Abstract

This focus review documents the developments in polymer synthesis that involve multicomponent reactions (MCRs) and related sequential reaction systems. Postpolymerization modification and step-growth polymerization reactions based on MCRs and sequential reactions such as the Kabachnik–Fields three-component reaction (KF-3CR) are described.

Similar content being viewed by others

Introduction

Since the establishment of modern polymer science by Staudinger, a number of organic transformations have been integrated into polymer science, resulting in large synthetic portfolios for both polymerization and postpolymerization techniques [1,2,3,4,5]. This intense research has led, for instance, to the development of mechanistically diverse and challenging living polymerizations [2,3,4, 6]. With regard to postpolymerization reactions, the use of so-called click reactions has contributed to the expansion of such techniques[1]. Along with the above developments in polymer synthesis, precise control over polymer architectures for the production of well-defined polymers is now feasible [4]. Despite the vast synthetic portfolio of reactions available for polymer chemistry, a fundamental evolution of the elementary reactions in polymer synthesis has not been addressed for many years. To be precise, the number of reactants in elementary reactions has remained intact regardless of their reaction mechanism and complexity, which is somewhat surprising considering the dramatic impact that further breakthroughs in this context would have on polymer chemistry in general.

In organic chemistry, multicomponent reactions (MCRs) are defined as chemical transformations that involve the reaction of three or more reactants in a one-pot manner to afford a single product [7,8,9,10]. Regardless of their complexity, MCRs have been known since the dawn of organic chemistry in the nineteenth century. Historically, one of the most important transformations has been the Strecker reaction, which is the reaction among an amine, an aldehyde, and a cyanide to produce the corresponding α-amino acid [11, 12]. Since the discovery of the Strecker reaction, a number of MCRs have been described. Despite the expected contributions that MCRs would offer polymer chemistry, MCR-based polymer synthesis only began to develop in the 2010s [13,14,15,16,17,18,19]. The most important advancement in this chemistry is the work by Meier et al. [20], in which the Passerini three-component reaction among aldehydes, carboxylic acids, and isocyanides was employed in both polymerization and postpolymerization reactions. Following this research, a novel method of polymer synthesis that takes advantage of the nature of MCRs has emerged as a result of contributions by the same author and other researchers.

This focus review will mainly discuss the author’s results on MCR-based polymer syntheses, as well as important contributions by other researchers. The discussions in this focus review, will be divided into four main sections with the synthetic benefits described in the last section.

Sequential reactions in polymer synthesis

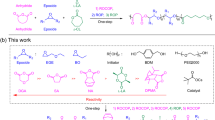

As mentioned in the introduction, MCRs refer to reactions in which three or more reactants concurrently react in a one-pot manner to generate a single product. In this context, sequential reactions should also be considered novel elementary reactions in polymer chemistry because they also involve three or more reactants undergoing a series of organic transformations. An example of a sequential reaction among reactants A, B, and C is depicted in Scheme 1 along with the MCR counterpart. In the sequential reaction, reactant A reacts with B to produce an isolatable intermediate AB*. Next, generated species AB* is allowed to react with reactant C to generate product D. It is worth noting at this point that (1) intermediate AB* features a new reactive site that is generated by the reaction between reactants A and B, and (2) the two reactions need to be conducted separately due to the lack of orthogonality. As the number of sequential reactions applied in polymer synthesis is limited as well, the former class is described in this section. First, the group of Khan employed a sequential reaction based on epoxide chemistry [21,22,23]. Epoxides are well known to undergo nucleophilic ring-opening reactions to provide β-hydroxyl derivatives. Here, the generated β-hydroxyl derivatives can behave as nucleophiles toward carboxylic chlorides to afford the corresponding β-esterified derivatives. These successive processes constitute a sequential reaction system. With this epoxide-based sequential reaction, Khan et al. synthesized a number of polymers [21,22,23]. Another example is a synthetic approach by the group of Du Prez who used a sequential reaction that exploits the unique reactivity of thiolactones [24, 25]. In their systems, thiolactones are subjected to an initial nucleophilic ring-opening reaction with an amine, and the liberated thiols in the amide products are then used for further thiol-click reactions. Along with the above systems, a sequential system was also reported and developed by the groups of Kohsaka [26] and Yamada [27].

