Abstract

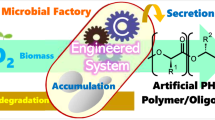

The use of autotrophic microorganisms to fabricate biochemical products has attracted much attention in both academia and industry. Unlike heterotrophic microorganisms that require carbohydrates and amino acids for growth, autotrophic microorganisms have evolved to utilize either light (photoautotrophs) or chemical compounds (chemolithotrophs) to fix carbon dioxide (CO2) and drive metabolic processes. Several biotechnological approaches, including synthetic biology and metabolic engineering, have been proposed to harness autotrophic microorganisms as a sustainable/green production platform for commercially essential products such as biofuels, commodity chemicals, and biopolymers. Here, we review the recent advances in natural autotrophic microorganisms (photoautotrophic and chemoautotrophic), focusing on the biopolymer production. We present current state-of-the-art technologies to engineer autotrophic microbial cell factories for efficient biopolymer production.

Similar content being viewed by others

Introduction

Within this past decade, petroleum fuel inadequacy, together with global warming due to greenhouse gas emissions (e.g., CO2), has motivated scientists to search for a new and renewable resource for commodity chemical production. CO2 gas has high potential as a renewable carbon source when utilized through an autotrophic system. The ability of autotrophic microorganisms to fix CO2 and convert it into biomass and potentially valuable products is of particular interest in the field of green production within academia and industry. Autotrophic microorganisms require an energy source, either light (photoautotrophy) or an inorganic electron donor (chemolithoautotrophy), to incorporate CO2 into biomass [1] (Fig. 1A). Autotrophic biorefineries, which are considered a more sustainable use of carbon and an energy-efficient alternative to heterotrophic cultivation, are used to convert organic carbon materials into similar products.

Summary of the different types of microbial trophic growth modes. A Heterotrophic microorganisms utilize organic carbon as an energy source and convert it into biomass and bioproducts. In contrast, autotrophic microorganisms harness energy from nature (e.g., light or inorganic electron donors) to incorporate an inorganic carbon source (CO2) into their metabolism. B The Calvin–Benson–Bassham (CBB) cycle is found in most photoautotrophic microorganisms, including some chemoautotrophs, such as C. necator. C The Wood–Ljungdahl (WL) pathway is a noncyclic carbonic fixation pathway that forms acetyl-CoA from CO2 and is found in acetogenic microorganisms

In recent decades, the bioproduction of commodity chemicals in autotrophic microorganisms has been well studied. For example, photoautotrophic cyanobacteria have been well optimized to enable the sustainable bioproduction of small molecules such as butanol, propanol, ethylene, and fatty acids. Such studies have been well documented in review articles elsewhere [2,3,4,5]. Recently, autotrophic microorganisms have also attracted great interest as promising platforms for biopolymer production. Biopolymers biosynthesized from microbial hosts are obtained through a green process for industrial-scale production. They are synthesized through an enzymatic process inside the cytoplasm or other cell organelles by harnessing biotechnological approaches. There have been several attempts to produce biopolymers from either model heterotrophs or autotrophs. However, research conducted on biopolymer production under autotrophic conditions is still limited due to production efficiency. In this review, we focus on the recent biotechnological aspects of autotrophic microbial cell factory development and provide insight into microbial-based biopolymer production.

Natural photoautotrophic hosts

Photoautotrophic microorganisms, which refer to both oxygenic and anoxygenic photoautotrophs, use light as an energy source to generate phosphate bond energy (ATP). Like plants and algae, oxygenic photoautotrophic microorganisms, such as cyanobacteria, can generate a reducing power and proton gradient to be used for ATP regeneration in the metabolic pathway by the water-splitting oxygen-generating photosystem I and II complexes. Light-induced electron transport generates energy and reducing power, which drives CO2 fixation via the Calvin–Benson–Bassham (CBB) cycle, which produces cellular materials and other valuable metabolites autotrophically (Fig. 1A, B). Moreover, cyanobacteria exhibit highly efficient solar energy capture and a CO2 concentrating mechanism to overcome negative effects from photorespiration [5]. Owing to their ability to perform photosynthesis and fix CO2, cyanobacteria have ideal biosynthetic machinery for the sustainable production of various commodity chemicals and biofuels. Metabolic engineering and synthetic biology approaches have been employed to enable cyanobacteria to autotrophically produce commodity chemicals such as ethanol, 1-butanol, l-lactic acid, 2,3-butanediol, and polyhydroxyalkanoate biopolyester [6, 7]. Among the cyanobacteria strains, the freshwater species Synechococcus elongatus PCC7942, Synechocystis PCC6803, marine Synechococcus PCC7002, and Anabaena sp. PCC7120 are considered model strains due to their extensive study and the availability of genetic toolkits [8, 9].

Unlike oxygenic photoautotrophs, anoxygenic photolithoautotrophs have only one photosystem, which is not powerful enough to split water. Anoxygenic photolithoautotrophs can use both organic and inorganic electron donors (e.g., H2 and sulfur) to generate reducing power to drive light-dependent CO2 fixation via the CBB cycle (Fig. 1A, B). Their versatile metabolism that enables aerobic, anaerobic, autotrophic, and heterotrophic growth, ability to adapt to extreme conditions, low maintenance cost, and high biomass yield make anoxygenic photolithoautotrophs ideal for the production of high-value chemicals [10, 11]. Anoxygenic purple nonsulfur photosynthetic bacteria such as the freshwater Rhodobacter sphaeroides, Rhodospirillum rubrum, Rhodopsudomonas palustris, and marine Rhodovulum sulfidophilum have been demonstrated to be bioproduction hosts for several value-added chemicals, including biopolymers such as poly-β-hydroxyalkanoates and recombinant spider silk (Fig. 3A, B) [12,13,14,15,16,17].

This section provides the current developments in bioengineering photoautotrophic microorganisms, focusing on cyanobacteria and purple photosynthetic bacteria, as an autotrophic bioproduction platform related to biopolymer production. In addition, the current insights into the metabolic engineering of autotrophic metabolism in photoautotrophs for further biotechnological purposes will be reviewed.

Recent developments of cyanobacteria as an autotrophic cell factory and their use for biopolymer production

Cyanobacteria have been proposed as an ideal photoautotrophic host for sustainable bioproduction. Recently, metabolic engineering techniques in cyanobacteria have rapidly developed, which has expanded the diversity of the bioproducts derived from the intracellular metabolites of cyanobacteria into a range of alcohols, organic acids, fatty acids, biofuels, and bioplastic precursors [6, 7]. Under photoautotrophic conditions, bioproducts are synthesized from the central intracellular metabolism of cyanobacteria, and the CBB cycle is the main contributor to this process. Thus, the use of metabolic engineering has been considered to improve CO2 fixation efficiency, endogenous carbon flux distribution, redox balance, and product conversion efficiency, which facilitates the development of cyanobacterial cell factories.

