Abstract

Birefringence and its wavelength dependence are important properties for optical applications, such as liquid crystal displays and pick-up lenses. Cellulose esters, which are eco-friendly materials from biomass resources, have been used in optical materials due to their transparency and heat resistance. This review summarized our recent works on birefringence control of cellulose esters by substitution of multiple ester groups, addition of low-mass molecules, and formation of a porous structure. Cellulose acetate propionate (CAP), which has acetyl and propionyl groups in a pyranose unit, exhibited positive birefringence with extraordinary wavelength dispersion owing to contributions from its two esters, while cellulose triacetate (CTA) showed negative birefringence with ordinary dispersion. Moreover, the effect of substitution sites (C-2, C-3, and C-6) on birefringence and its wavelength dependence was investigated by comparing birefringence data of CTA and xylan acetate. The addition of low-mass molecules improved the value of birefringence due to the intermolecular orientation correlation with the matrix cellulose esters. The anisotropic porous structure in CTA films, which was prepared by thermoinduced phase separation, generated extraordinary wavelength dispersion of birefringence.

Similar content being viewed by others

Introduction

Cellulose derivatives have been used as eco-friendly materials for various applications because they are derived from biomass resources [1,2,3,4,5]. Various types of cellulose esters (Fig. 1) have been investigated for optical applications due to their attractive properties, such as heat resistance and transparency [5,6,7]. For example, cellulose triacetate (CTA) is used for protection and retardation films for liquid crystal displays.

The optical properties of polymeric materials are important for their applications in optical and electrical usages. In particular, birefringence (∆n), which is a difference in refractive index between two axes (∆n = n1 − n2), should be precisely controlled for optical applications. Recently, the demand for precise control of birefringence has become larger with the downsizing of optical devices, such as flat panel displays and smart phones.

Birefringence has the ability to control the polarization of light as a function of optical retardation. Optical retardation (Re) is a product of birefringence and light path length (d), which corresponds to film thickness.

For example, a quarter waveplate, which can convert linear polarized light to circular polarized light, has 1/4 of the wavelength (λ) as the value of Re. As represented by Eq. 1, for thinner polymer films, an enhancement in birefringence is required to fix the value of optical retardation. Furthermore, since the wavelength range of visible light for display applications is from 450 to 700 nm, the birefringence of polymer films should be adjusted at each wavelength. For the quarter waveplate over a wide range of wavelengths, the Re value must be controlled to be 1/4 of each λ. Therefore, the Re value (∝ birefringence) needs to be proportional to λ.

To improve the birefringence and its wavelength dependence of optical films, various techniques, such as blending with other polymers [8, 9] or low-mass molecules [10,11,12], copolymerization [13,14,15], and sheet piling [16], have been proposed. For industrial applications, sheet piling is simple and inexpensive but has some practical problems, such as piling out due to the mismatch of laminated sheets. Copolymerization can be applied to only synthetic polymers, such as vinyl polymers. In contrast, the cellulose derivatives focused on in this review have three substitution sites in a pyranose unit, suggesting that various types of ester groups can be introduced to control birefringence.

Recently, we have reported methods for improving the birefringence of cellulose esters (Fig. 1) by using multiple ester groups, stretching-induced crystallization, the addition of aromatic low-mass molecules, and the formation of a porous structure. In this review, the origins of birefringence for polymeric materials are mentioned, and our recent works related to the birefringence control of cellulose esters are briefly explained.

Origins of birefringence in polymers

Birefringence in polymerscan be categorized into three types: (a) orientation birefringence (∆nor), (b) glassy birefringence (∆nglass), and (c) form birefringence (∆nform). Since these three types are independent, the birefringence of polymers is written as

The first term, ∆nor, is associated with the chain orientation of polymers, as represented by

Here, ∆n0 is an intrinsic birefringence, which is determined by the repeating unit of the polymer. F is an orientation function, which shows the degree of orientation of the polymer chain. In general, polymers having aromatic groups have a larger value of ∆n0 than those without aromatic groups because of the larger polarizability anisotropy in the repeating unit. For example, the absolute values of ∆n0 for aromatic polymers, such as polycarbonate (PC) and poly(ethylene terephthalate) (PET) are 0.1 – 0.2 [17, 18], while those for cellulose esters without aromatic groups are <0.02 [19]. Therefore, to use low-birefringence polymers, such as poly(methyl methacrylate) (PMMA) for retardation films, an enhancement in birefringence is required.

