samples incubated with A. terreus regardless of pre-treatments compared to E. album. There is a possibility of microbial propagation originating from these cracks11,27. This action is a fundamental prerequisite for the biodeterioration of PP. On the other hand, various crevices and pits formed on the surface were results of microbial activity27. After pre-treatments with UV, heat and Fenton, relatively minimal irregularities were transformed into a highly porous and uneven surface. These surface changes observed in SEM micrographs denoted surface damage to PP samples treated with A. terreus and E. album.

a–f SEM micrographs of PP without pre-treatment (WPC–a GPP, b FPP, c MFPP) and pre-treated (d, UV-GPP; e, H-FPP and f, FR-MFPP) controls. g–l, GPP samples of with pre-treatments incubated in both fungi where g–i are UV g, heat h, and Fenton-treated i GPP incubated in A. terreus while j–l are UV j, heat k, and Fenton-treated l GPP incubated in E. album. m–r, FPP samples of with pre-treatments incubated in both fungi where m–o are UV m, heat n, and Fenton-treated o FPP incubated in A. terreus while p–r are UV p, heat q, and Fenton-treated r FPP incubated in E. album. s–x MFPP samples of with pre-treatments incubated in both fungi where s–u are UV s, heat t, and Fenton-treated u MFPP incubated in A. terreus while v–x are UV v, heat w, and Fenton-treated x FPP incubated in E. album.

These outcomes suggested that A. terreus and E. album could grow and colonise on the surface of PP samples, which subsequently caused surface damage. From the micrograph, A. terreus was perceived to colonise PP surface comparatively more than E. album for GPP, FPP and MFPP in all pre-treatments. In addition, the extent of A. terreus colonisation on UV and heat-treated GPP was more significant than on Fenton-treated GPP. In contrast, greater colonisation was observed on heat-treated FPP and MFPP than UV and Fenton-treated samples. Overall, A. terreus colonised pre-treated MFPP more than GPP and FPP, while E. album showed moderate coverage of colonisation on FPP and MFPP. These results indicated a synergistic effect between the type of polymer, pre-treatments and incubation conditions11.

A. terreus and E. album colonising PP sample surface can undertake further actions by forming biofilms. Biofilms, composed of exopolymeric substance (EPS) composed primarily of polysaccharides40, enable the fungi to attach to one another or on biotic and abiotic surfaces such as PP. Although PP is regarded as having high hydrophobicity properties, the formation of biofilms is made possible by a small class of amphipathic proteins called hydrophobins41. Hydrophobins mediate the adhesion in filamentous fungi and play a significant role in fungal biofilm development41. While few hyphae-like structures observed on heat-treated PP samples (Fig. 6n) resulted from the formation of biofilm, secretion of extracellular enzymes might have taken place27. Hence, these ideal conditions established an essential role in transporting the depolymerising enzymes to the polymer surface. In addition, enzymes produced by microorganisms could enable the fungi to enter the cracks and grow, increasing the crevices’ size41. This situation will subsequently deteriorate PP’s properties and eventually cause polymer weight loss. Previous studies on biodeterioration and biodegradation of synthetic polymers such as PP and LDPE have reported similar morphological changes observed with SEM11,13,42,43.

In a study conducted by Auta et al. 27, SEM analysis confirmed that Bacillus sp. strain 27 and Rhodococcus sp. strain 36 from mangrove sediments accumulated on PP’s surface. These bacteria are proven to cause PP surface damage as they became physically coarse and pitted after removing the bacteria. Jeyakumar et al. 11 have summarised the possibility of surface degradation by E. album to be higher than P. chrysosporium due to its extent of colonisation on UV-treated metal-ions blended PP film. Their study also compares the magnitude of surface degradation between neat and starch-blended PP. They concluded that high biomass, total protein, and total carbohydrate content in pre-treated PP suggested ease of fungi colonisation compared to untreated samples.

