Abstract

Continuous passive motion (CPM) is an adjunct therapy to the standard postoperative rehabilitation regimen of joint injuries. The capability of real-time monitoring actual bending angle of knee joints is highly desired for treatment strategies of personalized postoperative rehabilitation and telemedicine. Here we report an intelligent CPM system for personalized rehabilitation and telemedicine based on the flexible and versatile ionotronic that possesses impressive mechanical properties (2.56 MPa tensile strength; 11.63 MJ m−3 toughness), fast self-recovery ability (60 s) and broaden environmental tolerance (−60–45 °C). Especially, the ionotronic responds fast and shows stability for cyclic strain sensing, ensuring the detection of actual joint bending angle with high sensitivity and reliability. The intelligent CPM system assembled with this ionotronic and a wireless transmitter was constructed, opening up a horizon for developing digital intelligent medical that can remotely monitor the movement of hospitalized/at-home patients who use CPM for personalized postoperative rehabilitation.

Similar content being viewed by others

Introduction

In the world, more than 300 million people suffer from joint injuries1. As an essential part of treatment plan, the objective of postoperative rehabilitation is to restore the injured joints to their nature biomechanical features2. To achieve the athletic functions as close as possible to original and pre-injury functions, postoperative recovery of injured joints needs a long-term process in the range of several weeks to months, or even years3. Currently, continuous passive motion (CPM), which provides constantly passive moves (do not require muscle work) of injured joint through a controlled range of motion to help patients restore joint movement, has become an adjunct therapy to the standard postoperative rehabilitation regimen of joint injuries.

CPM is a multi-task therapy with recreational activities that allow patients to exercise on the equipment while doing anything stationary like watching TV or listening to the radio, holding high promise for patients completing the therapy at home4. However, it still requires medical staff to assist patients in repetitive training, hindering personalized treatment and telemedicine. Instead to regularly traveling to rehabilitation center, it’s highly desired to develop a mobile, convenient training, and self-service device for the intelligent monitoring manipulation of joints at home. In addition, it will be better to accurately measure and record the angle of joint motion to quantify rehabilitation effects. Therefore, an intelligent CPM system linking the athletic information of a patient’s joints and compliance with doctor’s guidance is critically important for the rehabilitation and telemedicine with the advantages of safe, reliability, convenience, and effectiveness.

Herein, we developed an intelligent telemedicine CPM system for personalized rehabilitation and telemedicine based on a fast self-recovery and responsive flexible ionotronic. The flexible ionotronics assembled by intrinsically stretchable ionic conductive hydrogels, have received tremendous attention owning to widely applications in human-machine interface5, human activity monitoring6, and personal healthcare diagnosis7,8. However, in addition to the deformation-sensitive conductivity, the properties of self-recovery and responsive speed after repeated deformation are also critical factors9, especially for the application of CPM system in joint rehabilitation. Therefore, it is expected to develop an intelligent CPM system equipped with a flexible ionotronic that can maintain its conformal deformation and contact with moving/stretched joint, as well as synchronously provide fast responsive electric signals and rapid self-recovery performance within the maximum deformation of joint motion. Herein, this ionotronic is made of physically crosslinked organogel that is improved on our modified gel-nacre10,11, through the facile two steps of polymerization in salt solution and solvent-exchange process. This organogel showed good mechanical properties (tensile strength: 2.56 MPa; toughness: 11.63 MJ m−3, full recovery at 30% strain within only 60 s) and broaden environmental tolerance (−60–45 °C), that could meet the requirements for intelligent CPM system. Notably, the corresponding flexible ionotronic based on this organogel exhibits rapid self-recovery, fast response time, and outstanding cycling stability for strain sensing, ensuring the reliable detection of actual joint motion and bending angle. Particularly, an intelligent CPM system assembled with this organogel-based ionotronic and a wireless transmitter for personalized rehabilitation and telemedicine was constructed successfully, as illustrated in Fig. 1. The most important features of this system are the capability to real-time monitor and distinguish the angles of joint motions, as well as continuously output the real-time data to client terminal with the assistance of wireless Bluetooth transmission module. This system can realize personalized rehabilitation and telemedicine through improving doctor-centered postoperative care (subjectivity evaluation) with the capture of patient-centered recovery data and regard of surgical recovery.

a Schematic illustration of the intelligent exercise rehabilitation sensing system, including flexible ionotronic, wireless transmitter and CPM equipment, and the patient can use this intelligent CPM system at home. b Schematic illustrations of preparation process (free radical polymerization (i, ii) and solvent-exchange process (iii)) of organogel, and physical interactions (iv) within the organogel. c Photos demonstrate the brilliant mechanical properties of the organogel via showing the slingshot made of organogel could send the metal bullet flying by driving force of stretching-fast releasing process (Scale bar: 10 cm). d Photos of the anti-freezing behavior of organogel before and after being frozen at −60 °C (Scale bar: 1 cm). e Comparison of some features of typical gel-nacre, ionic hydrogel and organogel.

