Abstract

Molecularly imprinted hydrogel layers with lectin-recognition sites were prepared on surface plasmon resonance (SPR) sensor chips via surface-initiated atom transfer radical polymerization (SI-ATRP) combined with molecular imprinting. The lectin-imprinted hydrogel layer sensor chips showed larger SPR signal change in response to a target lectin than nonimprinted hydrogel layer sensor chips. The larger SPR signal change was attributed to the strong affinity constant of the lectin-imprinted hydrogel layer for the target lectin. These results suggest that molecular recognition sites for the lectin were formed within the hydrogel layers by molecular imprinting. On the other hand, the SPR signal change of the lectin-imprinted hydrogel layer chip in the presence of other lectin was very small. Poly(2-methacryloxyethyl phosphorylcholine) as a main chain of the hydrogel layer inhibited nonspecific adsorption of other lectin. This paper describes that SI-ATRP with biomolecular imprinting is a useful method to design highly sensitive and selective SPR sensor chips with molecular recognition sites for a target lectin.

Similar content being viewed by others

Introduction

Surface plasmon resonance (SPR) spectroscopy have been established as a powerful technique for the investigation of biomolecular interactions, including DNA hybridizations, lectin-saccharide interaction, antigen-antibody binding because it enables us to monitor the binding events rapidly, in real time, with labels free and sensitive detection limits [1,2,3,4,5,6,7,8]. SPR sensors are sensitive to the reflective index changes that occur when an analyte partner (target molecule) in a solution binds to a recognition element (ligand) immobilized on the surface of a sensor chip. The SPR analysis provides important information about the affinity constants, binding kinetics and specificity of the biomolecular interaction. In fabricating SPR sensor chips, a standard amine coupling method has been used for direct immobilization of ligand biomolecules onto an activated sensor chip surface, which produces the two-dimensionally ligand-immobilized sensor chips [2, 9]. In other way, we reported the preparation of three-dimensionally antibody-immobilized hydrogel layer chips by surface-initiated atom transfer radical polymerization (SI-ATRP) [10]. Our previous study revealed that the SPR signals of the three-dimensionally antibody-immobilized hydrogel layer chips were dramatically enhanced compared with a two-dimensionally antibody-immobilized SPR sensor chip because a larger amount of antibodies was immobilized within the three-dimensional hydrogel network. In SPR sensor systems, the immobilization of ligands onto the surface of sensor chips must be individually optimized according to the kind and amount of ligands and target molecules [1, 11].

Molecular imprinting is a promising method to create artificial receptors in polymeric network with highly sensitive, specific and stable bio-recognition sites [12,13,14,15,16,17]. In molecular imprinting, complexes between the functional monomers as ligands and a template molecule (target molecule) are pre-formed through covalent, non-covalent or semi-covalent bonding. After the functional monomers are copolymerized with cross-linker in the presence of a template, molecularly imprinted polymers (MIPs) are obtained by extraction of the template from the resulting networks. Specific molecular recognition sites that are complementary in shape, size, and functional groups to the original template can be created by the extraction of the template molecule after network formation. Recently a variety of MIPs with molecular recognition sites for target biomolecules such as proteins were strategically designed using functional monomers with carboxyl and amino groups as ligands. Such MIPs have been successfully employed in many applications such as purification, separation, catalysis, immunoassays, and biosensing [18,19,20,21]. We reported that biomolecules like proteins and saccharides are useful ligands in molecular imprinting for target biomolecules with high molecular weight such as proteins [22, 23]. For example, protein-recognition layers were prepared on SPR sensor chips by molecular imprinting using a rabbit immunoglobulin G (IgG) as a template and both an anti-rabbit immunoglobulin G (anti-IgG) and lectin concanavalin A (ConA) as ligands. The affinity constant of the IgG-imprinted layer sensor chips with both anti-IgG and ConA ligands was much higher than that of the nonimprinted sensor chips. Strategical designs of MIPs for target proteins with complicated three-dimensional structures are still challenges for the developments of SPR sensing devices with high sensitivity and selectivity under harsh conditions because sensing various marker proteins enables early detections and treatments of diseases.

