Abstract

Structural phase-change materials are of great importance for applications in information storage devices. Thermally driven structural phase transitions are employed in phase-change memory to achieve lower programming voltages and potentially lower energy consumption than mainstream nonvolatile memory technologies. However, the waste heat generated by such thermal mechanisms is often not optimized, and could present a limiting factor to widespread use. The potential for electrostatically driven structural phase transitions has recently been predicted and subsequently reported in some two-dimensional materials, providing an athermal mechanism to dynamically control properties of these materials in a nonvolatile fashion while achieving potentially lower energy consumption. In this work, we employ DFT-based calculations to make theoretical comparisons of the energy required to drive electrostatically-induced and thermally-induced phase transitions. Determining theoretical limits in monolayer MoTe2 and thin films of Ge2Sb2Te5, we find that the energy consumption per unit volume of the electrostatically driven phase transition in monolayer MoTe2 at room temperature is 9% of the adiabatic lower limit of the thermally driven phase transition in Ge2Sb2Te5. Furthermore, experimentally reported phase change energy consumption of Ge2Sb2Te5 is 100–10,000 times larger than the adiabatic lower limit due to waste heat flow out of the material, leaving the possibility for energy consumption in monolayer MoTe2-based devices to be orders of magnitude smaller than Ge2Sb2Te5-based devices.

Similar content being viewed by others

Introduction

Phase-change materials have long been studied for their applications in thermal energy storage1 and information storage.2,3 For thermal energy storage, water is one of the most common phase-change substances due to its large heat of fusion. For information storage, the most widely used phase-change material is Ge2Sb2Te5 alloy,2 which can exist in both amorphous and crystalline forms, each having different optical and electrical properties.4,5 The fast and reversible phase transition in Ge2Sb2Te5 alloys can be achieved by Joule heating,5 and this process can be employed in nonvolatile phase-change memory with lower programming voltages and higher memory densities than mainstream nonvolatile memory technologies.2,3,6,7

Some layered and two-dimensional (2D) materials including MoTe2 have been reported or predicted to exhibit structural phase changes during chemical processes,8,9 temperature changes,10,11,12,13,14 and tensile strains.15,16 Some single layer transition metal dichalcogenide (TMD) monolayers, including monolayer MoTe2, can exist in a semiconducting trigonal prismatic state found in the bulk 2H structure, a semimetallic distorted octahedral state found in the bulk 1T′ monoclinic and orthorhombic (sometimes referred to as Td) phases, and possibly other structures. These are structures of the individual single layers, and not merely associated with different stacking sequences of the bulk material. The monoclinic and orthorhombic phases exhibit similar single layer structure and are distinguished by slightly different stacking arrangements.

Our recent theoretical work suggests that a structural phase transition can be driven in specific monolayer materials through electrostatic gating,17 including monolayer MoTe2 and potentially TaSe2. This transition has been reported to occur in subsequent experiments employing ionic liquids to achieve the requisite charge densities.18 In the case of monolayer MoTe2, the transition is between the single layer structures of the 2H and 1T′ phases. The switching between these two different phases can be achieved through electrostatic gating, allowing excess charge to enter or leave the monolayer.17 Note that the transition is driven by the addition or removal of charge from the material rather than the electric field associated with gating, i.e., a charge neutral monolayer in an applied field will not necessarily exhibit the effect. This mechanism is fundamentally distinct from thermally driven phase transitions. One can also envision devices that manipulate both temperature and charge independently to efficiently manipulate the stable phase and kinetics of the transition.

Other studies have reported that transitions between charge density wave (CDW) states on the (001) surface of layered TaS2 occur with changes in temperature.19,20 In addition, electrostatic gating has been reported to exhibit some control over the transition temperatures.21 While these CDW transitions are largely electronic rather than structural, their existence, and manipulation in layered materials suggests there may also be other materials and mechanisms for nonvolatility in very thin materials. However, practical widespread use of these CDW transitions for electronic applications may be limited due to the low transition temperatures between phases, which usually occur below room temperature.

For nonvolatile information storage applications, heat dissipation to the surroundings produced during the phase change can place an undesirable practical limit in achieving high device densities on a chip.22 Research into lower energy consumption phase change memory is active and ongoing,23,24,25 with efforts to scale down device sizes. As the spatial dimension of thermally controlled phase change materials decreases, the thermal resistances of adjacent interfaces play a dominant role in energy consumption,22,26 so that decreasing device size alone does not allow one to approach the adiabatic lower limit of energy consumption. We predict electrostatically driven phase change materials to consume less energy and dissipate less heat to the surroundings, therefore offering advantages over thermally driven phase change materials for scaling down device sizes.

In this work, we investigate the theoretical limits of the energy consumption properties of electrostatically driven phase transitions and compare them to thermally driven phase transitions. Taking monolayer MoTe2 and Ge2Sb2Te5 alloys as examples, we compute theoretical bounds on energy consumption per unit volume for electrostatically-induced and thermally-induced phase changes, employing density functional theory27,28 based approaches to compute the thermal and electrical properties. We find that the electrostatically driven phase transition in monolayer MoTe2 at room temperature has the potential to consume 9% of the energy per unit volume of the adiabatic lower limit of the thermally driven phase transition in Ge2Sb2Te5 alloys. In addition, the experimentally measured energy consumption of a Ge2Sb2Te5-based device is several orders of magnitude larger than the adiabatic lower limit, leaving the possibility for monolayer MoTe2 to consume several orders of magnitude less energy than state-of-the-art Ge2Sb2Te5-based devices. Furthermore, because monolayer MoTe2 consumes less energy on a per-volume basis than Ge2Sb2Te5-based devices, and because MoTe2 devices would be thinner than Ge2Sb2Te5-based devices, the savings from reduced volumes has the potential to further reduce the energy required to operate MoTe2-based devices, as well as enable device miniaturization.

