Abstract

Electrically actuated optomechanical resonators provide a route to quantum-coherent, bidirectional conversion of microwave and optical photons. Such devices could enable optical interconnection of quantum computers based on qubits operating at microwave frequencies. Here we present a platform for microwave-to-optical conversion comprising a photonic crystal cavity made of single-crystal, piezoelectric gallium phosphide integrated on pre-fabricated niobium circuits on an intrinsic silicon substrate. The devices exploit spatially extended, sideband-resolved mechanical breathing modes at ~3.2 GHz, with vacuum optomechanical coupling rates of up to g0/2π ≈ 300 kHz. The mechanical modes are driven by integrated microwave electrodes via the inverse piezoelectric effect. We estimate that the system could achieve an electromechanical coupling rate to a superconducting transmon qubit of ~200 kHz. Our work represents a decisive step towards integration of piezoelectro-optomechanical interfaces with superconducting quantum processors.

Similar content being viewed by others

Introduction

Recent years have seen the advent of quantum computers based on superconducting microwave circuits and their rapid development1,2 towards commercial systems that outperform classical computers. Due to their low energy, the microwave qubits are bound to the millikelvin environment of a dilution refrigerator, which presents a variety of challenges for building systems with large numbers of qubits. A particularly interesting approach to solving the scaling problem is networking of smaller machines via quantum-coherent interconnects3,4,5. Communication between quantum processing units at microwave frequencies must, however, be carried out through cryogenically cooled waveguides6 to avoid decoherence. An attractive alternative is to map the quantum state from the microwave domain to the optical domain, where information can be transmitted quantum coherently through low-loss optical fibers7. Numerous methods have been proposed for microwave-to-optical conversion8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26; the most efficient to date make use of an intermediary mechanical state27,28,29,30,31,32,33,34,35.

Great strides have been made in the field of cavity optomechanics36 during the past decade in demonstrating the building blocks needed for quantum-coherent optical interconnects, including the demonstration of quantum control of single-phonon states in mechanical modes at gigahertz frequencies with single photons37, the realization of optomechanically mediated quantum entanglement of separate mechanical systems38, and the conversion of a superconducting qubit excitation to an optical photon39. Progress has also been made in the manipulation of quantum states of a mechanical oscillator through interaction with a superconducting qubit40,41,42.

We introduce here a platform for microwave-optical conversion that combines a microwave circuit fabricated on an intrinsic silicon substrate with an optomechanical element made of single-crystal gallium phosphide (GaP), using direct wafer bonding. For the optical cavity, we employ a quasi-one-dimensional optomechanical crystal cavity43 with extended mechanical modes that permit electrical actuation remote from the optical mode to reduce losses. The extended modes nevertheless maintain substantial optomechanical coupling. Due to the relatively high index of refraction of GaP (3.05 at λvac = 1550 nm) and the consequent strong light confinement, GaP cavities have vacuum optomechanical coupling rates similar to those of devices made of silicon44,45 and significantly larger than those of lithium niobate30 or aluminum nitride33 devices. In terms of heating in pulsed experiments, GaP devices compare favorably to structures made of gallium arsenide and other piezoelectric materials45,46. Making use of the piezoelectric properties of GaP, we demonstrate at room temperature actuation of the mechanical modes of the optomechanical device with integrated electrodes and coherently transduce microwave signals to optical frequencies.

Results

Device design

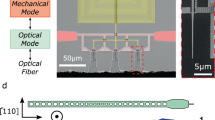

Our transducer consists of an asymmetric quasi-one-dimensional optomechanical crystal cavity made of GaP suspended over a niobium electrode at one end, with a second, coplanar niobium electrode displaced to one side, as illustrated in Fig. 1a. Laser light is coupled in and out of the device through a waveguide attached to it on the right side. The geometry of the optomechanical crystal cavity is adapted from the design introduced by Chan et al.43,47 and consists of a series of elliptical holes etched in a rectangular beam. The hole radii and pitch are, however, modified to create distributed mechanical modes extending between the center of the cavity and the electrode position39. Finite-element-method (FEM) simulations are employed to model both the photonic and phononic band structure, determine the intrinsic, radiation-limited optical quality factor, Q0, and estimate the vacuum optomechanical coupling rate, g0.

a Illustration of the cavity suspended over an electrode pair. b Schematic of unit cell (t = 300 nm, w = 550 nm). c Variation of unit-cell parameters as indicated in b along the cavity x-axis. The shading indicates the phononic waveguide (red), cavity (white), and input-mirror (blue) regions. d–f Photonic band structure of the unit cell for the phononic waveguide, cavity center, and input mirror, respectively. The light line is indicated in red. The red-shaded region in e is the intersection of the photonic bandgaps in d and f. g–i Phononic band structure of the unit cell ordered as in d–f. The mechanical breathing modes are indicated in blue and orange. The red shaded region in g and h corresponds to the phononic bandgap in i. For comparison, the upper breathing mode band for the unit cell at the cavity center is overlayed in g as a dashed green line scaled for the difference in period p. j FEM simulation of the localized optical mode. The color scale indicates the magnitude of the electric field ∣E∣. k FEM simulation of three extended mechanical breathing modes. The color scale indicates the magnitude of the mechanical displacement ∣u∣.

