Abstract

Cellulose-containing polymer composites have advantages in addressing environmental issues because cellulose is a biobased filler that enhances the mechanical properties of the polymer composites. The enhanced mechanical properties reduce the amount of polymer waste generated. Although it is important to establish strategies for enhancing the mechanical properties of polymer composites, there are limited nanoscale studies on the polymer matrices. Usually, polymer composites focus on interactions between the matrices and fillers on the molecular scale and the distribution degrees of the fillers. The lack of structural studies is particularly obvious for polymer composites containing citric acid-modified cellulose. Herein, we study the structures of polymer composites with X-ray scattering measurements, thermal property measurements, and the finite element method. We reveal that an appropriate phase separation structure enables the formation of effective hydrogen bonds with high toughness values. We expect this report to provide material designs for polymer composites.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

DiBenedetto AT. Tailoring of interfaces in glass fiber reinforced polymer composites: a review. Mater Sci Eng A. 2001;302:74–82.

Chang TE, Kisliuk A, Rhodes SM, Brittain WJ, Sokolov AP. Conductivity and mechanical properties of well-dispersed single-wall carbon nanotube/polystyrene composite. Polymer. 2006;47:7740–6.

Antich P, Vázquez A, Mondragon I, Bernal C. Mechanical behavior of high impact polystyrene reinforced with short sisal fibers. Compos Part A Appl Sci Manuf. 2006;37:139–50.

Barzegari MR, Alemdar A, Zhang Y, Rodrigue D. Mechanical and rheological behavior of highly filled polystyrene with lignin. Polym Compos. 2012;33:353–61.

Fujisawa S, Ikeuchi T, Takeuchi M, Saito T, Isogai A. Superior reinforcement effect of TEMPO-oxidized cellulose nanofibrils in polystyrene matrix: optical, thermal, and mechanical studies. Biomacromolecules. 2012;13:2188–94.

Ramanathan T, Abdala AA, Stankovich S, Dikin DA, Herrera-Alonso M, Piner RD, et al. Functionalized graphene sheets for polymer nanocomposites. Nat Nanotechnol. 2008;3:327–31.

Yamanobe T, Takeda H, Takada Y, Nagai D, Yoneyama M, Uehara H, et al. Structure and physical properties of poly(lactic acid) and cyclodextrin composite. J Incl Phenom Macrocycl Chem. 2019;93:117–26.

Park J, Murayama S, Osaki M, Yamaguchi H, Harada A, Matsuba G, et al. Reinforced polystyrene through host-guest interactions using cyclodextrin as an additive. Eur. Polym J. 2020;134:109807.

Yano H, Sugiyama J, Nakagaito AN, Nogi M, Matsuura T, Hikita M, et al. Optically transparent composites reinforced with networks of bacterial nanofibers. Adv Mater. 2005;17:153–5.

Klemm D, Heublein B, Fink HP, Bohn A. Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed. 2005;44:3358–93.

Saito T, Kimura S, Nishiyama Y, Isogai A. Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules. 2007;8:2485–91.

Nogi M, Yano H. Transparent nanocomposites based on cellulose produced by bacteria offer potential innovation in the electronics device industry. Adv Mater. 2008;20:1849–52.

Klemm D, Kramer F, Moritz S, Lindström T, Ankerfors M, Gray D, et al. Nanocelluloses: a new family of nature-based materials. Angew Chem Int Ed. 2011;50:5438–66.

Isogai A, Saito T, Fukuzumi H. TEMPO-oxidized cellulose nanofibers. Nanoscale. 2011;3:71–85.

Santmarti A, Teh JW, Lee KY. Transparent poly(methyl methacrylate) composites based on bacterial cellulose nanofiber networks with improved fracture resistance and impact strength. ACS Omega. 2019;4:9896–903.

Yasim-Anuar TAT, Ariffin H, Norrrahim MNF, Hassan MA, Andou Y, Tsukegi T, et al. Well-dispersed cellulose nanofiber in low density polyethylene nanocomposite by liquid-Assisted extrusion. Polymers. 2020;12:927.