Hydrogels are water-swollen polymers that maintain distinct three-dimensional structures formed by cross-linking. They have been widely utilized as foods, adsorbents, contact lenses, and protein immobilization because their hydrophilic structure can absorb large amounts of water, which provides their good biocompatibility [24, 25]. In addition, some hydrogels can undergo reversible changes in the volume in response to external stimuli such as temperature, pH, ionic strength, light, electric field, etc [26]. Such stimuli-responsive hydrogels have attracted much attention as smart biomaterials for biomedical applications such as drug delivery, sensors, and scaffolds for cell cultures. We have designed biomolecularly stimuli-responsive hydrogels that exhibit swelling-shrinking behaviors in response to a target biomolecule such as an antigen, tumor-marker glycoprotein, and endocrine disruptor, based on the strategy using biomolecular complexes as dynamic cross-links of their networks [27,28,29,30,31,32,33]. Our previous studies revealed that molecular imprinting using proteins as ligands enables us to well-design biomolecularly stimuli-responsive hydrogels that exhibit unique shrinkage in response to a target proteins.

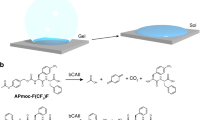

This paper describes the preparation of protein-imprinted hydrogel thin layers on SPR sensor chips by SI-ATRP combined with molecular imprinting for a target protein. In this study, we focused on three-dimensional networks with molecular recognition sites formed by molecular imprinting and 2-methacryloxyethyl phosphorylcholine (MPC) components that inhibit nonspecific protein adsorption, and fabricated SPR sensor chips for detecting a lectin ConA as a target protein. Target ConA that is a carbohydrate-binding protein and a monomer with pendant glucose (2-glucosyloxyethyl methacrylate: GEMA) were employed as a template molecule and its ligand to create recognition cavities in the thin hydrogel layers in molecular imprinting, respectively. In this paper, the binding event of ConA to the ConA-imprinted hydrogel layer sensor chip was compared with that to the nonimprinted hydrogel layer sensor chip. We also discussed the specificity of the ConA-imprinted hydrogel layer sensor chips for lectin ConA by the comparison in SPR signals for other lectin.

Experimental section

Materials

SPR sensor chips (SIA Kit Au) were purchased from GE Healthcare Japan Co., Ltd. (Tokyo, Japan). 2-Glucosyloxyethyl methacrylate (GEMA) and 2-methacryloyloxyethyl phosphorylcholine (MPC) were kindly provided by Nippon Fine Chemical Co., Ltd. (Osaka, Japan) and NOF Co., Ltd. (Tokyo, Japan), respectively. Lectin concanavalin A (ConA) and lectin peanut agglutinin (PNA) were purchased from Funakoshi Co., Ltd. (Tokyo, Japan). Tris(2-pyridylmethyl)amine (TPMA), 2-bromoisobutyric acid (BIBA), and 2-bromoisobutyryl bromide were purchased from Tokyo Chemical Industry Co., Ltd. (Tokyo, Japan). Copper(I)bromide (CuBr), copper(II)bromide (CuBr2), N,N′-methylenebisacrylamide (MBAA), and pyridine were purchased from Wako Pure Chemical Industries, Ltd. (Osaka, Japan). 11-mercapto-1-undecanol (11-MUD) was purchased from Sigma Aldrich Japan Co., Ltd. (Osaka, Japan). As other reagents and solvents, D(+)-glucose (Dextrose, Anhydrous), anhydrous magnesium sulfate (MgSO4), activated alumina, sodium dihydrogenphosphate dihydrate, disodium hydrogenphosphate 12-water, sodium dodecyl sulfate, dry dichloromethane (CH2Cl2), tetrahydrofuran, ethanol, were of analytical grade obtained from commercial sources and were used without further purification.

