Abstract

Natural rubber is a naturally occurring nanocomposite with an island-nanomatrix structure. It is composed of cis-1,4-polyisoprene particles with an average diameter of ~1 μm dispersed in a nanomatrix (several tens of nanometers thick) of nonrubber components such as proteins and phospholipids. The island-nanomatrix structure is stabilized by physical and chemical pinning with proteins and phospholipids that is based on the fact that cis-1,4-polyisoprene of natural rubber is a branched polymer. In this paper, the effects of the island-nanomatrix structure on the mechanical properties of natural rubber are demonstrated with experimental results. Essential facts are described. First, the island-nanomatrix structure disappears, and the mechanical properties of natural rubber decrease, as proteins are removed from rubber. Second, the mechanical properties are recoverable to the original level when the island-nanomatrix structure reforms in natural rubber after protein is removed. Third, the outstanding mechanical properties of natural rubber are attributed to a ten-fold increase in the modulus of cis-1,4-polyisoprene present as a bound rubber in the nanomatrix. Fourth, the effects of the nanomatrix structure on the mechanical properties are confirmed by forming the island-nanomatrix structure in synthetic cis-1,4-polyisoprene.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Kawahara S. Rubber, natural. In: Encyclopedia of polymer science and technology. New York: John Wiley & Sons, Inc.; 2023.

Kawahara S, Chaikumpollert O, Akabori K, Yamamoto Y. Morphology and properties of natural rubber with nanomatrix of non-rubber components. Polym Adv Technol. 2011;22:2665–7.

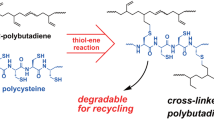

Kawahara S, Nishioka H, Yamano M, Yamamoto Y. Synthetic rubber with the tensile strength of natural rubber. ACS Appl Polym Mater 2022;4:2323–8.

Kosugi K, Kawahara S. Natural rubber with nanomatrix of non-rubber components observed by focused ion beam-scanning electron microscopy. Colloid Polym Sci 2015;293:135–41.

Kroschwitz JI. Concise encyclopedia of polymer science and engineering. New York: John Wiley & Sons; 1990.

Furuta I, Kimura SI, Iwama M. Physical contents of rubbery polymers. In: Brundrup J, Immergut EH, Grulke EA, editors. Polymer handbook. 4th ed. Vol. 1. New York: John Wiley & Sons; 1999. p. V/1-7.

Yamashita S. Natural rubber. In: Horie K, Sanui K, editors. Kobunshi Jiten. 3rd edn. The Society of Polymer Science, Japan. Tokyo: Asakura Shoten; 2005. p. 417.

Ikeda Y. Gomu no Kagaku. In: Okuyama M, Kohjiya S, Nishi T, Yamaguchi K, editors. Gomu no Jiten. Tokyo: Asakura Shoten; 2000. p. 21–38.

Cyr DRS. Rubber, natural. In: Grayson M, Eckroth D, editors. Kirk-Othmer encyclopedia of chemical technology. 3rd ed. Vol. 20. Tokyo: John Wiley & Sons; 1976. p. 468–91.

Cyr DRS. Rubber, natural. In: Mark HF, Bikales NM, Overberger CG, Manges G, Kroschwits JI, editors. Encyclopedia of polymer science and technology. Vol.14. New York: John Wiley & Sons; 1988. p. 687–716.

Wypych G. Handbook of polymers. 2nd ed. Toronto: ChemTech Publishing; 2016.

Takenaka K. Microstructure (synthetic rubber). In Division report, Division13 Polymer. The Chemical Society of Japan; 2014. https://division.csj.jp/div-report/13/1310702.pdf.

Kaita S, Doi Y, Kaneko K, Horiuchi AC, Wakatsuki Y. An efficient Gadolinium metallocene-based catalyst for the synthesis of isoprene rubber with perfect 1,4-cis microstructure and marked reactivity difference between Lanthanide metallocenes toward dienes as probed by butadiene-isoprene copolymerization catalysis. Macromolecules. 2004;37:5860–2.

Faraday M. On Pure Caoutchouc, and the substances by which it is accompanied in the State of Sap, or Juice. Q J Sci. 1826;21:19–28.

Williams CG. IV. On isoprene and caoutchine. Proc R Soc London. 1860;10:516–9.

Tilden WA. XLVI. On the decomposition of terpenes by heat. J Chem Soc. 1884;47:411.

Staudinger H. Über polymerisation. Ber Dtsch Chem Ges. 1920;53:1073–8.