The second term, ∆nglass, is caused by deformation stress (tensile, compression, bending, shear, and twisting stress) with small strain. The value of ∆nglass is proportional to the applied stress [20]. Since glassy birefringence relaxes after releasing the stress, the second term is negligible for the discussion in this review. The third term, ∆nform, originates from the nano- or microscale structure, such as the microphase separation of block copolymers and a nanostripe pattern on a material surface [21, 22]. Molecular orientation and applied stress do not affect form birefringence, but the difference in refractive indices between components is important. Theoretical prediction methods have been reported for transparent materials with microphase separation and optical materials with regular convex-concave surfaces [23]. As explained here, orientation and form birefringence are the focus of this review.

Birefringence and its wavelength dispersion for cellulose esters by substitution of multiple ester groups

CTA, which has three acetyl groups in a pyranose unit, exhibits negative birefringence and ordinary wavelength dispersion, as shown in Fig. 2. “Ordinary dispersion” means that the absolute value of birefringence decreases with increasing wavelength. In contrast, “extraordinary dispersion” indicates that the birefringence increases with the wavelength.

Wavelength dependence of birefringence for cellulose triacetate (CTA) and cellulose acetate propionate [26]. Copyright © 2017 Elsevier Ltd

As shown in Fig. 2, Yamaguchi et al. [24] reported that cellulose esters, such as cellulose acetate propionate (CAP) with two substitutional groups exhibit extraordinary wavelength dispersion for birefringence. The mechanism underlying the extraordinary dispersion in CAP is explained as follows. Considering that CAP has two ester groups, namely, an acetyl and a propionyl groups, in a repeating pyranose unit, orientation birefringence (∆nor) can be considered to originate from the sum of three components: the pyranose ring in main chain (main) and the acetyl (Ac) and propionyl (Pr) groups, as given by,

The first term (∆nmain) is negligibly small due to the small degree of polarizability anisotropy in the pyranose ring. Therefore, one can consider that the birefringence and its wavelength dependence are contributed by the two ester groups.

The second term (∆nAc) in Eq. 4 is negative because the birefringence of CTA, which has only the Ac group as the substitution group, is negative, as shown in Fig. 3. For the positive birefringence of CAP, the third term (∆nPr) for the Pr group should be positive, as shown in Fig. 3. In addition, both the Ac and Pr groups show ordinary dispersion; i.e., the absolute value of birefringence decreases with increasing wavelength. Moreover, the wavelength dependence for Ac is stronger than that for Pr, resulting in extraordinary dispersion of the orientation birefringence for CAP as the sum of two components (∆nAc, ∆nPr) [24].

Effect of acetyl (Ac) and propionyl (Pr) groups on birefringence and its wavelength dependence for cellulose acetate propionate (CAP) [24]

Since the pyranose unit of cellulose has three hydroxyl groups for substitution (C-2, C-3, and C-6 in Fig. 1), the site position will affect the birefringence property. Recently, we found that the substitution position affects the sign of birefringence for cellulose esters in comparison with the birefringence of xylan [25]. Xylan has two possible sites for substitution, C-2 and C-3 (without the C-6 site). As shown in Fig. 1, the C-2 and C-3 sites are symmetric, implying that the two sites make the same contribution to birefringence. Therefore, comparison of birefringence between CTA and xylan acetate (XylAc), which has two Ac groups in a pyranose repeating unit, suggests the signs of birefringence contributed by the Ac groups at C-2, C-3, and C-6.

Unfortunately, the birefringence of pure XylAc could not be evaluated because the film is brittle due to its lower molecular weight. In the experiment, CTA/XylAc blends were prepared to investigate the birefringence and its wavelength dependence for XylAc. As presented in Fig. 4, XylAc shows positive birefringence and weak ordinary wavelength dispersion, while CTA exhibits negative birefringence and strong ordinary wavelength dispersion. The difference in birefringence between CTA and XylAc suggested the contributions from the three Ac groups at C-2, C-3, and C-6, as shown in Fig. 4. The birefringence from the Ac groups at C-2 and C-3 is positive and shows weak ordinary dispersion. In contrast, the birefringence from C-6 is negative and shows strong ordinary dispersion. Regarding the effect of Pr and butyryl (Bu) groups on birefringence, other investigations indicated that ester groups at C-2 and C-3 show positive birefringence irrespective of ester species, such as Ac and Pr.

