Abstract

Functionalized colloidal particles are fascinating due to their huge range of potential and reported applications. In this focus review, the recent development of a novel “interfacial photoreaction” for the preparation of functional polymer particles is summarized. Recently, we discovered the phenomenon of the interfacial selective cross-linking of spherical polymer particles bearing photoreactive groups, and this reaction was successfully used to synthesize hollow polymer particles. As these hollow polymer particles have a cross-linked shell, solvent exchange can lead to the posteriori encapsulation of various molecules, yielding capsule particles. Functionalization of hollow/capsule particles was successfully achieved by introducing functional groups to the parent spherical polymer particles. In addition, the spatially controlled interfacial photoreaction enabled the formation of non-spherical bowl-shaped polymer particles. Furthermore, the photoinduced interfacial cross-linking strategy was successfully combined with molecular imprinting, and functional polymer particles with a molecular recognition capability were developed by utilizing the novel photoinduced post-cross-linked molecular imprinting method. We believe that photoinduced interfacial cross-linking will allow for the creation of new functional polymer particles suitable for a range of versatile applications.

Similar content being viewed by others

Introduction

Polymer particles possessing controlled morphologies and sophisticated functions are fascinating in terms of developing advanced research fields and industrial applications. Indeed, the particle morphology is a fundamental feature of polymer particles, since the particle morphology strongly influences the physical properties of the particles. For example, hollow polymer particles are used in industry as organic white pigments [1] due to their unique light-scattering properties. In addition, the encapsulation of imaging agents, drugs, and precursor compounds into such hollow particles yields capsule particles, which have been employed in attractive applications, such as in vivo imaging [2, 3], drug delivery [4,5,6], microreactors [7, 8], and self-healing materials [9, 10]. Furthermore, non-spherical polymer particles exhibit interesting characteristics in terms of light-scattering and rheological properties [11,12,13,14,15]. Moreover, the particle morphology is known to affect aspects of bio-related applications, such as the cellular uptake, intracellular distribution, and in vivo behaviors of particles [16,17,18,19,20]. The chemical functionalization of polymer particles is also an important requirement to ultimately permit their application in advanced research fields [21,22,23,24].

This focus review therefore aims to present our developed novel approach for creating functional polymer particles possessing controlled morphologies by subjecting spherical polymer particles to an interfacial photoreaction. This approach should allow for the fabrication of hollow, capsular, non-spherical polymer particles from spherical polymer particles via a simple procedure that does not require the use of sacrificial template particles or toxic solvents, which are used for template removal. Furthermore, the ability of this approach to synthesize morphology controlled particles possessing sophisticated functions, such as stimuli responsiveness and molecular recognition capability, was also described in this paper.

Synthetic routes to produce hollow polymer particles

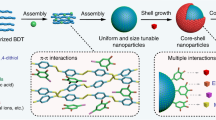

Remarkable progress has been made in the preparation of hollow polymer particles, where synthetic approaches are generally separated into template-assisted approaches and template-free molecular self-assembly-based approaches (Fig. 1). For example, Caruso et al. [25] reported a layer-by-layer template-assisted approach; in this approach, a polymeric shell layer was formed on an inorganic particle template via the step-by-step alternating adsorption of two pairs of polymers (e.g., cationic/anionic, hydrogen donor/acceptor), leading to the formation of core-shell particles comprising a polymer shell and an inorganic particle core. The hollow polymer particles were then obtained by removing the inorganic particles from the core-shell particles [25, 26]. Other template-assisted routes have also been reported, such as seeded dispersion polymerization [27] and surface-initiated polymerization [28, 29]. A common requirement of the template-assisted approach is the use of sacrificial inorganic particles (e.g., silica or gold particles) and their subsequent removal following the formation of the core-shell morphology. This tends to require the use of a highly toxic solvent (e.g., hydrogen fluoride or aqua regia) to remove these sacrificial inorganic particles. Okubo et al. developed a self-assembling phase-separated polymer (SaPSeP) method, which is a powerful strategy used for the preparation of hollow polymer particles [30, 31]. The SaPSeP method is generally performed in suspension polymerization systems with hydrophobic organic solvents containing a monomer and a cross-linker. During the polymerization process, the polymers precipitate as microgels in the monomer droplets, and these microgels are self-assembled at the water/oil interface to reduce the interfacial free energy. This implies that this methodology is limited by the fact that the polymer species and core materials (i.e., organic solvents) must be combined, and a highly hydrophobic core material is necessary. In contrast, the template-free molecular self-assembly-based approach is based on micelle and vesicle formation. For example, shell-cross-linked hollow micelles are formed by block copolymer self-assembly, which is followed by subsequent shell-cross-linking and core-selective degradation [32]. Various approaches used for the shell-cross-linking and core degradation processes have been reported, and excellent review articles concerning shell-cross-linked micelles have been published [33, 34]. In addition, Kataoka et al. reported vesicle formation based on the formation of polyion complexes (PICsomes) using block copolypeptides [35, 36], while Yusa et al. reported PICsome formation using amphiphilic vinyl polymers [37, 38]. Furthermore, Armes et al. pioneered the preparation of nanoobjects, such as polymer vesicles, via polymerization-induced self-assembly (PISA), and as a result, the preparation of functional vesicles has been reported by several different research groups [39,40,41,42,43,44,45].