The design is composed of three sections (Fig. 1c). At the right end of the GaP beam (which is 300 nm thick and 550 nm wide), the unit cell is chosen to form a partially transparent photonic mirror with an optical bandgap for TE-polarized light between 177 and 208 THz, where the optical coupling rate to the cavity can be controlled by varying the number of holes. This section also has a bandgap for mechanical breathing modes between 1.82 and 3.69 GHz and thus serves as a phononic mirror as well. On the left side of the device, the unit-cell geometry is again chosen to create a photonic bandgap, this time between 172 and 202 THz, but now has a phonon dispersion that supports mechanical breathing modes within the phononic bandgap of the input mirror on the right side of the device. Between these two regions, in the central portion of the beam, the unit-cell dimensions are varied to produce a confined optical mode, with the variations on each side following Gaussian functions of width σ = 1 μm. The result is a cavity supporting a localized optical mode (Fig. 1j) at ωo/2π = 193.2 THz with Q0 = 1.8 × 106. Crucially, the dispersion of the mechanical breathing modes is nearly identical at the center of the cavity and on the left side of the device (see the dashed green line in Fig. 1g), resulting in an impedance-matched phononic waveguide. The device is terminated on the left with a phononic reflector exhibiting a complete bandgap between 2.84 and 3.51 GHz, implemented as a crenulation of the nanobeam. This reflector, in combination with the phononic mirror on the right side of the device, forms a Fabry-Pérot-like cavity for mechanical breathing modes. Examples of the mechanical breathing modes are shown in Fig. 1k, the frequencies and estimated vacuum optomechanical coupling rates of which are given in Table 1. Because the mechanical breathing modes extend along the beam, they can be directly actuated by electrodes that are spatially separated from the localized optical mode.

Fabrication

Device fabrication makes use of the processes described in our previous work on integrated GaP photonics44,48, with the important distinction that GaP is not bonded onto an oxidized silicon wafer but instead onto a prefabricated microwave circuit. The process flow is illustrated in Fig. 2. First, a 250 nm thick niobium film is deposited on an intrinsic silicon wafer by magnetron sputtering and patterned by chlorine-based dry etching into electrode structures. The vicinity of the photonic crystal cavity is then recessed 2 μm by dry etching of the silicon with a HBr/O2 mixture to minimize optical losses to the substrate. The wafer is then covered with a sacrificial SiO2 layer and the surface planarized for bonding of GaP. The thickness of the SiO2 layer determines the eventual gap (~300 nm) between the GaP beam and the underlying niobium electrode. The GaP source wafer comprises a 300 nm thick GaP device layer on top of an Al0.1Ga0.9P etch-stop layer on a 2-inch, [100]-oriented GaP substrate. Prior to direct bonding, a thin film (5 nm) of Al2O3 is deposited on both the GaP device layer and the target wafer. After removal of the substrate and etch-stop layer, the bonded wafer is diced into chips, and the GaP device layer is patterned by electron-beam lithography to form the photonic crystal cavity and the attached waveguide. The waveguide has a tapered end for adiabatic coupling to a fiber with a tapered tip formed by etching. The free-standing portion of the device is defined photolithographically and released by removal of the sacrificial SiO2 layer with buffered HF. Finally, the entire chip is coated with 8 nm of Al2O3 to protect the surface and prevent photooxidation during measurement. Further details, including a description of the adiabatic fiber coupling to the device, are given in the Supplementary Notes 1 and 3.

a Deposition and patterning of Nb electrodes. b Local recessing of the Si substrate. c Deposition and planarization of the sacrificial SiO2 layer. d Direct wafer bonding of the GaP device layer. e Patterning of the integrated GaP photonic circuit. f Release of the free-standing portion of the device. g False-color scanning electron microscope (SEM) image of the finished device with annotation of microwave and optical ports. h Close-up false-color SEM image of the optomechanical crystal cavity.