Increased CO2 fixation in cyanobacterial cell factories

CO2 is the primary carbon source in cyanobacteria. Ribulose-1,5-bisphosphate carboxylase/oxygenase (Rubisco) is the central enzyme that mediates CO2 fixation by catalyzing ribulose-1,5-bisphosphate (RuBP) carboxylation to generate two molecules of 3-phosphoglycerate (3-PGA), which are further used in the CBB cycle. However, Rubisco is one of the most inefficient enzymes found in nature because it cannot differentiate O2 from CO2. During photorespiration (using O2 as a substrate), Rubisco catalyzes the oxygenation of RuBP and releases one molecule of 2-phosphoglycolate (2-PG), which is toxic to cyanobacterial cells. To convert 2-PG into a nontoxic substance, cyanobacteria have applied rescue strategies to recycle two molecules of 2-PG to generate one molecule of 3-PGA while releasing CO2 and consuming ATP (Fig. 1B). These processes decrease the carbon fixation efficiency and energy conversion of the CBB cycle [18, 19].

Several strategies have been applied to engineer Rubisco, either to enhance its carboxylation activity or to suppress its oxygenation activity. However, limited success has been achieved due to the complexity of Rubisco. A direct evolution strategy has been employed to enhance Rubisco activity. Libraries of Rubisco mutants were generated and screened for their activities in an E. coli reporter strain that was engineered to grow dependently on the carboxylation function [20]. Using this E. coli screening system, a single mutation in the large subunit of Synechocystis sp. PCC 6803 Rubisco (RbcLF140I) significantly increased the carboxylation efficiency by 2.9-fold compared to the wild-type [21]. Further reintroduction of this Rubisco point mutation into Synechocystis sp. PCC 6803 improved the photosynthesis rate by ~55% [21]. Apart from improving Rubisco activity, the overexpression of CBB-related enzymes also increased the total CO2 fixation rate and heterologous ethanol production in an engineered Synechocystis sp. PCC 6803 [22].

The cyanobacterial CO2 concentrating mechanism (CCM) is one strategy to avoid competing oxygenase activity since the carboxylation reaction of Rubisco is restrained in the carboxysome structure. Manipulating the cyanobacterial CCM is also an approach to enhance CO2 fixation. Increasing the activity of the bicarbonate transporter helps improve the Rubisco CO2 fixation rate. It has been demonstrated that introducing an additional bicarbonate transporter resulted in a 2-fold increase in the growth and biomass of Synechocystis sp. PCC6803 [23]. Furthermore, the overexpression of two bicarbonate transporters (SbtA and BicA) in marine Synechococcus sp. PCC7002 enhanced biomass and intracellular glycogen accumulation by 50% and increased extracellular carbohydrates up to 3-fold [24].

Biopolymer production in cyanobacteria

Glycogen is a branched α-polyglucan (Fig. 2), one of the carbon biopolymers that naturally accumulates in cyanobacteria. Glycogen metabolism is the most important natural carbon sink mechanism and cellular carbon reservoir, storing a large portion of carbon and energy from the CBB cycle. Thus, this process is a promising target to optimize the efficiency of cyanobacterial cell factories [25, 26]. Many studies have tried to manipulate glycogen metabolism to rewire the carbon flow to increase the production of other metabolites. However, disturbing glycogen metabolism results in weakened cellular physiology and diminishes metabolic robustness because glycogen metabolism is vital for cellular homeostasis [27]. Flexible and dynamic regulation tools seem to be essential for the engineering of glycogen metabolism. The theophylline-responsive riboswitch has been applied to control the gene expression of glgC (this gene encodes ADP-glucose pyrophosphorylase, which is the rate-limiting step of glycogen biosynthesis) in glycogen metabolism, resulting in a 300% increase in glycogen accumulation (approximately 70% of the cell dry weight, Table 1) and a slightly increase in the growth in the presence of theophylline in S. elongatus PCC7942 [28]. In the absence of theophylline, glycogen accumulation was significantly decreased, and cellular tolerance toward environmental stresses was weakened, confirming the importance of glycogen accumulation in cellular homeostasis [28]. In addition, the fast-growing cyanobacterium Synechococcus sp. PCC 7002 successfully demonstrated CO2 bioconversion into hyaluronic acid, a natural biopolymer composed of N-acetylglucosamine and glucuronic acid units (Fig. 2). Heterologous overexpression of hyaluronic acid synthases from gram-negative Pasteurella multocida (encoded by pmHAS genes) together with metabolic alterations to impair the competitive route resulted in the photoautotrophic production of hyaluronic acid in a quantity reaching 112 mg/L [29] (Table 1).

The other important carbon biopolymers are the polyhydroxyalkanoates (PHAs), a class of polyester consisting of (R)-hydroxyalkanoic acid units (Fig. 2). The most common PHA polymer produced in cyanobacteria is poly[(R)-3 hydroxybutyrate] (PHB). Unlike glycogen metabolism, which is conserved in all cyanobacteria, only a few cyanobacteria genera, such as Nostoc, Arthrospira, Synechocystis, and Synechococcus, naturally synthesize PHB as additional cellular carbon storage [30,31,32]. Unlike Capriavidus necator, the main PHA producer that naturally accumulates PHB at a high level (~70% of its biomass weight) [33], cyanobacteria accumulate PHB in a lower amount (~4.1% of its biomass weight) [34]. One of the differences between them is the form of PHA synthase (PhaC), the key enzyme in PHA biosynthesis. In cyanobacteria, PHB is synthesized by class III PHA synthase, consisting of two subunits, PhaC and PhaE [35]. The in vitro specific activity of the class III PHA synthase (PhaCE) from Synechocystis sp. PCC 6803 has been demonstrated using cell-free synthesis, and it was revealed that the specific activity of PhaCE is comparable to that of PhaC (a class I PHA synthase, single subunit) from C. necator H16 [36]. These results suggest that the low PHA productivity of cyanobacteria is not due to PHA synthase activity but might be caused by other pathways related to PHA synthesis [36]. Several genetic manipulation strategies have been applied to enhance PHB production in cyanobacteria. The overexpression of the RNA polymerase sigma factor sigE in Synechocystis sp. PCC 6803 resulted in the alteration of the metabolic pathway starting from glycogen to enhance PHB production under nitrogen starvation conditions. PHB production reached 14 mg/L (1.4% of its biomass weight, Table 1), showing a 2.3-fold increase compared to the control strain [37]. In another study, overexpression of the endogenous pha genes for PHB biosynthesis using a high copy number vector in Synechocystis sp. PCC 6803 successfully enhanced PHB production up to 10.59 mg/L (7% of its biomass weight, Table 1), which showed a 12-fold increase in productivity compared to the control strain [38]. Furthermore, random mutagenesis using UV radiation has been employed to generate the high PHB-producing strain Synechocystis sp. PCC 6714. The resulting strain could produce PHB up to 37% of its biomass weight, which is a more than 2.5-fold increase in PHB production compared to the wild-type under photoautotrophic growth [39] (Table 1). The introduction of heterologous phaCAB genes from C. necator into the fast-growing cyanobacteria S. elongatus UTEX 2973, which does not have a natural PHB production pathway, yielded a strain that produced PHB up to 420 mg/L (16.7% of its biomass weight, Table 1) under photoautotrophic growth [40]. A recent strategy to maximize PHB production was developed using the Synechocystis sp. PCC 6803 pirC mutant strain ΔpirC [41]. The PirC protein was found to play a role in glycolytic carbon flux in a PII-dependent manner to regulate cyanobacterial carbon flow [42]. By introducing heterologous phaCAB genes into Synechocystis sp. PCC 6803 (ΔpirC), the resulting strain produced PHB up to 61% of its biomass weight (Table 1), which represents an approximately 6.1-fold increase in PHB production compared to the wild-type under photoautotrophic growth [41].