The interfacial photoreaction of polymer particles: a novel synthetic route toward the production of hollow polymer particles

A new approach for the preparation of hollow polymer particles based on the interfacial photoreaction of spherical polymer particles has recently been developed by our group [46]. In this system, a photoinduced cross-linking reaction based on the [2π+2π] dimerization reaction of photoreactive groups, such as cinnamoyl, stilbene, and coumarin groups, can be adopted [47,48,49,50]. In the [2π+2π] cycloaddition reaction, a cyclobutane ring was formed from two alkene moieties by ultraviolet (UV) light irradiation, which excites the alkene groups from the ground state to an excited state. The [2π+2π] cycloaddition reaction can therefore be used to cross-link the polymers when the reaction occurs in the polymer side chains.

Thus, for the purpose of our studies, the cinnamoyl group was selected as a photoreactive alkene group, and poly(2-cinnamoylethyl methacrylate-co-methyl methacrylate) (P(CEMA-MMA); the CEMA content: 46%, as measured by 1H NMR spectroscopy; Mn: 12,000 and Mw/Mn: 2.8, as measured by GPC) was prepared as a photoreactive polymer by radical polymerization (Fig. 2a). A P(CEMA-MMA) thin film (~6.75 μm) was prepared on a glass Petri dish by a solvent-casting procedure, and the UV–Vis measurements confirmed that the P(CEMA-MMA) thin film exhibited a maximum absorption at ~280 nm derived from the cinnamoyl groups. The film was then subjected to photoirradiation at 254 nm, which led to the [2π+2π] dimerization reaction taking place in the polymer side chains. This was confirmed by the decreasing absorbance at 280 nm, which corresponds to a reduction in the number of cinnamoyl groups. It was also found that the cross-linking ratio (i.e., the gel fraction) increased upon increasing the photoirradiation time, and the cross-linking ratio became saturated at ~33% after 90 min of irradiation. In addition, the saturated gel fraction increased linearly upon increasing the photoirradiation area, as controlled by altering the base area of the Petri dish exposed to irradiation (Fig. 3). These results indicate that the photoinduced cross-linking of the P(CEMA-MMA) film proceeded only in the surface region, and the photo-cross-linked film thickness from three different Petri dishes with various base areas was estimated to be ~2.2–2.3 μm. Our results therefore confirmed that the interfacial photoreaction can be performed using P(CEMA-MMA)-based materials.

a Chemical structure of P(CEMA-MMA). SEM images of the spherical polymer particles (b) before and (c) after photoirradiation, and the subsequent removal of the non-cross-linked polymers in the core region (d: high magnification; e: low magnification). Adapted from ref. [46] with permission from the American Chemical Society, copyright 2016

a Schematic representation of the interfacial photo-cross-linking used for the preparation of the photoreactive polymer films. Variation in the cross-linked polymer ratio (b) with various photoirradiation times using a fixed irradiation area and (c) using various irradiation areas and a fixed photoirradiation time. Adapted from ref. [46] with permission from the American Chemical Society, copyright 2016

Hollow polymer particles can be synthesized by three key steps using the interfacial photoreaction: (i) preparation of spherical polymer particles bearing photoreactive groups; (ii) photoirradiation of the photoreactive polymer particles to promote interfacial cross-linking; and (iii) removal of the non-cross-linked polymer in the core region [46]. For the preparation of the spherical polymer particles possessing photoreactive groups, two main synthetic routes can be employed: the direct synthesis of particles via aqueous heterogeneous polymerization and the transformation of linear polymers to form polymer particles. Miniemulsion, (micro)suspension, emulsion, dispersion, and precipitation polymerization techniques can be used as aqueous heterogeneous polymerization methods for the direct synthesis of spherical polymer particles, and the particle size can be controlled by the selection of an appropriate polymerization method [51,52,53,54,55]. For example, solvent evaporation and self-organized precipitation can be employed as a linear polymer processing procedure [56,57,58]. In the solvent evaporation method, a linear polymer is dissolved in an organic solvent, and the resulting polymer solution is dispersed in a surfactant-containing aqueous medium using either a vortex, a homogenizer, sonication, or membrane emulsification. Using this technique, the polymer particle size and size distribution can be controlled, as the organic solvents are evaporated from the polymer-containing oil droplets, leading to the formation of spherical polymer particles dispersed in an aqueous medium.

In our previous study, we successfully prepared micrometer-sized P(CEMA-MMA) particles using a solvent evaporation method with homogenizers (Fig. 2) [46]. For the interfacial photoreaction, photoirradiation was carried out at 254 nm on the dispersed photoreactive polymer particles, resulting in the formation of cross-linked polymer particles through selective photo-cross-linking in the interfacial region. Following the removal of the non-cross-linked polymers from the P(CEMA-MMA) particles, shell-cross-linked hollow polymer particles were obtained. The particle morphology was confirmed by optical microscopy and confocal laser scanning microscopy, with fluorescent monomer-copolymerized photoreactive polymers.

