Abstract

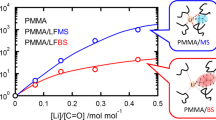

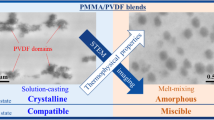

To improve the transparency and tensile properties of immiscible poly(methyl methacrylate) (PMMA) and ethylene-vinyl alcohol copolymer (EVOH) blended films, lithium (trifluoromethane sulfonyl) imide (LiTFSI) was added in small amounts. The addition of LiTFSI improved the transparencies of the PMMA/EVOH blends. However, scanning electron microscopy (SEM) images revealed that the blends with LiTFSI still maintained a sea-island morphology of the PMMA and EVOH phases with strong interfacial adhesion. A comparison of the SEM and energy-dispersive X-ray spectroscopy (EDS) images revealed the localization of LiTFSI in the EVOH domains. By comparing the refractive index data for the EVOH/LiTFSI blends, we established that the refractive indexes of the EVOH phases at LiTFSI concentrations of 20 or 30 wt% matched that of pure PMMA, which accounted for the improvement in transparency. The localization of LiTFSI interrupted the intra- and intermolecular hydrogen bonds of the OH groups in EVOH, resulting in a decrease in crystallinity. Consequently, the amorphous and flexible EVOH domains dispersed in the PMMA matrix prevented stress concentration during tensile deformation, improving the tensile properties.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Bubmann T, Seidel A, Ruckdäschel H, Altstädt V. Transparent PC/PMMA blends with enhanced mechanical properties via reactive compounding of functionalized polymers. Polymers. 2021;14:73.

Sinha Ray S, Bousmina M, Maazouz A. Morphology and properties of organoclay modified polycarbonate/poly(methyl methacrylate) blend. Polym Eng Sci. 2006:1121–9.

Xi S, Huang Y, Yang Q, Li G. Compatibilization of PMMA/PC blends with different strategies: transesterification catalyst versus nanoparticles. Ind Eng Chem Res. 2014;53:5916–24.

Ishigami A, Watanabe K, Kurose T, Ito H. Physical and morphological properties of tough and transparent PMMA-based blends modified with polyrotaxane. Polymers. 2020;12:1790–802.

Li Y, Shimizu H. Compatibilization by homopolymer: significant improvements in the modulus and tensile strength of PPC/PMMA blends by the addition of a small amount of PVAc. ACS Appl Mater Interfaces. 2009;1:1650–5.

Laatsch J, Kim GM, Michler GH, Arndt T, Süfke T. Investigation of the micromechanical deformation behavior of transparent toughened poly(methylmethacrylate) modified with core-shell particles. Polym Adv Technol. 1998;9:716–20.

Giménez E, Lagarón JM, Maspoch ML, Cabedo L, Saura JJ. Uniaxial tensile behavior and thermoforming characteristics of high barrier EVOH-based blends of interest in food packaging. Polym Eng Sci. 2004;44:598–608.

Soni R, Hsu YI, Asoh TA, Uyama H. Cellulose nanofiber reinforced starch film with rapid disintegration in marine environments. J Appl Polym Sci. 2022;139:e52776.

Lessard JJ, Garcia LF, Easterling CP, Sims MB, Bentz KC, Arencibia S, et al. Catalyst-free vitrimers from vinyl polymers. Macromolecules. 2019;52:2105–11.

Ito A, Phulkerd P, Ayerdurai V, Soga M, Courtoux A, Miyagawa A, et al. Enhancement of the glass transition temperature of poly(methyl methacrylate) by salt. Polym J. 2018;50:857–63.

Miyagawa A, Ayerdurai V, Nobukawa S, Yamaguchi M. Viscoelastic properties of poly(methyl methacrylate) with high glass transition temperature by lithium salt addition. J Polym Sci B Polym Phys. 2016;54:2388–94.

de Lima JA, Felisberti MI. Poly(ethylene-co-vinyl alcohol) and poly(methyl methacrylate) blends: phase behavior and morphology. Eur Polym J. 2008;44:1140–8.

de Lima JA, Felisberti MI. Porous polymer structures obtained via the TIPS process from EVOH/PMMA/DMF solutions. J Membr Sci. 2009;344:237–43.

Freymond C, Guinault A, Gervais M, Pluta M, Makowski T, Piorkowska E, et al. Crystallization behavior and morphological features of ethylene-vinyl alcohol 44 copolymer. Express Polym Lett. 2022;16:338–53.

Tsugawa N, Ito A, Yamaguchi M. Effect of lithium salt addition on the structure and optical properties of PMMA/PVB blends. Polymer. 2018;146:242–8.

Olmedo-Martínez JL, Meabe L, Basterretxea A, Mecerreyes D, Müller AJ. Effect of chemical structure and salt concentration on the crystallization and ionic conductivity of aliphatic polyethers. Polymers. 2019;11:452–64.

