Abstract

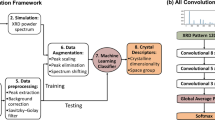

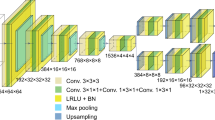

The construction of a deep learning model and visualization of judgment regions were conducted for X-ray diffraction and scattering images of aliphatic polyesters. Due to recent progress in measurement methods, a large amount of image data can be obtained in a short time; therefore, machine learning methods are useful to determine the important regions for a given objective. Although techniques to visualize the judgment regions using deep learning have recently been developed, there have been few reports discussing whether such models can determine the important regions of X-ray diffraction and scattering images of polymeric materials. Herein, we demonstrate classification models based on convolutional neural networks (CNNs) for wide-angle X-ray diffraction and small-angle X-ray scattering images of aliphatic polyesters to predict the types of polymers and several crystallization temperatures. Furthermore, the judgment regions of the X-ray images used by the CNNs were visualized using the Grad-CAM, LIME, and SHAP methods. The main regions were diffraction and scattering peaks recognized by experts. Other areas, such as the beam centers were recognized when the intensity of the images was randomly changed. This result may contribute to developing important features in deep learning models, such as the recognition of structure–property relationships.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Nguyen HK, Inutsuka M, Kawaguchi D, Tanaka K. Direct observation of conformational relaxation of polymer chains at surfaces. ACS Macro Lett. 2018;7:1198–202.

Ueda E, Liang XB, Ito M, Nakajima K. Dynamic moduli mapping of silica-filled styrene-butadiene rubber vulcanizate by nanorheological atomic force microscopy. Macromolecules. 2019;52:311–9.

Kakubo T, Shimizu K, Kumagai A, Matsumoto H, Tsuchiya M, Amino N, et al. Degradation of a metal-polymer interface observed by element-specific focused ion beam-scanning electron microscopy. Langmuir. 2020;36:2816–22.

Kobayashi S, Kaneko S, Kiguchi M, Tsukagoshi K, Nishino T. Tolerance to stretching in Thiol-terminated single-molecule junctions characterized by surface-enhanced raman scattering. J Phys Chem Lett. 2020;11:6712–7.

Yamamoto Y, Hoshina H, Sato H. Differences in intermolecular interactions and flexibility between Poly(ethylene terephthalate) and poly(butylene terephthalate) studied by far-infrared/Terahertz and low-frequency raman spectroscopy. Macromolecules. 2021;54:1052–62.

Amamoto Y, Kikuchi M, Otsuka H, Takahara A. Arm-replaceable star-like nanogels: arm detachment and arm exchange reactions by dynamic covalent exchanges of alkoxyamine units. Polym J. 2010;42:860–7.

Mitamura K, Yamada NL, Sagehashi H, Torikai N, Arita H, Terada M, et al. Novel neutron reflectometer SOFIA at J-PARC/MLF for in-situ soft-interface characterization. Polym J. 2013;45:100–8.

Dechnarong N, Kamitani K, Cheng CH, Masuda S, Nozaki S, Nagano C, et al. In situ synchrotron radiation x-ray scattering investigation of a microphase-separated structure of thermoplastic elastomers under uniaxial and equi-biaxial deformation modes. Macromolecules. 2020;53:8901–9.

Hiroi T, Hirosawa K, Okazumi Y, Pingali SV, Shibayama M. Mechanism of heat-induced gelation for ovalbumin under acidic conditions and the effect of peptides. Polym J. 2020;52:1263–72.

Mayumi K. Molecular dynamics and structure of polyrotaxane in solution. Polym J. 2021;53:581–6.

Tashiro K, Yamamoto H, Yoshioka T, Ninh TH, Tasaki M, Shimada S, et al. Hierarchical structural change in the stress-induced phase transition of poly(tetramethylene terephthalate) as studied by the simultaneous measurement of FTIR spectra and 2D synchrotron undulator WAXD/SAXS data. Macromolecules. 2014;47:2052–61.