a Wavelength dependence of birefringence of cellulose triacetate (CTA)/xylan acetate (XylAc) blends. b Contributions of Ac groups at C-2, C-3, and C-6 to birefringence [25]. Copyright © 2015, Springer Science Business Media Dordrecht

Effect of draw ratio on the wavelength dispersion of birefringence

As represented in Eq. 3, the orientation birefringence (∆nor) is the product of the intrinsic birefringence (∆n0) and orientation function (F). For stretched films with various draw ratios, the wavelength (λ) dependence of ∆nor is the same as that of ∆n0 because F is independent of λ, as represented by

Here, λ0 is the reference wavelength. Equation 5 cannot explain the change in the wavelength dependence induced by drawing conditions, such as draw ratio and draw rate. In fact, synthetic optical polymers, such as PMMA and PC show a uniform wavelength dependence of birefringence for stretched films.

Recently, we found that the wavelength dependence of the orientation birefringence for a CAP film can be controlled by the draw ratio and draw rate [24, 26]. Stretched CAP films were prepared by hot-stretching at 163 °C, which is higher than the Tg (=140 °C). Figure 5a shows the wavelength dependence of birefringence at various draw ratios (1.5, 2.0, 3.0, and 4.0). The vertical axis is normalized by the birefringence at λ0 (=589 nm). Obviously, the wavelength dependence becomes stronger with increasing draw ratio, unlike PMMA and PC. Moreover, stretching-induced crystallization was also suggested from the thermal measurements. As shown in Fig. 5b, the unstretched CAP film (draw ratio = 1.0) has no endothermic peak, but the stretched films show a melting peak at draw ratios greater than 2.0. Since the melting point (Tm) is observed at 160–170 °C, which is close to or higher than the drawing temperature (=163 °C), crystallization is induced during hot-stretching. Moreover, after stretching, the films were quickly cooled to room temperature, implying that the cooling process did not induce the crystallization. The thermal measurement data indicated that the hot-stretching process caused the crystallization of CAP before the cooling process.

a Comparison of wavelength dependence of normalized birefringence by reference wavelength value for cellulose acetate propionate (CAP) films at various draw ratios. b Effect of draw ratios on DSC curves for stretched CAP films [26]. Copyright © 2017 Elsevier Ltd

The two-dimensional X-ray diffraction (XRD) pattern of the stretched CAP film (draw ratio = 4.0) indicated the orientation of the induced crystal to the stretching direction. Furthermore, the peak angles in the XRD pattern of CAP are similar to those of CTA, which is a semicrystalline polymer [27]. This result suggests that the Ac orientation in CAP becomes stronger than the Pr orientation because CTA has only Ac groups. This speculation is reasonable because the Ac group in CAP is more tightly bound to the pyranose unit in a crystal than the Pr group. The stronger orientation of Ac than Pr increases the wavelength dependence of the orientation birefringence for the stretched CAP film because the Ac contribution becomes larger, as explained in Fig. 3.

As indicated in Eq. 2, form birefringence (∆nform) can also contribute to the total birefringence. However, a larger value of ∆nform requires a difference in refractive indices between two phases, as explained later. For CAP, the refractive indices of the amorphous and crystalline phases are probably not so different, although no data have been reported. Therefore, one can consider that crystallization does not affect the ∆nform in CAP films. In conclusion, stretching-induced crystallization can improve the wavelength dependence of the orientation birefringence (∆nor) for cellulose ester films.

Enhancement of birefringence by addition of low-mass molecules

In the previous sections, the effects of ester groups on birefringence and its wavelength dependence for cellulose esters were explained. However, the level of birefringence of cellulose esters is still lower than that of PC and PET because they have no aromatic group with high polarizability anisotropy. To use cellulose esters in thinner retardation films, the absolute value of birefringence must be enhanced.

The orientation birefringence of the blend, Δnblend, is expressed by a simple addition rule given by

ϕi, ∆ni0, and Fi are the volume fraction, intrinsic birefringence, and orientation function for component i, respectively. Since the intrinsic birefringence is related to the polarizability anisotropy, the additive components with aromatic groups can increase the birefringence.