Optomechanical characterization

The optical cavity mode is first interrogated in reflection with a tunable diode laser at low power (~130 nW) to determine the resonance frequency ωo and the loaded quality factor Q. For a Lorentzian resonance, reflection from the cavity as a function of detuning Δ = ωL − ωo with respect to the laser frequency ωL is described by

where κ0 is the intrinsic cavity decay rate and κex is the external coupling rate36. A fit of (1) to the resonance observed at ωo/2π = 196.5 THz (Fig. 3a) gives a loaded optical quality factor Q = ωo/κ = 6.73 × 104. The coupling factor is \({\eta }_{{{{{{{{\rm{c,opt}}}}}}}}}=\frac{{\kappa }_{{{{{{{{\rm{ex}}}}}}}}}}{{\kappa }_{{{{{{{{\rm{ex}}}}}}}}}+{\kappa }_{0}}=0.383\), yielding an intrinsic quality factor Q0 = 1.09 × 105. Similar values have been achieved with GaP optomechanical crystal cavities reported in other work44,45. In addition to surface roughness and fabrication imperfections, absorption in the bulk of the GaP or at the surface may be limiting the intrinsic quality factor. We also find an optical mode frequency that is 1.7% higher than expected from simulations, which we attribute to small deviations from the design geometry.

a Fit (orange) of Eq. (1) to the optical reflection spectrum (blue) of the cavity resonance. b Thermo-mechanical spectrum (blue) plotted as symmetrized frequency noise spectral density Sω(Ω) with a fit to a sum of Lorentzian functions (orange). The data are calibrated with an added tone created by a phase modulator. The assignment to the modes shown in Fig. 1(k) is indicated by A, B, and C.

Thermally driven mechanical motion of the photonic crystal cavity modulates the cavity resonance frequency, which, for a detuned probe laser, produces amplitude fluctuations in the reflected light. We measure the resulting thermo-mechanical spectrum by direct detection with a fast photoreceiver. At frequencies above 500 MHz, the only modes with appreciable optomechanical coupling are observed in a narrow band between 3.21 and 3.35 GHz (Fig. 3b), in good agreement with the simulated mechanical breathing modes. As the total optical decay rate is measured to be κ = κ0 + κex = 2π × 2.92 GHz, the system is narrowly in the resolved-sideband regime.

The vacuum optomechanical coupling rate g0 of individual modes was determined via noise calibration49. To that end, the thermo-mechanical spectrum is measured at low cooperativity (\({{{{{{{\mathcal{C}}}}}}}}={\bar{n}}_{{{{{{{{\rm{cav}}}}}}}}}\frac{4{g}_{0}^{2}}{{{{\Gamma }}}_{{{{{{{{\rm{m}}}}}}}}}\kappa }\approx 6.9\times 1{0}^{-3}\), where Γm is the mechanical damping rate and \({\bar{n}}_{{{{{{{{\rm{cav}}}}}}}}}\) is the average number of photons in the cavity), so that effects due to dynamical backaction can be neglected. A reference signal generated by a phase modulator is added close to the mechanical modes to calibrate the spectrum. The modulation depth ϕ0 = πV0/Vπ (where V0 is the amplitude of the radio-frequency voltage applied to the modulator and Vπ is the half-wave voltage) at frequency \({{{\Omega }}}_{{{{{{{{\rm{mod}}}}}}}}}\) is determined from the first sideband ratio (see Supplementary Note 11). The vacuum optomechanical coupling rate is then calculated as49

where \(\langle {n}_{{{{{{{{\rm{th}}}}}}}}}\rangle \approx \frac{{k}_{B}T}{\hslash {{{\Omega }}}_{{{{{{{{\rm{m}}}}}}}}}}\) is the average thermal occupation of the mode, SV(Ω) is the symmetrized voltage noise spectral density produced by the photoreceiver, Γm is the mechanical damping rate, and fENBW is the effective noise bandwidth of the spectrum analyzer’s filter function. We fit the mechanical noise spectrum with a sum of Lorentzians, as each mode produces a voltage noise spectral density that is uncorrelated with the other modes.

The device exhibits appreciable optomechanical coupling (g0/2π > 100 kHz) for three modes in the frequency range ascribed to the breathing modes, which we tentatively assign to the modes depicted in Fig. 1k. The observed mechanical resonance frequencies and coupling rates are listed in Table 1. We attribute the higher frequency of the experimentally observed modes to the Al2O3 protective coating, which increases the stiffness of the nanobeam (see Supplementary Note 4). The noise calibration measurement was carried out at blue and red laser detuning; the coupling rates for blue detuning are slightly higher than for red detuning, consistent with a small contribution from residual dynamical backaction.