Giese M, Blusch LK, Khan MK, Hamad WY, Maclachlan MJ. Responsive mesoporous photonic cellulose films by supramolecular cotemplating. Angew Chem Int Ed. 2014;53:8880–4.

Siaueira G, Bras J, Dufresne A. Cellulose whiskers versus microfibrils: Influence of the nature of the nanoparticle and its surface functionalization on the thermal and mechanical properties of nanocomposites. Biomacromolecules. 2009;10:425–32.

Eichhorn SJ. Cellulose nanowhiskers: promising materials for advanced applications. Soft Matter. 2011;7:303–15.

Yang X, Liu G, Peng L, Guo J, Tao L, Yuan J, et al. Highly efficient self-healable and dual responsive cellulose-based hydrogels for controlled release and 3D cell culture. Adv. Funct. Mater. 2017;27:1703174.

McKee JR, Appel EA, Seitsonen J, Kontturi E, Scherman OA, Ikkala O. Healable, stable and stiff hydrogels: combining conflicting properties using dynamic and selective three-component recognition with reinforcing cellulose nanorods. Adv. Funct. Mater. 2014;24:2706–13.

Erb RM, Sander JS, Grisch R, Studart AR. Self-shaping composites with programmable bioinspired microstructures. Nat Commun. 2013;4:1712.

Habibi Y, Lucia LA, Rojas OJ. Cellulose nanocrystals: chemistry, self-assembly, and applications. Chem Rev. 2010;110:3479–500.

Eyley S, Thielemans W. Surface modification of cellulose nanocrystals. Nanoscale. 2014;6:7764–79.

Araki J, Wada M, Kuga S. Steric stabilization of a cellulose microcrystal suspension by poly(ethylene glycol) grafting. Langmuir. 2001;17:21–7.

Harrisson S, Drisko GL, Malmström E, Hult A, Wooley KL. Hybrid rigid/soft and biologic/synthetic materials: polymers grafted onto cellulose microcrystals. Biomacromolecules. 2011;12:1214–23.

Bragd PL, Van Bekkum H, Besemer AC. TEMPO-mediated oxidation of polysaccharides: survey of methods and applications. Top Catal. 2004;27:49–66.

Pérez S, Samain D. Structure and engineering of celluloses. Adv Carbohydr Chem Biochem. 2010;64:25–116.

Boufi S, Belgacem MN. Modified cellulose fibres for adsorption of dissolved organic solutes. Cellulose. 2006;13:81–94.

Braun B, Dorgan JR. Single-step method for the isolation and surface functionalization of cellulosic nanowhiskers. Biomacromolecules. 2009;10:334–41.

Braun B, Dorgan JR, Hollingsworth LO. Supra-molecular ecobionanocomposites based on polylactide and cellulosic nanowhiskers: synthesis and properties. Biomacromolecules. 2012;13:2013–9.

Cui X, Honda T, Asoh TA, Uyama H. Cellulose modified by citric acid reinforced polypropylene resin as fillers. Carbohydr Polym. 2020;230:115662.

Tsuchiya H, Sinawang G, Asoh TA, Osaki M, Ikemoto Y, Higuchi Y, et al. Supramolecular biocomposite hydrogels formed by cellulose and host-guest polymers assisted by calcium ion complexes. Biomacromolecules. 2020;21:3936–44.

Sinawang G, Asoh T-A, Osaki M, Yamaguchi H, Harada A, Uyama H, et al. Citric acid-modified cellulose-based tough and self-healable composite formed by two kinds of noncovalent bonding. ACS Appl Polym Mater. 2020;2:2274–83.

Tsuchiya H, Asaki Y, Sinawang G, Asoh TA, Osaki M, Park J, et al. Cellulose nanofiber composite polymeric materials with reversible and movable cross-links and evaluation of their mechanical properties. ACS Appl Polym Mater. 2022;4:403–12.