This study observed the combined effects of pre-treatment techniques and fungal biodeterioration on PP samples—GPP, FPP, and MFPP. The highest biodeterioration rate was observed on UV and heat-treated MFPP by A. terreus, compared to FPP, GPP, and PP samples in E. album. High gravimetric weight loss (25.29% and 22.13%, respectively), reduction rate (removal constant: 0.0032 day−1 and 0.0028 day−1; half-life: 214.52 days and 245.74 days, respectively), decreased carbonyl index (0.12 to 0.10 and 0.61 to 0.34, respectively) and surface morphology changes demonstrated biodeterioration. Higher biomass production in UV (1.07 mg/ml), heat (0.81 mg/ml) and Fenton-treated (0.63 mg/ml) PP indicates ease of fungal colonisation and proved to accelerate biodeterioration of PP. Consequently, the low S/X ratio deduced that UV and heat pre-treatment after 90 days of incubation with A. terreus is the ideal condition for PP degradation, while MFPP was a highly degradable form of PP. The confirmed synergistic effect of pre-treatments combined with fungal degradation is an important steppingstone in designing practical biological implementations to treat PP waste and subsequently other synthetic polymer degradations at larger scales.

Methods

Polypropylene samples

Polypropylene (PP) samples were prepared using commercial PP with specific sizes and thicknesses. Three types of PP samples used in this research were PP granule (GPP), PP film (FPP) and PP metallised film (MFPP). PP granule is an isotactic PP (white, pelleted) with an average molecular weight of ~250,000 Da, average Mn of ~67,000, density of 0.9 g/ml at 25 °C, and CAS number 9003-07-0 was purchased from Sigma-Aldrich®. PP film is in biaxially oriented condition (transparent), with a thickness of 0.05 mm, 600 × 600 mm in size and product number GF00254944 was manufactured by Goodfellow Corp., USA, purchased through Sigma-Aldrich®. PP metallised film has an aluminium-coated surface on one side (metallic), a thickness of 0.008 mm, 0.5 m × 75 mm in size and product number GF80085922 was manufactured by Goodfellow Corp., USA, purchased through Sigma-Aldrich®.

Pre-treatment of polypropylene samples

The samples obtained were first disinfected with 70% ethanol, dried and weighed. Samples were labelled as PP granule (GPP), PP film (FPP), PP metallised film (MFPP), UV pre-treated PP granule (UV-GPP), UV pre-treated PP film (UV-FPP), UV pre-treated PP metallised film (UV-MFPP), heat pre-treated PP granule (H-GPP), heat pre-treated PP film (H-FPP), heat pre-treated PP metallised film (H-MFPP), Fenton reagent’s pre-treated PP granule (FR-GPP), Fenton reagent’s pre-treated PP film (FR-FPP) and Fenton reagent’s pre-treated PP metallised film (FR-MFPP). Three different pre-treatment strategies were employed on these three different PP samples. In the first method, PP samples were thermally pre-treated at 200 °C for 15 min in an air frying oven (Smart Oven™ Air Fryer, Breville BOV860BSS4JAN1), to induce oxidation (modified from Arkatkar et al. 44). In the following method, PP samples were subjected to UV radiation (Air Science UV-Box™ UVB-15, 254 nm wavelength) for 24 hours, placed at 5 cm from UV light (modified from Jeyakumar et al. 11). For the third method, PP samples were pre-treated with Fenton’s reagent (Fe (II) salt, at pH 5.5, dropwise addition of 30% H2O2) for seven days44,45. About 40 mg of untreated or pre-treated PP samples were incubated in 500 ml Erlenmeyer flasks containing 200 ml of mineral salt medium (MSM) and 2 ml of fungi culture (modified from Jeyakumar et al. 11). All chemicals used were supplied by Sigma-Aldrich® unless stated otherwise.

Preparation and growth of Aspergillus terreus (ATCC 20542) and Engyodontium album (BRIP 61534a)

The A. terreus strain was restored according to the supplier’s recommendations (ATCC Product Sheet Aspergillus terreus ATCC® 20542TM). The freeze-dried fungus was rehydrated with 1 mL of sterile deionised water for 2 h at room temperature (25 °C) before being transferred to and maintained on Potato Dextrose Agar (PDA) at 30 °C for 2–3 days. The E. album strain was supplied by the Department of Agriculture and Fisheries, State of Queensland, Australia. The fungus was received in PDA plates and stored at room temperature (25 °C) before being subcultured and maintained into a fresh PDA media at 25 °C. All chemicals used were supplied by Sigma-Aldrich® unless stated otherwise.