Piezoelectric coupling

We now turn the focus of the discussion to piezoelectrically mediated actuation of the optomechanical cavity and analyze the frequency dependence of the coupling with a multiphysics FEM simulation in which the signal voltage is applied to the electrode directly under the GaP beam and the other electrode is ground (Fig. 4). The zinc-blende crystal structure of GaP dictates that mechanical breathing modes are most effectively actuated with the axis of the optomechanical crystal cavity aligned with the [011] direction of the GaP crystal lattice and the electric field oriented along the [100] direction (z-axis in Fig. 4). As can be seen from Fig. 4a, the electric field for our coplanar electrode geometry has a component along the z-axis but is in general oriented at an angle. The coplanar electrode arrangement simplifies fabrication but is clearly not ideal. An optimized geometry is discussed below.

a Cross-section of the electric potential between the coplanar microwave signal (red) and ground (blue) electrodes. The black arrows indicate the electric field direction. The orange box is the GaP beam. b FEM simulation of mechanical breathing mode C showing the position of the signal electrode. c Imaginary part of the simulated piezoelectric admittance Y11 (blue) and fit to an LC network (orange). d Circuit representation of the series network of parallel LC resonators used for the admittance fit.

The admittance Y11 of the device as a function of frequency is calculated and fit to that of an equivalent network consisting of a series of parallel LC resonators50 (Fig. 4e). A small imaginary part is introduced to the elasticity tensor of GaP to broaden the spectral response of the individual modes and permit a coarser sampling of the spectrum. The resulting added loss is modeled as parallel resistors in the LC elements. The imaginary part of the admittance is shown in Fig. 4d along with the fit to the LC network, where the electrostatic contribution of the coupling capacitor C0 (which is determined by the geometry and dominates the admittance) has been subtracted for clarity. We find that the equivalent network provides an accurate representation of the electromechanical coupling.

With an equivalent circuit model in place, we can estimate the coupling of each mechanical mode to the microwave probe used experimentally by employing a semi-infinite transmission-line model. Specifically, the coupling capacitor C0 is assumed to be connected to a load impedance Z0 = 50 Ω, yielding for the nth mode an electromechanical coupling rate of

with \({{{\Omega }}}_{{{{{{{{\rm{m}}}}}}}},n}^{2}=1/{L}_{n}{C}_{n}\) (see Supplementary Note 7 for details). The values simulated for Γex,n with a coupling capacitance of C0 = 0.42 fF are listed in Table 1.

Microwave-to-optical transduction

We demonstrate microwave-to-optical transduction by driving the electrode below the device with a vector network analyzer (VNA) and measuring the optical signal from a detuned pump laser reflected from the cavity. The optomechanically induced modulation is observed by direct detection with a fast photoreceiver. The results are shown in Fig. 5. We evaluate the microwave-to-optical transduction by considering the system as a two-port network in which port 1 is the microwave probe and port 2 the photoreceiver. The scattering parameter S21(Ω) as a function of the VNA frequency Ω is then given by

as derived in Supplementary Note 9. Here, ΓD denotes a detection gain factor that is determined by the optical pump power, the photoreceiver’s quantum efficiency, as well as all electrical and optical loss and gain in the system. The subscript n denotes the parameters for the nth mechanical mode. The mechanical susceptibility is

with the mechanical damping rate Γm,n and eigenfrequency Ωm,n. The signal delay through the cables and optical fiber is described by a frequency dependent phase offset Ωτ + θ, where τ is the propagation time through the signal path and θ is a fixed arbitrary phase offset. Additionally, there is a mode-dependent phase offset ϕm,n ∈ {0, π}, corresponding to the relative phase difference between the mechanical displacement at the electromechanical and the optomechanical coupling positions. The optomechanically induced phase modulation is transduced into amplitude modulation detected by the photoreceiver according to the function

where

is the optical susceptibility. The measured microwave-to-optical transmission amplitude ∣S21∣ is shown in Fig. 5a, along with the thermo-mechanical spectrum for comparison. The clear correspondence between the spectra indicates that the transduction is indeed mechanically mediated.

a Thermo-mechanical noise power spectral density (PSD) (top) and microwave-to-optical transmission amplitude ∣S21∣ (bottom). b Quadrature components of the demodulated photoreceiver output voltage distribution Vout when the device is driven at 3.317 GHz (indicated by red arrow in the bottom panel of a) at three microwave powers. For each power level, 105 points were collected at a bandwidth of 10 kHz. The insets show histograms of the real and imaginary part of the noise distribution at −20 dBm along with Gaussian fits (upper left) and the average output voltage 〈Vout〉 versus the average microwave input voltage 〈Vin〉 (lower left). c Amplitude and phase of the transduced signal versus drive frequency, where the contribution due to cable delay τ has been removed. d In-phase versus quadrature component of the transduced signal. Actuation at the measured eigenfrequencies of the dominant modes is indicated by green phasors, with the assignment to the modes shown in Fig. 1k indicated by A, B, and C.