Preparation of hydrogel layers on SPR sensor chips

Thin ConA-imprinted hydrogel layers were prepared on the surface of SPR sensor chips via SI-ATRP with molecular imprinting as follows. After the SPR sensor chips were cleaned with a UV ozone cleaner, they were immersed in ethanol containing 1 mM ω-mercaptoundecyl bromoisobutyrate (MUBiB) [34] for 24 h to introduce an alkyl bromide group as an ATRP initiator onto the sensor chip surface (Scheme 1(a)). GEMA (500 mg; 1.7 mmol) as a ligand monomer was mixed with ConA (50 mg) as a template lectin in 1 mL of a phosphate buffer solution (20 mM, pH 7.4) (PB) and then incubated at 37 °C for 1 h for their complex formation. The GEMA-ConA complex was mixed with MPC (6.7 mmol) as a main monomer, MBAA (0.05 mmol) as a cross-linker, and CuBr (0.5 mmol), CuBr2 (0.05 mmol), and TPMA (0.5 mmol) as catalysts for SI-ATRP in PB (4.5 mL). The MUBiB-modified SPR sensor chip, on which MUBiB as a ATRP initiator was introduced, was immersed into the mixture and then the reaction was carried out at room temperature under an argon atmosphere for 24 h. ConA-imprinted hydrogel layer chips were obtained by removing the template ConA from the resultant networks in PB containing 0.5 M glucose for dissociating the GEMA-ConA complexes (Scheme 1(b)). As reference sensor chips, P(MPC) and nonimprinted P(MPC-co-GEMA) hydrogel layer chips were also prepared by copolymerization of MPC with MBAA and of GEMA and MPC with MBAA without using the template ConA (Scheme 1(c) and 1(d)), respectively.

Surface characterizations of hydrogel layer SPR sensor chips

Surfaces of modified SPR sensor chips were characterized with a Fourier transform infrared spectrometer (Spectrum 100: Perkin Elmer, Inc.) with reflection-absorption spectroscopy mode (FT-IR-RAS) after the chips were freeze-dried. All FT-IR-RAS spectra represent an average of 16 scans taken in the wave number range of 4000–800 cm−1. The sensor chip surfaces were also analyzed with an X-ray photoelectron spectroscope (XPS) (ESCA-3400, Shimadzu Co., Ltd.). In the XPS analysis, an Mg Kα X-ray source was used at a power of 200 W (20 mA × 10 kV) and the pass energy was set at 75 eV. The pressure in the analysis chamber was ca. 4.0 × 10−7 Pa. The charge correction in the binding energy scale was done by setting the –CH2– peak in the carbon spectra to 285.0 eV. The surface compositions (in atomic %) of modified SPR sensor chips were determined by considering the integrated peak areas of Au4f, C1s, O1s, S2p, Br3d, N1s, and P2p and their experimental sensitivity factors. Surface morphology of the modified SPR sensor chips was observed with Atomic force microscope (SPM E-sweep: SII NanoTechnology Inc.). The atomic force microscopic (AFM) images were taken in dynamic force microscope mode. SI-DF3 cantilevers with a resonance frequency of 3000 kHz and a force contact of 3 Nm−1 were applied. Thicknesses of hydrogel layers formed on the surface of SPR sensor chips under dry conditions were measured with a spectroscopic ellipsometer (M-2000X-KMy Ellipsometer: J.A. Woolley Co., Inc.) using 75 W Xenon arc lamp with auto angle ESM-300 base and CompleteEASE software. The thickness of the hydrogel layers was determined by measuring thickness of at least three spots on each substrate.

SPR measurements

Interaction of the nonimprinted and imprinted hydrogel layer chips with ConA and PNA as analyte lectins was analyzed with the SPR biosensor (BIAcore T200, GE Healthcare). In SPR biosensor, the SPR sensor chips were first exposed to 20 mM PB (pH 7.4) until a stable baseline was established, and then PB with ConA (0.10, 0.25, 0.50, 0.75, and 1.00 μM) was flowed over the surface of the SPR sensor chips at 25 °C with a flow rate of 30 μL min−1. The apparent affinity constants can be derived using an analysis software (BIAcore T200 Evaluation Software version: 2.0).