The author proposed a different sequential reaction in polymer chemistry based on the reactivity of sulfonamides. In a manner similar to that of carboxylic amides, sulfonamides are accessible via amidation reactions of activated sulfonate esters [28]. Nevertheless, sulfonamides show different chemical properties and thus reactivity compared to the corresponding carboxylic amides. To be precise, sulfonamides feature strongly electron-withdrawing sulfonyl groups that make the sulfonamide NH protons more acidic than carboxylic amides, which results in a wider range of organic transformations that can be carried out with sulfonamides, such as alkylations. In light of the above properties of sulfonamides, a new sequential synthetic approach was proposed as follows [29]. The first step is the reaction between activated sulfonate esters and amines to afford the corresponding sulfonamide derivatives [28]. Next, the generated sulfonamides are allowed to react with an alcohol through a modified Mitsunobu reaction. Based on this, the author established a novel postpolymerization modification system that allows the dual modification of identical monomeric units (Scheme 2). Thus, the author first prepared poly(pentafluorophenyl 4-vinylbenzenesulfonate) (poly(PFP-4VS)), which features activated sulfonate ester moieties in the polymer pendants. Next, poly(PFP-4VS) was reacted with amines to afford the corresponding polymeric sulfonamides with almost quantitative conversion of the activated sulfonates. Then, the generated polymeric sulfonamides were further reacted with alcohols in the presence of Mitsunobu reagents. In the case of classical mediators, such as diisopropylazodicarboxylate and triphenylphosphine, the sulfonamide was alkylated with limited NH conversion (~78.0%). In contrast, the modified Mitsunobu mediator involving N,N,N′,N′-tetramethylazodicarboxamide and tri(n-butyl)phosphine resulted in the complete consumption of the sulfonamide NH moieties to afford doubly modified polymeric sulfonamides [30]. With the above sequential reaction system in hand, a library of functional polymers was accessible from poly(PFP-4VS) by simply varying the amine and alcohol reactants. With the developed method, the author demonstrated a novel sequential postpolymerization reaction that allows the installation of two reactants on one monomeric unit.

Postpolymerization modification reactions based on MCRs

Having described the sequential systems, MCRs in polymer chemistry are now discussed. In general, polymer syntheses can mainly be divided into two groups, namely, polymerization and postpolymerization reactions. MCRs involved in postpolymerization reactions are examined first in this section. Despite the large number of MCRs that have been developed, the rare examples suitable for polymer synthesis that have been reported include the Biginelli [31], the Passerini [20], the Hantzsch [32, 33], and Cu-catalyzed three-component click-type reactions [34]. An MCR relevant for polymer synthesis is the Kabachnik–Fields three-component reaction (KF-3CR) among amines, aldehydes, and phosphites, which affords α-amino phosphonate esters in a one-pot manner. Although the KF-3CR was discovered in the 1950s [35, 36], it has not been integrated into polymer chemistry despite its synthetic utility and the potentially unique properties of the generated α-amino phosphonate esters. In addition, the integration of the heteroatoms into polymer structures is well known to drastically alter the polymer properties, making the synthetic utility of the KF-3CR, which can install nitrogen and phosphorous atoms, incredibly high. Motivated by this, the author evaluated the synthetic benefits of the KF-3CR for polymer synthesis in a postpolymerization modification reaction [37]. To this end, poly(4-vinyl benzaldehyde) (PSt-CHO) was used as the polymeric aldehyde and subjected to the KF-3CR with various amines and phosphites. The KF-3CR of PSt-CHO was conducted in 1,4-dioxane with excess amines and phosphites at 80 °C for 8 h without additional activators or catalysts. Except for aliphatic amines, any desired aromatic amine or phosphite gave almost quantitative conversions of the starting PSt-CHO, leading to the corresponding polymeric α-amino phosphonate esters in high yields, as summarized in Table 1. The reaction mechanism for the KF-3CR with PSt-CHO was confirmed to involve (1) fast imine formation upon reaction between PSt-CHO and the amine and (2) phosphite addition to the generated polymeric imines as the rate-limiting step (Fig. 1). Therefore, taking advantage of the reaction mechanism, the amine concentration in the KF-3CR with PSt-CHO could be successfully reduced to an approximately equimolar amount (only 5 mol% excess) relative to the aldehyde. As postpolymerization modification reactions usually require a large excess of the reactants, this kinetic feature of the KF-3CR should be advantageous for polymer functionalization protocols.