In this new approach based on the interfacial photoreaction, hollow polymer particles can be prepared by templating the core region of the spherical polymer particles without the use of sacrificial template particles, such as the previously described inorganic particles. Accordingly, this approach can be categorized as a novel approach based on the self-templating methodology (Fig. 1). Such self-templating is advantageous, as no toxic solvents (e.g., hydrogen fluoride or aqua regia) are required to remove the template particles, since the non-cross-linked polymers can easily be removed using common organic solvents. Furthermore, the functionalization of the hollow polymer particles can be achieved simply by adding specific functional groups to the spherical polymer particles. The functionalization of the hollow polymer particles prepared by the interfacial photoreaction are explained in the section Functionalization of the hollow and capsule particles.

Note that, in the interfacial photoreaction of the P(CEMA-MMA), the particle size is an important parameter to permit the successful synthesis of hollow polymer particles. Thus, to investigate the effect of particle size, submicrometer-sized P(CEMA-MMA) particles were prepared by a solvent evaporation method with ultrasonication, and the estimated cross-linking ratio was found to reach ~100% after 16 h of photoirradiation. These results indicate that hollow particle formation resulted from the photoinduced cross-linking of only the shell layer in the micrometer-sized P(CEMA-MMA) particles [46]. Furthermore, the effect of the CEMA content of the photoreactive polymers was another important factor in terms of the interfacial photoreaction. More specifically, upon increasing the CEMA content in the polymers, the cross-linked gel fraction of the P(CEMA-MMA) increased rapidly, resulting in the hollow polymer particles being obtained in a shorter amount of time [46].

The versatility of the comonomer species was also investigated by changing the comonomer from MMA to either n-butyl methacrylate (nBMA), hydroxylethyl methacrylate (HEMA), or glycidyl methacrylate (GMA) [59] to prepare hollow polymer particles via the interfacial photoreaction. In addition, phenyl methacrylate (PhMA), which possesses UV absorbance properties, was also employed in the interfacial photoreaction, and hollow poly(CEMA-co-PhMA) (P(CEMA-PhMA)) particles were successfully prepared. The obtained results indicate that the photoirradiation shielding effect in the shell layer derived from the phenyl groups may be weak, thereby resulting in some non-dimerized cinnamoyl groups in the shell regions of the particles. Indeed, the presence of the remaining cinnamoyl groups in the hollow polymer particles was confirmed by Fourier transform infrared (FT-IR) spectroscopy after the removal of the non-cross-linked polymers. The molar absorption coefficient of CEMA at 280 nm (ε280nm) was 17,000 [L mol−1 cm−1], which is significantly higher than that of PhMA at 280 nm (ε280nm = 250 L mol−1 cm−1). Based on these results, the remaining cinnamoyl groups could inhibit UV irradiation from reaching the particle core region.

Capsule particles

The encapsulation of molecules into hollow polymer particles is critical to the application of these materials in various research fields. As the hollow polymer particles obtained via the interfacial photoreaction contain a cross-linked shell layer, this could allow the posteriori loading of various materials into the hollow polymer particles.

In our previous study, a solvent exchange method was used to prepare the capsule polymer particles, where a good solvent was used to disperse the cross-linked shell polymers, and the good solvent was exchanged with a poor solvent [60]. Initially, the shell-cross-linked hollow polymer particles were mixed with a good solvent to dissolve the functional molecules that we wished to encapsulate (e.g., dyes, drugs, or precursors), thereby allowing these molecules to transport into the core region of the hollow polymer particles by passing through the cross-linked polymer shell layer. This was possible, as the good solvent reduced the cross-linked network density, thereby allowing the molecules of interest to pass through the shell. The solvent exchange was then carried out, where the good solvent was replaced with a poor solvent, resulting in the shrinkage of the cross-linked shell and the enclosure of the functional molecules inside the hollow polymer particles, and thus, capsule particles were obtained (Fig. 4). Indeed, the authors successfully encapsulated fluorescent molecules, polymer precursors, and anticancer drugs into the shell-cross-linked hollow particles using this solvent exchange procedure, and the encapsulation was confirmed by fluorescent spectral measurements and confocal laser scanning microscopy.

a Solvent exchange procedure used for capsule particle synthesis. b, e Bright field, (c, f) fluorescence, and (d, g) merged images of the hollow P(MCC-MMA) particles dispersed in water (b, c, d) after and (e, f, g) before the introduction of rhodamine B. Adapted from ref. [60] with permission from WILEY-VCH Verlag GmbH & Co, copyright 2017

Functionalization of the hollow and capsule particles

The functionalization of capsule particles is attractive in terms of their use in bio-related applications, such as drug delivery and theranostics. For example, the introduction of stimuli-responsive properties to these particles is of great importance for the controlled release of encapsulated drugs from the capsule particles. In this context, note that cancer tissues and cells have specific conditions that differ from those of normal tissues, and so the intracellular reducing environment caused by a high glutathione concentration in the cancer cells can be used as a trigger for the controlled release of a drug in vivo [61, 62]. An important advantage of the interfacial photoreaction is its simplicity in terms of functionalization of the hollow/capsule particles, with direct functionalization of the parent spherical polymer particles bearing the photoreactive groups, leading to the formation of functionalized hollow/capsule particles.

