Abstract

Perovskite iridates are a promising material platform for hosting unconventional superconductivity. Transport measurements of Sr2IrO4 thin-film field-effect transistors are expected to provide irrefutable evidence for the existence of superconductivity. However, these experiments have revealed a remarkably robust insulating state over wide electron and hole doping ranges; this finding is in contrast to the case of the bulk material, in which metallicity appears upon moderate electron doping by substituting cations in place of Sr. The nature of this robust insulating state and whether any metallic state can be realized in the Sr2IrO4 thin film are two remaining challenges that preclude further progress in the search for superconductivity in this system. Here, we show that this insulating state is enhanced in Sr2IrO4 thin films by thermal annealing under vacuum conditions, while it can be destroyed upon annealing in an oxygen atmosphere within restricted ranges of oxygen pressure, annealing temperature and ion substitution levels. The resulting films exhibit metallic transport behavior near room temperature and a metal–insulator crossover at ~200 K. Our results point to the potentially important roles of the oxygen vacancies at different atomic sites in the formation of the robust insulating state and the new metallic state and to their interplay in the Sr2IrO4 thin film. This finding opens new possibilities in the search for unconventional superconductivity by further tailoring the as-found metallic state in properly oxygen-annealed Sr2IrO4 thin films.

Similar content being viewed by others

Introduction

Unconventional superconductivity remains a central topic of condensed matter physics1,2,3. Special attention has been given to compounds with crystal and electronic structures similar to those of cuprates with the hope of finding new superconductors and understanding the origin of cuprate superconductivity4,5,6,7,8,9. In addition to the few related systems that have been primarily focused on4,9, the 5d transition-metal oxide system Sr2IrO4 has attracted considerable interest. Undoped Sr2IrO4 features a unique Mott insulating state as a result of the interplay between strong spin–orbit coupling and Coulomb interactions10,11,12,13. Melting of this spin–orbit Mott phase upon electron and hole doping has been theoretically predicted to yield unconventional superconductivity14,15. Consistent with this finding, angle-resolved photoemission16 and scanning tunneling microscopy17 experiments have shown spectroscopic signatures consistent with a d-wave superconducting gap in surface electron-doped Sr2IrO4 at low temperatures. Nevertheless, transport evidence for the zero-resistance state is required to establish the occurrence of superconductivity in doped Sr2IrO4.

Electron18,19,20 and hole21,22 doping through cation substitution in bulk Sr2IrO4 can weaken and destroy the undoped insulating state at relatively high temperatures (>100 K) without the superconductivity observed at relatively low temperatures. Restricted by the solubility limits for various substitutional dopants, bulk doping cannot reach the sufficiently high electron or hole doping levels predicted for superconductivity to emerge. The ionic liquid gating technique presents a general solution to this problem, and it is capable of realizing ambipolar doping in excess of 10% in quite a few material systems23,24,25,26,27. However, in the case of Sr2IrO4, liquid gating experiments on thin-film samples have revealed remarkably robust insulating behaviors over enormously wide electron and hole doping ranges28,29. The origin of this behavior is unknown to date, but it may occur due to factors introduced by the gating technique27,30,31 and/or factors intrinsic to the thin-film samples20,32. Indications for the latter reasoning come from the observed increases in resistivity upon (Ce) electron33 and (charge-transfer) hole34 doping of the Sr2IrO4 thin films, in contrast to the bulk cases18,19,20,22. To our knowledge, no metallic state has thus far been found in the Sr2IrO4 thin film regardless of the thin film growth and doping methods28,29,33,34,35. The nature of the robust insulating state and whether any metallic state can be realized in the Sr2IrO4 thin film are two remaining questions36. Their resolutions are prerequisites for making progress on the important issue of unconventional superconductivity in Sr2IrO4.

In this work, we perform a systematic study of the effects of thermal annealing both under vacuum conditions and in an oxygen atmosphere on the transport property of the Sr2IrO4 thin film. We find that the robust insulating state is enhanced by vacuum annealing and weakened by oxygen annealing. This state can be destroyed near room temperature after oxygen annealing at ~50 atm and ~570 °C in a pristine thin film, where a new metallic state appears. These observations outline an emerging transport phase diagram of the Sr2IrO4 thin film featuring an interplay between the robust insulating state and the new metallic state. We argue that while the robust insulating state is likely dominated by the defect scattering effect of planar oxygen vacancies, the new metallic state likely reflects an intrinsic bulk-like property of the IrO2 planes with effective electron doping due to apical oxygen vacancies. This finding provides a new perspective for a unified understanding of the puzzling transport properties of the Sr2IrO4 thin film and suggests a new pathway for discovering superconductivity in Sr2IrO4 around the as-found metallic state.