Investigations into the kinetics or speed of phase transitions in monolayer MoTe2 and other monolayer materials are ongoing, but much remains unknown about the kinetics of these phase transitions. Experimental studies of thermal phase transitions in MoTe2 have been reported to occur on timescales of several hours at high temperatures,12,14 while other reports suggest that the kinetics can occur on timescales of minutes or less at ambient temperatures and below.16,18

Results

Phase diagram of monolayer MoTe2 under electrostatic gating

Using the DFT-based approach developed in ref. 17, we compute the voltage-excess charge phase diagram of monolayer MoTe2 under electrostatic gating. This DFT-based approach models the parallel plate capacitor structure shown in Fig. 1a to gate the monolayer. In this capacitor structure, a dielectric medium of thickness d is sandwiched between the monolayer and a metal plate (i.e., gate electrode). The Mo atoms in the monolayer (colored black in Fig. 1a) are located a distance s away from the dielectric and a gate voltage V is applied to this system. Upon electrostatic gating, excess charge will accumulate in the monolayer, potentially inducing a structural phase transition. Importantly, charge drives the transformation in this process, and not electric field—a monolayer of MoTe2 held at fixed charge as the bias voltage varies will not necessarily undergo the same phase transformation. Because the computational approach used here is described in detail in ref. 17, we give only a quick review of the method; details on the computational scheme can be found in the reference.

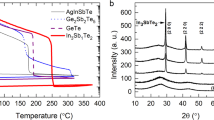

Structural phase transition in monolayer MoTe2 induced by electrostatic gating. a Illustrates a capacitor structure used to gate the monolayer material to induce a structural phase transition. A dielectric medium of HfO2 of thickness d = 4.5 nm is sandwiched between the monolayer and a gate electrode, upon which a gate voltage V is applied. The gate electrode is chosen to be aluminum of work function W = 4.08 eV. Mo atoms are shown in black, while Te atoms are shown in red. The distance between the Mo atoms in the monolayer and the dielectric is s = 3.78 Å. b Computed gate voltage V changing with the excess charge density σ in the monolayer. Note that we plot excess charge density instead of excess charge Q on the x axis. Black and red horizontal dashed lines represent the transition voltage at T = 0 K and T = 300 K, respectively. Note that the transition voltages are lower in magnitude at higher temperatures, as found from a modified form of the Clausius–Clapeyron relation, Eq. (9). Also shown are shaded blue, red, and green regions. The blue-shaded region indicates values for which 2H-MoTe2 is stable at T = 300 K, the red-shaded region indicates that a mixed 2H-1T′ phase is most stable at T = 300 K, and the green-shaded region indicates that 1T′-MoTe2 is most stable at T = 300 K

In this approach, the total energy E(Q) of the system when excess charge Q remains fixed on the monolayer consists of three parts:

Here Emono is the energy of the monolayer, s is a fixed parameter specifying the distance between the dielectric, and the Mo atoms in the monolayer (see Fig. 1a), −QW is the energy to move charge Q from the gate electrode of work function W to the dielectric, and Q2/2C is the energy stored in the dielectric, which has capacitance C. The term Emono in the total energy calculation accounts for Fermi energy changes when electrons are added or removed from the monolayer, so that Eq. (1) does not require an additional term to account for the quantum capacitance. Additional details on the calculation of Emono are included in the Supplementary Information.

To create the voltage-excess charge phase diagram shown in Fig. 1b, we find the stationary points of the grand potential ΦG,

where T is temperature and S is the total entropy. The stationary points are found at T = 0, such that

The solutions to Eq. (3) provide the points (Q, V) needed to generate a voltage-excess charge phase diagram. Taking the monolayer to be MoTe2, the gate electrode to be aluminum of work function W = 4.08 eV, the distance between the Mo atoms and the dielectric to be s = 3.78 Å, and the dielectric medium to be HfO2 of thickness d = 4.5 nm and dielectric constant k = 25, we compute the gate voltage-excess charge diagram for monolayer MoTe2, as shown in Fig. 1b. Note that in Fig. 1b, the excess charge density σ is plotted in e/f.u. instead of total excess charge Q. Here, e is the elementary electron charge; positive values of σ correspond to the removal of electrons from the monolayer, while negative values correspond to the addition of electrons to the monolayer.

Throughout this work, the monolayer is assumed to be under the mechanical constraint of constant zero stress. This condition is expected to hold when any friction between the monolayer and substrate is small enough that the monolayer can relax freely on the substrate. If friction between the monolayer and substrate is large, a mechanical constraint of constant lattice can be used, where the lattice constants of the material are fixed across the transition. In the fixed lattice case, the phase boundary of MoTe2 will change, so that roughly twice as much charge is required to drive the phase transition, as discussed in ref. 17. This means that up to four times as much energy will be required to drive the phase transition. This constant lattice case would therefore result in an energy consumption that is roughly 40% of the adiabatic lower limit of Ge2Sb2Te5 energy consumption. However, we again emphasize that this is orders of magnitude lower than the experimentally reported values of Ge2Sb2Te5 energy consumption, due to the fact that no waste heat generated by Joule heating is involved in the phase transformation process.

In Fig. 1b, the blue curve represents 2H-MoTe2, which is discontinuous at σ = 0 due to the band gap of semiconducting 2H-MoTe2, and the green curve represents semimetallic 1T′-MoTe2. Two zero-temperature transition gate voltages \(V_t^1(T = 0{\kern 1pt}\,{\mathrm{K}}) = - 1.6{\kern 1pt} {\mathrm{V}}\) and \(V_t^2(T = 0{\kern 1pt}\,{\mathrm{K}}) = 4.4{\kern 1pt} {\mathrm{V}}\) are depicted by the black horizontal dashed lines. Two T = 300 K transition gate voltages \(V_t^1(T = 300{\kern 1pt}\,{\mathrm{K}}) = - 1.1{\kern 1pt}\,{\mathrm{V}}\) and \(V_t^2(T = 300{\kern 1pt}\,{\mathrm{K}}) = 3.6{\kern 1pt}\,{\mathrm{V}}\) are depicted by red horizontal dashed lines. The transition voltages at non-zero temperatures are computed using a modified form of the Clausius–Clapeyron relation, Eq. (9). These calculations are described in Section “Impact of non-zero temperature on the phase transition induced by electrostatic gating”, as well as the Supplementary Information. An important point is that at non-zero temperatures, the transition voltages become lower in magnitude, therefore reducing the amount of electrostatic energy required to drive a phase transformation.