Diep PTN, Mochizuki M, Doi M, Takagi H, Shimizu N, Igarashi N, et al. Effects of a special diluent as an agent of improving the crystallizability of poly(L-lactic acid). Polym J. 2019;51:283–94.

Kishimoto M, Mita K, Ogawa H, Takenaka M. Effect of submicron structures on the mechanical behavior of polyethylene. Macromolecules. 2020;53:9097–107.

Nishitsuji S, Watanabe Y, Takebe T, Fujii N, Okano M, Takenaka M. X-ray scattering study on the changes in the morphology of low-modulus polypropylene under cyclic uniaxial elongation. Polym J. 2020;52:279–87.

Toda A, Taguchi K, Nozaki K, Guan XC, Hu WB, Furushima Y, et al. Crystallization and melting of poly(butylene terephthalate) and poly (ethylene terephthalate) investigated by fast-scan chip calorimetry and small angle X-ray scattering. Polymer. 2020;192:122303.

Fancher CM, Han Z, Levin I, Page K, Reich BJ, Smith RC, et al. Use of Bayesian inference in crystallographic structure refinement via full diffraction profile analysis. Sci Rep. 2016;6:31625.

Mototake Y, Mizumaki M, Akai I, Okada M. Bayesian hamiltonian selection in X-ray photoelectron spectroscopy. J Phys Soc Jpn. 2019;88:034004.

Saito K, Yano M, Hino H, Shoji T, Asahara A, Morita H, et al. Accelerating small-angle scattering experiments on anisotropic samples using kernel density estimation. Sci Rep. 2019;9:1526.

Suzuki Y, Hino H, Kotsugi M, Ono K. Automated estimation of materials parameter from X-ray absorption and electron energy-loss spectra with similarity measures. npj Comput Mater. 2019;5:39.

Miyazaki Y, Nakayama R, Yasuo N, Watanabe Y, Shimizu R, Packwood DM, et al. Bayesian statistics-based analysis of AC impedance spectra. Aip Adv. 2020;10:045231.

Ozaki Y, Suzuki Y, Hawai T, Saito K, Onishi M, Ono K. Automated crystal structure analysis based on blackbox optimisation. npj Comput Mater. 2020;6:75.

Amamoto Y, Kojio K, Takahara A, Masubuchi Y, Ohnishi T. Complex network representation of the structure-mechanical property relationships in elastomers with heterogeneous connectivity. Patterns. 2020;1:100135.

Hagita K, Higuchi T, Jinnai H. Super-resolution for asymmetric resolution of FIB-SEM 3D imaging using AI with deep learning. Sci Rep. 2018;8:5877.

Yamada H, Liu C, Wu S, Koyama Y, Ju SH, Shiomi J, et al. Predicting materials properties with little data using shotgun transfer learning. ACS Cent Sci. 2019;5:1717–30.

Ma BY, Wei XY, Liu CN, Ban XJ, Huang HY, Wang H, et al. Data augmentation in microscopic images for material data mining. npj Comput Mater. 2020;6:125.

Aoyagi T. Deep learning model for predicting phase diagrams of block copolymers. Comp Mater Sci. 2021;188:110224.

Ienaga N, Higuchi K, Takashi T, Gen K, Tsuda K, Terayama K. Vision-based egg quality prediction in Pacific bluefin tuna (Thunnus orientalis) by deep neural network. Sci Rep. 2021;11:6.

Matsumoto S, Ishida S, Araki M, Kato T, Terayama K, Okuno Y. Extraction of protein dynamics information from cryo-EM maps using deep learning. Nat Mach Intell. 2021;3:153–60.

Selvaraju RR, Cogswell M, Das A, Vedantam R, Parikh D, Batra D. Grad-CAM: visual explanations from deep networks via gradient-based localization. Int J Comput Vis. 2020;128:336–59.