We verify the phase-coherence of the transduced signal by recording the distribution of the photoreceiver output voltage demodulated by the VNA at a fixed frequency of 3.317 GHz (where the highest transmission magnitude was observed), as displayed in Fig. 5b. The symmetric Gaussian distribution, which is dominated by thermo-mechanical noise, and the linear dependence on microwave input power of the displacement in-phase space at constant phase confirm that the transduction is linear and coherent.

The amplitude and phase of the transduction spectrum in the relevant range from 3.22 to 3.35 GHz are shown in Fig. 5c together with a fit to (4). The fit makes use of a separate calibration of the optical cavity response to determine ΓD, performed by phase-modulating the optical pump with a pre-determined modulation depth (see Supplementary Note 10). Using the previously measured vacuum optomechanical coupling rates, the electromechanical coupling rate Γex is then determined from the microwave-to-optical transduction signal. The fit results for the three mechanical modes with the strongest transduction, which we assign to modes A, B, and C, are shown in Table 1. It is instructive to visualize the transduced signal in a phase space representation (Fig. 5d), where the harmonic response of the individual resonator modes follows a circular trajectory. In addition to a small rotation of each mode around the origin that is due to the optical cavity response, we observe a phase offset ϕm of each mode of either 0 or π. We understand this phenomenon to be a result of the shape of each breathing mode’s displacement field. When a mode is driven coherently, the mechanical displacement field in the portion of the GaP beam that overlaps with the electrode inherits its relative phase from the microwave drive. The optical mode, however, couples to a different region that might be in phase or out of phase by π with respect to the piezoelectrically coupled region (see Fig. 1k). Consequently, the optomechanically induced phase modulation of the optical field may also have an added phase offset of 0 (modes A and C) or π (mode B) with respect to the microwave drive. Note that, although the device possesses several other breathing modes, only the three modes A, B, and C provide a reasonable qualitative agreement between simulations and experiment with respect to mechanical frequency, optomechanical coupling rate, and mode-dependent phase offset, justifying the assignment.

Outlook for coupling to a transmon qubit

The total transduction efficiency of the system is given by30

where \({{{{{{{\mathcal{C}}}}}}}}={\bar{n}}_{{{{{{{{\rm{cav}}}}}}}}}\frac{4{g}_{0}^{2}}{\kappa {{{\Gamma }}}_{{{{{{{{\rm{m}}}}}}}}}}\) is the optomechanical cooperativity, and \({\eta }_{{{{{{{{\rm{c}}}}}}}},{{{{{{{\rm{mw}}}}}}}}}=\frac{{{{\Gamma }}}_{{{{{{{{\rm{ex}}}}}}}}}}{{{{\Gamma }}}_{{{{{{{{\rm{m}}}}}}}}}}\) and \({\eta }_{{{{{{{{\rm{c}}}}}}}},{{{{{{{\rm{opt}}}}}}}}}=\frac{{\kappa }_{{{{{{{{\rm{ex}}}}}}}}}}{\kappa }\) are the external microwave and optical coupling factors to the system, respectively. With \({{{{{{{\mathcal{C}}}}}}}}=6.9\times 1{0}^{-3}\) at an optical pump power of 130 nW, we find a maximum transduction efficiency for the device as measured of η = 1.4 × 10−11. The efficiency can be increased by raising the optical power to achieve the optimal value of \({{{{{{{\mathcal{C}}}}}}}}=1\), but the efficiency would still be quite low because of the extremely low microwave external coupling factor ηc,mw = 1.35 × 10−9, which is a consequence of coupling to a highly impedance-mismatched transmission line instead of a resonant microwave cavity. As such, this efficiency value is misleading.