Because we are interested in applications to phase-change memory devices which operate at roughly room temperature, we indicate in Fig. 1b the phase stability properties at T = 300 K. Between the two T = 300 K transition voltages, semiconducting 2H-MoTe2 has lower energy and is more stable; this is depicted by blue shading within this region. Outside this range, semimetallic 1T′-MoTe2 is more thermodynamically favorable; this is depicted by green shading. Between the 2H and 1T′ stability regions, we predict a coexistence of 2H and 1T′ in what is labeled a ‘Mixed’ phase region; this is depicted by red shading in Fig. 1b. When the gate voltage increases or decreases beyond the positive or negative transition voltage, a transition from 2H phase to 1T′ phase occurs if done sufficiently slowly for the transformation to occur. Rapid increases in gate voltage could move the material onto the metastable portions of the phase diagram. However, the detailed analysis of the kinetics involved in changing phase between 2H and 1T′ is beyond this work. We therefore assume thermodynamic equilibrium throughout and a smooth transition from the 2H to 1T′ phase along a constant voltage path in the mixed-phase region. The nature of the mixed phase of MoTe2 was recently studied using a phase-field microelasticity model.29

In addition, we point out that in general, the transition voltages depend on the dielectric medium used and the dielectric thickness. In particular, the transition voltage for the device in Fig. 1a has the following dependence on the dielectric thickness d,

where Emono, 2H is the energy of the 2H phase monolayer, Q′ is the value of charge at the onset of the mixed phase region, \(\epsilon _0\) is the permittivity of free space and A is the area of the dielectric in the plane of the monolayer. The transition voltage dependence on the dielectric thickness is described in more detail in ref. 17.

Comparison of thermally and electrostatically driven phase transitions

Figure 2 shows a schematic comparison of energy utilization in a thermally driven phase transition of Ge2Sb2Te5 and energy utilization in an electrostatically driven phase transition in a monolayer material. Figure 2a, b illustrate temperature changing with entropy in a thermally driven phase transition. In Fig. 2a, crystalline Ge2Sb2Te5 alloy is heated up from room temperature to melting temperature and then slowly heated at the melting temperature until the whole alloy is melted. In Fig. 2a, the energy input in this process, E1, obtained by integration \({\int} {\kern 1pt} T{\kern 1pt} {\rm d}S\), is depicted by the gray shaded region. This region is the theoretical lower bound of the energy consumed in driving the phase transformation and is the sum of the energy required to heat up the alloy from room temperature to the melting temperature plus the latent heat at the melting temperature,3 equivalent to

where C is the specific heat, Tm is the melting temperature, Ti is the initial temperature which we assume to be room temperature, and L is the latent heat of melting. Using the parameters of standard Ge2Sb2Te5 alloy3 (Tm ≈ 900 K, Ti = 300 K, C = 1.25 J/K/cm3, and L = 419 J/cm3, we estimate the energy consumption E1 = Emin ≈ 1.17 aJ/nm3, which is the energy input to drive the phase transformation in Ge2Sb2Te5 alloy. This quantity is provided in Table 1.

Comparison of energy consumption in thermally driven phase transitions and electrostatically driven phase transitions. a, b Illustrations of temperature changing with entropy in a thermally driven phase transition. The phase transition in Ge2Sb2Te5 alloy is chosen as an example. To change the state of crystalline Ge2Sb2Te5 alloy, it is slowly heated up to the melting temperature and melted to an amorphous phase. In a The gray shaded region represents the energy input to change the state, E1. b The temperature is lowered much faster than the kinetic timescale of the crystallization, the amorphous Ge2Sb2Te5 alloy can be quenched into a glassy state, and the red shaded region represents the heat dissipated to the surroundings, E2. c, d Illustrate the gate voltage dependence on excess charge in an electrostatically driven phase transition. The phase transition in monolayer MoTe2 is chosen as an example. c The gate voltage on 2H-MoTe2 is increased up to the transition voltage, the 2H-to-1T′ phase transition will occur via a mixed phase thermodynamic region. The gray shaded region represents the energy input in the gating process E3 if the voltage or charge are increased much slower than the kinetic timescale of the phase change. d The gating is rapidly turned off so that 1T′-MoTe2 will be quenched along the green curve. The red shaded region represents the electrostatic energy that will be lost to the surroundings, E4

In Fig. 2b, the temperature is lowered sufficiently fast that the amorphous Ge2Sb2Te5 alloy is quenched to room temperature, as denoted by the arrows and green curve. In the quenching process, an amount of heat, E2, is dissipated to the surroundings, depicted by the red shaded region in Fig. 2b. This wasted heat is unavoidable in a thermally driven phase transition and it is always nonzero.

Note that the experimentally measured energy input of Ge2Sb2Te5 is orders of magnitude larger than the adiabatic lower limit.22 The experimentally reported values indicate that the most significant part of the total energy consumption is heat dissipation into the surroundings in the process of Joule heating. The adiabatic lower limit holds only for a thermally isolated device with infinite thermal boundary resistance. Although much research has been conducted to reduce the heat dissipation of a Ge2Sb2Te5-based device as much as possible,23,24,25 the experimentally measured energy consumption is still at least 100–10,000 times higher than the adiabatic lower limit.22 This ratio increases as the device size scales down.