Katz JR. Rontenspektrographische Untersuchungen am gedehnten Kautschuk und ihremogliche Bedeutung fur das Problem fer Dehnungseigenschaften dieser Substanz. Naturwissenschaften. 1925;19:410–6.

Eng AH, Kawahara S, Tanaka Y. Trans-isoprene units in natural rubber. Rubber Chem Technol. 1994;67:159–68.

Tanaka Y. Structural characterization of naturally occurring cis- and trans- isoprenes by 13C-NMR spectroscopy. J Appl Polym Sci Appl Polym Symp. 1989;44:1–9.

Tanaka Y, Kawahara S, Tangpakdee J. Structural characterization of natural rubber. Kautsch Gummi Kunst. 1997;50:6–10.

Blackley DC. Polymer latices: science and technology. London 2nd Ed. London; New York : Chapman & Hall, 1997.

Cornish K, Wood DF, Windle JJ. Rubber particles from four different species, examined by transmission electron microscopy and electron-paramagnetic-resonance spin labeling, are found to consist of a homogeneous rubber core enclosed by a contiguous, monolayer biomembrane. Planta. 1999;210:85–96.

Berthelot K, Lecomte S, Estevez Y, Coulary-Salin B, Bentaleb A, Cullin C, et al. Rubber elongation factor (REF), a major allergen component in Hevea brasiliensis latex has amyloid properties. PLoS ONE. 2008;7:e48065.

Nawamawat K, Sakdapipanich J, Ho CC, Ma Y, Song J, Vancso GJ. Surface nanostructure of Hevea brasiliensis natural rubber latex particles. Colloids Surf Physicochem Eng Asp. 2011;390:157–66.

Rochette CN, Crassous JJ, Drechsler M, Gaboriaud F, Eloy M, de Gaudemaris B, et al. Shell structure of natural rubber particles: evidence of chemical stratification by electrokinetics and cryo-TEM. Langmuir. 2013;29:14655–65.

Chaikumpollert O, Yamamoto Y, Suchiva K, Phan TN, Kawahara S. Preparation and characterization of protein-free natural rubber. Polym Adv Technol. 2012;23:825–8.

Chaikumpollert O, Yamamoto Y, Suchiva K, Kawahara S. Colloid. Polym Sci. 2012;290:331–8.

Olabishi O, Robeson LM, Shaw MT. Polymer-polymer miscibility. New York: Academic Press; 1979.

Nghiem TT, Yamamoto Y, Phan TN, Kawahara S. Analysis of damage in commercial natural rubber through NMR spectroscopy. Polym Degrad Stab. 2016;123:155–61.

Kawahara S, Kakubo T, Sakdapipanich JT, Isono Y, Tanaka Y. Characterization of fatty acids linked to natural rubber—role of linked fatty acids on crystallization of the rubber. Polymer. 2000;41:7483–8.

Zhou YB, Kosugi K, Yamamoto Y, Kawahara S. Effect of non-rubber components on the mechanical properties of natural rubber. Polym Adv Technol. 2017;28:159–65.

Kawahara S, Tanak Y. Plasticization and crystallization of cis-1,4 polyisoprene mixed with methyl linoleate. J Polym Sci Polym Phys Ed. 1995;33:753–8.

Angulo-Sanchez JL, Carallero-Mata P. Long chain branching in natural hevea rubber-determination by gel permeation chromatography. Rubber Chem Technol. 1981;54:34–41.

Fuller KNG, Fullton WS. The influence of molecular weight distribution and branching on the relaxation behaviour of uncrosslinked natural rubber. Polymer. 1990;31:609–15.

Kawahara S, Sakdapipanich JT, Isono Y, Eng AH, Tanaka Y. Effect of gel on the green strength of natural rubber. Rubber Chem Technol. 2002;75:739–46.

Subramaniam A. Gel permeation chromatography of natural rubber. Rubber Chem Technol. 1972;45:346–58.

Eng AH, Ejiri S, Kawahara S, Tanaka Y. Structural characteristics of natural rubber: role of ester groups. J Appl Polym Sci Appl Polym Symp. 1994;53:5–14.

Tangpakdee J, Tanaka Y. Branching in natural rubber. J Rubber Res. 1998;1:14–21.

Ward IM, Hadley DW. An introduction to the mechanical properties of solid polymers. New York: John Wiley & Sons; 1993.