We then developed redox-responsive degradable capsule particles as functional capsule particles through the interfacial photoreaction [60]. To achieve these functional capsule particles, N-cinnamoyl-N′-methyacryloylcystamine (MCC) was synthesized as a newly designed monomer bearing a photoinduced post-cross-linking group (e.g., the cinnamoyl group) and a redox-responsive cleavable bond (e.g., the disulfide group). Using this monomer, disulfide linkages can be introduced between the polymer main chain and the photo-cross-linked cyclobutane ring in the shell-cross-linked hollow/capsule polymer particles prepared by interfacial photo-cross-linking. Spherical polymer particles comprising poly(MCC-co-MMA) (P(MCC-MMA, the MCC content: 27%, as measured by 1H NMR spectroscopy; Mn: 5300 and Mw/Mn: 3.1, as measured by GPC) were also prepared by conventional free radical polymerization and subsequent solvent evaporation. Moreover, shell-cross-linked hollow polymer particles were successfully obtained from the spherical P(MCC-MMA) particles. In addition, the encapsulation of various molecules through the solvent exchange procedure was confirmed. The redox-responsive properties of the P(MCC-MMA) hollow particles were subsequently investigated by measuring the turbidity derived from the hollow particles. After the addition of a reducing agent, the turbidity immediately decreased, which was attributed to the degradation of the cross-linked polymers of the P(MCC-MMA) shell via the reduction of the disulfide linkages (Fig. 5). In contrast, such reductive degradation properties were not observed in the reference P(CEMA-MMA) hollow particles bearing no disulfide groups. These results therefore confirmed that the design of the parent spherical polymer particles through the introduction of appropriate functional groups can lead to the functionalization of the resulting hollow/capsule particles. As photoreactive monomers were successfully functionalized for the preparation of the functionalized hollow polymer particles, it is expected that the functionalization of the comonomer species should be possible, where one potential example includes the copolymerization of stimuli-responsive comonomers instead of MMA.

Redox-responsive degradation of (a) P(CEMA-MMA) and (b) P(MCC-MMA) particles using a TCEP reducing agent. c, d The transmittances of these dispersions at 500 nm were measured. Adapted from ref. [60] with permission from WILEY-VCH Verlag GmbH & Co, copyright 2017

Non-spherical particles

The photoinduced reaction is fascinating due to the spatial and temporal control achieved by the reaction. More specifically, spatially and temporally controlled photoinduced chemical reactions can be employed in the patterning and surface modification of various substrates and three-dimensional scaffolds [63,64,65]. In a previous study, photoreactive spherical polymer particles were subjected to a spatially controlled interfacial photoreaction to create non-spherical polymer particles [59]. By performing the interfacial photoreaction on the polymer particles in the dispersed state, all particle surfaces were cross-linked due to the free rotation of the particles during photoirradiation. Thus, to achieve spatially controlled photoinduced interfacial cross-linking, photoirradiation was carried out in the non-dispersed dried state, thereby leading to the formation of particles with partially cross-linked surfaces, and ultimately, non-spherical polymer particles after removal of the non-cross-linked polymers. As expected, bowl-shaped non-spherical polymer particles were successfully obtained from the spherical photoreactive polymer particles after the interfacial photoreaction in the non-dispersed state, while hollow polymer particles were prepared from the same parent spherical polymer particles in the dispersed state (Fig. 6). Furthermore, the versatility of this strategy for controlling the morphology of the hollow polymer particles was examined using various photoreactive parent particles comprising various functional groups derived from the comonomer species.

Morphology control via the spatially controlled interfacial photoreaction of photoreactive polymer particles. The dispersed state control leads to spatial control of the photoirradiation process. Adapted from ref. [59] with permission from Elsevier, copyright 2018

Polymer particles with molecular recognition properties

In nature, proteins commonly exhibit molecular recognition properties, which are of key importance in living systems. For example, antibodies can recognize target antigens with high specificities and high affinities. As such, proteins capable of molecular recognition can be conjugated to specific particulate materials, thereby enabling these functionalized materials to be used in various bio-related applications, such as purification, proteomics, diagnostics, sensors, and drug delivery. Recently, artificial polymer-based molecular recognition materials have attracted increasing attention as substitutes for natural antibodies due to their low cost and additional functionalization capabilities. For example, molecularly imprinted polymers (MIPs) are promising artificial materials capable of molecular recognition [66,67,68,69,70,71,72,73,74]. During molecular imprinting, template molecules induce the supramolecular assembly of functional monomers that can interact with the template molecules. Subsequent radical polymerization with cross-linkers fixes the three-dimensional positions of the functional groups of the supramolecular complex, and the removal of the templates provides molecular recognition nanocavities within the polymer matrix.