Results

The concept of organogel-based flexible ionotronic for intelligent CPM rehabilitation system

To achieve accurate, reliable, and convenient clinic treatment coupling with personalized treatment and at-home therapeutic exercises, the intelligent CPM system with real-time monitoring and telemedicine system is necessary. Herein, we proposed a tough and rapid self-recovery organogel-based sensor to meet the requirements. With a wireless transmitter, the real-time assessment of joint motion and instruction of postoperative rehabilitation training can be facilely obtained. As shown in Fig. 1a, the intelligent telemedicine CPM system consists of three core components, including flexible ionotronic, wireless transmitters, and CPM equipment. As the most important component, flexible ionotronic was manufactured with integration of a tough and rapid self-recovery organogel as a realizable ionic conductor, copper tape as conductive connection and medical adhesive tape (polyurethane, PU) as a protective layer for skin. Among them, organogel as the main sensor component of flexible ionotronic, has been designed to possess the comprehensive multifunctions, including tough mechanical properties, rapid self-recovery, fast response, conductivity, linear sensitivity, and broaden environmental tolerance. The organogel can be facilely connected with copper tape, then adhered to a patient joint with the help of medical PU tape and convert motion into voltage pulses.

The assembly process is simple and can be large-scaled readily. The electrical signals from organogel are then collected and converted into currents by means of a Bluetooth transistor, realizing telemedicine for patient rehabilitation. The transistor can be subsequently used to interface with microcontroller unit to form a remote monitoring. Most importantly, the highlighted features of our design for the intelligent CPM system are the ability to discriminate and monitor the angles of joint motions in real-time, and the ability to send the electrical signals wirelessly to mobile terminals. To this end, the doctor can achieve telemedicine for patients, and medical institutions are able to collect and analyze big data to improve doctor-centered postoperative care (subjectivity evaluation) by capturing patient-centered data regarding surgical recovery.

Preparation of organogel-based ionotronic

The organogels are required to satisfy the key requirements for the intelligent CPM system: (1) Be stretchable, soft and adhesive enough to realize conformal deformation with reciprocating motion of knee joint, avoiding limited strain motions that hinder rehabilitation exercise; (2) Be tough enough to support the repeated rehabilitation exercises with a large energy-dissipative capacity; (3) Rapid self-recovery, fast response and maintain the periodic stability and durability of sensitivity during effective and long-term practical treatment. Therefore, the organogel-based ionotronic was designed to be soft enough for high mechanical compliance with knee motion, tough enough for sensor assembly and manipulation, and rapid self-recovery for fast responsiveness and high sensitivity.

Reasonably, a facile two-step approach was proposed to synthesize the physically crosslinked organogel with intrinsically versatile properties via free radical polymerization and exchanging solvent of ionic hydrogel into glycerol solution (Fig. 1b). The ionic hydrogel was composed of biocompatible polyvinyl alcohol (PVA), poly(acrylic acid) (PAA) and LiCl, where PVA and PAA were chosen for constructing the similar “brick-and-mortar” microphase separation structure within tough gel-nacre reported in our previous work10, and LiCl mainly acted as salting out agent to enhance mechanical properties, and as ionic conductor to ensure motion responsiveness.

Firstly, ionic hydrogel could be obtained through gelation of homogeneously brine solution of LiCl (1.0–4.0 M), containing polymer (PVA), monomer (acrylic acid, AA), initiator (α-ketoglutaric acid), triggering by radical polymerization under UV light. The transparency of ionic hydrogel declined with the rise of salt concentration, and became semi-transparent when LiCl concentration was high than 2.0 M (Supplementary Fig. 1). Because LiCl induces the polymer chains to form microphase separation structure via salting out effect (Fig. 1b (i, ii))10,11,12. It is worth noting that the gel-nacre prepared through immersing PVA/PAA hydrogel into high concentrated LiCl solution (12.0 M) in our previously reported work achieved high modulus (1.4 MPa) and toughness (48.05 MJ m−3), owing to high concentration of LiCl solution promotes the formation of intensive microphase separation structure and condensed polymer networks. However, excessive modulus reduced the deformation capacity of gel-nacre, which cannot meet the requirements for flexible ionotronic. Instead, direct gelation in LiCl solution with relatively low concentration in this work can obtain ionic hydrogel with more desired mechanical property in an efficient way, which is suitable for intelligent exercise rehabilitation sensing system.