Gent AN, Mars WV. Strength of elastomers. In: Erman B, Mark JE, Roland CM, editors. The science and technology of rubber. 4th ed. Oxford: Academic Press; 2013. p. 473–516.

Takayanagi M, Uemura S, Minami S. Application of equivalent model method to dynamic rheo-optical properties of crystalline polymer. J Polym Sci C Polym Symp. 1964;5:113–22.

Guth E, Gold O. On the hydrodynamical theory of the viscosity of suspensions. Phys Rev. 1938;53:322–5.

Guth E. Theory of filler reinforcement. J Appl Phys. 1945;16:20.

Kawahara S, Kawazura T, Sawada T, Isono Y. Preparation and characterization of natural rubber dispersed in nano-matrix. Polymer. 2003;44:4527–31.

Kawahara S, Yusof NH, Noguchi K, Kosugi K, Yamamoto Y. Organic-inorganic nanomatrix structure and properties of related naturally occurring rubbery macromolecules. Polymer. 2014;55:5024–7.

Gannoruwa A, Sumita M, Kawahara K. Highly enhanced mechanical properties in natural rubber prepared with a nanodiamond nanomatrix structure. Polymer. 2017;126:40–7.

Pukkate N, Kitai T, Yamamoto Y, Kawazura T, Sakdapipanich JT, Kawahara S. Nano-matrix structure formed by graft-copolymerization of styrene onto natural rubber. Eur Polym J. 2007;43:3208–14.

Kawahara S, Yamamoto Y, Fujii S, Isono Y, Niihara K, Jinnai H, et al. FIB-SEM and TEMT observation of highly elastic rubbery material with nano-matrix structure. Macromolecules. 2008;41:4510–3.

Akabori K, Yamamoto Y, Kawahara S, Jinnai H, Nishioka H. Field emission scanning electron microscopy combined with focused ion beam for rubbery material with nano-matrix structure. J Phys Conf Ser. 2009;184:012027.

Fukuhara L, Kado N, Nghiem TT, Loykulnant S, Suchiva K, Kosugi K, et al. Nanomatrix structure formed by graft copolymerization of styrene onto fresh natural rubber. Rubber Chem Technol. 2015;88:117–24.

Fukuhara L, Kosugi K, Yamamoto Y, Jinnai H, Nishioka H, Ishii H, et al. FIB processing for natural rubber with nanomatrix structure. Polymer. 2015;57:143–9.

Fukuhara L, Kosugi K, Yamamoto Y, Jinnai H, Nishioka H, Ishii H, et al. Frozen non-equilibrium structure for anisotropically deformed natural nubber with nanomatrix structure observed by 3D FIB-SEM and TEMT techniques. Colloid Polym Sci. 2015;293:2555–63.

Yamamoto Y, Sawada T, Kawahara S. Graft-copolymerization of acrylonitrile onto surfaces of natural rubber particles using deproteinized natural rubber latex. Kobunshi Ronbunshu. 2007;64:155–60.

Prukkaewkanjana K, Kawahara S, Sakdapipanich JT. Influence of reaction conditions on the properties of nano-matrix structure formed by graft-copolymerization of acrylonitrile onto natural rubber. Adv Mater Res. 2014;844:365–8.

Yusof NH, Song TK, Kosugi K, Kawahara S. Preparation and characterization of poly(stearyl methacrylate) grafted natural rubber in latex stage. Polymer. 2016;88:43–51.

Yamamoto Y, Suksawad P, Pukkate N, Horimai T, Wakisaka O, Kawahara S. Photoreactive nanomatrix structure formed by graft-copolymerization of 1,9-nonandiol dimethacrylate onto natural rubber. J Polym Sci Part A Polym Chem 2010;48:2418–24.

Yusof NH, Noguchi K, Fukuhara L, Yamamoto Y, Kawahara S. Preparation and properties of natural rubber with filler nanomatrix structure. Colloid Polym Sci. 2015;293:2249–56.

Nghiem TT, Phan TN, Kawahara S. Formation of an in situ nanosilica nanomatrix via graft copolymerization of vinyltriethoxysilane onto natural rubber. Polym Adv Technol. 2020;31:482–91.

Nghiem TT, Tran AD, Yusof NH, Kawahara S. Controlling the size of silica nanoparticles in filler nanomatrix structure of natural rubber. Polymer. 2020;195:122444.

Nghiem TT, Nguyen TN, Yusof NH, Kawahara S. Effect of naturally occurring proteins on graft copolymerization of vinyltriethoxysilane on natural rubber. Polym J. 2022;54:633–41.