In addition to carbon biopolymers, cyanobacteria also accumulate amino acid polymer granules intracellularly for nitrogen storage, known as cyanophycin (multi-L-arginyl-poly-L-aspartic acid, Fig. 2). Cyanophycin is of particular interest in biotechnology as a source of polyaspartic acid, a biocompatible and biodegradable polymer used in several industrial, agricultural, and medical applications [43, 44]. In cyanobacteria, the cyanophycin accumulation pattern is correlated with the nitrogen fixation phases, in which nitrogenase enzymes are inactivated in aerobic environments [45, 46]. Therefore, cyanophycin is synthesized during low-light periods, during which aerobic photosynthesis does not occur, and is consumed during high-light periods [46]. Maximizing the accumulation of cyanophycin in cyanobacteria was demonstrated in an engineered Synechocystis sp. PCC 6803. By replacing the PII protein (which regulates nitrogen assimilation) with its mutated variant (PII(I86N)), arginine content is enhanced more than tenfold compared to its wild-type and maximizes the accumulated cyanophycin to reach up to 57.3% of its biomass [47] (Table 1). Furthermore, the cyanophycin production yield in this strain can be enhanced by applying the high-density cultivation technique, thus reaching up to 1 g/L [48] (Table 1).

Recent developments in purple photosynthetic bacteria as an autotrophic cell factory and their use for biopolymer production

The metabolic versatility and ability of anoxygenic purple photosynthetic bacteria (PPB) to assimilate CO2 are highly promising properties to develop them as autotrophic cell factories for the production of a wide-range of bioproducts. They have been extensively studied for use in wastewater treatment and resource recovery due to their robustness and versatile metabolism, which allow them to use a variety of carbon sources. However, compared to microalgae and cyanobacteria, PPB-based bioproduction has gained less attention due to the availability of genetic tools and genome data. Within the past few years, many studies have demonstrated the use of PPB as a phototrophic production platform for valuable bioproducts, including the heterologous production of plant-derived bioactive compounds such as pinene (monoterpene) in R. sphaeroides [49], valencene (a sesquiterpene aroma compound) in R. sphaeroides [50], and botryococcene (a triterpene hydrocarbon) in Rhodobacter capsulatus [51].

Biopolymer production in purple photosynthetic bacteria

PPB can fix CO2 into cell material through an effective CO2-fixing CBB cycle. It has also been proposed as a photoautotrophic platform for biopolymer production. Some PPB strains have been found to naturally accumulate PHA biopolymers during carbon storage. The freshwater PPB R. rubrum is a well-studied PPB due to its ability to simultaneously produce PHA. Under phototrophic nitrogen-limited conditions, R. rubrum could accumulate PHA up to 50% of its biomass [12]. It has also been extensively studied for its ability to convert synthetic gas (syngas) to PHAs under photoautotrophic conditions. Despite the toxicity of carbon monoxide (CO) to most organisms, R. rubrum has the ability to utilize CO from syngas under anaerobic conditions as a sole carbon and energy source [52,53,54]. When R. rubrum is exposed to CO, carbon monoxide dehydrogenase (CODH) and CO-insensitive hydrogenase are induced to catalyze the oxidation reaction of CO into CO2 and H2, and CO2 is then assimilated into biomass and other metabolites through the CBB cycle. During syngas fermentation with acetate supplementation, R. rubrum accumulated PHA up to 20% of its dry weight under both light and dark conditions [53] (Table 1). The engineered R. rubrum S1, which harbored heterologous genes encoding the membrane-bound transhydrogenase (PntAB) from E. coli MG1655 and the phaB1 gene coding for an NADPH-dependent acetoacetyl-CoA reductase from Ralstonia eutropha H16, successfully synthesized the copolymer poly(3-hydroxybutyrate-co-3-hydroxyvalerate) [P(HB-HV)] up to 5.1% of its dry cell weight (Table 1), with a 3-hydroxyvalerate (3HV) fraction of 28.3 mol% from syngas [55]. By further introducing genes encoding enzymes responsible for producing mcl-PHA from Pseudomonas putida into R. rubrum S1, a heteropolymer mainly consisting of 3-hydroxydecanoic acid and 3-hydroxyoctanoic acid [P(3HD-co-3HO)] was successfully obtained in up to 7.1% of its dry cell weight from artificial syngas [56] (Table 1). Moreover, R. rubrum was tested for its potential to utilize syngas obtained by microwave pyrolysis of household wastes as feedstock for PHA biosynthesis. By fermenting R. rubrum using syngas obtained from microwave-induced pyrolysis with trace amounts of acetate supplementation, PHA was obtained in up to 16% of its dry cell weight (Table 1) with approximately 37% CO conversion efficiency [54].

Apart from the freshwater PPB R. rubrum, marine PPB have also been proposed as ideal microbial hosts for sustainable bioproduction due to several potential advantages, such as metabolic versatility and high salt tolerance, which can eliminate biological contamination during large-scale cultivation [57]. Marine PPB have been studied for their ability to naturally biosynthesize and accumulate PHA as intracellular granules [14, 58] (Fig. 3A). Among the tested strains, Rhodovulum euryhalinum, Rhodovulum imhoffii, Rhodovulum visakhapatnamense, and Rhodovulum sulfidophilum were reported to naturally accumulate some PHA under photoautotrophic culture conditions [14, 15]. In the group of marine PPB, R. sulfidophilum is the most studied for its ability to biosynthesize PHA and for its potential to be developed as a host for biopolymer production. Improving culture conditions to enhance PHA accumulation in R. sulfidophilum has been extensively studied. Salt and iron concentrations in culture have been studied in terms of their influence on PHA accumulation [59, 60]. The optimum iron concentration (~1–2 μΜ) was found to be essential to promote cell growth and led to the highest PHA accumulation with a dry biomass content of 32.4 wt.% [59] (Table 1). Furthermore, a salinity of 4.5% was found to be the best stress-growth condition to reach the highest concentration of PHA in an R. sulfidophilum culture (820 mg/L) with a PHA dry biomass fraction of 33% [60] (Table 1). The R. sulfidophilum strain has been recently improved by employing genome-wide mutagenesis coupled with high-throughput screening [61]. With this method, the improved strain showed a 1.7-fold increase in PHA production while also accumulating PHA faster than the original strain [61] (Table 1).

A TEM images of the intracellular PHA granules in R. visakhapatnamense under nitrogen-limited medium; the figure is adapted from Higuchi-Takeuchi et al., PLoS One, 2016 [14]. B Production of the MaSp1-(6-mer) artificial spidroin from the marine purple bacterium R. sulfidophilum and a representative fiber; the figure is adapted from Foong et al., Commun. Biol., 2020 [13]

However, PHA production by R. sulfidophilum under photoautotrophic cultivation conditions remains highly challenging since photoheterotrophic conditions are preferable for PHA accumulation. The recent application of engineered nanoparticles to facilitate microbial cell factories is a fascinating approach. This newly developed cultivation method implementing the use of engineered nanogel particles in R. sulfidophilum photoautotrophic cultivation has been demonstrated [62]. This technique successfully enhanced PHA accumulation up to 157-fold compared to the control without nanogel particle supplementation [62] (Table 1). The benefit of using the engineered nanogel particle strategy is to enable PHA bioproduction where the genetic use of modified microorganisms for practical production is not allowed or is difficult due to biosafety regulations. However, this strategy is not meant to replace other strategies (such as genetic modification to engineer metabolic pathways) but rather to complement them to synergistically further enhance biorefinery efficiency.