To further enhance toughness and endow broaden environmental tolerance performance, the as-prepared ionic hydrogel was soaked into glycerol solution for 10 h to obtain the organogel until no more volume and mass change was observed (Fig. 1b (iii)). As a nontoxic humectant and cryoprotectant, glycerol is a simple polyol compound with three alcohol hydroxyl groups13. The anti-freezing property of glycerol is attributed to strong hydrogen bonds in the binary solution, which disrupts ice formation and significantly reduces saturated vapor pressure14. Therefore, glycerol was applied for further enhancing the multi-environmental tolerance of the produced ionic hydrogel. During the soaking process, some water and salt ions in the ionic hydrogel could be displaced by glycerol due to osmotic pressure15, leading to gradually reduced conductivity (Supplementary Fig. 2) and improved transmittance16 (Supplementary Fig. 3). The optimized soaking time was set as 10 h after comprehensively considering the trade-off relationship between anti-freezing property, conductivity, and high mechanical performance to the organogel at the same time. Moreover, FTIR confirmed that the glycerol molecules can form more hydrogen bonds with polymer chains and water molecules (Supplementary Fig. 4), enhancing physical crosslinking within the organogel (Fig. 1b (iii, iv)). Besides, the swollen glycerol was able to strengthen the crystallization among PVA polymer chains, as verified in XRD patterns (Supplementary Fig. 5).

Accordingly, the abundant hydrogen bonds and microphase separation structure of polymer chains endowed the obtained organogel with suitable mechanical properties, including tensile stress (2.56 MPa), strain toughness (11.63 MJ m−3), anti-fatigue, rapid self-recovery ability (full recovery at 30% strain within only 60 s) and strong adhesion (Supplementary Figs. 6–9) for the application in intelligent CPM system. As illustrated in Fig. 1c, a slingshot assembled by a Y-shaped stick attaching organogel band can easily send a metal bullet (5.80 g) flying by driving force of large stretch and fast release process (Supplementary Video 1), demonstrating the impressive mechanical performances of organogel, such as superior elasticity, high toughness, and outstanding shape-recovery performance. In addition, the binary cryoprotectants (LiCl and glycerol) swollen in polymer networks synergistically endow the organogel with broaden environmental tolerances. The organogel could maintain the flexibility even under ultra-low temperature (−60 °C) (Fig. 1d). Therefore, the organogel exhibits more advantages than gel-nacre and ionic hydrogels, especially in rapid self-recovery, mechanical properties and environmental tolerance (Fig. 1e), which could satisfy the demands for the intelligent CPM rehabilitation system.

Mechanical properties of organogel

The optimized organogel shows very impressive mechanical characterizations, highly dependent on the concentration of LiCl and the immersion time of glycerol solution (Supplementary Fig. 10). By adjusting the concentration of LiCl solution (0–4.0 M) and immersion time (0–10 h), particularly, the sample with 3.0 M LiCl and immersion time of 10 h exhibited the largest 2.56 MPa tensile strength and 0.25 MPa Young’s modulus, which was 17.0 and 2.6 times higher than that of original hydrogel (0.15 MPa, 95.38 kPa), respectively. The large strength and propriate elasticity of this organogel can be highly matched with human tissue17. Moreover, the toughness of this organogel dramatically increased 120 times from 0.097 to 11.63 MJ m−3 as well. It worth noting that with the excessive LiCl, such as 4.0 M LiCl, the tensile stress, Young′s modulus, and toughness dramatically decreased to 0.23 MPa, 0.06 MPa, and 1.39 MJ m−3, respectively, due to the fact that excessive Li+ precipitate the polymers through phase separation induced by ions, which destroy the uniformity of organogel precursor (Supplementary Fig. 11). In a word, the optimized organogel can achieve the maximum fracture stress of 2.56 MPa with Young′s modulus of 0.25 MPa and toughness of 11.63 MJ m−3 when fixing 3.0 M LiCl concentration and immersing in glycerol solution for 10 h.

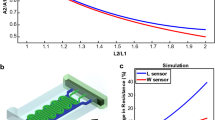

Further, the comprehensive mechanical properties of the organogel were better than other three kinds of hydrogels, even the tough gel-nacre that we have prepared in our previous work11. As shown in the Fig. 2, considering the application in intelligent CPM system, the organogel showed the most suitable mechanical performances. Both organogel and gel-nacre exhibited more significant mechanical properties than PVA/PAA hydrogel and ionic hydrogel. However, the difference between them was that the tensile stress and toughness of organogel were much higher than gel-nacre’s (Fig. 2a), while the Young’s modulus was much less (Fig. 2b). This is very important for the achievement of the ionotronic that is not only stretchable and soft enough for conformal deformation but also tough enough to support repeated rehabilitation exercises.

a, b Stress-strain curves and the corresponding tensile stress, Young’s modulus and toughness for PVA/PAA hydrogel, ionic hydrogel, organogel and gel-nacre. c Loading-unloading curves of successive cyclic tensile (5000) of organogel at a strain of 65% without resting between each cycle. d Energy dissipation of 5000 cyclic tests with 1, 10, 100, 1000, 3000, and 5000 cycles. e Loading-unloading curves of organogel at a strain of 30% with various resting time (1, 30, 60, 90 s). f Comparison of the recovery ratios of organogel and gel-nacre at a strain of 30% with different rest time (1, 30, 60, 90 s).