Because Ge2Sb2Te5 alloy has a relatively high melting temperature, we may ask how the energy input to drive a thermal phase transformation in Ge2Sb2Te5 compares to the energy input to drive a thermal phase transformation in materials with lower melting temperatures. VO2 has been studied extensively for its metallic to insulating phase transitions in a range of application areas.30,31 The commonly studied transitions in vanadates are crystal to crystal rather than the melting transition of Ge2Sb2Te5 alloys. The transition temperature of the monoclinic to rutile phase of VO2 is Tm = 340 K,30 well below the transition temperature for Ge2Sb2Te5 or bulk MoTe2. Using (from ref. 30) T i = 300 K, C = 3.54 J/K/cm3, and L = 241 J/cm3, we find from Eq. (5) that Emin ≈ 0.38 aJ/nm3 for VO2. This value is also listed in Table 1. Together with the minimum energy input required for a thermal phase transition in Ge2Sb2Te5, these values provide a rough estimate of the range of input energies required to drive phase transitions of this type.

While requiring lower energy input to drive a phase transition than Ge2Sb2Te5, the low transition temperature of VO2 may preclude its practical use in electrical devices, where temperatures of electrical components may come close to the transition temperature and therefore unintentionally change the phase of the component. For this reason, higher transition temperatures are desired in phase-change memory electronic devices. In addition, VO2 is a volatile material, which precludes its use in non-volatile memory applications.

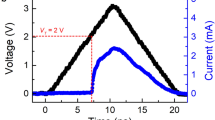

Figure 2c, d are schematic illustrations of gate voltage changing with excess charge in an electrostatically driven phase transition. For simplicity, we describe here the case of a system at T = 0 K, so that no heat is transferred to the monolayer while the gate voltage is applied. We revisit the case of non-zero temperature in the following section. The curves in Fig. 2c, d are based on the computed MoTe2 phase diagram in Fig. 1b and the black dashed T = 0 K transition voltage line depicted in the figure. When a gate voltage greater than or equal to the transition gate voltage V t (red curve in Fig. 2c) is applied to monolayer 2H-MoTe2, a 2H-to-1T′ phase transition will occur in the monolayer. At the transition gate voltage, the monolayer is a mixed phase of 2H and 1T′, analogous to the melting process shown in Fig. 2a. As the region of 1T′ phase grows in the mixed phase, the excess charge Q in the monolayer will increase while the gate voltage is maintained at the transition voltage. The gray shaded region shown in Fig. 2c represents the minimum energy input (i.e., E3) needed to transform monolayer MoTe2 from the 2H phase to the 1T′ phase. This quantity assumes that the voltage is increased sufficiently slowly, so that the system remains at thermodynamic equilibrium throughout. Physically, this means that the voltage increases on a timescale much slower than the kinetics of the 2H to 1T′ transition.

Figure 2d shows that upon reducing the voltage sufficiently fast, the material remains in the 1T′ phase and excess charge flows out of the monolayer, denoted by the arrows and the green curve. In this plot, it is assumed that the voltage is reduced on a timescale faster than the kinetics of the 1T′ to 2H transition, so that the material remains metastable in the 1T′ state in analog to the quenching process in Fig. 2b.

Importantly, the two cases of thermally driven and electrostatically driven phase transitions differ in a fundamental way. Figure 2d shows that, in principle, an amount of electrostatic energy, E4, has the potential to be recovered by the system. The gated 2D material system is essentially a charged capacitor. This energy could potentially be recovered by discharging the capacitor into a reservoir or external capacitor. In the limit that this energy can be recovered with perfect efficiency, the net energy consumption to drive a phase transition from 2H to 1T′ and subsequently relax to 2H is E3 − E4. However, electronic devices are not typically configured to recover such energy and we therefore assume this energy to be lost to the surrounding environment.

Given the qualitative picture of the phase transformations in monolayer MoTe2 and Ge2Sb2Te5 in Fig. 2, we now compute the zero-temperature energy input required to drive the phase transition in monolayer MoTe2. Figure 3a shows the T = 0 K transition process of monolayer MoTe2 under electrostatic gating for the device specifications of Fig. 1a. The gray shaded region represents the input energy required to drive the 2H-to-1T′ phase transition, analogous to the transition path in Fig. 2c. Figure 3b shows the transition path when the gate voltage is turned off, analogous to Fig. 2d. The red shaded region in Fig. 3b represents the electrostatic energy which we assume to be lost. The energy input to drive the phase transition is

where the first integral is taken over the blue 2H transition path in Fig. 3a and the second integral is taken over the red mixed transition path in Fig. 3a. For MoTe2, two different transition pathways can be used: one for positive charging and the other for negative charging.

Phase transition path in monolayer MoTe2 under electrostatic gating. a,b These figures show the phase transition path in monolayer MoTe2 under electrostatic gating, as schematically illustrated in Fig. 2c, d. In each figure, there are two sets of arrows, representing the phase change under both positive charging and negative charging. The meanings of the shaded regions are the same as in Fig. 2c, d

From Fig. 3a at T = 0 K, we find that the energy input per volume for Eq. (6) at positive bias is 0.61 aJ/nm3, while the energy input for negative bias is 0.13 aJ/nm3. These values are also listed in Table 1 and compared to the T = 300 K values. Note that to get a per-volume comparison of monolayer MoTe2, we use the bulk 2H-MoTe2 interlayer distance d = 6.98Å to compute a volume per formula unit of MoTe2.

Impact of non-zero temperature on the phase transition induced by electrostatic gating

The phase transition diagram in Fig. 3 is drawn at zero temperature. To model a practical phase change memory device, we would like to know how the device in Fig. 1a would operate at room temperature. The effects of non-zero temperature on the device are important in two different respects. First, heat transfer between the monolayer and the surrounding environment can occur during the phase transformation, adding an important term to the total energy consumption. This can be seen via reference to the total differential of internal energy, which at non-zero temperature and constant zero stress becomes

Second, it has been shown that non-zero temperatures can have a large quantitative impact on the voltage-temperature phase boundary.11,15 The reported 2H-to-1T′ phase transition at high temperature10 suggests that the transition voltage should decrease as temperature increases, and our results corroborate this finding. This is important because it indicates that at higher temperatures, less electrostatic energy is needed to drive the phase transformation. In this section, we discuss both the heat transferred to the monolayer during the phase transformation and the temperature dependence of the gate voltage using a modified form of the Clausius–Clapeyron relation. Details on the calculation are included in the Supplementary Information.