We recently applied the interfacial photoreaction to the molecular imprinting strategy for the development of post-cross-linked molecular imprinting. For this purpose, linear functional polymers bearing interacting groups and photoreactive groups were employed as the building blocks for the MIPs [75]. For example, poly(CEMA-co-methacrylic acid-co-MMA) (P(CEMA-MAA-MMA, the CEMA and MAA contents: 69% and 14%, respectively, as measured by 1H NMR spectroscopy; Mn: 7700 and Mw/Mn: 2.0, as measured by GPC) contains carboxylic acid and cinnamoyl groups, which act as the interacting and photoreactive groups, respectively, and was used in the post-cross-linked molecular imprinting process (Fig. 7). Photoinduced cross-linking was therefore performed on the supramolecular complex between the functional polymers and the template molecules, and the subsequent template removal gave the desired MIPs. Interactions between the P(CEMA-MAA-MMA) and the target molecules were confirmed by 1H NMR titrations, and the photo-cross-linking properties were demonstrated using UV–Vis measurements. When bisphenol A (BPA) was employed as the template molecule, the obtained BPA-imprinted polymers (BPA-MIPs) exhibited a high affinity and selectivity toward BPA compared with the reference non-imprinted polymers (NIPs). Furthermore, post-cross-linked molecular imprinting could be applied to the polymer particles as well as to the bulk polymers. Thus, to create polymer particles with molecular recognition properties, parent spherical polymer particles comprising template-interacting functional polymers were first prepared by a solvent evaporation method, and subsequently, the interfacial photoreaction was performed to promote cross-linking. After the removal of the template molecules, polymer particles with the desired molecular recognition properties were obtained (Fig. 8). Moreover, the versatility of this molecular imprinting technique for application in the post-cross-linked molecular imprinting strategy has also been confirmed using various target molecules, including atrazine, which has amino groups, and ketoprofen, which has a carboxylic acid group. In this case, the chiral recognition between (S)-ketoprofen and (R)-ketoprofen was achieved. From these results, it was apparent that the interfacial photo-cross-linking reaction could be employed in the preparation of functional polymer particles with molecular recognition properties, and the obtained materials can be used as sensing materials, separation media, and drug delivery vehicles.

Photoinduced post-cross-linked molecular imprinting using functional polymers possessing interaction groups and photo-cross-linking groups. Adapted from ref. [75] with permission from the American Chemical Society, copyright 2016

Scanning electron microscopy images of (a) BPA-MIP particles and (b) NIP particles. c Binding isotherms of the BPA-MIP and NIP particles toward BPA. d Selectivity tests for the BPA-MIP particles with BPA and reference compounds at a concentration of 25 μM. Adapted from ref. [75] with permission from American Chemical Society, copyright 2016

Summary and outlook

In this focus review, we summarized a novel strategy based on the interfacial photoreaction, thus enabling the creation of functional polymer particles. The uniqueness of this approach stands in the facile, simple, and direct preparation of hollow polymer particles from spherical polymer particles without the requirement for sacrificial template particles. As such, the addition of various functionalities to the parent spherical particles allows for the direct functionalization of the obtained hollow polymer particles. We also noted that the encapsulation properties of such particles is of particular importance, while the spatially controlled interfacial photoreaction enabled non-spherical particles to be prepared. Furthermore, molecular recognition capabilities were successfully introduced into the polymer particles through the newly developed post-cross-linked molecular imprinting technique, thereby resulting in functional polymer particles with molecular recognition properties. Based on our experimental data, it appeared that the obtained shells had micrometer thicknesses; however, we are currently attempting to tune the thickness of this cross-linked shell by altering the photoirradiation power and time to ultimately obtain nanometer-sized capsule particles, and our results will be reported in the near future. This is of particular importance, as nanometer-sized particles are preferred for drug delivery applications based on intravenous injections. Furthermore, the [2π+2π] photodimerization process is reversible, and so the photoreversible properties of the obtained hollow/capsule particles should be studied in further detail. We believe that the described novel method based on the interfacial photoreaction will aid in the development of sophisticated functional polymer particles leading to breakthroughs in a variety of applications.

References

Nuasaen S, Tangboriboonrat P. Optical properties of hollow latex particles as white pigment in paint film. Prog Org Coat. 2015;79:83–9.

Javier AM, Kreft O, Semmling M, Kempter S, Skirtach AG, Bruns OT, et al. Uptake of colloidal polyelectrolyte-coated particles and polyelectrolyte multilayer capsules by living cells. Adv Mat. 2008;20:4281–7.

Kim J, Arifin DR, Muja N, Kim T, Gilad AA, Kim H, et al. Multifunctional capsule-in-capsules for immunoprotection and trimodal imaging. Angew Chem Int Ed. 2011;50:2317–21.

Motornov M, Roiter Y, Tokarev I, Minko S. Stimuli-responsive nanoparticles, nanogels and capsules for integrated multifunctional intelligent systems. Prog Polym Sci. 2010;35:174–211.

Stadler B, Price AD, Zelikin AN. A critical look at multilayered polymer capsules in biomedicine: drug carriers, artificial organelles, and cell mimics. Adv Funct Mat. 2011;21:14–28.

Kataoka K, Harada A, Nagasaki Y. Block copolymer micelles for drug delivery: design, characterization and biological significance. Adv Drug Deliv Rev. 2001;47:113–31.