Kawahara S, Suksawad P, Yamamoto Y, Kuroda H. Nanomatrix channel for ionic molecular transportation. Macromolecules. 2009;42:8557–60.

Suksawad P, Kosugi K, Yamamoto Y, Akabori K, Kuroda H, Kawahara S. Polymer electrolyte membrane with nanomatrix channel prepared by sulfonation of natural rubber grafted with polystyrene. J Appl Polym Sci. 2011;122:2403–14.

Kado N, Suksawad P, Akabori K, Yamamoto Y, Kawahara S. Fabrication of a completely continuous nanomatrix channel and its proton conductivity. Kautsch Gummi Kunst. 2012;65:26–9.

Fukuhara L, Kado N, Kosugi K, Suksawad P, Yamamoto Y, Ishii H, et al. Preparation of polymer electrolyte membrane with nanomatrix channel through sulfonation of natural rubber grafted with polystyrene. Solid State Ion. 2014;268:191–7.

Kosugi K, Sutthangkul R, Chaikumpollert O, Yamamoto Y, Sakdapipanich JT, Isono Y, et al. Preparation and characterization of natural rubber with soft nanomatrix structure. Colloid Polym Sci. 2012;290:1457–62.

Kosugi K, Arai H, Zhou YB, Kawahara S. Formation of organic–inorganic nanomatrix structure with nanosilica networks and its effect on properties of rubber. Polymer. 2016;102:106–11.

Nguyen TH, Do QV, Tran AD, Kawahara S. Preparation of hydrogenated natural rubber with nanomatrix structure. Polym Adv Technol. 2020;31:86–93.

Nguyen TH, Tran TT, Kawahara S, Ougizawa T. Preparation of polyaniline nanomatrix formed in natural rubber. Polym J. 2020;52:1357–65.

Nguyen TH, Vu HH, Nguyen HN, Phan TN, Ougizawa T, Kawahara S. Electrically conductive membrane based on epoxidized natural rubber-graft-polyaniline nanomatrix. Vietnam J Chem. 2021;59:580–4.

Nghiem TT, Yusof NH, Kawahara S. A polystyrene/silica hybrid nanomatrix formed in natural rubber. Polym J. 2023;55:631–7.

Gannoruwa A, Sumita M, Kawahara S. Highly enhanced mechanical properties in natural rubber prepared with a nanodiamond nanomatrix structure. Polymer. 2017;126:40–7.

Gannoruwa A, Kawahara S. Distribution of nanodiamond inside the nanomatrix in natural rubber. Langmuir. 2018;34:6861–8.

Kawahara S, Gannoruwa A, Nakajima K, Liang X, Akiba I, Yamamoto Y. Nanodiamond glass with rubber bond in natural rubber. Adv Funct Mater. 2020;30:1909791.

Mochalin VN, Shenderova O, Ho D, Gogotsi Y. The properties and applications of nanodiamonds. Nat Nanotechnol. 2012;7:11–23.

Gannoruwa A, Yamamoto Y, Zhou YB, Kawahara S. Origin of energetic elasticity and entropic elasticity. Rubber Chem Technol. 2021;94:704–19.

Hess WM, Ford FP. Microscopy of pigment-elastomer systems. Rubber Chem Technol. 1963;36:1175–229.

Kruse J. Rubber microscopy. Rubber Chem Technol. 1973;46:653–785.

Ban LL, Hess WM, Papazian LA. New studies of carbon-rubber gel. Rubber Chem Technol. 1974;47:858–94.

Fukahori Y. The mechanics and mechanism of the carbon black reinforcement of elastomers. Rubber Chem Technol. 2003;76:548–66.

Nakajima K, Ito M, Nguyen HK, Liang X. Nanomechanics of the rubber-filler interface. Rubber Chem Technol. 2017;90:272–84.

Yamamoto Y, Endo K, Tévenot Q, Kosugi K, Nakajima K, Kawahara S. Entropic and energetic elasticities of natural rubber with a nanomatrix structure. Langmuir. 2020;36:11341–8.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kawahara, S. Discovery of island-nanomatrix structure in natural rubber. Polym J 55, 1007–1021 (2023). https://doi.org/10.1038/s41428-023-00797-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-023-00797-2

This article is cited by

-

Revealing the Structure-Property Difference of Natural Rubber Prepared by Different Methods: Protein and Gel Content are Key Factors

Chinese Journal of Polymer Science (2023)