We first consider the amount of heat transferred to the monolayer under an applied voltage at non-zero temperature. As a thermodynamic constraint, we consider an isothermal process in which the monolayer and all other components of the system shown in Fig. 1a remain at a constant temperature throughout the phase transformation of the monolayer. This constraint applies for cases in which phase-change memory devices operate at roughly room temperatures and heat is allowed to flow in and out of the device. Theoretically, adiabatic constraints are also possible, but we do not consider such constraints in this work.

When the system is held at constant temperature, the main contribution to the heat flow into the system comes from the change in entropy in transforming from the 2H to 1T′ phase, ΔS = S1T′ − S2H. Given this entropy change, we can reimagine the phase transformation process of Fig. 3 via reference to Fig. 1b. As in Fig. 3, we may consider a process in which the monolayer starts in the 2H phase at V = 0 V and a fixed temperature T = 300 K. Upon gating the device, charge enters the monolayer and for voltages of sufficiently small magnitude, the monolayer remains in the 2H phase, exactly as depicted in the blue path of Fig. 3a. For all points along this blue path, any entropy change during this process is regarded as negligible, since no phase transformation has occurred.

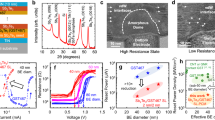

Because the device now operates at room temperature, the magnitude of gating voltage necessary for MoTe2 to enter a mixed phase is smaller than in the T = 0 K case (see Fig. 4a). The monolayer must be gated to \(V_t^1(T = 300{\kern 1pt} {\mathrm{K}})\) in the negative bias case or \(V_t^2(T = 300{\kern 1pt} {\mathrm{K}})\) in the forward bias case for the phase transformation to occur (see Fig. 1b). When reaching the T = 300 K transition voltage, the bias is held fixed and the system enters a mixed phase of 2H and 1T′. Upon completing the transformation from 2H to 1T′, the monolayer has experienced an entropy change of ΔS(T = 300 K), and therefore an additional latent heat energy L = TΔS is required to drive the transformation.

Temperature-voltage and temperature-excess charge phase diagrams for the device in Fig. 1a, computed using the modified Clausius–Clapeyron relation in Eq. 9. a Temperature-gate voltage phase diagram of monolayer MoTe2 under electrostatic gating. In the blue shaded region, semiconducting 2H phase is more stable; in the green shaded region, semi-metallic 1T′ phase is more stable. b Temperature-excess charge phase diagram of monolayer MoTe2 under electrostatic gating. In addition to blue and green shading, the red shading indicates regions where a mixed 2H and 1T′ phase is most stable. The peak value of temperature is T = 690 K. Note that for conditions of constant lattice, rather than constant zero stress, the amount of excess charge required to drive a transition will be approximately twice as large as the values shown here, as discussed in ref. 17

Upon transforming to the 1T′ phase, the gate voltage is decreased quickly so that the monolayer remains metastable in the 1T′ phase, exactly as is shown in the green dashed line of Fig. 3b. As in the zero-temperature case, we assume any electrostatic energy to be lost to the surroundings during this process, so that no energy is recovered in this process.

To compute the entropy change ΔS, we note that the total entropy of the 2H or 1T′ phase is the sum of a vibrational (phonon) contribution and an electronic contribution, so that ΔS(T, Q2H, Q1T′) = ΔSph(T) + ΔSel(T, Q2H, Q1T′). Note that the electronic entropy difference ΔSel depends on both temperature T and the excess charge of the 2H and 1T′ phases, Q2H and Q1T′. This is due to the fact that adding charge changes the Fermi level of each phase, altering the local density of states that gives rise to the occupational entropy. Technically, the phonon contribution to the entropy difference ΔSph can also depend on the excess charge of each phase, but these effects are small and are therefore ignored below, as discussed in the Supplementary Information.

We compute the phonon contribution to the entropy using the phonon density of states at zero excess charge (Q = 0) using VASP and the Phonopy package32 (see the Supplementary Information for details). The electronic contribution is computed using VASP with electronic Fermi smearing to determine the entropy from partial electronic occupancies of the Kohn-Sham states. We compute the electronic entropy for both the 2H and 1T′ phases at a large range of values of excess charge and temperature, as shown in Supplementary Information Figure 2.

Because the electronic entropy difference between the 2H and 1T′ phases depends on the sign of charge added to the monolayer at a given temperature, the latent heat term associated with the transformation also depends on the sign of charge added to the monolayer. The exact values of the electronic entropy difference between the 2H and 1T′ phases along the phase transformation boundary are shown in Supplementary Information Figure 4. The values in this figure can be used to compute the latent heat at all temperatures up to the zero excess charge transition temperature.

Given the computed change in entropy ΔSph between the 2H and 1T′ phases from the phonon density of states at T = 300 K and the electronic difference in entropy ΔSel at T = 300 K and the corresponding values of Q2H and Q1T′ shown in Fig. 1b for both positive and negative values of V, we compute the latent heat transferred to the system as

This quantity is roughly 5% of the total energy input required to drive a phase transformation at T = 300 K for the forward bias (V > 0) case and roughly 30% of the total energy input for the reverse bias (V < 0) case.

Although the latent heat L adds to the total energy required to drive the 2H to 1T′ phase transformation, it turns out that the amount of electrostatic energy required to drive the phase transformation at T = 300 K actually decreases significantly from the T = 0 K case. Using a modified form of the Clausius-Clapeyron relation,

where ΔQ = Q1T′(V) − Q2H(V), we compute the temperature-voltage phase diagram shown in Fig. 4a (see the Supplementary Information for details). By combining this temperature-voltage phase diagram with the voltage-excess charge data in Fig. 1b, we compute the temperature-excess charge phase diagram shown in Fig. 4b. The phase diagrams in Fig. 4 indicate that the magnitudes of the voltage and/or excess charge along the phase boundaries decrease as temperature is increased. The semiconducting 2H phase is more stable in the blue shaded region, the semimetallic 1T′ phase is more stable in the green shaded region, and a mixed phase is most stable in the red shaded region. The transition gate voltage increases as temperature decreases and achieves its maximum at T = 0 K. We also find that at Q = 0, the transition temperature is roughly T = 690 K. This agrees well with ref. 11, which predicts that under stress free conditions, the single layer 2H phase will transform to the 1T′ phase at T = 610 K without electrostatic gating.