Shchukin DG, Sukhorukov GB. Nanoparticle synthesis in engineered organic nanoscale reactors. Adv Mat. 2004;16:671–82.

Stadler B, Chandrawati R, Price AD, Chong SF, Breheney K, Postma A, et al. A microreactor with thousands of subcompartments: enzyme-loaded liposomes within polymer capsules. Angew Chem Int Ed. 2009;48:4359–62.

White SR, Sottos NR, Geubelle PH, Moore JS, Kessler MR, Sriram SR, et al. Autonomic healing of polymer composites. Nature. 2001;409:794–7.

Shchukin DG, Zheludkevich M, Yasakau K, Lamaka S, Ferreira MGS, Mohwald H. Layer-by-layer assembled nanocontainers for self-healing corrosion protection. Adv Mat. 2006;18:1672–8.

Marechal M, Kortschot RJ, Demirors AF, Imhof A, Dijkstra M. Phase behavior and structure of a new colloidal model system of bowl-shaped particles. Nano Lett. 2010;10:1907–11.

Hinch EJ, Leal LG. Effect of brownian motion on rheological properties of a suspension of non-spherical particles. J Fluid Mech. 1972;52(APR25):683-&.

Zheng F. Thermophoresis of spherical and non-spherical particles: a review of theories and experiments. Adv Colloid Interface Sci. 2002;97:255–78.

Madivala B, Fransaer J, Vermant J. Self-assembly and rheology of ellipsoidal particles at interfaces. Langmuir. 2009;25:2718–28.

Lu Y, Yin YD, Xia YN. Three-dimensional photonic crystals with non-spherical colloids as building blocks. Adv Mat. 2001;13:415–20.

Shimoni O, Yan Y, Wang YJ, Caruso F. Shape-dependent cellular processing of polyelectrolyte capsules. ACS Nano. 2013;7:522–30.

Li HY, Zhang WB, Tong WJ, Gao CY. Enhanced cellular uptake of bowl-like microcapsules. ACS Appl Mat Interfaces. 2016;8:11210–4.

Decuzzi P, Ferrari M. The adhesive strength of non-spherical particles mediated by specific interactions. Biomaterials. 2006;27:5307–14.

Truong NP, Whittaker MR, Mak CW, Davis TP. The importance of nanoparticle shape in cancer drug delivery. Expert Opin Drug Deliv. 2015;12:129–42.

Champion JA, Katare YK, Mitragotri S. Particle shape: a new design parameter for micro- and nanoscale drug delivery carriers. J Control Release. 2007;121:3–9.

Talelli M, Rijcken CJF, Oliveira S, van der Meel R, Henegouwen P, Lammers T, et al. Nanobody - shell functionalized thermosensitive core-crosslinked polymeric micelles for active drug targeting. J Control Release. 2011;151:183–92.

Koo AN, Min KH, Lee HJ, Lee SU, Kim K, Kwon IC, et al. Tumor accumulation and antitumor efficacy of docetaxel-loaded core-shell-corona micelles with shell-specific redox-responsive cross-links. Biomaterials. 2012;33:1489–99.

Xu XW, Flores JD, McCormick CL. Reversible imine shell cross-linked micelles from aqueous RAFT-synthesized thermoresponsive triblock copolymers as potential nanocarriers for “pH-Triggered” drug release. Macromolecules. 2011;44:1327–34.

Takemoto H, Miyata K, Hattori S, Ishii T, Suma T, Uchida S, et al. Acidic pH-responsive siRNA conjugate for reversible carrier stability and accelerated endosomal escape with reduced IFN alpha-associated immune response. Angew Chem Int Ed. 2013;52:6218–21.

Caruso F, Caruso RA, Mohwald H. Nanoengineering of inorganic and hybrid hollow spheres by colloidal templating. Science. 1998;282:1111–4.

Richardson JJ, Cui JW, Bjornmalm M, Braunger JA, Ejima H, Caruso F. Innovation in layer-by-layer assembly. Chem Rev. 2016;116:14828–67.

Xu XL, Asher SA. Synthesis and utilization of monodisperse hollow polymeric particles in photonic crystals. J Am Chem Soc. 2004;126:7940–5.

Chen YW, Kang ET, Neoh KG, Greiner A. Preparation of hollow silica nanospheres by surface-initiated atom transfer radical polymerization on polymer latex templates. Adv Funct Mat. 2005;15:113–7.

Fu GD, Zhao JP, Sun YM, Kang ET, Neoh KG. Conductive hollow nanospheres of polyaniline via surface-initiated atom transfer radical polymerization of 4-vinylaniline and oxidative graft copolymerization of aniline. Macromolecules. 2007;40:2271–5.

Minami H, Kanamori H, Hata Y, Okubo M. Preparation of microcapsules containing a curing agent for epoxy resin by polyaddition reaction with the self-assembly of phase-separated polymer method in an aqueous dispersed system. Langmuir. 2008;24:9254–9.

Minami H, Okubo M, Oshima Y. Preparation of cured epoxy resin particles having one hollow by polyaddition reaction. Polymer. 2005;46:1051–6.