Tagaya et al. [10] and Tagaya and Koike [28] has reported that the addition of aromatic low-mass molecules (LMs), such as stilbene can cancel out the negative birefringence of PMMA. Nobukawa et al. [29] revealed that rod-like molecules, such as cyano-biphenyl improve the intrinsic birefringence of polystyrene (PS). In general, LMs are difficult to orient to the stretching direction of polymer films because their orientational relaxation is quite fast due to their molecular weight being lower than that of polymers. According to this concept, LMs cannot enhance the birefringence of matrix polymers. Therefore, the improvement in birefringence induced by LMs indicates that LMs orient to the stretching direction with polymer chains in the blends due to intermolecular orientation correlation, which is called nematic interaction (NI) [29, 30].

By using orientation correlation, we have recently successfully improved the birefringence of the cellulose esters CTA [11, 31] and CAP [12, 32,33,34] by adding a small amount of LMs. For CTA, the addition of tricresyl phosphate (TCP) and cyano-biphenyl could change the sign of birefringence from negative to positive. Furthermore, TCP modified the ordinary wavelength dispersion to extraordinary dispersion, as TCP acts as a Pr component of CAP in Fig. 3.

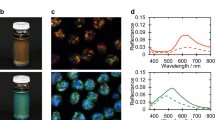

For CAP, both TCP and poly(alkyl naphthalate) oligomers improved its birefringence. In particular, poly(ethylene naphthalate) (PEN) oligomer [34] increased the birefringence value of CAP from 10 × 10−4 to 45 × 10−4 (more than four times), as shown in Fig. 6. For CAP/poly(alkyl terephthalate) and poly(alkyl naphthalate) oligomer blends, a study of their Fourier-transform infrared (FT-IR) dichroism and birefringence revealed that the oligomers with shorter alkyl groups strongly oriented parallel to the chain orientation of the polymer [32, 34]. This result suggests that the rigidity of low-mass molecules affects the degree of orientation correlation with the matrix polymer. Additionally, comparison of the orientation behaviors of poly(alkyl naphthalate) oligomers in CAP films indicated a mismatch between orientation times of the flexible (alkylene) and rigid (naphthalate) parts during hot-stretching [34]. This phenomenon is useful for adjusting the birefringence properties without changing the composition of the blends because the flexible and rigid parts of oligomers show different contributions to birefringence.

Effect of poly(alkyl naphthalate) oligomers on the birefringence of cellulose acetate propionate (CAP) at 633 nm. The inset figures represent the orientation of rigid and flexible parts in the oligomers due to a nematic interaction [34]. Copyright © 2014, Springer Nature

Design of extraordinary wavelength dispersion of birefringence by porous structure

As indicated in Eq. 2, the form birefringence (∆nform) is generated by nano- or microstructures. Based on an anisotropic dielectric theory [35] for form birefringence, Ibn-Elhaj and Schadt [21] investigated the birefringence of polymer films by introducing an anisotropic nanocorrugated surface pattern. Since the generation of form birefringence requires a difference in refractive indices between two components, the microporous structure can change the birefringence of cellulose ester films.

To generate a porous structure in CTA films, we added a poor solvent such as di(2-ethylhexyl) adipate (DOA) and used thermo- and stretching-induced phase separation [36, 37]. The DOA in the phase-separated films was removed by immersion in methanol. The details of the preparation were explained in previous papers.

Birefringence data of stretched CTA and CTA/DOA films before/after immersion in methanol are shown in Fig. 7a. Since methanol is a nonsolvent for CTA, the immersion process could remove only DOA from the blend film without changing the crystalline structure of CTA. This conclusion is supported by the birefringence data, which indicates that the birefringence of the CTA film does not change before/after immersion. On the other hand, the CTA/DOA film shows anomalous changes in birefringence from negative to positive and in wavelength dispersion from ordinary to extraordinary.

a Extraordinary wavelength dispersion of birefringence for a porous cellulose triacetate (CTA) film. b Scanning electron microscopy (SEM) cross-sectional images of porous CTA films. c Schematic illustration of calculating form birefringence by using an optical theory [36]. Copyright © 2014 Elsevier Ltd