The total energy input to drive a phase transition in monolayer MoTe2 is the sum of the electrostatic energy input and latent heat (Eq. 8) at room temperature. For the electrostatic energy input, we integrate \({\int} {\kern 1pt} V{\mathrm{d}}Q\) along the 2H transition path up to the transition voltage \(V_t^{1,2}(T = 300{\kern 1pt} {\mathrm{K}})\), so that the total energy consumption at T = 300 K becomes

The T = 300 K energy input for forward and reverse bias using Eq. (10) are 0.44 and 0.10 aJ/nm3, respectively. For comparison, the T = 0 K electrostatic energy input values are 0.61 and 0.13 aJ/nm3. These values are listed in Table 1.

As a final point of interest, we also compute the energy input required to drive a thermal 2H to 1T′ phase transition in monolayer MoTe2. We consider heating the monolayer at zero excess charge from T = 300 K up to the computed transition temperature T = 690 K found in Fig. 4. This value is exactly analogous to the adiabatic energy input required to drive the phase transition of Ge2Sb2Te5 alloy and VO2 in Eq. (5). In Supplementary Information Figure 5, we compute the heat capacity of monolayer 2H-MoTe2 to be C2H = 1.61 J/K/cm3 at T = 690 K. This is very close to experimentally reported values of bulk 2H-phase MoTe2, C = 1.65 J/K/cm3.33,34 In addition, we use Supplementary Information Figure 3 to compute ΔSph + ΔSel at T = 690 K. Using these values, we find C2H(Tm − Ti) ≈ 0.63 aJ/nm3 and L = 0.08 aJ/nm3, leading to (from Eq. 5) Emin = 0.71 aJ/nm3. This value is also provided in Table 1. For comparison, note that Song et al.16 report the latent heat of Te-deficient MoTe2 powder to be L = 0.03 aJ/nm3 for measurements done at T = 1128 K.

We also point out that recent experimental investigations report that the thermal boundary resistance (TBR) of MoS2 on a SiO2 substrate is around 70 m2/GW/K,35 while the TBR of Ge2Sb2Te5 on a SiO2 substrate is around 30 m2/GW/K.36 For MoTe2, the TBR is expected to be even higher than that of MoS2 because the larger mass density per unit area of MoTe2 gives rise to higher acoustic impedance. These findings indicate that thermally driven monolayer TMD-based phase change memory devices should naturally dissipate less heat to the surroundings than Ge2Se2Te5-based devices. However, we again emphasize that the electrostatically driven phase change mechanism in monolayer MoTe2 is distinct from this thermal mechanism, and that in the electrostatically driven case, heat dissipation to the surroundings is a relatively small contribution to the total per-volume energy consumption.

Discussion

Table 1 shows that the T = 300 K electrostatically driven phase transformation of monolayer MoTe2 from the 2H to 1T′ phase under constant zero stress conditions requires roughly 38 and 9% of the energy input per unit volume of the adiabatic lower limit to drive a phase transition in Ge2Sb2Te5 for positive and negative voltage bias, respectively. Furthermore, the adiabatic lower limit Ge2Sb2Te5 energy consumption is 100–10,000 times smaller than the experimentally measured values due primarily to waste heat generated in the process of Joule heating of Ge2Sb2Te5-based devices. This opens the opportunity for monolayer MoTe2 to consume several orders of magnitude less energy per unit volume than Ge2Sb2Te5.

Fabricated devices that employ monolayer or few layer forms of MoTe2, rather than bulk, may see an additional energy savings from smaller thicknesses leading to smaller overall volumes. Chemical stability at very thin thicknesses may be a potential advantage of using layered materials over bulk materials. However, tunneling current through the device is expected to place a practical limit on the minimum thickness of the material. For devices that can be made from a single or few layer thickneses with acceptable performance, additional energy savings are expected that are not explicitly accounted for in our energy per unit volume numbers given in Table 1. We also point out that the write energy per bit for a typical Ge2Sb2Te5 phase change device is around 10 pJ for cells roughly of size 10 × 10 × 10 nm3,6,23 including thermal conduction effects. For a relatively large 50 × 50 × 0.5 nm3 monolayer MoTe2 storage bit, our calculations predict the write energy per bit is on the order of 0.1 fJ, roughly five orders of magnitude smaller than Ge2Sb2Te5 devices.

The calculations of critical charge required to drive the transition in ref. 17 indicate that the nature of the mechanical constraint of the material has a large impact on the critical charge required. The difference in charge required differs by approximately a factor of two between the constant zero stress case (shown in Table 1) and the fixed lattice case. In the former, the monolayer is assumed to be able to slide freely on the substrate, while the latter case assumes substrate friction sufficient to constrain the lattice constants. A recent electrostatic gating experimental report indicates that the transition is centered around a charge density associated with the fixed lattice case of ref. 17, suggesting that the appropriate mechanical constraint may be closer to the fixed lattice case for a monolayer on a substrate. The energy consumption for the fixed lattice case is expected to be roughly four times larger than the constant zero stress case, due to larger critical transition charges. However, this quantity is still orders of magnitude lower than the experimentally reported Ge2Sb2Te5 energy consumption values in Table 1.

There may exist opportunities for engineering single layer materials to consume less energy than those shown in Table 1. For example, ref. 17 discusses the potential for the alloy Mo x W1−xTe2 to exhibit the transition at smaller voltages and charge densities, tunable with alloy composition x. Moving the transition voltage closer to zero is expected to reduce the energy requirements in Table 1. Figure 4a shows a similar reduction in transition voltage can be achieved with increasing operating temperature. The calculations of ref. 11 and ref. 15 report that tensile strain moves the transition closer to ambient conditions, and may constitute a further mechanism for reduction of the critical gate voltages and and energy consumption.