Instead, we consider the more meaningful situation of coupling to a superconducting transmon qubit and estimate the expected electromechanical coupling rate. We restrict the discussion here to an optimized configuration with one electrode below and the other above the photonic crystal cavity with equal gaps to the electrodes (Fig. 6a). The capacitive qubit-resonator coupling scheme is depicted in Fig. 6b, with the circuit parameters C0, L, and C extracted from an admittance fit similar to that described above. In this case, we simulate only the admittance of mechanical mode C, as it exhibits the highest simulated electromechanical coupling in the coplanar geometry. The bilinear coupling between the qubit and the resonator is given by

where CΣ is the qubit shunt capacitance, and the first qubit transition frequency is Ωge (see Supplementary Note 8 for details). For optimal coupling, we assume that the qubit is tuned into resonance with the mechanical oscillator, i.e., Ωge = Ωm. The estimated coupling rate is shown in Fig. 6e for various gap sizes between the electrodes and the optomechanical crystal cavity as a function of the ratio of Josephson energy EJ to charging energy of the qubit EC. For the qubit to exhibit low charge dispersion, a ratio EJ/EC ≫ 1 is required51. For a gap to the electrodes of 50 nm, which can be realistically fabricated, we calculate a coupling rate of gpe/2π = 204 kHz for EJ/EC = 30, well within the transmon regime, with CΣ = 91 fF. Previously, mechanical quality factors of Qm ≈ 2 × 105 have been reported for similar GaP optomechanical crystal cavities at the cryogenic temperature required for single-phonon manipulation45, which corresponds at Ωm/2π = 3 GHz to a mechanical damping rate of Γm/2π = 15 kHz. We therefore estimate that the system presented here would be deep enough in the strong coupling regime to permit a faithful swap of the qubit and mechanical resonator states, if the qubit lifetime T1 ≳ 10 μs. Given the small contribution of the piezoelectric portion (C0 ≈ 0.79 fF) to the total capacitance of such a system, we expect this T1 to be achievable with current technology.

a Cross-section of a FEM simulation of the electric potential between the microwave signal (red) and ground (blue) electrodes for the optimized geometry. The black arrows indicate the electric field direction. The orange box is the GaP beam. b Circuit representation of a transmon qubit coupled to a parallel LC resonator. c FEM simulation of a mechanical breathing mode showing the electrode geometry. d Imaginary part of the simulated piezoelectric admittance Y11 (blue) and fit to an LC resonator (orange). e Calculated qubit shunt capacitance CΣ and coupling rates to a transmon qubit as function of EJ/EC for various gap sizes between the electrodes and the photonic crystal cavity.

Discussion

In summary, we have presented a platform for microwave-to-optical conversion based on single-crystal GaP optomechanical devices integrated directly on prefabricated niobium-on-silicon electrode structures. The extended mechanical breathing modes of our optomechanical crystal cavities were designed for both high optomechanical coupling rates (up to g0/2π = 300 kHz) and piezoelectric actuation by the microwave electrodes. Despite the asymmetric cavity structure and the close proximity of the metal electrodes, high optical quality factors (Q0 ~ 105) were obtained, placing the system in the resolved-sideband regime (Ωm/κ ~ 1.1). Coherent microwave-to-optical transduction in a transmission-line coupled device was demonstrated. The electromechanical coupling rates observed experimentally were substantially smaller than expected from simulations. The discrepancy could be fabrication-related or may be due to insufficient knowledge of the piezoelectric properties of GaP. In future experiments, we aim to integrate the cavity design presented here with superconducting transmon qubits, for which our simulations indicate that strong coupling can be achieved (gpe/2π ≈ 200 kHz). Due to the small participation ratio of the device in the overall qubit energy, we expect long qubit lifetimes.

Data availability

Data supporting the plots within this paper and other findings of this study are available through Zenodo at https://doi.org/10.5281/zenodo.6419115. Further information is available from the corresponding author upon reasonable request.

Code availability

Numerical codes used in this study are available from the corresponding author upon reasonable request.

References

Kjaergaard, M. et al. Superconducting qubits: current state of play. Annu. Rev. Condens. Matter Phys. 11, 369–395 (2020).

Jurcevic, P. et al. Demonstration of quantum volume 64 on a superconducting quantum computing system. Quantum Sci. Technol. 6, 025020 (2021).

Cirac, J. I., Zoller, P., Kimble, H. J. & Mabuchi, H. Quantum state transfer and entanglement distribution among distant nodes in a quantum network. Phys. Rev. Lett. 78, 3221 (1997).

Duan, L.-M., Lukin, M. D., Cirac, J. I. & Zoller, P. Long-distance quantum communication with atomic ensembles and linear optics. Nature 414, 413–418 (2001).

Kimble, H. J. The quantum internet. Nature 453, 1023–1030 (2008).

Magnard, P. et al. Microwave quantum link between superconducting circuits housed in spatially separated cryogenic systems. Phys. Rev. Lett. 125, 260502 (2020).

Landry, O., van Houwelingen, J. A. W., Beveratos, A., Zbinden, H. & Gisin, N. Quantum teleportation over the Swisscom telecommunication network. J. Optical Soc. Am. B 24, 398–403 (2007).

Lauk, N. et al. Perspectives on quantum transduction. Quantum Sci. Technol. 5, 020501 (2020).