Noteworthy, the organogel presents fast-recovery and fatigue resistances. To evaluate it, 5000 successive cyclic tensile loading-unloading were carried out on the organogel at comparatively large strain of 65% (> 45%, the largest deformation of joint training18) without resting between each test (Fig. 2c). Comparing the 1st and 5000th cycle stretching of organogel, only a minimal of residual strain was found, indicating that the physical interaction of reversible bonds is temporarily damaged during stretching and then quickly rearrange and recover in the reloading process. The hysteresis loops during the initial cyclic loading indicate that the organogel could effectively dissipate energy. The hysteresis loop and the maximum tensile stress of the organogel decreased after the first cycle, then remained almost unchanged after the following successive and long-term cycles, and the corresponding energy dissipation tended to be stable within the 10 cycles (Fig. 2d). These results indicate that during the initial cycle of large strain, the organogel released its unreversible stored energy-dissipative capacity of 6.39 kJ m−3. Whereas, after the initial cycle, it demonstrated a more elastic behavior with almost identical energy-dissipation (3.14–3.30 kJ m−3). The special merits are derived from the fast recoverability of multiple reversible physical bonds, which impart the organogel with energy-dissipative capability while simultaneously maintaining fast self-recoverability after each successive cycle.

To quantitively explore the behavior of self-recoverability, the recovery ratio was calculated after selected time interval (0, 1…, 90 s) under a typical strain of 30% (average human joint activity range). As shown in Fig. 2e, only a minimal residual strain can be seen with very short resting time of 1 s, indicating the rapid self-recovery property of the organogel. Corresponding self-recovery rates for different periodic time were presented in Fig. 2f. Noticeably, after 30 s rest, the self-recovery rate of organogel could reach up to as high as 92%, moreover the hysteresis loop at strain of 30% could fully return to the original state after only 60 s rest. However, the self-recovery rate of gel-nacre only could reach 70% even after a long rest of 90 s. Compared with gel-nacre, the rapid self-recovery rate within 30 s of organogel can meet the requirement for continuously and highly efficient rehabilitation training system. It was due to the synergistic effects of reversibility of dynamic hydrogen-bonding topology and entanglement of polymers inside the organogel. However, the hysteresis loop at strain of 65% could not return to the original state even increasing resting time to 600 s, indicating the fast-recoverable and irreversible bonds within the organogel can only interact among themselves within a certain large deformation range. Beyond that range, unreversible sacrificial damages such as chain sliding, micro-domain dislocation, and even polymer chain breakage may occur.

Last but not least, as integrated CPM device, self-adhesiveness of the organogel is vital to be settled into circuit and directly connected with copper electrodes, medical bandage, and skin without any glue. The organogels also achieve strong, fast, and repeatable adhesiveness toward diverse substrates at room temperature, owing to abundant reversible hydrogen bonds formed between gel matrices and substrates19,20,21 (Supplementary Fig. 7). As shown in Supplementary Fig. 8, the organogel has good self-adhesion to both hard substrates (metal, glass) and soft surfaces (skin, medical PU film, rubber), not requiring any glue or extra energy, demonstrating a strong automatic adhesion. The adhesion strength maintained even after 5 cycles of sticking and tearing. Meanwhile, the adhesion strength exhibited the positive correlation (Supplementary Fig. 9) with temperature due to the high mobility of polymer chains and glycerol22. Consequently, this good adhesion property makes the organogel able to be applicated in CPM system to keep stable adhesion during joint motion (Supplementary Video 2).

Mechanosensing behavior of organogel for intelligent CPM system

During stretching process, the resistance (R) of organogel (R = ρL/S, where ρ is specific resistivity, L denotes length, and S stands for cross-sectional area) gradually increased with strain owing to the rise of L and descent of S (Fig. 3a, b), resulting in gradually decreasing conductivity. Benefiting from fast self-recovery capability, the conductive pathway in the organogel can be fast and completely recovered once unloading the strain, leading to reduced resistance. Consequently, the organogel can be applied as a rapid self-recovery and responsive strain sensor via monitoring the change of resistance23. Thus, the mechanosensing behavior of organogel is further evaluated. The gauge factor (GF) was used to evaluate the sensitivity for the organogel-based sensor, which is defined as GF = (∆R/R0)/ɛ (ΔR = R−R0, R and R0 stand for the resistance with or without applied external force, respectively, ε means tensile strain). It can be observed from Fig. 3b that organogel presented a relatively high sensing sensitivity at a broad strain range (0–1250%) with three liner (R2 ≥ 0.99) sections: a GF of 1.50 for 0–200% strain, a GF of 3.15 for 200–400% strain and a GF of 4.14 for 400–1250% strain. Considering the CPM machine works under different speeds and a stepwise amount of training in the rehabilitation treatment of patients, we analyzed the sensing performances of the sensor under different strains and frequencies during stepwise cycles. Thus, to investigate sensing stability and durability of the sensor, the periodic stretching-releasing tests with strains of 5–60% were conducted in Fig. 3c. The electrical sensing outputs could be precisely perceived under different strains and kept stable values under a certain stain, showing good and stable strain-responsiveness. Impressively, this good sensing performance of organogel could be maintained after being stored at 25 °C as long as six months. In addition, the organogel could accurately monitor and distinguish various frequencies from 0.05 to 0.5 Hz (Fig. 3d), and exhibited prominent reversibility and rapid recovery during the stretching-holding processes with strains from 0 to 60% (Supplementary Fig. 12). To evaluate the response time of organogel-based sensor, we recorded cyclic and reversible changes of resistance under periodic stretching-releasing (0–60%). Upon loading a strain of 5%, the responsive time appeared to be very short within 300 ms (Fig. 3e) with the recovery time of 400 ms. This is comparable to the healthy people’s reaction time (100–300 ms)24.