Results and discussions

Preparation of hydrogel layers on SPR sensor chips

After MUBiB as an ATRP initiator was introduced onto the SPR sensor chips, MPC, GEMA, and MBAA were copolymerized on the resulting MUBiB-modified sensor chips by SI-ATRP without and with a template ConA for molecular imprinting. Figure 1 shows FT-IR-RAS spectra of the bare gold, MUBiB-modified, P(MPC), nonimprinted P(MPC-co-GEMA), and ConA-imprinted P(MPC-co-GEMA) hydrogel layer SPR sensor chips. In the spectrum of the MUBiB-modified chips, the peaks assigned to an alkyl bromide were observed at a wavelength of 1200–1250 cm−1. This means that the alkyl bromide group as an ATRP initiator was successfully introduced onto the SPR sensor chip surface by the surface modifications shown in Scheme 1(a). After SI-ATRP of MPC, GEMA, and MBAA on the sensor chips, the FT-IR-RAS spectra of the P(MPC), nonimprinted P(MPC-co-GEMA), and ConA-imprinted P(MPC-co-GEMA) hydrogel layer sensor chips displayed transmission bands at 980, 1080, and 1240 cm−1 corresponding to the phosphate group of the MPC component. Transmission bands assigned to the ester groups of the MPC and GEMA components also appeared at a wavelength of 1700–1750 cm−1. These clearly indicated the formation of P(MPC), nonimprinted P(MPC-co-GEMA), and ConA-imprinted P(MPC-co-GEMA) hydrogel layers on the SPR sensor chip surfaces. The fact that the FT-IR-RAS spectrum of the ConA-imprinted P(MPC-co-GEMA) hydrogel layer was similar to that of the nonimprinted P(MPC-co-GEMA) hydrogel layer demonstrates that their GEMA contents were similar.

Table 1 shows the surface atomic ratios of the modified SPR sensor chips, which were characterized by XPS. The modification with MUBiB for introducing an alkyl bromide group as an ATRP initiator resulted in an increased in atomic ratio of C, O, S, and Br on the resulting MUBiB-modified SPR sensor chips, compared to a bare SPR sensor chip. In the XPS spectra of the P(MPC), nonimprinted P(MPC-co-GEMA), and ConA-imprinted P(MPC-co-GEMA) hydrogel layer SPR sensor chips, the atomic ratios of C, O, N, and P increased, compared to the MUBiB-modified SPR sensor chip. These results suggested that the P(MPC) and P(MPC-co-GEMA) hydrogel layers were successfully formed from the SPR sensor chip surfaces by “grafting from” method using SI-ATRP. The similar atomic ratios of the nonimprinted P(MPC-co-GEMA) and ConA-imprinted P(MPC-co-GEMA) hydrogel layers mean that their composition was similar.

AFM is a powerful tool to observe the surface morphology of the modified sensor chips. Figure 2 shows the AFM images of bare gold, P(MPC), nonimprinted P(MPC-co-GEMA), and ConA-imprinted P(MPC-co-GEMA) SPR sensor chips. In the AFM images, three-dimensional structures of hydrogel layers were observed on the surfaces of SPR sensor chips after SI-ATRP, differing from the bare gold sensor chip surface. Therefore, we concluded that the P(MPC), nonimprinted P(MPC-co-GEMA), and ConA-imprinted P(MPC-co-GEMA) hydrogel layers were successfully formed on the surface of SPR sensor chips by “grafting from” method using SI-ATRP. In general, SI-ATRP has been conducted in organic solvents such as ethanol and benzene, and buffer solutions are not suitable as solvents. However, SI-ATRP in the presence of biomolecules such as proteins requires uses of buffer solutions as solvents because biomolecules are easily denatured by organic solvents. In this study, we used PB as a solvent because SI-ATRP must be performed in the presence of template ConA for molecular imprinting. Under our SI-ATRP condition, the hydrogel layers were successfully formed by SI-ATRP in a buffer solution. The condition to form hydrogel layers on the SPR sensor chips provides a general method for designing polymer hydrogel layers with biomolecule on the sensor chips by the “grafting from” method in buffer solutions.

Thicknesses of the nonimprinted and imprinted hydrogel layer on the surface of SPR sensor chips were determined with a spectroscopic ellipsometer. The ellipsometry revealed that the thicknesses of P(MPC), nonimprinted P(MPC-co-GEMA), and ConA-imprinted P(MPC-co-GEMA) hydrogel layers on the sensor chip surfaces were 132, 121, and 125 nm, respectively. In the previous paper, we reported that the thickness of hydrogel layers on the sensor chip surface influences SPR responsive signals strongly, and that the resonance angle shifts of the polymeric layer chips in response to a target analyte decreased with an increase in the thickness of more than 300 nm [10]. Controlling the thickness of hydrogel layers is an important factors in designing hydrogel layer SPR sensor chips for detecting a target biomolecule. These suggest that the P(MPC), nonimprinted P(MPC-co-GEMA), and ConA-imprinted P(MPC-co-GEMA) hydrogel layers prepared in this study were suitable as hydrogel layer sensor chips because of their thickness of less than 300 nm.