Materials and methods

High-quality thin films of pristine Sr2IrO4 and 5% Ce-doped Sr2IrO4 [(Sr0.95Ce0.05)2IrO4] were grown on atomically flat (LaAlO3)0.3(Sr2AlTaO6)0.35 (LSAT) (001) substrates by the pulsed laser deposition (PLD) method using a KrF excimer laser (wavelength of 248 nm) as in our previous study33. Ceramic targets of stoichiometric Sr2IrO4 and (Sr0.95Ce0.05)2IrO4 were fabricated by conventional solid-state reactions. The energy density of the pulsed laser was approximately 0.3 J cm−2, and the frequency was 5 Hz. During thin-film deposition, the substrate temperature was maintained at 800 °C with an oxygen partial pressure of 0.13 Pa. Upon the completion of the deposition, the sample was first cooled to 650 °C in an oxygen atmosphere of 0.13 Pa and then cooled to room temperature at a 5 × 104 Pa oxygen pressure and a cooling rate of 20 °C min−1. All films were ∼20 nm thick, and the growth rate was ∼0.02 nm s−1. Thermal annealing of the as-grown films was conducted in a chamber under vacuum conditions exceeding 1 × 10−10 mbar. Thermal annealing of the as-grown films in an oxygen atmosphere was conducted in a high-pressure tube furnace (OTF-1200X-HP-55, MTI Co.) with high-purity oxygen gas (purity > 99.995%). The oxygen pressure was initially set and subsequently maintained for each annealing at a given pressure value, with the aid of an electromagnetic valve for automatic gas release (deviation < ±2%), during temperature increase (rate of 10 °C min−1) and maintenance (duration of 1 h) stages. During the cooling stage (rate of −10 °C min−1), the oxygen pressure naturally decreased with decreasing temperature for a fixed amount of oxygen gas inside the furnace. The structural properties of the films before and after oxygen annealing (Fig. S1) were characterized by four-circle X-ray diffraction (Bruker D8 Discover) with a Cu Kα1 wavelength of 1.5406 Å. The chemical states of the films were characterized by X-ray photoelectron spectroscopy (XPS; Thermo Scientific ESCALAB Xi+) with Al Kα radiation (1486.6 eV).

The electrical transport properties of the samples were measured with the four-point probe method to effectively eliminate the lead and contact resistance from the measurement. Gold electrodes with thicknesses of 50 nm were deposited on the surface of each sample by thermal evaporation to ensure good electrical contact. A Keithley 6221 current source and a Keithley 2182A nanovoltmeter were used for the resistance measurement along the crystallographic a-axis or b-axis of the thin film. The geometric dimensions of each sample were accurately measured with an optical microscope, and the a-axis (or b-axis) resistivities of the samples were calculated based on the measured resistance values and cross-sectional areas of the thin films. Transport measurements were conducted in a cryostat over the temperature range of 3.5–300 K at a cooling/heating rate of 1 K min−1. To minimize the effects of possible sample-to-sample variation due to the growth process, each study of the annealing temperature (TA) or pressure of oxygen atmosphere (POA) dependence was performed on samples in small pieces (∼2.5 mm × 5 mm) that were cut from the same large piece (10 mm × 10 mm) of the as-grown sample using a wire saw.

Results

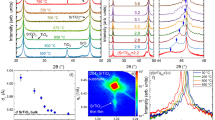

The temperature dependence of the electrical resistivity (R–T curve) of the as-grown Sr2IrO4 thin film is shown in Fig. 1a. The resistivity of the sample decreases with increasing temperature, which depicts typical insulating behavior. Figure 1a shows the R–T curves of Sr2IrO4 thin films after thermal annealing at different temperatures (TA = 350, 450, and 600 °C) under vacuum conditions. The resistivity of the TA = 350 °C film at room temperature is nearly one order of magnitude higher than that of the as-grown film. Upon a further increase in TA, the sample resistivity increases, and the insulating behavior persists.

a Vacuum annealing at different TA as indicated. b Oxygen annealing under POA = 1 atm at different TA values as indicated. c Oxygen annealing at TA = 570 °C under different POA values as indicated. The insets in b and c summarize the resistivity values at room temperature of the corresponding R–T curves as a function of TA and POA, respectively. d R–T curves (resistivity normalized at room temperature) of samples annealed under nearly optimal conditions (POA ~ 50 atm, TA = 570 °C). Error bars in the insets of b and c mainly reflect the reproducibility of the resistivity measurement on the given sample and the sample-to-sample variations in multiple samples (if available) grown/annealed/measured under nominally the same conditions.