To investigate the birefringence change in the CTA/DOA film, scanning electron microscopy (SEM) was carried out. SEM images are shown in Fig. 7b. In the images, anisotropic porous structures are observed, and the long axis is consistent with the stretching direction. Although the SEM images are not shown in this review, the unstretched CTA/DOA film has no phase separation. In addition, another poor solvent, diisodecyl adipate (DIDA), also induced similar phase separation in a CTA film [37]. In the CTA/DIDA film, annealing without stretching beyond the Tg generated a smaller pore than the micropore shown in Fig. 7b. Therefore, phase separation occurs at high temperature to some degree due to the low miscibility between CTA and DOA. The micropore is deformed along the stretching direction and enlarged by hot-stretching. Both heating and hot-stretching are important as critical factors for generating the anisotropic microphase structure.

By applying form birefringence theory to the structure represented in Fig. 7c, we could explain the increase in birefringence by the generated porous structure as follows. Although the CTA/DOA film before immersion shows phase separation similar to a sea-island structure, in which the CTA phase is the sea and DOA domain is the island, the birefringence is the same as that of the CTA film without the additive. The form birefringence is determined by the difference in refractive indices between two components. Two values of the refractive index for CTA and DOA at 589 nm are 1.47 and 1.44, respectively, while the value for pore in the film is 1.00. Since the difference in the refractive index between CTA and DOA is small (=0.03), the contribution of the form birefringence to the total birefringence is negligible. Therefore, the birefringence of CTA/DOA is the same as that of CTA. On the other hand, for the porous CTA film, the difference in refractive index between the two components is larger (=0.47), and form birefringence is therefore generated. As a result, the porous CTA film exhibits positive birefringence and extraordinary wavelength dispersion.

In this section, we explained that a microporous structure has the potential to improve the birefringence property of polymeric films based on experimental and theoretical approaches. However, to control the birefringence more precisely, the effect of pore size on form birefringence should be investigated because optical theory does not mention the dependence of birefringence on pore size.

Conclusions

In this review, we summarized our recent works, which investigated the control methods of birefringence and its wavelength dependence of cellulose esters based on substitution groups, strain-induced crystallization, small additive molecules, and microporous structures. In particular, the application of cellulose esters to high-performance retardation films requires both enhanced birefringence values and extraordinary wavelength dispersion, in which the absolute value of birefringence increases with increasing wavelength. However, cellulose triacetate (CTA), which is one of most well-known cellulose esters, shows negative birefringence and ordinary wavelength dispersion, which means the opposite dependence to extraordinary dispersion.

In the first method, the effect of ester species was investigated by comparing CTA and CAP, which have acetyl (Ac) and propionyl (Pr) groups in a pyranose unit. Due to the different contributions of the Ac and Pr groups, CAP exhibited positive birefringence and extraordinary wavelength dispersion. In addition, the effect of three substitution sites (C-2, C-3, and C-6) in a pyranose unit was also investigated by using xylan acetate (XylAc), which has two substitution sites. For the stretched CAP film, the wavelength dependence of birefringence could be controlled by the draw ratio because crystallization was induced during stretching and the crystal oriented to the stretching direction.

In the second, the addition of small aromatic molecules increased the birefringence value of CTA and CAP due to intermolecular orientation correlation, which is called a nematic interaction (NI). Data of the enhancement in CAP birefringence by two low-mass molecules indicated that the degree of NI was dependent on the rigidity of the chemical structure. Strong NIs between the low-mass molecule and cellulose ester can make the birefringence higher. Third, the anisotropic porous structure changed the birefringence of CTA from negative to positive and the ordinary wavelength dispersion to extraordinary. This result was explained by using an optical theory for form birefringence.

These methods, modification of substitution groups, addition of low-mass molecules, and formation of a porous structure, were focused on improving the birefringence of cellulose esters. However, to design higher performance optical films, further investigation is necessary. Moreover, we think that these techniques can be useful for other polymers, such as poly(methyl methacrylate) and polycarbonate, by considering chemical structures. We hope that our recent works introduced in this review contribute to developing the field of optical polymeric materials.

References

Edgar KJ, Buchanan CM, Debenham JS, Rundquist PA, Seiler BD, Shelton MC, et al. Advances in cellulose ester performance and application. Prog Polym Sci. 2001;26:1605–88.

Kondo T, Sawatari C, Manley RS, Gray DG. Characterization of hydrogen bonding in cellulose-synthetic polymer blend systems with regioselectively substituted methylcellulose. Macromolecules. 1994;27:210–5.