SPR response of ConA-imprinted hydrogel layers on SPR sensor chips

The interaction of the nonimprinted and imprinted hydrogel layer chips with ConA as a target biomolecule was investigated with the SPR sensor. In SPR measurements, after the sensor chips were first exposed to PB and stable baselines were established, PB was switched to PB containing ConA with various concentrations. Figure 3 shows changes in resonance angle shift of the P(MPC), nonimprinted P(MPC-co-GEMA), and ConA-imprinted P(MPC-co-GEMA) hydrogel layer SPR sensor chips in response to ConA and PNA as target analytes. As can be seen in Figure 3(A), the resonance angle shifts of the nonimprinted P(MPC-co-GEMA) and ConA-imprinted P(MPC-co-GEMA) hydrogel layer sensor chips increased immediately by the injection of ConA, but decreased after PB with ConA was switched to PB again. In particular, the ConA-imprinted P(MPC-co-GEMA) hydrogel layer sensor chips exhibited a greater change in resonance angle shift in the presence of ConA than the nonimprinted P(MPC-co-GEMA) hydrogel layer sensor chips. On the other hand, when the SPR sensor chips were exposed to PB containing PNA with various concentrations, the P(MPC), nonimprinted P(MPC-co-GEMA), and ConA-imprinted P(MPC-co-GEMA) hydrogel layer sensor chips displayed no resonance angle shift in response to lectin PNA, as shown in Figure 3(B).

The SPR signal changes of the P(MPC), nonimprinted P(MPC-co-GEMA), and ConA-imprinted P(MPC-co-GEMA) hydrogel layer SPR sensor chips are shown as a function of the concentration of ConA and PNA as analyte lectins in Figure 4. As can be seen in Figure 4(A), the resonance angle shifts of the nonimprinted and ConA-imprinted P(MPC-co-GEMA) sensor chips increased with increasing ConA concentration although the P(MPC) sensor chip exhibited no dependence of ConA concentration on the resonance angle shift. This implies that GEMA component acted as a ligand for recognizing ConA and that MPC component inhibited nonspecific adsorption of ConA onto the hydrogel layers. As ConA has four carbohydrate-binding sites for glucose and mannose, it can bind with glucose moiety of the GEMA component. Therefore, the binding of ConA to the glucose moieties of the ConA-imprinted and nonimprinted P(MPC-co-GEMA) hydrogel layer chips induced resonance angle shifts in response to ConA. It should be noted that the resonance angle shift of the ConA-imprinted P(MPC-co-GEMA) hydrogel layer chip was much larger than that of the nonimprinted P(MPC-co-GEMA) hydrogel layer chip in spite of their similar GEMA content. The apparent affinity constants of the ConA-imprinted and nonimprinted P(MPC-co-GEMA) hydrogel layer chips for ConA were determined from the changes in the resonance angle shift as a function of ConA concentration using an analysis software. The apparent affinity constants of the nonimprinted and the ConA-imprinted P(MPC-co-GEMA) hydrogel layer chips were 2.37 × 103 M−1 and 2.32 × 106 M−1, respectively. The much higher apparent affinity constant of the ConA-imprinted P(MPC-co-GEMA) hydrogel layer chip than nonimprinted chip suggests that molecular imprinting enabled glucose moieties as ligands to be arranged at optimal positions for binding of a ConA molecule with four glucose moieties, followed by creating molecular recognition sites for ConA, as shown in Figure 5(a). Thus, the resonance angle shifts and apparent affinity constants of SPR sensor chips were greatly enhanced by combining SI-ATRP with molecular imprinting for creating molecular recognition sites within the three-dimensional (3D) structure of hydrogels. In the previous study, we prepared molecularly imprinted hydrogel/conducting polymer matrix on quartz crystal microbalance (QCM) sensor chips for detecting bisphenol A (BPA) with has a low molecular weight, which is well-known as an endocrine disrupting chemical [35]. The BPA-imprinted gel layer chip, which was prepared from poly-L-lysine (PLL) with cyclodextrin (CD) (CD-PLL) by molecular imprinting, showed a greater QCM response (ΔF) as a function of BPA concentration than the nonimprinted CD-PLL gel layer chip and the directly CD-immobilized chip. Standard QCM sensor systems have limitation in detecting a low molecular weight molecule as they measure a mass change as a frequency change induced by binding a target analyte to the ligand attached with a quartz crystal surface. On the other hand, the BPA-imprinted CD-PLL gel layer chip detected minute amounts of BPA with a low molecular weight in QCM measurements. This is attributed to the fact that a large amount of molecular BPA-recognition sites was created within the 3D structure of hydrogel layers by molecular imprinting. Similarly to the previous study using QCM measurements, SPR measurements in this study demonstrate that the formation of the recognition sites within 3D gel layer molecular imprinting is a very effective strategy for fabricating highly sensitive and selective chemical and biological sensor systems.