a The strain sensing mechanism of the organogel-based sensor during the stretching and recover process. b ΔR/R0 value of organogel sensor versus the applied strain. c Relative resistance response of organogel senor stored for half a year (25 °C) under different strains. d Relative resistance response of organogel senor at different frequencies under a strain of 60%. e Response and recovery time. f Stability and durability test over successive 2000 cycles (tensile rate 200 mm min−1, 60% strain). g, h Weight changes and conductivity changes of organogel, ionic hydrogel, and PVA/PAA hydrogel after being placed in 25 °C with test time. i Conductivity of organogel in high (45 °C) and low (−60 °C) temperature environment.

Considering that leg bearing capacity is also an important rehabilitation parameter for patients to get out of bed and walk independently without rehabilitation equipment, we carried out a long-term cyclic loading experiment on organogel to simulate the real-time monitoring of the patient’s joint movement and leg bearing capacity by this system (Fig. 3f). Although the initial resistance drifts slightly, the sensor presented rapid sensing response during 2000 cycles under a successive cyclic strain, demonstrating remarkable durability and impressive repeatability of the sensor during long-term loading-unloading processes.

This remarkable sensing stability and reversibility in a long-term service process can be attributed to the good water-retention capability and conductive stability of the organogel. The anti-dehydration is very important for the gel-based devices that can be used in the open environment for a long time without serious degradation of mechanical properties and electricity performance15. To explore the practical application scope of the organogel, we further systematically investigated the environmental tolerance of organogel under diverse harsh temperature and storage conditions. It could be anticipated that the abundant existence of two kind of cryoprotectants (LiCl and glycerol) in the organogel would synergistically bring anti-dehydration and anti-freezing capabilities to the organogel. In water retention experiments, the long-term anti-dehydration behaviors of various gels at ambient temperature (25 °C and 45 °C) was evaluated. As depicted in Fig. 3g and Supplementary Fig. 13, the organogel exhibited a slight increase in weight ratio after airing at 25 °C for two days and then maintained stable, while the glycerol-free ionic hydrogel shrunk severely due to serious water evaporation. The increase here is ascribed to the low vapor pressure of glycerol and its strong hydrogen bonding with polymer networks and water molecules, which synergistically contributed to reducing water evaporation (i.e., water holding capacity) and absorbing moisture from air14. In a high temperature (45 °C) environment, organogel showed a slight weight decrease due to a little water evaporation (Supplementary Fig. 14a). Despite all this, organogel still demonstrated much more stable water-retention capability than ionic hydrogel and PVA/PAA hydrogel.

In addition to daily dehydration, another challenge for hydrogels needs to be addressed is low-temperature icing. As expected, the organogel displayed good flexibility to be twisted at will and could be easily bent and twisted after freezing for 2 h under a subzero temperature as low as −60 °C (Fig. 1d). As verified in the DSC curve (Supplementary Fig. 15), no apparent freezing peak was detected during cooling process of organogel, even after cooling to −80 °C, indicating that no ice crystals formation and anti-freezing capability of the organogel. While the ionic hydrogel was frozen completely, which became stiff and lost flexibility owing to the formation of ice crystals. This is reasonable because LiCl and glycerol swollen in organogel synergistically prevent water from freezing by interrupting the hydrogen bonds in ice crystals.

Accordingly, the conductivity of the gels would be influenced by temperature change due to the fluctuation of water content. Notably, the conductivity of organogel was about 5 mS m−1, much higher and more stable than that of PVA/PAA hydrogel and ionic hydrogel in a storage period as long as 7 days. However, ionic hydrogel and PVA/PAA hydrogel showed a decrease of 99.1% and 99.7% of conductivity, respectively, after two days in ambient condition (25 °C and 65 RH%) (Fig. 3h). Besides, when the temperature reaching 45 °C, the organogel showed a descent of the conductivity and maintained a stable value of 2 mS m−1 after 4.5 h (Supplementary Fig. 14b), owing to water evaporation from the hydrogel under high temperature. Moreover, the organogel also presented stable conductivity as 2 mS m−1 even at low temperature of −60 °C (Fig. 3i), which still can be served as a conductor connection in a closed circuit to light up a light-emitting diode (LED) (Supplementary Fig. 14c).

In a word, these results indicate that the organogel possesses optimal capabilities of anti-dehydration, anti-freezing and stable conductivity, ensuring mechanical flexibility, as well as stable and reversible sensing ability for the ionotronics during long-term service (Supplementary Tables 1 and 2) suggesting the great potential of organogel-based stretching sensor in timely monitoring strain changes during cyclic motion that is important in exploration of intelligent CPM system.