Kinetic study and plausible reaction mechanism for the Kabachnik–Fields reaction of PSt-CHO with p-anisidine and diisopropyl phosphite (line; guidance). The reaction conditions are as follows: 1,4-dioxane as the solvent; the initial aldehyde concentration was adjusted to 1.5 mol L−1; under an Ar atmosphere; the [CHO]0/[amine]0/[phosphite]0 ratio was adjusted to 1/3/6. The chemical compositions of the recovered polymers were determined by 1H NMR spectroscopy in CDCl3. Reprinted with permission from ref. [37]. Copyright 2014 American Chemical Society

Step-growth polymerizations based on MCRs

Considering the Carothers equation \(\left( {{\mathrm{DP}} = \frac{1}{{1 - conv.}}} \right)\), almost quantitative conversions would be an important requirement for facile step-growth polymerizations. This has indeed limited the number of MCRs that are suitable as elementary reactions in step-growth polymerization reactions. In this context, the author evaluated the applicability of KF-3CR in step-growth polymerization reactions [38]; in particular, the KF-3CR-based polycondensation reaction (KF-PCR) of aromatic diamines, dialdehydes, and phosphite was examined. Thus, the KF-PCR between 1,10-bis-(4-formylphenyl)-1,4,7,10-tetraoxadecane, p-phenylenediamine, and diisopropylphosphite was carried out in a mixture of 1,4-dioxane and DMSO at 80 °C for 20 h under an inert atmosphere. This reaction afforded main chain-type polymeric α-amino phosphonate esters with a high molecular weight (17,300 g mol−1) that afforded a unimodal SEC trace. As summarized in Table 2, this polycondensation reaction tolerates a range of aromatic diamines and phosphites, leading to a variety of main chain-type polymeric α-amino phosphonate esters with molecular weights ranging from 4500 to 54,700 g mol−1. With this reaction in hand, photodegradable polymeric α-amino phosphonate esters were prepared via the KF-PCR of 1,10-bis-(3-formyl-4-nitrophenyl)-1,4,7,10-tetraoxadecane, diaminobenzene, and diisopropylphosphite. The key step of this process is the generation of an o-nitrobenzyl unit during the KF-PCR. The obtained polymeric α-amino phosphonate esters were found to be photochemically cleaved upon irradiation with a 50-W light at 365 nm in CHCl3 solution for 10 min (Fig. 2). Therefore, the KF-3CR was demonstrated to be a facile elementary reaction for step-growth polymerization, providing polymeric α-amino phosphonate esters that are difficult to access by other means.

Schematic representation of photodegradable polymers synthesized via the Kabachnik–Fields polycondensation reaction and their photodegradation under 365 nm light irradiation. Reprinted with permission from ref. [38]. Copyright 2016 American Chemical Society

Miscellaneous applications and inherent advantages of MCR-based polymer synthesis