The specific carbohydrate-binding properties of lectins are useful for the fabrication of sensor systems [36]. PNA is a lectin that interacts specifically with lactose and galactose, whereas ConA interacts specifically with glucose and mannose. For investigating selectivity of the hydrogel layer SPR sensor chips, SPR responses of the nonimprinted and ConA-imprinted hydrogel layer chips after the injection of PNA as a function of its concentration were measured with the SPR sensor. As shown in Figure 4(B), changes in the resonance angle shift of the P(MPC), nonimprinted P(MPC-co-GEMA), and ConA-imprinted P(MPC-co-GEMA) hydrogel layer chips in response to PNA were very minute, compared with those in response to ConA. The very minute SPR signal changes for PNA means that the P(MPC), the nonimprinted P(MPC-co-GEMA), and the ConA-imprinted P(MPC-co-GEMA) hydrogel layer sensor chips had no affinity for PNA and no nonspecific adsorption, as shown in Figure 5(b). As PNA is the lectin that binds with lactose and galactose selectively, it cannot interact with the glucose moiety of the GEMA component. It should be noted that the ConA-imprinted P(MPC-co-GEMA) hydrogel layer sensor chip showed no nonspecific adsorption of PNA although the sensor chip surface was not treated by blocking buffers for inhibiting nonspecific adsorption. In general, the MPC component provides excellent resistance to nonspecific protein adsorption according to their super-hydrophilic properties [37]. Therefore, no nonspecific adsorption of PNA onto the hydrogel layer sensor chips is attributed to hydrophilic and biocompatible MPC component. As a result, the ConA-imprinted P(MPC-co-GEMA) hydrogel layer sensor chips can recognize a target ConA specifically and sensitively because of both an arrangement of glucose moieties as ligands at optimal positions by molecular imprinting and no nonspecific adsorption by MPC components. The combination of SI-ATRP with molecular imprinting and the utilization of MPC component can provide the tools for fabricating selective and sensitive sensor chips with a wide variety of uses. Even though such molecularly imprinted hydrogel layer chips designed by SI-ATRP still require further research work into possible applications, they are likely to become quite important materials for detecting a target protein in the future.

Conclusion

Molecularly imprinted hydrogel layers with molecular recognition sites for lectin ConA were formed on SPR sensor chips via SI-ATRP of MPC, GEMA and MBAA in order to develop SPR sensor systems for sensitively and selectively detecting a target protein. SI-ATRP combined with molecular imprinting provided hydrogel layers with a thickness of 120–130 nm on the SPR sensor chips. The SPR measurements revealed that the resonance angle shift and apparent affinity constant of the ConA-imprinting hydrogel layer chip for a target lectin ConA were significantly larger than those of the nonimprinted hydrogel layer chips. This is attributed to the formation of molecular recognition sites by the arrangement of glucose moieties of GEMA at optimal positions via molecular imprinting. In addition, the ConA-imprinting hydrogel layer chip exhibited no resonance angle shift for a non-target lectin PNA. Use of MPC component as a main chain of hydrogel layers inhibited nonspecific protein adsorption. Thus the ConA-imprinted hydrogel layer sensor chips had ConA-recognition sites and inhibited nonspecific protein adsorption by the MPC component. Our strategy using SI-ATRP with molecular imprinting and MPC component as a main chain enables to fabricate highly sensitive and selective SPR sensing devices for detecting a target protein. The fascinating properties of such molecularly imprinted hydrogel layer sensor chips can provide the useful tools for construct biosensor systems with a wide variety of uses.