Huang HY, Remsen EE, Kowalewski T, Wooley KL. Nanocages derived from shell cross-linked micelle templates. J Am Chem Soc. 1999;121:3805–6.

Read ES, Armes SP. Recent advances in shell cross-linked micelles. Chem. Commun. 2007;3021–35.

O’Reilly RK, Joralemon MJ, Wooley KL, Hawker CJ. Functionalization of micelles and shell cross-linked nanoparticles using click chemistry. Chem Mater. 2005;17:5976–88.

Kishimura A, Koide A, Osada K, Yamasaki Y, Kataoka K. Encapsulation of myoglobin in PEGylated polyion complex vesicles made from a pair of oppositely charged block lonomers: a physiologically available oxygen carrier. Angew Chem Int Ed. 2007;46:6085–8.

Koide A, Kishimura A, Osada K, Jang WD, Yamasaki Y, Kataoka K. Semipermeable polymer vesicle (PICsome) self-assembled in aqueous medium from a pair of oppositely charged block copolymers: physiologically stable micro-/nanocontainers of water-soluble macromolecules. J Am Chem Soc. 2006;128:5988–9.

Kwolek U, Nakai K, Pluta A, Zatorska M, Wnuk D, Lasota S, et al. Polyion complex vesicles (PICsomes) from strong copolyelectrolytes. Stability and in vitro studies. Colloids Surf B Biointerfaces. 2017;158:658–66.

Ohno S, Ishihara K, Yusa S. Formation of polyion complex (PIC) micelles and vesicles with anionic pH-responsive unimer micelles and cationic diblock copolymers in water. Langmuir. 2016;32:3945–53.

Blanazs A, Madsen J, Battaglia G, Ryan AJ, Armes SP. Mechanistic insights for block copolymer morphologies: how do worms form vesicles? J Am Chem Soc. 2011;133:16581–7.

Karagoz B, Esser L, Duong HT, Basuki JS, Boyer C, Davis TP. Polymerization-induced self-assembly (PISA) - control over the morphology of nanoparticles for drug delivery applications. Polym Chem. 2014;5:350–5.

Delaittre G, Dire C, Rieger J, Putaux JL, Charleux B. Formation of polymer vesicles by simultaneous chain growth and self-assembly of amphiphilic block copolymers. Chem. Commun. 2009;2887–9.

Zhou DW, Dong SM, Kuchel RP, Perrier S, Zetterlund PB. Polymerization induced self-assembly: tuning of morphology using ionic strength and pH. Polym Chem. 2017;8:3082–9.

Fielding LA, Derry MJ, Ladmiral V, Rosselgong J, Rodrigues AM, Ratcliffe LPD, et al. RAFT dispersion polymerization in non-polar solvents: facile production of block copolymer spheres, worms and vesicles in n-alkanes. Chem Sci. 2013;4:2081–7.

Lv F, An ZS, Wu PY. Scalable preparation of alternating block copolymer particles with inverse bicontinuous mesophases. Nat. Commun. 2019;10:1397.

Xu XF, Pan CY, Zhang WJ, Hong CY. Polymerization-induced self-assembly generating vesicles with adjustable pH-responsive release performance. Macromolecules. 2019;52:1965–75.

Kitayama Y, Yoshikawa K, Takeuchi T. Efficient pathway for preparing hollow particles: site-specific crosslinking of spherical polymer particles with photoresponsive groups that play a dual role in shell crosslinking and core shielding. Langmuir. 2016;32:9245–53.

Fritzsche J. Ueber die festen Kohlenwasserstoffe des Steinkohlentheers. J Prakt Chem. 1867;101:333–43.

Frisch H, Marschner DE, Goldmann AS, Barner-Kowollik C. Wavelength-gated dynamic covalent chemistry. Angew Chem Int Ed. 2018;57:2036–45.

Bertrand O, Gohy JF. Photo-responsive polymers: synthesis and applications. Polym Chem. 2017;8:52–73.

Kaur G, Johnston P, Saito K. Photo-reversible dimerisation reactions and their applications in polymeric systems. Polym Chem. 2014;5:2171–86.

Narumi A, Kimura Y, Kawaguchi S. Precipitation polymerization of N-tert-butylacrylamide in water producing monodisperse polymer particles. Colloid Polym Sci. 2012;290:379–84.

Nomura M, Tobita H, Suzuki K. Emulsion polymerization: Kinetic and mechanistic aspects. In: Okubo M, editor. Polymer particles. Springer, Berlin, Heidelberg. 2005. Vol. 175, p. 1–128.

Okubo M, Kagawa Y, Matsuda M, Terada A. Preparation of polymer particles having ethyleneurea groups at their surfaces by emulsifier-free seeded emulsion polymerization and wet adhesion of its emulsion film. Colloid Polym Sci. 2003;282:88–91.

Kureha T, Aoki D, Hiroshige S, Iijima K, Aoki D, Takata T, et al. Decoupled thermo- and pH-responsive hydrogel microspheres cross-linked by rotaxane networks. Angew Chem Int Ed. 2017;56:15393–6.

Kawaguchi S, Ito K. Dispersion polymerization. In: Okubo M, editor. Polymer particles. Springer, Berlin, Heidelberg. 2005. Vol. 175, p. 299–328.