As previously mentioned, MCRs have gradually emerged as facile elementary reactions in the field of polymer synthesis. In this section, the novelty and advantages of MCR-based polymer synthesis are discussed in comparison with conventional polymerization chemistry. The most important feature of MCRs is molecular sorting during the reaction. Throughout the MCR, the reactants are sorted in a certain manner that is strictly governed by the nature of the MCR. Depending solely on conventional bimolecular reactions, the precise control of monomer sequences has been one of the most difficult synthetic tasks [39, 40]. Conversely, the monomer sequence can be inherently coded during a polymerization processes using a MCR as the elementary reaction. As a result, sequence-controlled polymerizations have now been realized by MCR-based step-growth polymerizations [41, 42]. Another important feature of MCRs in polymer chemistry is their high compatibility with biobased compounds. Considering the increasing importance of wood biomass (lignocellulose) that do not compete with human foods, the author turned his attention to aldehyde derivatives that can be readily obtained from lignocellulose [43, 44]. Lignin-derived compounds such as vanillin and syringaldehyde contain aldehyde groups, which should make them compatible with MCRs since most MCRs involve aldehyde reactants. Thus, the author prepared the known polymers poly(methacrylated vanillin) (PMV) and poly(methacrylated syringaldehyde) (PMS) bearing lignin-sourced pendants (Table 3) [45]. As a representative MCR, the author selected the KF-3CR to demonstrate the compatibility of PMV and PMS with MCR-based polymer modifications. The KF-3CRs of both PMV and PMS were conducted in 1,4-dioxane in the presence of a wide range of aromatic amines and phosphites at 80 °C. Interestingly, the KF-3CR reactivities of both PMV and PMS were found to be equal to or higher than that discussed above for PSt-CHO. In addition, the obtained polymeric α-amino phosphonate esters showed unique thermal properties due to the introduced heteroatoms (Table 4). To be precise, the obtained lignin-sourced polymers show increased residual weight at 600 °C, owing to the installed nitrogen and phosphorous atoms. In addition, the above lignin-based polymers were successfully immobilized on cellulose fabrics to realize biomass-derived organic hybrids that allow surface KF-3CRs [46]. With these, the author provides a platform for the utilization of biomass-derived compounds in MCR-based polymer chemistry.

Summary and outlook of MCR-based polymer synthesis

In this focus review, the author discussed new trends in the field of polymer synthesis based on MCR chemistries. Despite the long history and applications of MCRs in organic chemistry, merging MCRs into polymer synthesis only began very recently. The author believes that the use of MCRs as elementary reactions in polymer chemistry should open the door to new methods of polymer synthesis and the concomitant development of novel materials and applications.

References

Blasco E, Sims MB, Goldmann AS, Sumerlin BS, Barner-Kowollik C. 50th anniversary perspective: polymer functionalization. Macromolecules. 2017;50:5215–52.

Grubbs RB, Grubbs RH. 50th anniversary perspective: living polymerization—emphasizing the molecule in macromolecules. Macromolecules. 2017;50:6979–97.

Perrier S. 50th anniversary perspective: RAFT polymerization—a user guide. Macromolecules. 2017;50:7433–47.

Polymeropoulos G, Zapsas G, Ntetsikas K, Bilalis P, Gnanou Y, Hadjichristidis N. 50th anniversary perspective: polymers with complex architectures. Macromolecules. 2017;50:1253–90.

Ouchi M, Terashima T, Sawamoto M. Transition metal-catalyzed living radical polymerization: toward perfection in catalysis and precision polymer synthesis. Chem Rev. 2009;109:4963–5050.

Ouchi M, Sawamoto M. 50th anniversary perspective: metal-catalyzed living radical polymerization: discovery and perspective. Macromolecules. 2017;50:2603–14.

Zhu J, Bienaymé H (eds). Multicomponent reactions. Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim; 2005.

Armstrong RW, Combs AP, Tempest PA, Brown SD, Keating TA. Multiple-component condensation strategies for combinatorial library synthesis. Acc Chem Res. 1996;29:123–31.

Dömling A, Wang W, Wang K. Chemistry and biology of multicomponent reactions. Chem Rev. 2012;112:3083–135.