Wireless transmission and remote monitoring for intelligent CPM system

Owing to impressive mechanical properties, environmental tolerances and prominent sensor capabilities, the durable and resilient organogel enables to be employed as flexible ionotronic for assembling intelligent CPM system. We successfully developed an intelligent rehabilitation sensing and telemedicine system based on the organogel-based sensor. The sensing signals of CPM sensors can be recorded, analyzed, and then sent to the mobile terminal by a wireless transmitter, which can be synchronized to user interface via Bluetooth, as illustrated in Fig. 4a in detail. The microcontroller unit (MCU, E104) is mainly composed of microprocessors, Bluetooth, and LEDs. Bluetooth module was used to add networking capabilities to the existing devices. The powerful on-chip processing and storage capabilities of MCU enable the integration of CPM sensors through general-purpose input/output port and then receive and send digital/analog signals for LED or other modules. All modules were installed on a mounting plate for convenience, with general-purpose output connected with LEDs to make debug process. Upon testing, resistance changes could be collected and processed by analog-to-digital converter in the processors. Therefore, sensing responses of CPM sensor can be transmitted to mobile terminal, and then synchronized to user interface.

a Circuit scheme showing signal transduction, processing, and wireless transmission from sensing system to mobile terminal. b Relationship between bending angle and arc length during knee rotation. c Photos of patient’s in situ monitoring by passive motion at different angle with the assembled organogel sensors on intelligent CPM machine in Xi’an Honghui Hospital (Scale bar: 50 cm). d Relationships between measured angle and calculated angle of CPM system at different bending angles, respectively. e, f Angle and relative resistance changes of joint movement assembled of intelligent CPM system.

Upon bending, the relationship between resistance changing rate of these model-based sensors and bending angle can be expressed as (Fig. 4b):

Merge formula 1, 2, 3 and formula 4:

Merge formula 2 and formula 5:

where α is the angle of the knee, r is the radius of the knee, L0 is the perimeter of individual’s straight knee, L1 is the perimeter of individual’s straight knee after bending, R is the resistance during the bending of knee.

The stretchable intelligent CPM sensor system provides multi-dimensional sensing capabilities, which can monitor a full range of human motion from tiny vibrations to large limb deformations and long-term exercises. Figure 4c, d presents the photos of practical intelligent CPM sensor system mounted on an individual’s knees with different bending angles, and the corresponding data obtained from the intelligent CPM system, indicating the good linear relationship between the bending angle and ∆R/R0. Figure 4e, f clearly presented the angle changes from 0° to 90° according to the resistance changes, demonstrating the stable and reversible sensing performance during the operation processes. Consequently, this intelligent CPM sensor system realized the translation between resistance changes and bending angles, which is a good guideline for doctors to fully understand the situation of rehabilitation and adjust the training program timely. In addition to knee joint, the organogel-based sensor also can be used in ankle joint (Supplementary Fig. 16), which also exhibits a stable electrical output during ankle pump.

Most importantly, this intelligent CPM sensor system based on organogel make home rehabilitation training possible. By fixing the organogel-based sensor with a knee-ankle-foot orthosis, which is used to assist the patient to stand and walk through the movements at knee, ankle, and foot joint. The bending angle of knee joint could be detected accurately, as shown in Fig. 5a. As a result, patients can be trained under certain bending angle at home (Fig. 5b), such as 30°, 60°, 90°, and 120°, and convey the information to doctors with the help of a Bluetooth transmitter without going to hospital frequently. Figure 5c depicted the photographs of intelligent CPM system on knee, and showed the data windows before and after bending. It can be observed that bending angles can be displayed on the mobile terminal in real time, when patient performs knee rehabilitation training. Besides, the capability to provide continuous physiological data permits the development of treatment plans and athlete-training programs to potentially alleviate injuries. The electrical signal of the sensor system during skipping and running was detected in Fig. 5d, e and Supplementary Video 3, in which the bending angles can be vividly seen in the data windows in real time, showing considerable potential in monitoring the rehabilitation processes and situations. In a word, this intelligent telemedicine sensing system based on organogel is expected to be applied in online elderly health assessment, motor function evaluation, and rehabilitation training guidance.

a Photos of actively motion at home with various angles (Scale bar: 10 cm) b Angle changes curve calculated according to Fig. 4d. c Photos of single-leg squats and corresponding data windows with remote and wireless (Wi-Fi) monitoring system before and after bending 90° (Scale bar: 5 cm). d Real-time monitoring of bending angles received wirelessly by a smartphone with progressively increasing the cycle number of single-leg squats (Scale bar: 30 cm). e Specific data windows for bending angles at different time when running outdoors (Scale bar: 30 cm).