Incubation condition of A. terreus and E. album

Fresh mycelium of the grown fungi on PDA plates was scraped off and suspended in 10 ml of sterile water and vortexed. 2 ml of these suspensions were inoculated into 500 ml Erlenmeyer flask containing approximately 20 mg of PP samples and 200 ml of mineral salt medium11. The mineral salt medium consists of 1 g/l KH2PO4, 0.2 g/l NaH2PO4, 0.5 g/l MgSO4.7H2O, 0.1 g/l CaCl2, 0.169 g/l (1 mM) MnSO4.H2O, 1 g/l yeast extract, and 1 ml of vitamin solution were used in all experiments46. Vitamin solution consists of 40 mg of 4-aminobenzoate, 10 mg of biotin, 100 mg of nicotinic acid, 50 mg of calcium pantothenate, 150 mg of pyridoxamine hydrochloride, 100 mg of thiamine hydrochloride, 50 mg of cyanocobalamin, 10 mg of DL-6,8-thioctic acid, 10 mg of riboflavin and 4 mg of folic acid in 1 L of deionised water47. The inoculated fungi were incubated at 30 °C and 200 rpm on an orbital shaker (Thermoline TU-400 and Senova ST-203×2). PP samples were withdrawn after 30 days under aseptic conditions, washed in sterile water and oven-dried overnight at 50 °C before further analysis. PP samples (pre-treated and untreated) without the fungi served as abiotic control, while flasks with the pure culture but without PP samples served as the biotic control (Table 1). All controls were incubated the same way as the test (PP and fungi) samples. All chemicals used were supplied by Sigma-Aldrich® unless stated otherwise.

Total biomass determination of A. terreus and E. album

1 ml of the culture was transferred into a 1.5 ml microcentrifuge tube using a 1000 µl micropipette and pelleted down at 12000 rpm for 25 min (Eppendorf® Centrifuge 5424). The pellet was dried for a few days at 50 °C until the dry weight was constant and the weight was recorded (modified from Artham and Doble28). Fresh mycelium of the fungi in 10 ml sterile water suspension was filtered, dried and used as initial reading48.

Gravimetric weight loss determination

Gravimetric weight loss of residual PP samples27 was determined by weighing PP samples recovered from mineral salt media through sterile filtration by using an analytical balance with a sensitivity of 0.001 g (Mettler Toledo ME204E) and repeatability of 0.1 mg49. The fungi colonising PP samples were removed (four-step washing, with an incubation time of 2 min for each step) with 70% ethanol and then dried in a hot air oven at 50 °C overnight. The residual PP samples’ weight were determined to measure the extent of degradation. The weight loss of PP samples in percentage was determined using Eq. (3):

where W0 is the initial weight of the polymer (g) and W is the residual weight of the PP samples (g).

Reduction rate determination

The data were further processed to determine the rate constant of PP samples reduction by using the first-order kinetic model based on the initial and final weights along specific intervals (90 days) (modified from27,50). Equation (4) was as follows:

where K is the first-order rate constant for PP samples uptake per day, t is time in days, W is the weight of residual PP samples (g) and W0 is the initial weight of PP samples (g). This model was adopted as it gives a constant fraction per unit time present/removed within the PP samples. A plot of ln [W/Wo] vs. time yields a straight line with slope K (day−1) = biodegradation rate constant and Half-life (t1/2) = ln 2/K, was also derived.

Fourier transform infrared (FTIR) analysis of PP samples

The changes in the structure of GPP, FPP and MFPP samples with subsequent fungi incubation were analysed using FTIR-ATR spectroscopy (Thermo Scientific Nicolet 6700) in the frequency range of 4000–450 cm−1. The analysis was conducted on PP samples incubated with fungi strains and uninoculated PP samples27. During the degradation process, the formation or disappearances of carbonyl and methyl groups to the methylene group were monitored32. The carbonyl index measures the concentration of carbonyl groups, and the double bond index is a measure of the concentration of PP’s double bond51. In addition, the hydroxyl index measures the oxidation of PP and is generally applied for degradation rate evaluation52. It was assumed that no changes would occur in the methylene groups during the degradation process11.