Finally, the kinetics of this transition are expected to play a critical role in the utility of practical devices. As previously discussed, investigations into the kinetics of phase transitions in monolayer MoTe2 and other monolayer materials are nascent and much remains unknown. Experimental studies of thermal phase transitions in MoTe2 have been reported to occur on timescales of several hours at high temperatures,12,14 while other reports suggest that the kinetics can occur on timescales of minutes or less at ambient temperatures and below.16,18 The large variability in these reports suggests that there is potential to engineer the kinetics of these phase transitions to achieve desired electronic or other device timescales.

In this work, we compared the energy consumption in electrostatically driven phase transitions of monolayer MoTe2 to the energy consumption in thermally driven phase transitions of Ge2Sb2Te5 alloys. In the thermally driven phase transition of Ge2Sb2Te5, the vast majority of energy consumed is dissipated as waste heat to the surrounding environment, thus limiting energy efficiency and miniaturization of device sizes. In electrostatically driven phase transitions of monolayer MoTe2, however, we find that only a small amount of heat enters and leaves the system, so that heat dissipation is not as great an issue for device miniaturization. We discover that the net energy consumption per unit volume in MoTe2 is 9% of the adiabatic lower limit of energy consumption per unit volume in Ge2Sb2Te5 alloy. Furthermore, the adiabatic lower limit of energy consumption in Ge2Sb2Te5 alloy is several orders of magnitude lower than experimentally-measured values. These factors may enable electrostatic devices based on monolayer MoTe2 and potentially other 2D-materials to consume several orders of magnitude less energy than their Ge2Sb2Te5 counter-parts.

Methods

All periodic DFT calculations were performed with the Vienna Ab initio Simulation Package (VASP),37 version 5.3.3 and/or 5.3.5. The calculations use the projector augmented-wave38 method and the electron exchange-correlation interaction was treated by the generalized gradient approximation (GGA) functional of Perdew, Burke, and Ernzerhof (PBE).39 A kinetic energy cutoff of 350 eV for the plane-wave basis set was used for all calculations. All atomic structures and in-plane lattice constants were relaxed using the conjugate gradient algorithm. The convergence thresholds for ionic and electronic relaxations were 0.5 × 10−7 eV per formula unit and 0.5 × 10−8 eV per formula unit, respectively. A 2 f.u. unit cell with an 18 × 18 × 1 Monkhorst-Pack40 k-point mesh for the Brillouin zone sampling was employed for the calculations done in Figs. 1 and 3. These Figures also used a 36 Å vacuum space along the z direction (perpendicular to the plane of the monolayer) to prevent interaction between periodic cell repeats, as well as a Gaussian electronic energy distribution smearing of 50 meV to aid in energy convergence. These calculations also included non-colinear spin-orbit coupling. The electronic entropies of 2H and 1T′ phases of MoTe2 were computed directly from VASP using Fermi-Dirac smearing without spin-orbit coupling (details are found in the Supplementary Information). The vibrational (phonon) entropies of 2H- and 1T′-MoTe2 were computed from the phonon density of states using the Phonopy32 Python package (see the Supplementary Information for details). These phonon calculations used VASP’s built-in density functional perturbation theory method (IBRION = 8) and a 2 × 2 × 1 (8 f.u.) supercell generated from the relaxed lattice positions of the 2 f.u. unit cell used in Figs. 1 and 3. The supercell uses a vacuum space of 16 Å along the z direction and an 18 × 18 × 1 Monkhorst-Pack k-point mesh. These simulations also included non-colinear spin–orbit coupling, with an electronic relaxation threshold of 0.5 × 10−5 eV/f.u.

Data availability

All code and data used to generate figures and results in this paper can be found at https://github.com/rehnd/MoTe2PhaseChangeEnergy.

References

Zalba, B., Marín, J. M., Cabeza, L. F. & Mehling, H. Review on thermal energy storage with phase change: materials, heat transfer analysis and applications. Appl. Therm. Eng. 23, 251–283 (2003).

Hudgens, S. & Johnson, B. Overview of phase-change chalcogenide nonvolatile memory technology. MRS Bull. 29, 829–832 (2004).

Raoux, S., Xiong, F., Wuttig, M. & Pop, E. Phase change materials and phase change memory. MRS Bull. 39, 703–710 (2014).

Lee, B.-S. et al. Investigation of the optical and electronic properties of Ge2Sb2Te5 phase change material in its amorphous, cubic, and hexagonal phases. J. Appl. Phys. 97, 093509 (2005).

Wuttig, M. & Yamada, N. Phase-change materials for rewriteable data storage. Nat. Mater. 6, 824 (2007).

Yu, S. & Chen, P.-Y. Emerging memory technologies: recent trends and prospects. IEEE Solid-State Circuits Mag. 8, 43–56 (2017).

Meena, J., Sze, S., Chand, U. & Tseng, T.-Y. Overview of emerging nonvolatile memory technologies. Nanoscale Res. Lett. 9, 526 (2014).

Sandoval, S. J., Yang, D., Frindt, R. & Irwin, J. Raman study and lattice dynamics of single molecular layers of MoS2. Phys. Rev. B 44, 3955 (1991).

Zhou, Y. & Reed, E. J. Structural phase stability control of monolayer MoTe2 with adsorbed atoms and molecules. J. Phys. Chem. C. 119, 21674–21680 (2015).

Brown, B. E. The crystal structures of WTe2 and high-temperature MoTe2. Acta Crystallogr. 20, 268–274 (1966).

Duerloo, K.-A. N. & Reed, E. J. Structural phase transitions by design in monolayer alloys. ACS Nano 10, 289–297 (2015).

Oliver, S. M. et al. The structural phases and vibrational properties of Mo1−xW x Te2 alloys. 2D Mater. 4, 045008 (2017).