Olmedo-Martínez JL, Pastorio M, Gabirondo E, Lorenzetti A, Sardon H, Mecerreyes D, et al. Polyether single and double crystalline blends and the effect of lithium salt on their crystallinity and ionic conductivity. Polymers. 2021;13:2097–110.

Yamamoto T, Kanda T, Ooshima T, Saito Y. Correlation study among oxygen permeability, molecular mobility, and amorphous structure change of poly(ethylene-vinylalcohol copolymers) by moisture. J Appl Polym Sci. 2009;47:1181–91.

Sun B, Mindemark J, Morozov EV, Costa LT, Bergman M, Johansson P, et al. Ion transport in polycarbonate based solid polymer electrolytes: experimental and computational investigations. Phys Chem Chem Phys. 2016;18:9504–13.

Lee JY, Jang J. IR study on the character of hydrogen bonding in novel liquid crystalline epoxy resin. Polym Bull. 1997;38:447–54.

Venugopal G, Krause S, Wnek GE. Phase behaviour of poly(ethylene oxide)/poly(methyl methacrylate) blends containing alkali metal salts. Polymer. 1993;34:3241–6.

Coates J. Interpretation of infrared spectra, a practical approach. In: Meyers RA, Editor-in-Chief. Encyclopedia of analytical chemistry. 2006. p. 1–23.

Zhang Z, Britt IJ, Tung MA. Water absorption in EVOH films and its influence on glass transition temperature. J Polym Sci B Polym Physiol. 1999;37:691–9.

Vannini M, Marchese P, Celli A, Lorenzetti C. Strategy to modify the crystallization behavior of EVOH32 through interactions with low-molecular-weight molecules. Ind Eng Chem Res. 2016;55:3517–24.

Hughes LJ, Britt GE. Compatibility studies on polyacrylate and polymethacrylate systems. J Appl Polym Sci. 1961;5:337–48.

Song JY, Kim JW, Suh KD. Poly(methyl methacrylate) toughening with refractive index-controlled core-shell composite particles. J Appl Polym Sci. 1999;71:1607–14.

Park JG, Kim JY, Suh KD. Preparation of toughened PMMA through PEG-modified urethane acrylate/PMMA core-shell composite particles. J Appl Polym Sci. 1998;69:2291–302.

Takahashi S, Okada H, Nobukawa S, Yamaguchi M. Optical properties of polymer blends composed of poly(methyl methacrylate) and ethylene-vinyl acetate copolymer. Eur Polym J. 2012;48:974–80.

Boldrini B, Ostertag E, Rebner K, Oelkrug D. Exploring the hidden depth by confocal Raman experiments with variable objective aperture and magnification. Anal Bioanal Chem. 2021;413:7093–106.

Franke H, Festl HG, Kratzig E. Light induced refractive index changes in PMMA films doped with styrene. Polym Sci. 1984;262:213–6.

Bodurov I, Yovcheva T, Sainov S. PMMA films refractive index modulation via TiO2 nanoparticle inclusions and corona poling. Colloid Polym Sci. 2014;292:3045–8.

Seki S, Tsuzuki S, Hayamizu K, Umebayashi Y, Serizawa N, Takei K, et al. Comprehensive refractive index property for room-temperature ionic liquids. J Chem Eng Data. 2012;57:2211–6.

Shimizu K, Tariq M, Costa Gomes MF, Rebelo LP, Canongia Lopes JN. Assessing the dispersive and electrostatic components of the cohesive energy of ionic liquids using molecular dynamics simulations and molar refraction data. J Phys Chem B. 2010;114:5831–4.

Sun ST, Wang H, Huang D, Ding YL, Zhang Y, Song DP, et al. Refractive index engineering as a novel strategy toward highly transparent and tough sustainable polymer blends. Chin J Polym Sci. 2020;38:1335–44.

Aly KA. On the study of the optical constants for different compositions of Snx(GeSe)100−x thin films in terms of the electronic polarizability, electronegativity and bulk modulus. Appl Phys A Mater Sci Process. 2015;120:293–9.

Acknowledgements

We would like to appreciate Mitsubishi Chemical Corporation for providing EVOH samples and advising to the experimental data. We would like to also thank Ms. Atsuko Mori of Nagoya Institute of Technology, for SEM and EDS analyses. DMA measurement was supported by the Equipment Sharing Division, Organization for Co-Creation Research and Social Contributions, Nagoya Institute of Technology.

Author information

Authors and Affiliations

Contributions

The manuscript was written with contributions from all authors. All authors approved the final version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Watanabe, H., Horada, M., Inomata, K. et al. Enhancing the transparency and tensile properties of immiscible poly(methyl methacrylate)/ethylene-vinyl alcohol copolymer blends by lithium salt addition. Polym J 56, 173–183 (2024). https://doi.org/10.1038/s41428-023-00866-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-023-00866-6