Discussion

In summary, we report an intelligent telemedicine CPM system for personalized rehabilitation and telemedicine. The flexible ionotronic is made of organogel which is designed to possess versatile multifunctions, including good mechanical properties, rapid self-recovery, fast response, conductivity, linear sensitivity, and remarkable environmental tolerance. The integration of rich and strong hydrogen bonds, entanglement of polymer chains, as well as microphase separation structure in an organogel, achieves a balance of flexibility, stretchability, toughness, and rapid self-recovery. We believe the intelligent sensing system with the function of angle detection can be used as a wirelessly remote interactive device to provide special population (doctors, athletes, patients, etc.) with precise and customized services, and has huge potential to improve doctor-centered postoperative care (subjectivity evaluation) by capturing patient-centered recovery data regarding surgical recovery. Furthermore, the intelligent system exhibits a great potential to detect movement during co-deformation, large deformation with high linear sensitivity, such as wearable electronics, human-machine interfaces, soft robotics, and angle correction fields.

Methods

Materials

Acrylic acid (AA), polyvinyl alcohol, Mw ~205,000 (PVA), and α-ketoglutaric acid were purchased from Shanghai Macklin Biochemical Co., Ltd. Lithium chloride anhydrous (AR) was obtained from Tianjin Kemiou Chemical Reagent Co., Ltd. Glycerol (AR) was obtained from Tianjin Fuyu Fine Chemical Co., Ltd.

Synthesis of organogel

Organogel was synthesized through a facile two-step approach. First, PVA polymer was dispersed in deionized water at 95 °C for 6 h. The viscous and clear solution was cooled down to room temperature (25 °C), followed by mixing with acrylic acid (AA) monomer, LiCl, and α-ketoglutaric acid (photoinitiator, 0.5 wt% as to AA monomers). This mixture was later kept in a vacuum chamber for 10 min to remove trapped air, followed by transferring to a glass cell (100 × 100 × 2 mm3) separated with a 2-mm-thick silicone spacer. The entire package could be cured under UV (365 nm, 40 W) for 6 h at room temperature (25 °C) to obtain ionic hydrogel. Second, the organogel was obtained via soaking the ionic hydrogel into glycerol for 10 hours. All gels derive from the same experiment and that they were processed in parallel.

Characterizations

Fourier transform infrared (FTIR) spectrum was collected at ambient temperature using a Vertex70 FTIR spectrometer (Bruker, Germany) over a wavelength ranged from 500 to 4000 cm−1 after 64 scans at 2 cm−1 resolution. X-ray diffraction (XRD) patterns of the gels were obtained at room temperature on a Smart Lab 9 kW (Rigaku, Japan), using Cu-Kα radiation (λ = 1.5406 Å) in the range of 2θ = 10–90° and the scanning rate was set at 0.02° s−1. The freezing and ice melting temperatures of organogel were obtained using DSC-25 (TA, USA). The prepared organogel was cooled from 20 °C to −80 °C at a rate of −5 °C min−1 and then heated to 20 °C. The mechanical tests were conducted through a tensile machine (CMT4304, Sansi, China). For tensile test, a 500 N load cell was used, and the upper clamp was pulled by the load cell at a constant velocity of 200 mm min−1. Nominal stress is obtained by dividing the load force with the measured cross-sectional area. Nominal strain could be obtained by dividing absolute change in length (Δl) with original length (l0). Elastic modulus was calculated from the slope at 0–10% of strain. Dissipated energy or toughness (hysteresis loop: J m−3) was calculated by integrating the stress-strain curve of loop. For lap shear adhesive testing, organogel was directly adhered to various substrates to form a junction contact area (10 × 10 mm2) (Supplementary Fig. 6). The lap joint was slight pressurized with a finger for 30 s, then the ends of the substrate and organogel were clamped to the tensile machine (CMT4304, Sansi, China) for testing. The lap shear test was performed at a shear velocity of 100 mm min−1.

Data availability

The data that support the plots within this paper and other findings of this study are available from the corresponding authors upon reasonable request.

Code availability

The underlying code for this study is not publicly available but may be made available to qualified researchers on reasonable request from the corresponding author.

References

James, S. L. et al. Global, regional, and national incidence, prevalence, and years lived with disability for 354 diseases and injuries for 195 countries and territories, 1990-2017: a systematic analysis for the global burden of disease study 2017. Lancet 392, 1789–1858 (2018).

Place, E. S., Evans, N. D. & Stevens, M. M. Complexity in biomaterials for tissue engineering. Nat. Mater. 8, 457–470 (2009).

Bowyer, A. J. & Royse, C. F. Postoperative recovery and outcomes - what are we measuring and for whom? Anaesthesia 71, 72–77 (2016).

Fiore, J. F. & Feldman, L. S. Tracking postoperative recovery-making a case for smartphone technology. JAMA Surg. 155, 130–130 (2020).

Dobashi, Y. et al. Piezoionic mechanoreceptors: Force-induced current generation in hydrogels. Science 376, 502–507 (2022).

Zhao, Y. et al. Somatosensory actuator based on stretchable conductive photothermally responsive hydrogel. Sci. Robot. 6, eabd5483 (2021).