Figure 1b presents the R–T curves of Sr2IrO4 thin films after thermal annealing at different temperatures (TA = 400–600 °C) in a 1 atm oxygen atmosphere. As TA increases toward 570 °C, the resistivity of the oxygen-annealed film at room temperature decreases gradually and reaches a minimum value of 5.24 mΩ cm for TA = 570 °C, which is close to a quarter of the value of the as-grown sample. A further increase in TA leads to a rapid increase in resistivity. This phenomenon points to an overall nonmonotonic TA-dependent evolution of the resistivity across TA = 570 °C, which is exemplified in the inset of Fig. 1b for the resistivity value at room temperature.

Figure 1c shows the R–T curves of Sr2IrO4 thin films after thermal annealing at TA = 570 °C in an oxygen atmosphere at various high pressures (POA = 1–150 atm). With increasing POA, the sample resistivity at room temperature first decreases rapidly for POA < 9 atm and slows before increasing under high POA values (inset of Fig. 1c). The room-temperature resistivity reaches a minimum value of 2.61 mΩ cm at POA = 50 atm, which is approximately 8 times smaller than the value for the as-grown sample. Interestingly, nonmonotonic R–T curves can be robustly found in the samples annealed in oxygen under similar conditions at TA = 570 °C and POA ~ 50 atm, which commonly highlights a metal–insulator crossover at ~200 K, as shown in Fig. 1d.

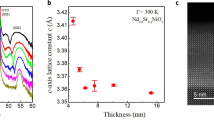

The temperature dependence of the resistivity of a semiconductor can be generally described by the formula \(\rho \left(T\right)={\rho }_{0}[1+{\alpha }_{0}(T-{T}_{0})]\), where \({\rho }_{0}\), \({\alpha }_{0}\) and \({T}_{0}\) are material-specific parameters37. Here, we apply this formula to fit the same R–T curves as shown in Fig. 1c and reproduced in Fig. 2a in the vicinity of room temperature (250–300 K), and we obtain the coefficient \({\alpha }_{0}\). Figure 2c depicts the evolution of \({\alpha }_{0}\) with increasing POA. With increasing POA, the magnitude of \({\alpha }_{0}\) first decreases and then increases. \({\alpha }_{0}\) is generally negative, which is indicative of the insulating behavior of the sample. The value becomes positive in the vicinity of POA = 50 atm, which is consistent with the metallic behavior observed near room temperature in Fig. 1d.

a, b R–T curves of the Sr2IrO4 (a) and (Sr0.95Ce0.05)2IrO4 (b) thin films annealed under different POA values, with each fitted by \(\rho \left(T\right)={\rho }_{0}[1+{\alpha }_{0}(T-{T}_{0})]\) in the temperature range between 250 and 300 K. c Fitted coefficient \({\alpha }_{0}\) and d room-temperature resistivity extracted from a and b for both types of samples under different POA values. Color ribbons in c and d are guides to the eye based on the spline interpolations to the experimental data. Error bars in the insets of c and d mainly reflect the reproducibility of the resistivity measurement on the given sample and the sample-to-sample variations in multiple samples (if available) grown/annealed/measured under nominally the same conditions.

As a comparison, we perform transport measurements on the (Sr0.95Ce0.05)2IrO4 thin films. The resistivity of the as-grown (Sr0.95Ce0.05)2IrO4 thin film is a few times larger than that of the pristine film (cf. Figs. S2 and 1a), which is consistent with our earlier report33. Oxygen annealing at TA = 570 °C at an increasing POA leads to an initial decrease in the resistivity of the Ce-doped film near room temperature followed by an increase for POA > 50 atm, which is reminiscent of the case of the pristine sample (Fig. 2d). The optimal POA value for obtaining the minimum resistivity is close to 50 atm in both cases, regardless of the difference in Ce doping. However, important differences are noted. The resistivity of the (Sr0.95Ce0.05)2IrO4 thin films is overall higher than that of the pristine films. The metal–insulator crossover observed at ~POA = 50 atm in the pristine samples is absent in the Ce-doped samples (Fig. S2).