Lundberg S, Lee S-I. A unified approach to interpreting model predictions. https://arxiv.org/abs/1705.07874v2. 2017.

Ribeiro MT, Singh S, Guestrin C. “Why Should I Trust You?”: explaining the predictions of any classifier. https://arxiv.org/abs/1602.04938. 2016.

Pokuri BSS, Ghosal S, Kokate A, Sarkar S, Ganapathysubramanian B. Interpretable deep learning for guided microstructure-property explorations in photovoltaics. npj Comput Mater. 2019;95:95.

Horwath JP, Zakharov DN, Megret R, Stach EA. Understanding important features of deep learning models for segmentation of high-resolution transmission electron microscopy images. npj Comput Mater. 2020;108:108.

Chollet F. Keras. https://keras.io. 2015.

Ihn KJ, Yoo ES, Im SS. Structure and morphology of poly(Tetramethylene Succinate) crystals. Macromolecules. 1995;28:2460–4.

Gan ZH, Abe H, Kurokawa H, Doi Y. Solid-state microstructures, thermal properties, and crystallization of biodegradable poly(butylene succinate) (PBS) and its copolyesters. Biomacromolecules. 2001;2:605–13.

Puchalski M, Szparaga G, Biela T, Gutowska A, Sztajnowski S, Krucinska I. Molecular and supramolecular changes in polybutylene succinate (PBS) and polybutylene succinate adipate (PBSA) copolymer during degradation in various environmental conditions. Polymers. 2018;10:251.

Hoogsteen W, Postema AR, Pennings AJ, Tenbrinke G, Zugenmaier P. Crystal-structure, conformation, and morphology of solution-spun poly(L-Lactide) fibers. Macromolecules. 1990;23:634–42.

Huang SY, Li HF, Jiang SC, Chen XS, An LJ. Crystal structure and morphology influenced by shear effect of poly(L-lactide) and its melting behavior revealed by WAXD, DSC and in-situ POM. Polymer. 2011;52:3478–87.

Wasanasuk K, Tashiro K, Hanesaka M, Ohhara T, Kurihara K, Kuroki R, et al. Crystal structure analysis of poly(L-lactic Acid) alpha form on the basis of the 2-dimensional wide-angle synchrotron X-ray and neutron diffraction measurements. Macromolecules. 2011;44:6441–52.

Molnar C. Interpretable machine learning. Lulu.com; 2020.

Acknowledgements

The synchrotron radiation experiments were performed at the BL40B2 and BL40XU beamlines of SPring-8 with the approval of the Japan Synchrotron Radiation Research Institute (JASRI) (Proposal no. 2020A1525 and 2019B1667). This work was supported by the Cabinet Office, Government of Japan, Cross-ministerial Strategic Innovation Promotion Program (SIP), “Technologies for Smart Bio-industry and Agriculture” (funding agency: Bio-oriented Technology Research Advancement Institution, NARO). The computer resources were supported by the “Joint Usage/Research Center for Interdisciplinary Large-scale Information Infrastructures” and the “High Performance Computing Infrastructure” in Japan (Project ID: jh200016-NAH). This work was also supported by the JSPS Grant-in-Aid for Scientific Research on Innovative Areas, Discrete Geometric Analysis for Materials Design: 20H04644, by the Grant-in-Aid for Scientific Research (B): 20H02800, and by Early-Career Scientists: 18K14273 from JSPS. YA and KT acknowledge the financial support of the Grant-in-Aid for RIKEN-Kyushu University Science and Technology Hub Collaborative Research Program.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Amamoto, Y., Kikutake, H., Kojio, K. et al. Visualization of judgment regions in convolutional neural networks for X-ray diffraction and scattering images of aliphatic polyesters. Polym J 53, 1269–1279 (2021). https://doi.org/10.1038/s41428-021-00531-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-021-00531-w