Genetic modification approaches toward biopolymer production in purple photosynthetic bacteria

A genetic modification strategy has also been employed to improve PPB strains in targeting the bioproduction of valuable compounds. Metabolically engineered R. sphaeroides, which disrupted a poly(3-hydroxyalkanoate) depolymerase (phaZ) gene along with overexpression of the PHB biosynthesis genes in specific isoforms (acetyltransferase, phaA2; acetoacetyl coenzyme A reductase, phaB2; and poly(3-hydroxyalkanoate) polymerase, phaC1), improved the PHB production yield up to 1.88 ± 0.08 g L−1 (~79% of its biomass weight, Table 1) under nitrogen-limited conditions [16]. Furthermore, the highly efficient Cas9‐based genomic DNA targeting system has been successfully employed to elucidate the essential genes in the PHB production pathway in the freshwater PPB R. sphaeroides. The developed tool was employed to elucidate genetic information in terms of PHB production in R. sphaeroides and to construct mutant strains with dramatically reduced PHB production capacity that did not affect growth [63]. This is one possible strategy to redirect the metabolic flow from PHB to other desired metabolites. In addition to the PHA carbon polymer, a spider silk protein polymer (Fig. 3B) was also successfully produced by introducing the MaSp1 gene from Nephila clavipes into R. sulfidophilum under photoautotrophic growth conditions [13] (Table 1). This study expands the possibility of using PPB to produce heterologous biopolymers other than those naturally synthesized.

Natural chemolithoautotrophic hosts

As an alternative to light, chemolithoautotrophs use reduced inorganic compounds (H2 or NH2) as an energy source. One of the most promising candidates is the “Knallgas” bacterium Capriavidus necator (formerly R. eutropha), which is a hydrogen-oxidizing bacterium that can grow using a mixture of H2, O2, and CO2 gases as substrates [64]. Under aerobic autotrophic growth conditions, C. necator fixes CO2 via the CBB cycle (Fig. 1A, B) and is capable of growing under ambient CO2 concentrations with a doubling time of 21 h [65]. It is considered a model chemolithoautotroph due to the relatively high availability of genetic engineering tools, which have been implemented to develop a biotechnological platform for commodity chemical production. C. necator can naturally accumulate an excess of the carbon-dense biopolymer poly[(R)-3-hydroxybutyrate] (PHB), which is a storage polymer and bioplastic precursor, in an amount equal to 70% of its biomass weight [33]. The carbon flux can be redirected by metabolic engineering to produce several value-added chemicals, such as branched-chain alcohols, isoprenoids, 1,3-butanediol, sucrose, and modified PHBs, along with a variety of commodity chemicals [66,67,68,69].

Another promising group of chemolithoautotrophs is the anaerobic acetogens, which are capable of growing anaerobically using H2 and CO2. All acetogens fix CO2 using the reductive acetyl-CoA or Wood–Ljungdahl (WL) pathway (Fig. 1A, C). Unlike the CBB cycle, the Wood–Ljungdahl pathway is a noncyclic carbonic fixation pathway that forms acetyl-CoA from CO2, and acetyl-CoA is ultimately converted into acetate [70] (Fig. 1C). Their high autotrophic flux to generate acetyl-CoA makes them attractive candidates for the autotrophic production of value-added chemicals. Apart from acetate, some acetogens naturally accumulate fermentative end products of industrial interest, such as ethanol, butanol, and 2,3-butanediol [71, 72]. Among the acetogens, Acetobacterium woodii and acetogenic Clostridium spp. such as C. ljungdahlii and C. autoethanogenum, are considered the most relevant candidates for further development as bioproduction platforms since genetic engineering tools are becoming more available for these genera than others [73]. This section reviews the recent developments and advances in the bioengineering of both C. necator and acetogens related to biopolymer production via an autotrophic metabolism. We also provide current insights into metabolic engineering for further biotechnological applications in chemolithoautotrophic hosts.

Recent development with C. necator as an autotrophic cell factory and its use for biopolymer production

C. necator has been used for polyhydroxyalkanoate (PHA) production in the past few decades. The native biosynthetic capacity of C. necator yields up to 70% of the dry cell weight under autotrophic conditions [74,75,76]. However, the growth of C. necator is relatively slow under ambient CO2 [65], which is the limiting factor for developing it as an autotrophic production host. Thus, research has been focused on improving the CO2 fixation efficiency by engineering the CBB cycle of C. necator. Using the combination approaches that introduced endogenous GroES/EL chaperons into the heterologous cyanobacterial Rubisco and fine-tuned the hydrogenase module in C. necator, both the autotrophic growth efficiency and PHB production were improved, with increases of 93.4% and 74.7%, respectively, compared to its parental strain [77] (Table 1).

The CBB cycle requires a high amount of ATP, which limits the biomass and production yields [18]. Recent research has proposed the replacement of the CBB cycle with the reductive glycine pathway (rGlyP), allowing C. necator to incorporate formate in an ATP-efficient route for C1 assimilation. By integrating heterologous rGlyP into C. necator, the growth yield was comparable to that of the native CBB cycle, demonstrating the practicability of using the heterologous inorganic carbon assimilation pathway in C. necator [65]. Although C. necator lacks the CO2 concentrating mechanism (CMM), it expresses four carbonic anhydrase-like enzymes to provide a sufficient amount of bicarbonate ions in the cytoplasm and a relatively CO2-specific Rubisco variant [78]. This supports the strategy of improving CO2 bioconversion yield by transplanting a heterologous CCM into C. necator. Recently, heterologous expression of CCM has been accomplished in heterotrophs. The functional α-carboxysome from Halothiobacillus neapolitanus was successfully transplanted into E. coli [79]. Furthermore, this design was used to develop a strategy for oxygen-sensitive enzyme encapsulation to construct a robust nanoreactor for hydrogen production in E. coli [80].

Furthermore, recent research has used genetic engineering to generate more tailored and versatile PHA-copolymers produced from CO2 and H2 to extend the use of C. necator for bioplastic production. Using approaches that combined the overexpression of engineered thioesterases (TEs) to produce fatty acids, fine-tuning the native PHA synthase PhaC and the addition of acrylic acid (a β-oxidation inhibitor) into C. necator showed the potential to genetically control the PHA-copolymer composition [69]. Apart from PHA, C. necator has been successfully used as an autotrophic host to produce the amino acid polymer cyanophycin. With heterologous expression of the cyanophycin synthetase gene (cphA) from Synechocystis sp. PCC6308 in C. necator, cyanophycin was successfully produced under autotrophic conditions with up to 5.5% of its dry cell weight [81] (Table 1). The C. necator mutant that is unable to biosynthesize PHB has been used for the synthesis of many commodity chemicals due to the large pool of acetyl-CoA and pyruvate precursors. Recently, 1,3-butanediol (1,3-BDO), an essential precursor for synthetic rubber, was successfully produced autotrophically by an engineered C. necator. Constructing the (R)-3-hydroxybutyraldehyde-Co-(R)-3-hydroxybutyryl-CoA)-dependent and pyruvate-dependent pathways in PHB-abolished C. necator together with reducing the flux through the tricarboxylic acid cycle enabled the engineered strain to produce up to 2.97 g/L 1,3-BDO from CO2 [66] (Table 1).