Lambert, N. J., Rueda, A., Sedlmeir, F. & Schwefel, H. G. Coherent conversion between microwave and optical photons-an overview of physical implementations. Adv. Quantum Technol. 3, 1900077 (2020).

Zhong, C. et al. Proposal for heralded generation and detection of entangled microwave–optical-photon pairs. Phys. Rev. Lett. 124, 010511 (2020).

Sahu, R. et al. Quantum-enabled operation of a microwave-optical interface. Nat. Commun. 13, 1276 (2022).

Hease, W. et al. Bidirectional electro-optic wavelength conversion in the quantum ground state. PRX Quantum 1, 020315 (2020).

Rueda, A., Hease, W., Barzanjeh, S. & Fink, J. M. Electro-optic entanglement source for microwave to telecom quantum state transfer. npj Quantum Inf. 5, 108 (2019).

Soltani, M. et al. Efficient quantum microwave-to-optical conversion using electro-optic nanophotonic coupled resonators. Phys. Rev. A 96, 043808 (2017).

Rueda, A. et al. Efficient microwave to optical photon conversion: an electro-optical realization. Optica 3, 597–604 (2016).

Fan, L. et al. Superconducting cavity electro-optics: a platform for coherent photon conversion between superconducting and photonic circuits. Sci. Adv. 4, eaar4994 (2018).

Witmer, J. D. et al. A silicon-organic hybrid platform for quantum microwave-to-optical transduction. Quantum Sci. Technol. 5, 034004 (2020).

Javerzac-Galy, C. et al. On-chip microwave-to-optical quantum coherent converter based on a superconducting resonator coupled to an electro-optic microresonator. Phys. Rev. A 94, 053815 (2016).

Hisatomi, R. et al. Bidirectional conversion between microwave and light via ferromagnetic magnons. Phys. Rev. B 93, 174427 (2016).

Vogt, T. et al. Efficient microwave-to-optical conversion using rydberg atoms. Phys. Rev. A 99, 023832 (2019).

Han, J. et al. Coherent microwave-to-optical conversion via six-wave mixing in rydberg atoms. Phys. Rev. Lett. 120, 093201 (2018).

Bartholomew, J. G. et al. On-chip coherent microwave-to-optical transduction mediated by ytterbium in YVO4. Nat. Commun. 11, 3266 (2020).

Everts, J. R., Berrington, M. C., Ahlefeldt, R. L. & Longdell, J. J. Microwave to optical photon conversion via fully concentrated rare-earth-ion crystals. Phys. Rev. A 99, 063830 (2019).

Williamson, L. A., Chen, Y.-H. & Longdell, J. J. Magneto-optic modulator with unit quantum efficiency. Phys. Rev. Lett. 113, 203601 (2014).

Tsang, M. Cavity quantum electro-optics. Phys. Rev. A 81, 063837 (2010).

Tsang, M. Cavity quantum electro-optics. ii. input-output relations between traveling optical and microwave fields. Phys. Rev. A 84, 043845 (2011).

Andrews, R. W. et al. Bidirectional and efficient conversion between microwave and optical light. Nat. Phys. 10, 321–326 (2014).

Bagci, T. et al. Optical detection of radio waves through a nanomechanical transducer. Nature 507, 81–85 (2014).

Higginbotham, A. P. et al. Harnessing electro-optic correlations in an efficient mechanical converter. Nat. Phys. 14, 1038–1042 (2018).

Jiang, W. et al. Efficient bidirectional piezo-optomechanical transduction between microwave and optical frequency. Nat. Commun. 11, 1166 (2020).

Balram, K. C., Davanço, M. I., Song, J. D. & Srinivasan, K. Coherent coupling between radiofrequency, optical and acoustic waves in piezo-optomechanical circuits. Nat. Photonics 10, 346–352 (2016).

Vainsencher, A., Satzinger, K., Peairs, G. & Cleland, A. Bi-directional conversion between microwave and optical frequencies in a piezoelectric optomechanical device. Appl. Phys. Lett. 109, 033107 (2016).

Bochmann, J., Vainsencher, A., Awschalom, D. D. & Cleland, A. N. Nanomechanical coupling between microwave and optical photons. Nat. Phys. 9, 712–716 (2013).

Shao, L. et al. Microwave-to-optical conversion using lithium niobate thin-film acoustic resonators. Optica 6, 1498–1505 (2019).

Han, X. et al. Cavity piezo-mechanics for superconducting-nanophotonic quantum interface. Nat. Commun. 11, 3237 (2020).