The keto carbonyl, ester carbonyl, vinyl and hydroxyl indices for the polyolefins were measured from the FTIR spectra using the following formula:

where relative intensities at 1740 cm−1,1715 cm−1,1640 cm−1, 3435 cm−1, and 1465 cm−1 correspond to ester and keto carbonyl, double bond (vinyl index), hydroxyl index, and methylene bands respectively28,51,52,53. Readings were taken in duplicate.

Scanning electron microscopy (SEM) of PP samples

The morphology of the degraded PP samples was viewed after the experimental time (30, 60, and 90 days) with SEM (Phenom XL). The samples were sputter-coated with a gold and palladium layer at 18 mA under an Argon (Ar) atmosphere at 150 kPa and visualised using SEM at a maximum magnification of 3800×54.

Statistical analysis

The statistical analysis of data was conducted using analysis of variance (ANOVA) in the GraphPad Prism 9 version 9.1.0 with the LSD post-hoc test at P-value = 0.05

Data availability

Authors can confirm that all relevant data are included in the article and/or its supplementary information files. Additionally, other related data are available upon request from the authors.

References

Mollasalehi, S., Fungal Biodegradation of Polyvinyl Alcohol in Soil and Compost Environments. 2013, ProQuest Dissertations Publishing.

Geyer, R., Jambeck, J. R. & Law, K. L. Production, use, and fate of all plastics ever made. Sci. Adv. 3, e1700782 (2017).

Saiter, J. M., Dobircau, L. & Leblanc, N. Are 100% green composites and green thermoplastics the new materials for the future? Int. J. Polym. Sci. 2012, 280181 (2012).

Cacciari, I. et al. Isotactic polypropylene biodegradation by a microbial community: physicochemical characterization of metabolites produced. Appl. Environ. Microbiol. 59, 3695–3700 (1993).

Danso, D., Chow, J., Streit, W. R. & Drake, H. L. Plastics: environmental and biotechnological perspectives on microbial degradation. Appl. Environ. Microbiol. 85, e01095–01019 (2019).

Fellows, P. J. 24 - Packaging, in Food Processing Technology (Fourth Edition) 949-1044. (P.J. Fellows, Woodhead Publishing, 2017).

Ebnesajjad, S. Plastic Films in Food Packaging: Materials, Technology and Applications (Elsevier Science & Technology Books, 2013).

Twede, D. & Goddard, R. Packaging Materials (Pira International, 1998).

Takeoka, H., et al. Development of polypropylene film capacitor using double metallizing technology. In Proceedings of the 7th International Conference on Properties and Applications of Dielectric Materials, 3, 1198–1201(Cat. No.03CH37417) (2003).

Huang, C.-Y., Roan, M.-L., Kuo, M.-C. & Lu, W.-L. Effect of compatibiliser on the biodegradation and mechanical properties of high-content starch/low-density polyethylene blends. Polym. Degrad. Stab. 90, 95–105 (2005).

Jeyakumar, D., Chirsteen, J. & Doble, M. Synergistic effects of pretreatment and blending on fungi mediated biodegradation of polypropylenes. Bioresour. Technol. 148, 78–85 (2013).

Morancho, J. M. et al. Calorimetric and thermogravimetric studies of UV-irradiated polypropylene/starch-based materials aged in soil. Polym. Degrad. Stab. 91, 44–51 (2006).

Sheik, S., Chandrashekar, K. R., Swaroop, K. & Somashekarappa, H. M. Biodegradation of gamma irradiated low density polyethylene and polypropylene by endophytic fungi. Int. Biodeterior. Biodegrad. 105, 21–29 (2015).

Badr, Y., Ali, Z., Zahran, A. H. & Khafagy, R. Characterization of gamma irradiated polyethylene films by DSC and X‐ray diffraction techniques. Polym. Int. 49, 1555–1560 (2000).

Abd El-Rehim, H. A., Hegazy, E.-S. A., Ali, A. M. & Rabie, A. M. Synergistic effect of combining UV-sunlight–soil burial treatment on the biodegradation rate of LDPE/starch blends. J. Photochem. Photobiol. A: Chem. 163, 547–556 (2004).