Recent acetogen autotrophic cell factory developments and their use in biopolymer production

Acetogens have great potential as a cell biofactory to convert C1 gases, such as CO2 and CO, into value-added chemicals using the WL pathway. However, their slow growth and low autotrophic production rate limit their industrial applications [82]. Research has focused on improving the C1-fixation efficiency of the WL pathway in acetogens to overcome these limitations. Overexpression of the four tetrahydrofolate-dependent enzymes, which have been considered a catabolic bottleneck of H2/CO2 in the WL pathway [83], resulted in an increase in CO2 fixation efficiency and enhanced acetate production of up to 50 g/L in A. woodii [84]. Due to the limitations of genetic tools, adaptive laboratory evolution has been implemented to improve the growth and tolerance of E. limosum under CO [85]. The resulting strain that evolved under CO over 150 generations significantly increased the microorganism growth rate and production of the target metabolite acetoin by 1.44- and 1.34-fold, respectively [85]. Moreover, a recent report showed the connection between the WL pathway and the glycine synthase-reductase (GSR) pathway in the CO2 fixation activity of Clostridium drakei [86]. Functional cooperation of these pathways has been employed to enhance growth and the CO2 consumption rate in the acetogen Eubacterium limosum under autotrophic conditions, which enhanced the growth rate by up to 1.4-fold and the acetate production rate by up to 2.1-fold compared to the parental strain [86].

Acetogens have been successfully employed as autotrophic hosts for the heterologous production of chemicals of industrial interest, such as acetone, isopropanol, butanol, and isoprene [87,88,89,90]. Moreover, acetogenic C. coskatii and C. ljungdahlii have been successfully used as hosts for PHB production [91]. PHB was produced up to 1.2% of the dry cell weight (Table 1) under autotrophic conditions in recombinant C. coskatii and C. ljungdahlii that expressed the synthetic PHB pathway containing the genes thlA (encoding thiolase A), hbd (encoding 3-hydroxybutyryl-CoA dehydrogenase), crt (encoding crotonase), phaJ (encoding (R)-enoyl-CoA hydratase), and phaEC (encoding PHA synthase) [91]. The efficient coproduction of three valuable chemicals, isopropanol, ethanol, and 3-hydroxybutyrate (3-HB; a metabolic precursor of PHB biosynthesis), using synthesis gas (CO2/CO) was successfully engineered in autotrophic C. ljungdahlii [92]. By constructing the artificial isopropanol-producing pathway, which included the thlA (encoding thiolase A), ctfAB (encoding CoA transferase subunits A and B), adc (encoding acetoacetate decarboxylase), and sadh (primary/secondary alcohol dehydrogenase) genes, fine-tuned acetic acid reassimilation in C. ljungdahlii could be used to autotrophically produce up to 13.4, 3.0, and 28.4 g/L isopropanol, 3-HB, and ethanol, respectively, during gas fermentation [92] (Table 1).

To unlock the potential of acetogens for bioproduction and overcome the limitations of genetic tools, genome editing technology such as the CRISPR-Cas system has been utilized [93]. Recently, CRISPR interference (CRISPRi), a derivative of the CRISPR-Cas system that uses nuclease-deficient Cas9 (dCas9) instead of Cas9 to block the transcription of a target gene, has been used to downregulate phosphotransacetylase (pta) to redirect acetyl-CoA flux to enhance the production of 3-HB in C. ljungdahlii [94]. A similar approach was developed using the CRISPR-Cas12a system for efficient gene deletion and regulation in C. ljungdahlii by downregulating adhE1, an essential ethanol dehydrogenase gene responsible for ethanol synthesis, to restore the acetyl-CoA flux to boost the autotrophic production titer of butyric acid (a metabolic precursor of PHA biosynthesis) [95].

Summary and perspectives

The rapidly changing climate due to greenhouse gas emissions necessitates new and renewable resources for commodity chemical production. The ability of autotrophic microorganisms to harness energy from nature, such as sunlight, to fix atmospheric CO2 is an exciting avenue for future sustainable bioproduction to support a carbon-negative bioeconomy. This review comprehensively presents recent research regarding the use of autotrophic microorganisms to produce biopolymers. However, these processes/technologies are still in their infancy and need additional attention to revolutionize mass production for industry. Indeed, further research to identify the fundamental bottleneck of these autotrophic microorganisms using a synthetic biology approach will aid in the development of manipulations to enhance their abilities. One critical and challenging issue is the development of a high-density culture system, since cell growth and polymer accumulation always reduce the light transmission of cells and the exposure conditions of cell culture. For further biotechnological advances, we need to develop such technology.

References

Claassens NJ, Sousa DZ, dos Santos VAPM, de Vos WM, van der Oost J. Harnessing the power of microbial autotrophy. Nat Rev Microbiol. 2016;14:692–706.

Kallio P, Kugler A, Pyytövaara S, Stensjö K, Allahverdiyeva Y, Gao X, et al. Photoautotrophic production of renewable ethylene by engineered cyanobacteria: Steering the cell metabolism towards biotechnological use. Physiologia Plant. 2021;173:579–90.

Choi Y-N, Wook Lee J, Woo Kim J, Moon Park J. Acetyl-CoA-derived biofuel and biochemical production in cyanobacteria: a mini review. J Appl Phycol. 2020;32:1643–53.

Liu X, Xie H, Roussou S, Lindblad P. Current advances in engineering cyanobacteria and their applications for photosynthetic butanol production. Curr Opin Biotechnol. 2022;73:143–50.

Miao R, Xie H, Liu X, Lindberg P, Lindblad P. Current processes and future challenges of photoautotrophic production of acetyl-CoA-derived solar fuels and chemicals in cyanobacteria. Curr Opin Chem Biol. 2020;59:69–76.

Angermayr SA, Gorchs Rovira A, Hellingwerf KJ. Metabolic engineering of cyanobacteria for the synthesis of commodity products. Trends Biotechnol. 2015;33:352–61.

Oliver JWK, Atsumi S. Metabolic design for cyanobacterial chemical synthesis. Photosynthesis Res. 2014;120:249–61.

Ciebiada M, Kubiak K, Daroch M. Modifying the cyanobacterial metabolism as a key to efficient biopolymer production in photosynthetic microorganisms. Int J Mol Sci. 2020;21:1–24.

Wang F, Gao Y, Yang G. Recent advances in synthetic biology of cyanobacteria for improved chemicals production. Bioengineered. 2020;11:1208–20.

George DM, Vincent AS, Mackey HR. An overview of anoxygenic phototrophic bacteria and their applications in environmental biotechnology for sustainable Resource recovery. Biotechnol Rep. 2020;28:1–20.

Nybo SE, Khan NE, Woolston BM, Curtis WR. Metabolic engineering in chemolithoautotrophic hosts for the production of fuels and chemicals. Metab Eng. 2015;30:105–20.