References

Whelan RJ, Wohland T, Neumann L, Huang B, Kobilka BK, Zare RN. Analysis of biomolecular interactions using a miniaturized surface plasmon resonance sensor. Anal Chem. 2002;74:4570–6.

Homola J. Surface plasmon resonance sensors for detection of chemical and biological species. Chem Rev. 2008;108:462–93.

Kooymann RPH, Kolkman H, Gent JV, Greve J. Surface plasmon resonance immunosensors: sensitivity considerations. Anal Chim Acta. 1988;213:34–5.

Liedberg B, Nylander C, Lunström I. Surface plasmon resonance for gas detection and biosensing. Sens Actuators. 1983;4:299–304.

Schuster SC, Swanson RV, Alex LA, Bourret RB, Simon MI. Assembly and function of a quaternary signal transduction complex monitored by surface plasmon resonance. Nature. 1993;365:343–7.

Silin V, Weetall H, Vanderah DJ. SPR studies of the nonspecific adsorption kinetics of human IgG and BSA on gold surfaces modified by self-assembled monolayers (SAMs). J Colloid Interface Sci. 1997;185:94–103.

Calakos N, Bennett MK, Peterson KE, Scheller RH. Protein-protein interactions contributing to the specificity of intracellular vesicular trafficking. Science. 1994;263:1146–9.

Stojanovic I, Schasfoort RB, Terstappen LW. Analysis of cell surface antigens by surface plasmon resonance imaging. Biosens Bioelectron. 2014;52:36–43.

Frederix F, Bonroy K, Reekmans G, Laureyn W, Campitelli A, Abramov MA, Dehaen W, Maes G. Reduced nonspecific adsorption on covalently immobilized protein surfaces using poly(ethylene oxide) containing blocking agents. J Biochem Biophy Methods. 2004;58:67–74.

Kurui Y, Ishikawa M, Kawamura A, Uragami T, Miyata T. SPR signals of three-dimensional antibody-immobilized gel layers formed on sensor chips by atom transfer radical polymerization. Chem Lett. 2012;41:1660–2.

Nieba L, Niebar-Axmann SE, Persson A, Hämäläinen M, Edebratt F, Hansson A, Lidholm J, Magnusson K, Karlsson AF, Plückthun A. Biacore analysis of histidine-tagged proteins using a chelating NTA sensor chip. Anal Biochem. 1997;252:217–28.

Wulff G. Molecular imprinting in cross-linked materials with the aid of molecular templates-a way towards artificial antibodies. Angew Chem Int Ed Engl. 1995;34:1812–32.

Shea K. Molecular imprinting of synthetic network polymers: the de novo synthesis of macromolecular binding and catalytic sites. Trends Polym Sci. 1994;2:155–73.

Bossi A, Bonini F, Turner AP, Piletsky SA. Molecularly imprinted polymers for the recognition of proteins: the state of the art. Biosens Bioelectron. 2007;22:1131–7.

Lépinay S, Kham K, Millot M-C, Carbonnier B. In-situ polymerized molecularly imprinted polymeric thin films used as sensing layers in surface plasmon resonance sensors: Mini-review focused on 2010–2011. Chem Pap. 2012;66:340–51.

Morelli I, Chiono V, Ciardelli G, Silvestri D, Giusti P. Molecularly imprinted submicronspheres for applications in a novel model biosensor-film. Sens Actuators B Chem. 2010;150:394–401.

Takeuchi T, Hayashi T, Ichikawa S, Kaji A, Masui M, Matsumoto H, Sasao R. Molecularly imprinted tailor-made functional polymer receptors for highly sensitive and selective separation and detection of target molecules. Chromatography. 2016;37:43–64.

Asliyuce S, Uzun L, Rad AY, Unal S, Say R, Denizli A. Molecular imprinting-based composite cryogel membranes for purification of anti-hepatitis B surface antibody by fast protein liquid chromatography. J Chromatogr B. 2012;889–990:95–102.

Zhang H, Ye L, Mosbach K. Non-covalent molecular imprinting with emphasis on its application in separation and drug development. J Mol Recognit. 2006;19:248–59.