Touré BB, Hall DG. Natural product synthesis using multicomponent reaction strategies. Chem Rev. 2009;109:4439–86.

Strecker A. Ueber die künstliche Bildung der Milchsäure und einen neuen, dem Glycocoll homologen Körper. Liebigs Ann Chem. 1850;75:27–45.

Strecker A. Ueber einen neuen aus Aldehyd—Ammoniak und Blausäure entstehenden Körper. Liebigs Ann Chem. 1854;91:349–51.

Theato, P, Multi-component and sequential reactions in polymer synthesis. Switzerland: Springer; 2015. p. 269.

Wu H, Gou Y, Wang J, Tao L. Multicomponent reactions for surface modification. Macromol Rapid Commun. 2018;39:1800064.

Zhao Y, Wu H, Wang Z, Wei Y, Wang Z, Tao, LJSCC, Training the old dog new tricks: the applications of the Biginelli reaction in polymer chemistry. 2016;59:1541–7.

Afshari R, Shaabani A. Materials functionalization with multicomponent reactions: state of the art. ACS Comb Sci. 2018;20:499–528.

Kakuchi R. Multicomponent reactions in polymer synthesis. Angew Chem Int Ed. 2014;53:46–8.

Rudick JG. Innovative macromolecular syntheses via isocyanide multicomponent reactions. J Polym Sci Part A. 2013;51:3985–91.

Yang B, Zhao Y, Wei Y, Fu C, Tao L. The Ugi reaction in polymer chemistry: syntheses, applications and perspectives. Polym Chem. 2015;6:8233–9.

Kreye O, Tóth T, Meier MAR. Introducing multicomponent reactions to polymer science: Passerini reactions of renewable monomers. J Am Chem Soc. 2011;133:1790–2.

Muzammil EM, Khan A, Stuparu MC. Post-polymerization modification reactions of poly(glycidyl methacrylate)s. RSC Adv. 2017;7:55874–84.

Stuparu MC, Khan A. Thiol-epoxy “click” chemistry: application in preparation and postpolymerization modification of polymers. J Polym Sci Part A Polym Chem. 2016;54:3057–70.

De S, Stelzer C, Khan A. A general synthetic strategy to prepare poly(ethylene glycol)-based multifunctional copolymers. Polym Chem. 2012;3:2342–5.

Espeel P, Du Prez FE. One-pot multi-step reactions based on thiolactone chemistry: a powerful synthetic tool in polymer science. Eur Polym J. 2015;62:247–72.

Espeel P, Goethals F, Du Prez FE. One-pot multistep reactions based on thiolactones: extending the realm of thiol-ene chemistry in polymer synthesis. J Am Chem Soc. 2011;133:1678–81.

Kohsaka Y, Hagiwara K, Ito K. Polymerization of α-(halomethyl)acrylates through sequential nucleophilic attack of dithiols using a combination of addition–elimination and click reactions. Polym Chem. 2017;8:976–9.

Yamada B, Oku F, Harada T. Substituted propenyl end groups as reactive intermediates in radical polymerization. J Polym Sci Part A Polym Chem. 2003; 41: 645–54.

Nilles K, Theato P. Polymerization of an activated ester monomer based on 4-vinylsulfonic acid and its polymer analogous reaction. Polym Chem. 2011;2:376–84.

Kakuchi R, Theato P. Sequential post-polymerization modification reactions of poly(pentafluorophenyl 4-vinylbenzenesulfonate). Polym Chem. 2014;5:2320–5.

Tsunoda T, Otsuka J, Yamamiya Y, Ito S. N,N,N′,N′-Tetramethylazodicarboxamide (Tmad), a new versatile reagent for Mitsunobu reaction—its application to synthesis of secondary-amines. Chem Lett. 1994;23:539–42.

Zhu C, Yang B, Zhao Y, Fu C, Tao L, Wei Y. A new insight into the Biginelli reaction: the dawn of multicomponent click chemistry? Polym Chem. 2013;4:5395–5400.