Brandl H, Knee EJ, Fuller RC, Gross RA, Lenz RW. Ability of the phototrophic bacterium Rhodospirillum rubrum to produce various poly (β-hydroxyalkanoates): potential sources for biodegradable polyesters. Int J Biol Macromolecules. 1989;11:49–55.

Foong CP, Higuchi-Takeuchi M, Malay AD, Oktaviani NA, Thagun C, Numata K. A marine photosynthetic microbial cell factory as a platform for spider silk production. Commun Biol. 2020;3:1–8.

Higuchi-Takeuchi M, Morisaki K, Toyooka K, Numata K. Synthesis of high-molecular-weight polyhydroxyalkanoates by marine photosynthetic purple bacteria. PLoS ONE. 2016;11:e0160981.

Higuchi-Takeuchi, M & Numata, K. Acetate-inducing metabolic states enhance polyhydroxyalkanoate production in marine purple non-sulfur bacteria under aerobic conditions. Front Bioeng Biotechnol. 2019;7:118.

Kobayashi J, Kondo A. Disruption of poly (3-hydroxyalkanoate) depolymerase gene and overexpression of three poly (3-hydroxybutyrate) biosynthetic genes improve poly (3-hydroxybutyrate) production from nitrogen rich medium by Rhodobacter sphaeroides. Microb Cell Factories. 2019;18:1–13.

Mukhopadhyay M, Patra A, Paul AK. Production of poly(3-hydroxybutyrate) and poly(3-hydroxybutyrate-co-3- hydroxyvalerate) by Rhodopseudomonas palustris SP5212. World J Microbiol Biotechnol. 2005;21:765–9.

Liang F, Lindberg P, Lindblad P. Engineering photoautotrophic carbon fixation for enhanced growth and productivity. Sustain Energy Fuels. 2018;2:2583–600.

Forchhammer K, Selim KA. Carbon/nitrogen homeostasis control in cyanobacteria. FEMS Microbiol Rev. 2019;44:33–53.

Cai Z, Liu G, Zhang J, Li Y. Development of an activity-directed selection system enabled significant improvement of the carboxylation efficiency of Rubisco. Protein Cell. 2014;5:552–62.

Duraõ P, Aigner H, Nagy P, Mueller-Cajar O, Hartl FU, Hayer-Hartl M. Opposing effects of folding and assembly chaperones on evolvability of Rubisco. Nat Chem Biol. 2015;11:148–55.

Roussou S, Albergati A, Liang F, Lindblad P. Engineered cyanobacteria with additional overexpression of selected Calvin-Benson-Bassham enzymes show further increased ethanol production. Metab Eng Commun. 2021;12:e00161.

Kamennaya NA, Ahn SE, Park H, Bartal R, Sasaki KA, Holman HY, et al. Installing extra bicarbonate transporters in the cyanobacterium Synechocystis sp. PCC6803 enhances biomass production. Metab Eng. 2015;29:76–85.

Gupta JK, Rai P, Jain KK, Srivastava S. Overexpression of bicarbonate transporters in the marine cyanobacterium Synechococcus sp. PCC 7002 increases growth rate and glycogen accumulation. Biotechnol Biofuels. 2020;13:1–12.

Carrieri D, Broadbent C, Carruth D, Paddock T, Ungerer J, Maness PC, et al. Enhancing photo-catalytic production of organic acids in the cyanobacterium Synechocystis sp.PCC 6803 ΔglgC, a strain incapable of glycogen storage. Microb Biotechnol. 2015;8:275–80.

Carrieri D, Paddock T, Maness PC, Seibert M, Yu J. Photo-catalytic conversion of carbon dioxide to organic acids by a recombinant cyanobacterium incapable of glycogen storage. Energy Environ Sci. 2012;5:9457–61.

Luan G, Zhang S, Wang M, Lu X. Progress and perspective on cyanobacterial glycogen metabolism engineering. Biotechnol Adv. 2019;37:771–86.

Chi X, Zhang S, Sun H, Duan Y, Qiao C, Luan G, et al. Adopting a theophylline-responsive riboswitch for flexible regulation and understanding of glycogen metabolism in Synechococcus elongatus PCC7942. Front Microbiol. 2019;10:1–9.

Zhang L, Toscano Selão T, Nixon PJ, Norling B. Photosynthetic conversion of CO2 to hyaluronic acid by engineered strains of the cyanobacterium Synechococcus sp. PCC 7002. Algal Res. 2019;44:1–8.

Beck C, Knoop H, Axmann IM, Steuer R. The diversity of cyanobacterial metabolism: Genome analysis of multiple phototrophic microorganisms. BMC Genomics. 2012;13:1–17.

Damrow R, Maldener I, Zilliges Y. The multiple functions of common microbial carbon polymers, glycogen and PHB, during stress responses in the non-diazotrophic cyanobacterium Synechocystis sp. PCC 6803. Front Microbiol. 2016;7:1–10.

Afreen R, Tyagi S, Singh GP, Singh M. Challenges and perspectives of polyhydroxyalkanoate production from microalgae/cyanobacteria and bacteria as microbial factories: an assessment of hybrid biological system. Front Bioeng Biotechnol. 2021;9:1–14.

Ishizaki A, Tanaka K, Taga N. Microbial production of poly-D-3-hydroxybutyrate from CO2. Appl Microbiol Biotechnol. 2001;57:6–12.

Wu GF, Wu QY, Shen ZY. Accumulation of poly-B-hydroxybutyrate in cyanobacterium Synechocystis sp. PCC6803. Bioresour Technol. 2001;76:85–90.

Zher Neoh S, Fey Chek M, Tiang Tan H, Linares-Pastén JA, Nandakumar A, Hakoshima T, et al. Polyhydroxyalkanoate synthase (PhaC): The key enzyme for biopolyester synthesis. Curr Res Biotechnol. 2022;4:87–101.

Numata K, Motoda Y, Watanabe S, Osanai T, Kigawa T. Co-expression of two polyhydroxyalkanoate synthase subunits from Synechocystis sp. PCC 6803 by cell-free synthesis and their specific activity for polymerization of 3-hydroxybutyryl-coenzyme A. Biochemistry. 2015;54:1401–7.

Osanai T, Numata K, Oikawa A, Kuwahara A, Iijima H, Doi Y, et al. Increased bioplastic production with an RNA polymerase sigma factor SigE during nitrogen starvation in Synechocystis sp. PCC 6803. DNA Res. 2013;20:525–35.

Hondo S, Takahashi M, Osanai T, Matsuda M, Hasunuma T, Tazuke A, et al. Genetic engineering and metabolite profiling for overproduction of polyhydroxybutyrate in cyanobacteria. J Biosci Bioeng. 2015;120:510–7.

Kamravamanesh D, Kovacs T, Pflügl S, Druzhinina I, Kroll P, Lackner M, et al. Increased poly-Β-hydroxybutyrate production from carbon dioxide in randomly mutated cells of cyanobacterial strain Synechocystis sp. PCC 6714: mutant generation and characterization. Bioresour Technol. 2018;266:34–44.

Roh H, Lee JS, Choi H, il, Sung YJ, Choi SY, Woo HM, et al. Improved CO2-derived polyhydroxybutyrate (PHB) production by engineering fast-growing cyanobacterium Synechococcus elongatus UTEX 2973 for potential utilization of flue gas. Bioresour Technol. 2021;327:1–9.