Krasovskii AN, Plodistyi AB, Polyakov DN. IR study of distribution of primary and secondary functional groups in highly substituted cellulose acetates, acetomaleates, and acetophthalates. Russ J Appl Chem. 1996;69:1048–54.

Heinze T, Dicke R, Koschella A, Kull AH, Klohr EA, Koch W. Effective preparation of cellulose derivatives in a new simple cellulose solvent. Macromol Chem Phys. 2000;201:627–31.

Sata H, Murayama M, Shimamoto S. Properties and applications of cellulose triacetate film. Heidelberg, Germany: Wiley-VCH; 2003.

Ilharco LM, de Barros RB. Aggregation of pseudoisocyanine iodide in cellulose acetate films: Structural characterization by FTIR. Langmuir. 2000;16:9331–7.

Songsurang K, Miyagawa A, Abd Manaf ME, Phulkerd P, Nobukawa S, Yamaguchi M. Optical anisotropy in solution-cast film of cellulose triacetate. Cellulose. 2012;20:83–96.

Saito H, Inoue T. Chain orientation and instrinsic anisotropy in birefringence-free polymer blends. J Poly Sci Part-B Poly Phys. 1987;25:1629–36.

Uchiyama A, Yatabe T. Analysis of extraordinary birefringence dispersion of uniaxially oriented poly(2,6-dimethyl 1,4-phenylene oxide)/atactic polystyrene blend films. Jpn J Appl Phys Part-1. 2003;42:3503–7.

Tagaya A, Iwata S, Kawanami E, Tsukahara H, Koike Y. Zero-birefringence polymer by the anisotropic molecule dope method. Appl Opt. 2001;40:3677–83.

Abd Manaf ME, Tsuji M, Shiroyama Y, Yamaguchi M. Wavelength dispersion of orientation birefringence for cellulose esters containing tricresyl phosphate. Macromolecules. 2011;44:3942–9.

Abd Manaf ME, Miyagawa A, Nobukawa S, Aoki Y, Yamaguchi M. Incorporation of low-mass compound to alter the orientation birefringence in cellulose acetate propionate. Opt Mater. 2013;35:1443–8.

Iwasaki S, Satoh Z, Shafiee H, Tagaya A, Koike Y. Design and synthesis of zero-zero-birefringence polymers in a quaternary copolymerization system. Polymer. 2012;53:3287–96.

Uchiyama A, Ono Y, Ikeda Y, Shuto H, Yahata K. Copolycarbonate optical films developed using birefringence dispersion control. Polym J. 2012;44:995–1008.

Cimrova V, Neher D, Kostromine S, Bieringer T. Optical anisotropy in films of photoaddressable polymers. Macromolecules. 1999;32:8496–503.

Cho CK, Kim JD, Cho K, Park CE, Lee SW, Ree M. Effects of the lamination temperature on the properties of poly(ethylene terephthalate-co-isophthalate) in polyester-laminated tin-free steel can-I. Characterization of poly(ethylene terephthalate-co-isophthalate). J Adh Sci Tech. 2000;14:1131–43.

Osaki K, Inoue T, Hwang EJ, Okamoto H, Takiguchi O. Dynamic birefringence of amorphous polymers. J Non-Cryst Sol. 1994;172:838–49.

Sakurai K, Fuji M. Optical properties of a low birefringence polyester containing fluorine side chain I. Polym J. 2000;32:676–82.

Maeda A, Inoue T. On the viscoelastic segment size of cellulose. Nihon Reoroji Gakkaishi. 2011;39:159–63.

Shafiee H, Tagaya A, Koike Y. Mechanism of generation of photoelastic birefringence in methacrylate polymers for optical devices. J Polym Sci Part B Polym Phys. 2010;48:2029–37.

Ibn-Elhaj M, Schadt M. Optical polymer thin films with isotropic and anisotropic nano-corrugated surface topologies. Nature. 2001;410:796–9.

Kunzner N, Diener J, Gross E, Kovalev D, Timoshenko VY, Fujii M. Form birefringence of anisotropically nanostructured silicon. Phys. Rev. B 2005;71:195304.

Richert R, Angell CA. Dynamics of glass-forming liquids. V. On the link between molecular dynamics and configurational entropy. J Chem Phys. 1998;108:9016–26.