Vidyasankar S, Arnold FH. Molecular imprinting: selective materials for separations, sensors and catalysis. Curr Opin Biotechnol. 1995;6:218–24.

Ertürk G, Uzun L, Tümer MA, Say R, Denizli A. Fab fragments imprinted SPR biosensor for real-time human immunoglobulin G detection. Biosens Bioelectron. 2011;28:97–104.

Naraprawatphong R, Kawanaka G, Hayashi M, Kawamura A, Miyata T. Development of protein-recognition SPR devices by combination of SI-ATRP with biomolecular imprinting using protein ligands. Mol Impr. 2006;4:21–30.

Kurui Y, Kawamura A, Uragami T, Miyata T. Formation of thin molecularly imprinted hydrogel layers with lectin recognition sites on SPR sensor chips by atom transfer radical polymerization. Chem Lett. 2014;43:825–7.

Wichterle O, Lím D. Hydrophilic gels for biological use. Nature. 1960;185:117–8.

Ahmed EM. Hydrogel: Preparation, characterization, and applications: A review. J Adv Res. 2015;6:105–21.

T Miyata, Stimuli-Responsive Polymers and Gels, Supramolecular Design for Biological Applications (ed. N Yui), Chapter 9, CRC Press, Boca Raton, 191–225 (2002).

Miyata T, Asami N, Uragami T. A reversibly antigen-responsive hydrogel. Nature. 1999;399:766–9.

Miyata T. Preparation of smart soft materials using molecular complexes. Polym J. 2010;42:277–89.

Miyata T, Asami N, Uragami T. Preparation of an antigen-sensitive hydrogel using antigen-antibody bindings. Macromolecules. 1999;32:2082–4.

Miyata T, Jige M, Nakaminami T, Uragami T. Tumor marker-responsive behavior of gels prepared by biomolecular imprinting. Proc Natl Acad Sci USA. 2006;103:1190–3.

Miyata T, Hayashi T, Kuriu Y, Uragami T. Responsive behavior of tumor-marker- imprinted hydrogels using macromolecular cross-linkers. J Mol Recognit. 2012;25:336–43.

Kawamura A, Kiguchi T, Nishihata T, Uragami T, Miyata T. Target molecule-responsive hydrogels designed via molecular imprinting using bisphenol A as a template. Chem Commun. 2014;76:11101–3.

Miyata T, Uragami T, Nakamae K. Biomolecule-sensitive hydrogels. Adv Drug Deliv Rev. 2002;54:79–98.

Jones DM, Brown AA, Huck WTS. Surface-initiated polymerizations in aqueous media: effect of initiator density. Langmuir. 2002;18:1256–69.

Matsumoto K, Tiu BDB, Kawamura A, Advincula RC, Miyata T. QCM sensing of bisphenol A using molecularly imprinted hydrogel/conducting polymer matrix. Polym J. 2016;48:525–32.

Miyata T, Nakamae K. Polymers with pendant saccharides –“Glycopolymers. Trend Polym Sci. 1997;5:198–206.

Ishihara K, Nomura H, Mihara T, Kurita K, Iwasaki Y, Nakabayashi N. Why do phospholipid polymers reduce protein adsorption? J Biomed Mater Res. 1998;39:323–30.

Acknowledgements

This work was supported in part by a Grant-in-Aid for Scientific Research (B) (No. 15H03026) and a Grant-in-Aid for challenging Exploratory Research (No. 17K19163) from the Japan Society of the Promotion of Science (JSPS) and by the AMED S-innovation Program for the development of biofunctional materials for the realization of innovative medicine.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Naraprawatphong, R., Kawamura, A. & Miyata, T. Preparation of molecularly imprinted hydrogel layer SPR sensor chips with lectin-recognition sites via SI-ATRP. Polym J 50, 261–269 (2018). https://doi.org/10.1038/s41428-017-0013-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-017-0013-7

), and ConA-imprinted P(MPC-co-GEMA) (

), and ConA-imprinted P(MPC-co-GEMA) ( ) hydrogel layer SPR sensor chips as a function of the concentration of ConA (A) and PNA (B) in PB at 25 °C (Color figure online)

) hydrogel layer SPR sensor chips as a function of the concentration of ConA (A) and PNA (B) in PB at 25 °C (Color figure online)