Aspelmeyer, M., Kippenberg, T. J. & Marquardt, F. Cavity optomechanics. Rev. Mod. Phys. 86, 1391 (2014).

Riedinger, R. et al. Non-classical correlations between single photons and phonons from a mechanical oscillator. Nature 530, 313–316 (2016).

Riedinger, R. et al. Remote quantum entanglement between two micromechanical oscillators. Nature 556, 473–477 (2018).

Mirhosseini, M., Sipahigil, A., Kalaee, M. & Painter, O. Superconducting qubit to optical photon transduction. Nature 588, 599–603 (2020).

Chu, Y. et al. Creation and control of multi-phonon fock states in a bulk acoustic-wave resonator. Nature 563, 666–670 (2018).

Satzinger, K. J. et al. Quantum control of surface acoustic-wave phonons. Nature 563, 661–665 (2018).

Arrangoiz-Arriola, P. et al. Resolving the energy levels of a nanomechanical oscillator. Nature 571, 537–540 (2019).

Chan, J. et al. Laser cooling of a nanomechanical oscillator into its quantum ground state. Nature 478, 89–92 (2011).

Schneider, K. et al. Optomechanics with one-dimensional gallium phosphide photonic crystal cavities. Optica 6, 577–584 (2019).

Stockill, R. et al. Gallium phosphide as a piezoelectric platform for quantum optomechanics. Phys. Rev. Lett. 123, 163602 (2019).

Forsch, M. et al. Microwave-to-optics conversion using a mechanical oscillator in its quantum ground state. Nat. Phys. 16, 69–74 (2020).

Chan, J., Safavi-Naeini, A. H., Hill, J. T., Meenehan, S. & Painter, O. Optimized optomechanical crystal cavity with acoustic radiation shield. Appl. Phys. Lett. 101, 081115 (2012).

Wilson, D. J. et al. Integrated gallium phosphide nonlinear photonics. Nat. Photonics 14, 57–62 (2020).

Gorodetksy, M., Schliesser, A., Anetsberger, G., Deleglise, S. & Kippenberg, T. J. Determination of the vacuum optomechanical coupling rate using frequency noise calibration. Opt. Express 18, 23236–23246 (2010).

Arrangoiz-Arriola, P. & Safavi-Naeini, A. H. Engineering interactions between superconducting qubits and phononic nanostructures. Phys. Rev. A 94, 063864 (2016).

Koch, J. et al. Charge-insensitive qubit design derived from the cooper pair box. Phys. Rev. A 76, 042319 (2007).

Acknowledgements

We gratefully acknowledge Katharina Schmeing, Yannick Baumgartner, Lukas Czornomaz, Ute Drechsler, Diana Davila, and Antonis Olziersky for their valuable contributions to development of the GaP-on-insulator platform. We also thank Gary Steele, Byoung-Moo Ann, Darius Urbonas, Matthias Mergenthaler, Thomas Karg, and Charles Möhl for useful discussions. This work was supported by the European Union’s Horizon 2020 Program for Research and Innovation under grant agreement No. 722923 (Marie Curie H2020-ETN OMT for S.H. and A.B.) and No. 732894 (FET Proactive HOT for S.H., T.J.K., and P.S.). All samples were fabricated at the Binnig and Rohrer Nanotechnology Center (BRNC) at IBM Research Europe, Zurich.

Author information

Authors and Affiliations

Contributions

S.H. designed the device and carried out the epitaxial growth of GaP as well as the microfabrication processes. S.H. performed FEM simulations of the photonic crystal cavities with support from A.B. Wafer bonding of GaP was done by D.C. Y.P. carried out chemical mechanical polishing with support from S.H. S.H. and P.S. wrote the manuscript with input from A.B. and T.J.K. P.S. conceived the project, and T.J.K. and P.S. supervised the work.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Harald Schwefel and the other anonymous reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hönl, S., Popoff, Y., Caimi, D. et al. Microwave-to-optical conversion with a gallium phosphide photonic crystal cavity. Nat Commun 13, 2065 (2022). https://doi.org/10.1038/s41467-022-28670-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-022-28670-5

This article is cited by

-

Electrically interfaced Brillouin-active waveguide for microwave photonic measurements

Nature Communications (2024)

-

Bidirectional microwave-optical transduction based on integration of high-overtone bulk acoustic resonators and photonic circuits

Nature Communications (2024)

-

Continuous wideband microwave-to-optical converter based on room-temperature Rydberg atoms

Nature Photonics (2024)

-

Optomechanical ring resonator for efficient microwave-optical frequency conversion

Nature Communications (2023)

-

Coherent memory for microwave photons based on long-lived mechanical excitations

npj Quantum Information (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.