Chutimasakul T, Uetake Y, Tantirungrotechai J, Asoh TA, Uyama H, Sakurai H. Size-controlled preparation of gold nanoparticles deposited on surface-fibrillated cellulose obtained by citric acid modification. ACS Omega. 2020;5:33206–13.

Sijbesma RP, Beijer FH, Brunsveld L, Folmer BJB, Hirschberg JHKK, Lange RFM, et al. Reversible polymers formed from self-complementary monomers using quadruple hydrogen bonding. Science. 1997;278:1601–4.

Yanagisawa Y, Nan Y, Okuro K, Aida T. Mechanically robust, readily repairable polymers via tailored noncovalent cross-linking. Science. 2018;359:72–6.

Huang X, Nakagawa S, Houjou H, Yoshie N. Insights into the role of hydrogen bonds on the mechanical properties of polymer networks. Macromolecules. 2021;54:4070–80.

Uchida J, Soberats B, Gupta M, Kato T. Advanced functional liquid crystals. Adv. Mater. 2022;34:2109063.

Lin Sun T, Kurokawa T, Kuroda S, Bin Ihsan A, Akasaki T, Sato K, et al. Physical hydrogels composed of polyampholytes demonstrate high toughness and viscoelasticity. Nat Mater. 2013;12:932–7.

Bose RK, Hohlbein N, Garcia SJ, Schmidt AM, Van Der Zwaag S. Connecting supramolecular bond lifetime and network mobility for scratch healing in poly(butyl acrylate) ionomers containing sodium, zinc and cobalt. Phys Chem Chem Phys. 2015;17:1697–704.

Rao YL, Chortos A, Pfattner R, Lissel F, Chiu YC, Feig V, et al. Stretchable self-healing polymeric dielectrics cross-linked through metal-ligand coordination. J Am Chem Soc. 2016;138:6020–7.

Nakahata M, Takashima Y, Harada A. Highly flexible, tough, and self-healing supramolecular polymeric materials using host-guest interaction. Macromol Rapid Commun. 2016;37:86–92.

Liu J, Tan CSY, Yu Z, Li N, Abell C, Scherman OA. Tough supramolecular polymer networks with extreme stretchability and fast room-temperature self-healing. Adv Mater. 2017;29:1605325.

Schmidt BVKJ, Barner-Kowollik C. Dynamic macromolecular material design—the versatility of cyclodextrin-based host–guest chemistry. Angew Chem Int Ed. 2017;56:8350–69.

Park J, Murayama S, Osaki M, Yamaguchi H, Harada A, Matsuba G, et al. Extremely rapid self-healable and recyclable supramolecular materials through planetary ball milling and host–guest interactions. Adv Mater. 2020;32:2002008.

Huang Z, Chen X, O’Neill SJK, Wu G, Whitaker DJ, Li J, et al. Highly compressible glass-like supramolecular polymer networks. Nat Mater. 2022;21:103–9.

Haque MA, Kurokawa T, Gong JP. Super tough double network hydrogels and their application as biomaterials. Polymer. 2012;53:1805–22.

Matsuda T, Kawakami R, Namba R, Nakajima T, Gong JP. Mechanoresponsive self-growing hydrogels inspired by muscle training. Science. 2019;363:504–8.

Sakai T, Matsunaga T, Yamamoto Y, Ito C, Yoshida R, Suzuki S, et al. Design and fabrication of a high-strength hydrogel with ideally homogeneous network structure from tetrahedron-like macromonomers. Macromolecules. 2008;41:5379–84. Il

Fujiyabu T, Sakumichi N, Katashima T, Liu C, Mayumi K, Chung U, et al. Tri-branched gels: rubbery materials with the lowest branching factor approach the ideal elastic limit. Sci Adv. 2022;8:eabk0010.

Kawai Y, Park J, Ishii Y, Urakawa O, Murayama S, Ikura R, et al. Preparation of dual-cross network polymers by the knitting method and evaluation of their mechanical properties. NPG Asia Mater. 2022;14:32.