Koch M, Bruckmoser J, Scholl J, Hauf W, Rieger B, Forchhammer K. Maximizing PHB content in Synechocystis sp. PCC 6803: a new metabolic engineering strategy based on the regulator PirC. Microb Cell Factories. 2020;19:1–12.

Orthwein T, Scholl J, Spät P, Lucius S, Koch M, Macek B, et al. The novel P II-interactor PirC identifies phosphoglycerate mutase as key control point of carbon storage metabolism in cyanobacteria. PNAS. 2021;118:e2019988118.

Adelnia H, Tran HDN, Little PJ, Blakey I, Ta HT. Poly(aspartic acid) in biomedical applications: from polymerization, modification, properties, degradation, and biocompatibility to applications. ACS Biomater Sci Eng. 2021;7:2083–105.

Gross RA, Kalra B. Biodegradable polymers for the environment. Science (1979). 2002;297:803–7.

Fay P. Oxygen relations of nitrogen fixation in Cyanobacteria. Microbiological Rev. 1992;56:340–73.

Li H, Sherman DM, Bao S, Sherman LA. Pattern of cyanophycin accumulation in nitrogen-fixing and non-nitrogen-fixing cyanobacteria. Arch Microbiol. 2001;176:9–18.

Watzer B, Engelbrecht A, Hauf W, Stahl M, Maldener I, Forchhammer K. Metabolic pathway engineering using the central signal processor PII. Microb Cell Factories. 2015;14:1–12.

Lippi L, Bähr L, Wüstenberg A, Wilde A, Steuer R. Exploring the potential of high-density cultivation of cyanobacteria for the production of cyanophycin. Algal Res. 2018;31:363–6.

Wu X, Ma G, Liu C, Qiu X, Yuan, Min L, Kuang J, et al. Biosynthesis of pinene in purple non-sulfur photosynthetic bacteria. Microb Cell Factories. 2021;20:1–8.

Beekwilder J, van Houwelingen A, Cankar K, van Dijk ADJ, de Jong RM, Stoopen G, et al. Valencene synthase from the heartwood of Nootka cypress (Callitropsis nootkatensis) for biotechnological production of valencene. Plant Biotechnol J. 2014;12:174–82.

Khan NE, Nybo SE, Chappell J, Curtis WR. Triterpene hydrocarbon Production engineered into a metabolically versatile host-Rhodobacter capsulatus. Biotechnol Bioeng. 2015;112:1523–32.

Revelles O, Calvillo I, Prieto A & Prieto MA. in Hydrocarbon and Lipid Microbiology Protocols. 105–19 (2017). https://doi.org/10.1007/8623_2015_168.

Revelles O, Tarazona N, García JL, Prieto MA. Carbon roadmap from syngas to polyhydroxyalkanoates in Rhodospirillum rubrum. Environ Microbiol. 2016;18:708–20.

Revelles O, Beneroso D, Menéndez JA, Arenillas A, García JL, Prieto MA. Syngas obtained by microwave pyrolysis of household wastes as feedstock for polyhydroxyalkanoate production in Rhodospirillum rubrum. Microb Biotechnol. 2017;10:1412–7.

Heinrich D, Raberg M & Steinbüchel A. Synthesis of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) from unrelated carbon sources in engineered Rhodospirillum rubrum. FEMS Microbiol Lett. 2015;362:fnv038.

Heinrich D, Raberg M, Fricke P, Kenny ST, Morales-Gamez L, Babu RP, et al. Synthesis gas (syngas)-derived medium-chainlength polyhydroxyalkanoate synthesis in engineered Rhodospirillum rubrum. Appl Environ Microbiol. 2016;82:6132–40.

Higuchi-Takeuchi M, Numata K. Marine purple photosynthetic bacteria as sustainable microbial production hosts. Front Bioeng Biotechnol. 2019;7:1–8.

Higuchi-Takeuchi M, Morisaki K & Numata K. A screening method for the isolation of polyhydroxyalkanoate-producing purple non-sulfur photosynthetic bacteria from natural seawater. Front Microbiol. 2016;7:1509.

Foong CP, Higuchi-Takeuchi M, Numata K. Optimal iron concentrations for growth-associated polyhydroxyalkanoate biosynthesis in the marine photosynthetic purple bacterium Rhodovulum sulfidophilum under photoheterotrophic condition. PLoS ONE. 2019;14:e0212654.

Carlozzi P, di Lorenzo T, Ghanotakis DF, Touloupakis E. Effects of pH, temperature and salinity on P3HB synthesis culturing the marine Rhodovulum sulfidophilum DSM-1374. Appl Microbiol Biotechnol. 2020;104:2007–15.

Foong CP, Higuchi-Takeuchi M, Ohtawa K, Asai T, Liu H, Ozeki Y, et al. Engineered mutants of a marine photosynthetic purple nonsulfur bacterium with increased volumetric productivity of polyhydroxyalkanoate bioplastics. ACS Synth Biol. 2022;11:909–20.

Srisawat P, Higuchi-Takeuchi M, Honda R, Shirai T, Kondo A, Hoshino Y, et al. Engineered nanogel particles enhance the photoautotrophic biosynthesis of polyhydroxyalkanoate in marine photosynthetic bacteria. ACS Sustain Chem Eng. 2022;10:4133–42.

Mougiakos I, Orsi E, Ghiffary MR, Post W, de Maria A, Adiego-Perez B, et al. Efficient Cas9-based genome editing of Rhodobacter sphaeroides for metabolic engineering. Microb Cell Factories. 2019;18:1–13.

Brigham C. Perspectives for the biotechnological production of biofuels from CO2 and H2 using Ralstonia eutropha and other ‘Knallgas’ bacteria. Appl Microbiol Biotechnol. 2019;103:2113–20.

Claassens NJ, Bordanaba-Florit G, Cotton CAR, de Maria A, Finger-Bou M, Friedeheim L, et al. Replacing the Calvin cycle with the reductive glycine pathway in Cupriavidus necator. Metab Eng. 2020;62:30–41.

Gascoyne JL, Bommareddy RR, Heeb S, Malys N. Engineering Cupriavidus necator H16 for the autotrophic production of (R)-1,3-butanediol. Metab Eng. 2021;67:262–76.

Müller J, MacEachran D, Burd H, Sathitsuksanoh N, Bi C, Yeh YC, et al. Engineering of Ralstonia eutropha H16 for autotrophic and heterotrophic production of methyl ketones. Appl Environ Microbiol. 2013;79:4433–9.

Lu J, Brigham CJ, Gai CS, Sinskey AJ. Studies on the production of branched-chain alcohols in engineered Ralstonia eutropha. Appl Microbiol Biotechnol. 2012;96:283–97.

Nangle SN, Ziesack M, Buckley S, Trivedi D, Loh DM, Nocera DG, et al. Valorization of CO2 through lithoautotrophic production of sustainable chemicals in Cupriavidus necator. Metab Eng. 2020;62:207–20.

Ragsdale SW, Pierce E. Acetogenesis and the Wood-Ljungdahl pathway of CO2 fixation. Biochimica et Biophysica Acta. 2008;1784:1873–98.