Okubo M, Takekoh R, Saito N. Some factors affecting “onion-like” multilayered morphology of micron-sized, monodisperse, poly(methyl methacrylate)/polystyrene composite particles reconstructed by the solvent-absorbing/releasing method. In: Tauer K, editor. Aqueous polymer dispersions. Springer-Verlag, Berlin, Heidelberg. 2004. Vol. 124, p. 73–6.

Tanaka T, Okayama M, Kitayama Y, Kagawa Y, Okubo M. Preparation of “mushroom-like” Janus particles by site-selective surface-initiated atom transfer radical polymerization in aqueous dispersed systems. Langmuir. 2010;26:7843–7.

Yabu H. Self-organized precipitation: an emerging method for preparation of unique polymer particles. Polym J. 2013;45:261–8.

Kitayama Y, Takeuchi T. Morphology control of shell-crosslinked polymer particles prepared by photo-induced shell-selective crosslinking approach via dispersed state control. J Colloid Interface Sci. 2018;530:88–97.

Kitayama Y, Takeuchi T. Fabrication of redox-responsive degradable capsule particles by a shell-selective photoinduced cross-linking approach from spherical polymer particles. Chem Eur J. 2017;23:12870–5.

Mura S, Nicolas J, Couvreur P. Stimuli-responsive nanocarriers for drug delivery. Nat Mat. 2013;12:991–1003.

Saito G, Swanson JA, Lee KD. Drug delivery strategy utilizing conjugation via reversible disulfide linkages: role and site of cellular reducing activities. Adv Drug Deliv Rev. 2003;55:199–215.

Delaittre G, Goldmann AS, Mueller JO, Barner-Kowollik C. Efficient photochemical approaches for spatially resolved surface functionalization. Angew Chem Int Ed. 2015;54:11388–403.

Chien HW, Chang TY, Tsai WB. Spatial control of cellular adhesion using photo-crosslinked micropatterned polyelectrolyte multilayer films. Biomaterials. 2009;30:2209–18.

Claus TK, Telitel S, Welle A, Bastmeyer M, Vogt AP, Delaittre G, et al. Light-driven reversible surface functionalization with anthracenes: visible light writing and mild UV erasing. Chem Commun. 2017;53:1599–602.

Komiyama M, Mori T, Ariga K. Molecular imprinting: materials nanoarchitectonics with molecular information. Bull Chem Soc Jpn. 2018;91:1075–111.

Haupt K. Molecular imprinting. Berlin: Springer; 2012.

Komiyama M, Takeuchi T, Mukawa T, Asanuma H. Molecularly imprinting: from fundamentals to applications. Weinheim: Wiler-VCH; 2003.

Takeuchi T, Kitayama Y, Sasao R, Yamada T, Toh K, Matsumoto Y, et al. Molecularly imprinted nanogels acquire stealth in situ by cloaking themselves with native dysopsonic proteins. Angew Chem Int Ed. 2017;56:7088–92.

Takeuchi T, Mori T, Kuwahara A, Ohta T, Oshita A, Sunayama H, et al. Conjugated-protein mimics with molecularly imprinted reconstructible and transformable regions that are assembled using space-filling prosthetic groups. Angew Chem Int Ed. 2014;53:12765–70.

Takeuchi T, Sunayama H. Beyond natural antibodies - a new generation of synthetic antibodies created by post-imprinting modification of molecularly imprinted polymers. Chem Commun. 2018;54:6243–51.

Takeuchi T, Sunayama H, Takano E, Kitayama Y. Post-imprinting and in-cavity functionalization. In: Mattiasson B, Ye L, editors. Molecularly imprinted polymers in biotechnology. Springer International Publishing, Switzerland. 2015. Vol. 150, p. 95–106.

Mori K, Hirase M, Morishige T, Takano E, Sunayama H, Kitayama Y, et al. A pretreatment-free, polymer-based platform prepared by molecular imprinting and post-imprinting modifications for sensing intact exosomes. Angew Chem Int Ed. 2019;58:1612–5.

Horikawa R, Sunayama H, Kitayama Y, Takano E, Takeuchi T. A programmable signaling molecular recognition nanocavity prepared by molecular imprinting and post-imprinting modifications. Angew Chem Int Ed. 2016;55:13023–7.

Kitayama Y, Yoshikawa K, Takeuchi T. Post-cross-linked molecular imprinting with functional polymers as a universal building block for artificial polymeric receptors. Macromolecules. 2017;50:7526–34.

Acknowledgements

The author is deeply indebted to Prof. Toshifumi Takeuchi (Kobe University) for his fruitful discussions and continuous encouragement. The author is also grateful to his coworkers, particularly Mr. Kazuki Yoshikawa (Kobe University). This work was supported by a JSPS KAKENHI grant (Grant number 17K05997) and partially supported by the Kawanishi Memorial Shin Meiwa Education Foundation, Japan.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that he has no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kitayama, Y. The interfacial photoreaction: an efficient strategy to create functional polymer particles. Polym J 51, 963–974 (2019). https://doi.org/10.1038/s41428-019-0219-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-019-0219-y