Niu, Y. et al. The new generation of soft and wearable electronics for health monitoring in varying environment: From normal to extreme conditions. Mater. Today 41, 219–242 (2020).

Liu, W. et al. A temperature responsive adhesive hydrogel for fabrication of flexible electronic sensors. NPJ Flex. Electron. 6, 68 (2022).

Sun, W. et al. Molecular engineering of metal coordination interactions for strong, tough, and fast-recovery hydrogels. Sci. Adv. 6, eaaz9531 (2020).

He, Y. et al. Saline tolerant tough-yet-strong fiber-reinforced gel-nacre for soft actuator. Chem. Eng. J. 446, 137091 (2022).

Zhao, X. et al. Puncture-resistant hydrogel: Placing molecular complexes along phase boundaries. ACS Appl. Mater. Interfaces 11, 19421–19428 (2019).

Chen, G. et al. Highly tough supramolecular double network hydrogel electrolytes for an artificial flexible and low-temperature tolerant sensor. J. Mater. Chem. A 8, 6776–6784 (2020).

Christoph, R., Schmidt, B., Steinberner, U., Dilla, W. & Karinen, R. Ullmann’s Encyclopedia of Industrial Chemistry (Wiley-VCH, 2006).

Sun, D. et al. Transparent, self-adhesive, conductive organohydrogels with fast gelation from lignin-based self-catalytic system for extreme environment-resistant triboelectric nanogenerators. Adv. Funct. Mater. 32, 2201335 (2022).

Chen, F. et al. Rational fabrication of anti-freezing, non-drying tough organohydrogels by one-pot solvent displacement. Angew. Chem. Int. Ed. 57, 6568–6571 (2018).

Liao, H., Guo, X., Wan, P. & Yu, G. Conductive MXene nanocomposite organohydrogel for flexible, healable, low‐temperature tolerant strain sensors. Adv. Funct. Mater. 29, 1904507 (2019).

Zhou, Y. et al. Highly stretchable, elastic, and ionic conductive hydrogel for artificial soft electronics. Adv. Funct. Mater. 29, 1806220 (2019).

Wessendorf, A. M. & Newman, D. J. Dynamic understanding of human-skin movement and strain-field analysis. IEEE Trans. Biomed. Eng. 59, 3432–3438 (2012).

Liao, M. et al. Wearable, healable, and adhesive epidermal sensors assembled from mussel-inspired conductive hybrid hydrogel framework. Adv. Funct. Mater. 27, 1703852 (2017).

Mo, F. et al. A highly stable and durable capacitive strain sensor based on dynamically super‐tough hydro/organo-gels. Adv. Funct. Mater. 31, 2010830 (2021).

Li, G. et al. A stretchable and adhesive ionic conductor based on polyacrylic acid and deep eutectic solvents. NPJ Flex. Electron. 5, 23 (2021).

Han, L. et al. Mussel-inspired adhesive and conductive hydrogel with long-lasting moisture and extreme temperature tolerance. Adv. Funct. Mater. 28, 1704195 (2018).

Yang, C. & Suo, Z. Hydrogel ionotronics. Nat. Rev. Mater. 3, 125–142 (2018).

Cai, Y. et al. Mixed-dimensional MXene-hydrogel heterostructures for electronic skin sensors with ultrabroad working range. Sci. Adv. 6, eabb5367 (2020).

Acknowledgements

The authors acknowledge the financial support by funding from National Key R&D Program of China (2022YFE0104200), the International Science & Technology Key Research and Development Program of Shaanxi (2020KWZ-006), Project of Foreign Experts (G20200241017), Chinese and Cee Countries Universities Joint Education Program (202015), National Natural Science Foundation of China (22005103, 11674263), the Joint Research Funds of Department of Science and Technology of Shaanxi Province and Northwestern Polytechnical University (2020GXLH-Z-025), Special Foundation of Shaanxi Provincial Department of Education (20JK0543). Natural Science Basic Research Program of Shaanxi (Program No.2023-JC-QN-0134). Prof. Y. M. Chen and Dr. Y. Yang are grateful to the startup fund from Shaanxi University of Science and Technology. J. Tang and Y. He are grateful to Innovative Talents International Cooperative Training Project from China Scholarship Council (Grant No. 202110470006 and No. 202110470001).

Author information

Authors and Affiliations

Contributions

All authors contributed to the preparation of this manuscript. Conceptualization: Y.C. and J.T. Methodology: Y.C., J.T., and Y.Y. Investigation: J.T., Y.H., D.X., W.Z., and Y.H. Visualization: J.T., H.S., and Y.Z. Supervision: Y.C., Y.Y., and K.Z. Writing—original draft: J.T., Y.H., and D.X. Writing—review & editing: Y.C., Y.Y., and K.Z.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tang, J., He, Y., Xu, D. et al. Tough, rapid self-recovery and responsive organogel-based ionotronic for intelligent continuous passive motion system. npj Flex Electron 7, 28 (2023). https://doi.org/10.1038/s41528-023-00259-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41528-023-00259-y