Arutchelvi, J. et al. Biodegradation of polyethylene and polypropylene. Indian J. Biotechnol. 7, 9–22 (2008).

Alariqi, S., Annamalai, P. K., Rao, M. & Singh, R. Biodegradation of γ-sterilized biomedical polyolefins under composting and fungal culture environments. Polym. Degrad. Stab. 91, 1105–1116 (2006).

Sepperumal, U. & Margandan, M. M. Growth of Actinomycetes and Pseudomonas sp., biofilms on abiotically pretreated polypropylene surface. Eur. J. Zool. Res. 3, 6–17 (2014).

Holt, G. et al. Fungal mycelium and cotton plant materials in the manufacture of biodegradable molded packaging material: evaluation study of select blends of cotton byproducts. J. Biobased Mater. Bioenergy. 6, 431–439 (2012).

Jones, M. et al. Waste-derived low-cost mycelium composite construction materials with improved fire safety. Fire Mater. 42, 816–825 (2018).

Jones, M., Mautner, A., Luenco, S., Bismarck, A. & John, S. Engineered mycelium composite construction materials from fungal biorefineries: a critical review. Mater. Des. 187, 108397 (2020).

John, A. G. Biological Degradation of Polymers in the Environment, in Plastics in the Environment Ch. 5. (G. Alessio, IntechOpen, 2019).

Samson, R. A. & Pitt, J. I. Modern Concepts in Penicillium and Aspergillus Classification Vol. 185 (Springer, 2013).

de Oliveira, T. A. et al. Fungal degradation of reprocessed PP/PBAT/thermoplastic starch blends. J. Mater. Res. Technol. 9, 2338–2349 (2020).

Strömberg, E. & Karlsson, S. The effect of biodegradation on surface and bulk property changes of polypropylene, recycled polypropylene and polylactide biocomposites. Int. Biodeterior. Biodegrad. 63, 1045–1053 (2009).

Ojha, N. et al. Evaluation of HDPE and LDPE degradation by fungus, implemented by statistical optimization. Sci. Rep. 7, 39515 (2017).

Auta, H., Emenike, C., Barasarathi, J. & Fauziah, S. H. Growth kinetics and biodeterioration of polypropylene microplastics by Bacillus sp. and Rhodococcus sp. isolated from mangrove sediment. Mar. Pollut. Bull. 127, 15–21 (2017).

Artham, T. & Doble, M. Biodegradation of physicochemically treated polycarbonate by fungi. Biomacromolecules 11, 20–28 (2010).

Bhardwaj, H., Gupta, R. & Tiwari, A. Communities of microbial enzymes associated with biodegradation of plastics. J. Polym. Environ. 21, 575–579 (2013).

Engineers, N. B. O. C. The Complete Book on Biodegradable Plastics and Polymers (Recent Developments, Properties, Analysis, Materials & Processes) (Asia Pasific Business Press, 2006).

Zeghal, E., Vaksmaa, A., Vielfaure, H., Boekhout, T., & Niemann, H. The potential role of marine fungi in plastic degradation – a review. Front. Mar. Sci. 8. https://doi.org/10.3389/fmars.2021.738877 (2021).

Sudhakar, M. et al. Biofouling and biodegradation of polyolefins in ocean waters. Polym. Degrad. Stab. 92, 1743–1752 (2007).

Mohanan, N., Montazer, Z., Sharma, P. K., & Levin, D. B. Microbial and Enzymatic Degradation of Synthetic Plastics. Front. Microbiol. 11, 580709–580709 (2020).

Thiounn, T. & Smith, R. C. Advances and approaches for chemical recycling of plastic waste. J. Polym. Sci. 58, 1347–1364 (2020).

Artham, T. et al. Biofouling and stability of synthetic polymers in sea water. Int. Biodeterior. Biodegrad. 63, 884–890 (2009).

Grause, G., Chien, M.-F. & Inoue, C. Changes during the weathering of polyolefins. Polym. Degrad. Stab. 181, 109364 (2020).

Hadad, D., Geresh, S. & Sivan, A. Biodegradation of polyethylene by the thermophilic bacterium Brevibacillus borstelensis. J. Appl. Microbiol. 98, 1093–1100 (2005).