Ikura R, Murayama S, Park J, Ikemoto Y, Osaki M, Yamaguchi H, et al. Fabrication and mechanical properties of knitted dissimilar polymeric materials with movable cross-links. Mol Syst Des Eng. 2022;7:733–45.

Okumura Y, Ito K. The polyrotaxane gel: a topological gel by figure-of-eight cross-links. Adv Mater. 2001;13:485–7.

Oku T, Furusho Y, Takata T. A concept for recyclable cross-linked polymers: topologically networked polyrotaxane capable of undergoing reversible assembly and disassembly. Angew Chem Int Ed. 2004;43:966–9.

Mayumi K, Ito K. Structure and dynamics of polyrotaxane and slide-ring materials. Polymer. 2010;51:959–67.

Iijima K, Aoki D, Otsuka H, Takata T. Synthesis of rotaxane cross-linked polymers with supramolecular cross-linkers based on γ-CD and PTHF macromonomers: the effect of the macromonomer structure on the polymer properties. Polymer. 2017;128:392–6.

Ikura R, Park J, Osaki M, Yamaguchi H, Harada A, Takashima Y. Supramolecular elastomers with movable cross-linkers showing high fracture energy based on stress dispersion. Macromolecules. 2019;52:6953–62.

Sawada J, Aoki D, Sun Y, Nakajima K, Takata T. Effect of coexisting covalent cross-links on the properties of rotaxane-cross-linked polymers. ACS Appl Polym Mater. 2020;2:1061–4.

Liu C, Morimoto N, Jiang L, Kawahara S, Noritomi T, Yokoyama H, et al. Tough hydrogels with rapid self-reinforcement. Science. 2021;372:1078–81.

Park J, Tamura H, Yamaguchi H, Harada A, Takashima Y. Supramolecular nylon-based actuators with a high work efficiency based on host–guest complexation and the mechanoisomerization of azobenzene. Polym J. 2022;54:1213–23.

Kwon G, Kim M, Jung WH, Park S, Tam TTH, Oh SH, et al. Designing cooperative hydrogen bonding in polyethers with carboxylic acid pendants. Macromolecules. 2021;54:8478–87.

Swatloski RP, Spear SK, Holbrey JD, Rogers RD. Dissolution of cellose with ionic liquids. J Am Chem Soc. 2002;124:4974–5.

Gupta KM, Hu Z, Jiang J. Molecular insight into cellulose regeneration from a cellulose/ionic liquid mixture: effects of water concentration and temperature. RSC Adv. 2013;3:4425–33.

Gupta KM, Hu Z, Jiang J. Cellulose regeneration from a cellulose/ionic liquid mixture: the role of anti-solvents. RSC Adv. 2013;3:12794–801.

Uetsuji Y, Yasuda S, Teramoto Y. Effect of fibre aspect ratio and aggregation on nonlinear material property of random cellulose reinforced composites: a multiscale computational study. Compos Struct. 2022;301:116201.

Acknowledgements

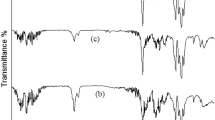

This research was funded by Scientific Research on Innovative Area JP19H05721 from MEXT of Japan, JST, the Core Research for Evolutional Science and Technology (CREST) program JPMJCR22L4 and COI-NEXT program JPMJPF2218, and Iketani Science and Technology Foundation (0341026-A). The authors would like to thank Dr. Kenichi Osaka (SPring-8, JASRI) for the synchrotron radiation scattering measurements. The synchrotron radiation experiments were performed at BL19B2 of SPring-8 with the approval of the Japan Synchrotron Radiation Research Institute (JASRI) (Proposal No. 2022A1797). We thank Dr. Naoya Inazumi and the Analytical Instrumental Facility, Graduate School of Science, Osaka University, for supporting the NMR and FT-IR measurements.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Park, J., Asaki, Y., Fujiwara, Y. et al. Tough citric acid-modified cellulose-containing polymer composites with three components consisting of movable cross-links and hydrogen bonds. Polym J 55, 1151–1164 (2023). https://doi.org/10.1038/s41428-023-00823-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-023-00823-3