Wu H, Wang Z, Tao L. The Hantzsch reaction in polymer chemistry: synthesis and tentative application. Polym Chem. 2017;8:7290–6.

Wu H, Yang L, Tao L. Polymer synthesis by mimicking nature’s strategy: the combination of ultra-fast RAFT and the Biginelli reaction. Polym Chem. 2017;8:5679–87.

Kakuchi R, Theato P. Three-component reactions for post-polymerization modifications. ACS Macro Lett. 2013;2:419–22.

Fields EK. The synthesis of esters of substituted amino phosphonic acids1a. J Am Chem Soc. 1952;74:1528–31.

Kabachnik MI, Medved TY. New synthesis of aminophosphonic acids. Dokl Akad Nauk SSSR. 1952;83:689–92.

Kakuchi R, Theato P. Efficient multicomponent postpolymerization modification based on Kabachnik–Fields reaction. ACS Macro Lett. 2014;3:329–32.

Moldenhauer F, Kakuchi R, Theato P. Synthesis of polymers via Kabachnik–Fields polycondensation. ACS Macro Lett. 2016;5:10–13.

Lutz J-F. Sequence-controlled polymerizations: the next Holy Grail in polymer science? Polym Chem. 2010;1:55–62.

Lutz J-F, Ouchi M, Liu DR, Sawamoto M. Sequence-controlled polymers. Science. 2013;341:628 -+.

Deng X-X, Li L, Li Z-L, Lv A, Du F-S, Li Z-C. Sequence regulated poly(ester-amide)s based on Passerini Reaction. ACS Macro Lett. 2012;1:1300–3.

Solleder SC, Meier MAR. Sequence control in polymer chemistry through the Passerini three-component reaction. Angew Chem Int Ed. 2014;53:711–4.

Alonso DM, Bond JQ, Dumesic JA. Catalytic conversion of biomass to biofuels. Green Chem. 2010;12:1493–513.

Kopetz H. Renewable resources: build a biomass energy market. Nature. 2013;494:29–31.

Kakuchi R, Yoshida S, Sasaki T, Kanoh S, Maeda K. Multi-component post-polymerization modification reactions of polymers featuring lignin-model compounds. Polym Chem. 2018;9:2109–15.

Hamada T, Yamashita S, Omichi M, Yoshimura K, Ueki Y, Seko N, et al. Multicomponent-reaction-ready biomass-sourced organic hybrids fabricated via the surface immobilization of polymers with lignin-based compounds. ACS Sustain Chem Eng. 2019;7:7795–803.

Acknowledgements

The author is deeply indebted to Prof. Patrick Theato (Karlsruhe Institute of Technology) and Prof. Katsuhiro Maeda (Kanazawa University) for their generous support. The author gratefully acknowledges the Leading Initiative for Excellent Young Researchers (LEADER) and a JSPS Research Fellowship for Research Abroad for financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kakuchi, R. The dawn of polymer chemistry based on multicomponent reactions. Polym J 51, 945–953 (2019). https://doi.org/10.1038/s41428-019-0209-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-019-0209-0

This article is cited by

-

Synthesis of photoresponsive biobased adhesive polymers via the Passerini three-component reaction

Polymer Journal (2023)

-

Multi-Polymerization: From Simple to Complex

Chinese Journal of Polymer Science (2023)

-

Application of new multi-H-bond catalyst for the preparation of substituted pyridines via a cooperative vinylogous anomeric-based oxidation

Research on Chemical Intermediates (2023)

-

Chitosan-EDTA-Cellulose network as a green, recyclable and multifunctional biopolymeric organocatalyst for the one-pot synthesis of 2-amino-4H-pyran derivatives

Scientific Reports (2022)

-

Synthesis of (E)-2-(1H-tetrazole-5-yl)-3-phenylacrylenenitrile derivatives catalyzed by new ZnO nanoparticles embedded in a thermally stable magnetic periodic mesoporous organosilica under green conditions

Scientific Reports (2022)