Yamaguchi M, Okada K, Abd Manaf ME, Shiroyama Y, Iwasaki T, Okamoto K. Extraordinary wavelength dispersion of orientation birefringence for cellulose esters. Macromolecules. 2009;42:9034–40.

Nobukawa S, Enomoto-Rogers Y, Shimada H, Iwata T, Yamaguchi M. Effect of acetylation site on orientation birefringence of cellulose triacetate. Cellulose. 2015;22:3003–12.

Nobukawa S, Nakao A, Songsurang K, Pulkerd P, Shimada H, Kondo M, et al. Birefringence and strain-induced crystallization of stretched cellulose acetate propionate films. Polymer. 2017;111:53–60.

Kono H, Numata Y, Nagai N, Erata T, Takai M. CPMAS C-13 NMR and X-ray studies of cellooligosaccharide acetates as a model for cellulose triacetate. J Polym Sci Pol Chem. 1999;37:4100–7.

Tagaya A, Koike Y. Compensation and control of the birefringence of polymers for photonics. Polym J. 2012;44:306–14.

Nobukawa S, Urakawa O, Shikata T, Inoue T. Evaluation of nematic interaction parameter between polymer segments and low-mass molecules in mixtures. Macromolecules. 2010;43:6099–105.

Doi M, Pearson D, Kornfield J, Fuller G. Effect of nematic interaction in the orientational relaxation of polymer melts. Macromolecules. 1989;22:1488–90.

Songsurang K, Shimada H, Nobukawa S, Yamaguchi M. Control of three-dimensional refractive indices of uniaxially-stretched cellulose triacetate with low-molecular-weight compounds. Eur Polym J. 2014;59:105–12.

Nobukawa S, Aoki Y, Yoshimura H, Tachikawa Y, Yamaguchi M. Effect of aromatic additives with various alkyl groups on orientation birefringence of cellulose acetate propionate. J Appl Polym Sci. 2013;130:3465–72.

Nobukawa S, Hayashi H, Shimada H, Kiyama A, Yoshimura H, Tachikawa Y, et al. Strong orientation correlation and optical anisotropy in blend of cellulose ester and poly(ethylene 2,6-naphthalate) oligomer. J Appl Polym Sci. 2014;131:40570.

Nobukawa S, Aoki Y, Fukui Y, Kiyama A, Yoshimura H, Tachikawa Y, et al. The effect of flexible chains on the orientation dynamics of small molecules dispersed in polymer films during stretching. Polym J. 2015;47:294–301.

Flanders DC. Submicrometer periodicity gratings as artificial anisotropic dielectrics. Appl Phys Lett. 1983;42:492–4.

Nobukawa S, Shimada H, Aoki Y, Miyagawa A, Vu Ahn D, Yoshimura H, et al. Extraordinary wavelength dispersion of birefringence in cellulose triacetate film with anisotropic nanopores. Polymer. 2014;55:3247–53.

Shimada H, Nobukawa S, Yamaguchi M. Development of microporous structure and its application to optical film for cellulose triacetate containing diisodecyl adipate. Carbohydr Polym. 2015;120:22–8.

Acknowledgements

This work was partly supported by the Japan Society for the Promotion of Science KAKENHI (grant numbers 23850008 and 25870268) and grants from the Ogasawara Foundation for the Promotion of Science and Engineering and the Kyoto Technoscience Center. We express sincere gratitude to Professor Masayuki Yamaguchi for his continuous and kind guidance and to Professor Tadahisa Iwata, Professor Yukiko Enomoto, Dr. Songsurang Kultida, Dr. Hikaru Shimada, Mr. Hiroki Hayashi, Mr. Yoshihiko Aoki, Mr. Akichika Nakao, and other colleagues for their great efforts toward these works.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that he has no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nobukawa, S. Design of birefringence and its wavelength dispersion for cellulose derivatives using substitution, low-mass additives, and porous structures. Polym J 51, 835–843 (2019). https://doi.org/10.1038/s41428-019-0199-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-019-0199-y

This article is cited by

-

Birefringence of cellulose: review, measurement techniques, dispersion models, biomedical applications and future perspectives

Wood Science and Technology (2024)

-

Structure and morphology of cellulose fibers in garlic skin

Scientific Reports (2020)