Köpke M, Mihalcea C, Liew FM, Tizard JH, Ali MS, Conolly JJ, et al. 2,3-Butanediol production by acetogenic bacteria, an alternative route to chemical synthesis, using industrial waste gas. Appl Environ Microbiol. 2011;77:5467–75.

Liew F, Henstra AM, Kӧpke M, Winzer K, Simpson SD, Minton NP. Metabolic engineering of Clostridium autoethanogenum for selective alcohol production. Metab Eng. 2017;40:104–14.

Katsyv A & Müller V. Overcoming energetic barriers in Acetogenic C1 conversion. Front Bioeng Biotechnol. 2020;8:621166.

Volova TG, Kalacheva GS, Altukhova OV. Autotrophic synthesis of polyhydroxyalkanoates by the bacteria Ralstonia eutropha in the presence of carbon monoxide. Appl Microbiol Biotechnol. 2002;58:675–8.

Volova TG, Kiselev EG, Shishatskaya EI, Zhila NO, Boyandin AN, Syrvacheva DA, et al. Cell growth and accumulation of polyhydroxyalkanoates from CO2 and H2 of a hydrogen-oxidizing bacterium, Cupriavidus eutrophus B-10646. Bioresour Technol. 2013;146:215–22.

Miyahara Y, Yamamoto M, Thorbecke R, Mizuno S, Tsuge T. Autotrophic biosynthesis of polyhydroxyalkanoate by Ralstonia eutropha from non-combustible gas mixture with low hydrogen content. Biotechnol Lett. 2020;42:1655–62.

Li Z, Xin X, Xiong B, Zhao D, Zhang X, Bi C. Engineering the Calvin–Benson–Bassham cycle and hydrogen utilization pathway of Ralstonia eutropha for improved autotrophic growth and polyhydroxybutyrate production. Microb Cell Factories. 2020;19:1–9.

Satagopan S, Tabita FR. RubisCO selection using the vigorously aerobic and metabolically versatile bacterium Ralstonia eutropha. FEBS J. 2016;283:2869–80.

Flamholz AI, Dugan E, Blikstad C, Gleizer S, Ben-Nissan R, Amram S, et al. Functional reconstitution of a bacterial CO2 concentrating mechanism in E. coli. Elife. 2020;9:1–30.

Li T, Jiang Q, Huang J, Aitchison CM, Huang F, Yang M, et al. Reprogramming bacterial protein organelles as a nanoreactor for hydrogen production. Nat Commun. 2020;11:5448.

Lütte S, Pohlmann A, Zaychikov E, Schwartz E, Becher JR, Heumann H, et al. Autotrophic production of stable-isotope-labeled arginine in Ralstonia eutropha strain H16. Appl Environ Microbiol. 2012;78:7884–90.

Jin S, Bae J, Song Y, Pearcy N, Shin J, Kang S, et al. Synthetic biology on acetogenic bacteria for highly efficient conversion of C1 gases to biochemicals. Int J Mol Sci. 2020;21:1–25.

Peters V, Janssen PH, Conrad R. Transient production of formate during chemolithotrophic growth of anaerobic microorganisms on hydrogen. Curr Microbiol. 1999;38:285–9.

Straub M, Demler M, Weuster-Botz D, Dürre P. Selective enhancement of autotrophic acetate production with genetically modified Acetobacterium woodii. J Biotechnol. 2014;178:67–72.

Kang S, Song Y, Jin S, Shin J, Bae J, Kim DR, et al. Adaptive laboratory evolution of Eubacterium limosum ATCC 8486 on carbon monoxide. Front Microbiol. 2020;11:402.

Song Y, Lee JS, Shin J, Lee GM, Jin S, Kang S, et al. Functional cooperation of the glycine synthase-reductase and Wood-Ljungdahl pathways for autotrophic growth of Clostridium drakei. PNAS. 2020;117:7516–23.

Arslan K, Schoch T, Höfele F, Herrschaft S, Oberlies C, Bengelsdorf F, et al. Engineering Acetobacterium woodii for the production of isopropanol and acetone from carbon dioxide and hydrogen. Biotechnol J. 2022;e2100515:1–12.

Flaiz M, Ludwig G, Bengelsdorf FR & Dürre P. Production of the biocommodities butanol and acetone from methanol with fluorescent FAST-tagged proteins using metabolically engineered strains of Eubacterium limosum. Biotechnol Biofuels. 2021;14:117.

Diner BA, Fan J, Scotcher MC, Wells DH, Whited GM, Drake HL. Synthesis of heterologous mevalonic acid pathway enzymes in Clostridium ljungdahlii for the conversion of fructose and of syngas to mevalonate and isoprene. Appl Environ Microbiol Downloaded. 2018;84:1723–40.

Hoffmeister S, Gerdom M, Bengelsdorf FR, Linder S, Flüchter S, Öztürk H, et al. Acetone production with metabolically engineered strains of Acetobacterium woodii. Metab Eng. 2016;36:37–47.

Flüchter S, Follonier S, Schiel-Bengelsdorf B, Bengelsdorf FR, Zinn M, Dürre P. Anaerobic production of poly(3-hydroxybutyrate) and its Precursor 3-hydroxybutyrate from synthesis gas by autotrophic Clostridia. Biomacromolecules. 2019;20:3271–82.

Jia D, He M, Tian Y, Shen S, Zhu X, Wang Y, et al. Metabolic engineering of gas-fermenting Clostridium ljungdahlii for efficient co-production of isopropanol, 3-hydroxybutyrate, and ethanol. ACS Synth Biol. 2021;10:2628–38.

Yao R, Liu D, Jia X, Zheng Y, Liu W, Xiao Y. CRISPR-Cas9/Cas12a biotechnology and application in bacteria. Synth Syst Biotechnol. 2018;3:135–49.

Woolston BM, Emerson DF, Currie DH, Stephanopoulos G. Rediverting carbon flux in Clostridium ljungdahlii using CRISPR interference (CRISPRi). Metab Eng. 2018;48:243–53.

Zhao R, Liu Y, Zhang H, Chai C, Wang J, Jiang W, et al. CRISPR-Cas12a-mediated gene deletion and regulation in Clostridium ljungdahlii and its application in carbon flux redirection in synthesis gas fermentation. ACS Synth Biol. 2019;8:2270–9.

Funding

This work was funded by the ImPACT Program of the Council for Science, Technology, and Innovation (Cabinet Office, Government of Japan) and JST ERATO (grant number JPMJER1602).

Author information

Authors and Affiliations

Contributions

PS, MH-T, and KN conceptualized and wrote the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Srisawat, P., Higuchi-Takeuchi, M. & Numata, K. Microbial autotrophic biorefineries: Perspectives for biopolymer production. Polym J 54, 1139–1151 (2022). https://doi.org/10.1038/s41428-022-00675-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-022-00675-3

This article is cited by

-

Characterization and seasonal variation in biofilms attached to leaves of submerged plant

World Journal of Microbiology and Biotechnology (2024)

-

Characterization and environmental applications of soil biofilms: a review

Environmental Chemistry Letters (2024)

-

The potential of CO2-based production cycles in biotechnology to fight the climate crisis

Nature Communications (2023)

-

A dirty job: dishwasher wastewater reuse and upcycle through an ad hoc engineered microbial consortium

npj Clean Water (2023)