Rhodes, D. et al. Engineering the structural and electronic phases of MoTe2 through w substitution. Nano Lett. 17, 1616–1622 (2017).

Empante, T. A. et al. Chemical vapor deposition growth of few-layer MoTe2 in the 2H, 1T, and 1T phases: tunable properties of MoTe2 films. ACS Nano 11, 900–905 (2017).

DuerlooK. -A. N., LiY.. & ReedE. J.. Structural phase transitions in two-dimensional mo-and w-dichalcogenide monolayers. Nat. Commun. 5, 4214 (2014).

Song, S. et al. Room temperature semiconductor-metal transition of MoTe2 thin films engineered by strain. Nano Lett. 16, 188–193 (2015).

Li, Y., Duerloo, K.-A. N., Wauson, K. & Reed, E. J. Structural semiconductor-to-semimetal phase transition in two-dimensional materials induced by electrostatic gating. Nat. Commun. 7, 10671 (2016).

Wang, Y. et al. Structural phase transition in monolayer MoTe2 driven by electrostatic doping. Nature 550, 487–491 (2017).

Tsen, A. W. et al. Structure and control of charge density waves in two-dimensional 1T-TaS2. Proc. Natl. Acad. Sci. 112, 15054–15059 (2015).

Yoshida, M., Suzuki, R., Zhang, Y., Nakano, M. & Iwasa, Y. Memristive phase switching in two-dimensional 1T-TaS2 crystals. Sci. Adv. 1, e1500606 (2015).

Yoshida, M. et al. Controlling charge-density-wave states in nano-thick crystals of 1T-TaS2. Sci. Rep. 4, 7302 (2014).

Lacaita, A. L. & Redaelli, A. The race of phase change memories to nanoscale storage and applications. Microelectron. Eng. 109, 351–356 (2013).

Xiong, F., Liao, A. D., Estrada, D. & Pop, E. Low-power switching of phase-change materials with carbon nanotube electrodes. Science 332, 568–570 (2011).

Behnam, A. et al. Nanoscale phase change memory with graphene ribbon electrodes. Appl. Phys. Lett. 107, 123508 (2015).

Zhu, C. et al. Low-energy phase change memory with graphene confined layer. Appl. Phys. Lett. 108, 252102 (2016).

Xiong, F. et al. Towards ultimate scaling limits of phase-change memory. In Proc. IEEE International Electron Devices Meeting 4.1.14.1.4 (IEEE, San Francisco, CA, USA, 2016).

Hohenberg, P. & Kohn, W. Inhomogeneous electron gas. Phys. Rev. 136, B864–B871 (1964).

Kohn, W. & Sham, L. J. Self-consistent equations including exchange and correlation effects. Phys. Rev. 140, A1133–A1138 (1965).

Berry, J., Zhou, S., Han, J., Srolovitz, D. J. & Haataja, M. P. Dynamic phase engineering of bendable transition metal dichalcogenide monolayers. Nano Lett. 17, 2473–2481 (2017).

Chandrashekhar, G., Barros, H. & Honig, J. Heat capacity of VO2 single crystals. Mater. Res. Bull. 8, 369–374 (1973).

Qiu, H. et al. The tetragonal-like to rutile structural phase transition in epitaxial VO2/TiO2 (001) thick films. New J. Phys. 17, 113016 (2015).

Togo, A. & Tanaka, I. First principles phonon calculations in materials science. Scr. Mater. 108, 1–5 (2015).

Kiwia, H. L. & Westrum, E. F. Low-temperature heat capacities of molybdenum diselenide and ditelluride. J. Chem. Thermodyn. 7, 683–691 (1975).

Sankar, R. et al. Polymorphic layered MoTe2 from semiconductor, topological insulator, to weyl semimetal. Chem. Mater. 29, 699–707 (2017).

Yalon, E. et al. Energy dissipation in monolayer MoS2 electronics. Nano Lett. 17, 3249–3433 (2017).

Yalon, E. et al. Spatially resolved thermometry of resistive memory devices. Sci. Rep. 7, 80 (2017).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169 (1996).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953 (1994).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865 (1996).

Monkhorst, H. J. & Pack, J. D. Special points for brillouin-zone integrations. Phys. Rev. B 13, 5188 (1976).

Böker, T. et al. Band structure of MoS2, MoSe2, and α-MoTe2: angle-resolved photoelectron spectroscopy and ab initio calculations. Phys. Rev. B 64, 235305 (2001).

Acknowledgements

This work was partially supported by NSF grants EECS-1436626 and DMR-1455050, Army Research Office grant W911NF-15-1-0570, Office of Naval Research grant N00014-15-1-2697, and a seed grant from Stanford System X Alliance. This work was supported in part by the U. S. Army Research Laboratory, through the Army High Performance Computing Research Center, Cooperative Agreement W911NF-07-0027.

Author information

Authors and Affiliations

Contributions

D.A.R. performed simulations of the thermal properties of monolayer MoTe2 and prepared the manuscript. Y.L. performed simulations of the zero temperature voltage-excess charge phase diagram. E.P. provided insights into the use of thermally-driven phase change materials and revised the manuscript. Y.L., D.A.R., and E.J.R. collectively worked on the interpretation of data and simulation design. E.J.R. served as the primary advisor for the project.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rehn, D.A., Li, Y., Pop, E. et al. Theoretical potential for low energy consumption phase change memory utilizing electrostatically-induced structural phase transitions in 2D materials. npj Comput Mater 4, 2 (2018). https://doi.org/10.1038/s41524-017-0059-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41524-017-0059-2

This article is cited by

-

Two-dimensional diamonds from sp2-to-sp3 phase transitions

Nature Reviews Materials (2022)

-

Phase transitions in 2D materials

Nature Reviews Materials (2021)

-

Valley phenomena in the candidate phase change material WSe2(1-x)Te2x

Communications Physics (2020)

-

Berry curvature memory through electrically driven stacking transitions

Nature Physics (2020)

-

The changing phase of data storage

Nature Nanotechnology (2019)