Russell, J. R. et al. Biodegradation of polyester polyurethane by endophytic fungi. Appl. Environ. Microbiol. 77, 6076–6084 (2011).

Hyde, K. D. et al. The amazing potential of fungi: 50 ways we can exploit fungi industrially. Fungal Divers 97, 1–136 (2019).

Costa-Orlandi, C. B. et al. Fungal biofilms and polymicrobial diseases. J. Fungi. 3, 22 (2017).

Ramage, G., Rajendran, R., Gutierrez-Correa, M., Jones, B. & Williams, C. Aspergillus biofilms: clinical and industrial significance. FEMS Microbiol. Lett. 324, 89–97 (2011).

Jeon, H. J. & Kim, M. N. Isolation of mesophilic bacterium for biodegradation of polypropylene. Int. Biodeterior. Biodegrad. 115, 244–249 (2016).

Gajendiran, A., Krishnamoorthy, S. & Abraham, J. Microbial degradation of low-density polyethylene (LDPE) by Aspergillus clavatus strain JASK1 isolated from landfill soil. 3 Biotech 6, 52 (2016).

Arkatkar, A., Juwarkar, A. A., Bhaduri, S., Uppara, P. V. & Doble, M. Growth of Pseudomonas and Bacillus biofilms on pretreated polypropylene surface. Int. Biodeterior. Biodegrad 64, 530–536 (2010).

Liu, P. et al. New insights into the aging behavior of microplastics accelerated by advanced oxidation processes. Environ. Sci. Technol. 53, 3579–3588 (2019).

Orhan, Y. & Büyükgüngör, H. Enhancement of biodegradability of disposable polyethylene in controlled biological soil. Int. Biodeterior. Biodegrad. 45, 49–55 (2000).

Janssen, P. H., Schuhmann, A., Mörschel, E. & Rainey, F. A. Novel anaerobic ultramicrobacteria belonging to the Verrucomicrobiales lineage of bacterial descent isolated by dilution culture from anoxic rice paddy soil. Appl. Environ. Microbiol. 63, 1382–1388 (1997).

Paço, A. et al. Biodegradation of polyethylene microplastics by the marine fungus Zalerion maritimum. Sci. Total Environ. 586, 10–15 (2017).

Mohan, A. J., Sekhar, V. C., Bhaskar, T. & Nampoothiri, K. M. Microbial assisted High Impact Polystyrene (HIPS) degradation. Bioresour. Technol. 213, 204–207 (2016).

Alaribe, F. O. & Agamuthu, P. Assessment of phytoremediation potentials of Lantana camara in Pb impacted soil with organic waste additives. Ecol. Eng. 83, 513–520 (2015).

Albertsson, A.-C., Andersson, S. O. & Karlsson, S. The mechanism of biodegradation of polyethylene. Polym. Degrad. Stab. 18, 73–87 (1987).

Tang, C.-C., Chen, H.-I., Brimblecombe, P. & Lee, C.-L. Morphology and chemical properties of polypropylene pellets degraded in simulated terrestrial and marine environments. Mar. Pollut. Bull. 149, 110626 (2019).

Rajakumar, K., Sarasvathy, V., Thamarai Chelvan, A., Chitra, R. & Vijayakumar, C. T. Natural weathering studies of polypropylene. J. Polym. Environ. 17, 191 (2009).

Sekhar, V. C. et al. Microbial degradation of high impact polystyrene (HIPS), an e-plastic with decabromodiphenyl oxide and antimony trioxide. J. Hazard. Mater. 318, 347–354 (2016).

Author information

Authors and Affiliations

Contributions

A.A. and A.F.S. conceptualised the study. A.F.S. designed and performed the experiments and analysed the data. A.A. and D.C. were involved in planning and supervising the work. A.F.S. drafted the manuscript in consultation with A.A. and D.C., in addition to designing the flow. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have influenced the work reported in this paper.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Samat, A.F., Carter, D. & Abbas, A. Biodeterioration of pre-treated polypropylene by Aspergillus terreus and Engyodontium album. npj Mater Degrad 7, 28 (2023). https://doi.org/10.1038/s41529-023-00342-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41529-023-00342-9