The results of the coefficients \({\alpha }_{0}\) are similarly defined for the R–T curves near room temperature of (Sr0.95Ce0.05)2IrO4 thin films, and they are shown in Fig. 2c. With increasing POA, the magnitude of \({\alpha }_{0}\) exhibits nonmonotonic behavior and reaches its minimum value at 50 atm, which is similar to the pristine case. However, \({\alpha }_{0}\) is always negative, and no significant change is observed at ~POA = 50 atm, as in the pristine case, which is consistent with the absence of a metallic state in the Ce-doped films. The above results suggest that the robust insulating state is enhanced while the metallic state is weakened by Ce doping in the Sr2IrO4 thin film.

Discussion

Our results obtained from the study of thermal annealing under vacuum conditions and in an oxygen atmosphere on the pristine and Ce-doped Sr2IrO4 thin films are consistent with an emerging transport phase diagram of the Sr2IrO4 thin film, as schematically depicted in Fig. 3. A hypothetical resistivity (\(\rho\)) surface near room temperature is shown as a function of the Ce doping (\(x\)) and oxygen content (\(p\)). The pink/blue (dashed) curve on the \(x=0\)/\(x=0.05\) plane is the hypothetical \(\rho -p\) curve for the pristine/Ce-doped sample near room temperature. Specifically, the pink curve can be divided into three regimes, as labeled in Fig. 3.

The as-grown state of the Sr2IrO4 thin film sits close to the boundary between Regimes I and II, where oxygen vacancies created during the thin film growth are likely abundant in both the apical and planar oxygen sites. Consistent with this finding, our XPS measurement on the as-grown Sr2IrO4 thin film suggests the coexistence of 4+ and 3+ chemical states of Ir (Fig. S3). The planar oxygen vacancies (on the IrO2 planes) can serve as defect scattering centers that effectively disrupt the in-plane electrical conduction, which is a well-known effect for the case of CuO2 planes in cuprates38,39,40. Depending on the density of oxygen vacancies, the resulting state can have insulating transport behavior dominated by planar oxygen vacancies rather than carrier concentration. This state is expected to be minimally affected by the electrostatic doping of carriers; it can be further enhanced by thermal annealing under vacuum conditions, increasing the number of planar oxygen vacancies (with decreasing oxygen content moving the system toward/further into Regime I in Fig. 3). This trend offers a simple explanation for the robust insulating state of the Sr2IrO4 thin film.

Thermal annealing in the oxygen atmosphere upon increasing TA and/or POA causes the oxygen vacancies to be increasingly filled (with increasing oxygen content moving the system toward/further into Regime II in Fig. 3). Consistent with this finding, our X-ray diffraction measurements on the oxygen annealed thin films show notable c-axis contractions that have been commonly observed in oxide materials upon filling oxygen vacancies41,42,43 (Fig. S1). Thus, we still do not know which types of oxygen vacancies are filled. In this regard, we note that the planar Ir–O bond length is smaller than the apical bond length in Sr2IrO420,44. On thermodynamic grounds, a larger bonding strength of the planar Ir–O bond suggests that an oxygen atom can bind more easily with the planar oxygen vacancy than with the apical oxygen vacancy, as their binding reduces the energy of the system by the amount of Ir–O bond strength. A caveat is that the thermodynamic energy minimum associated with the filling-in of a planar oxygen vacancy can be preceded by some energy barrier that tends to block the access of the oxygen atom to the planar oxygen vacancy. We speculate that this sort of energy barrier might have been overcome due to the increased mobility of oxygen atoms during the high-pressure oxygen annealing of our samples at high temperatures. This phenomenon can potentially lead to the planar oxygen vacancies being preferentially filled in over the apical oxygen vacancies.

As a result, the robust insulating state is weakened, and the inherent in-plane conduction can eventually be restored, as all planar oxygen sites are replenished. Moreover, the IrO2 planes remain electron-doped due to the unfilled apical oxygen vacancies that act as effective donors. Metallic transport can thus occur, as in the case of bulk electron-doped Sr2IrO4. This finding can explain why a metallic state can be found in the pristine samples under proper oxygen annealing conditions.

Oxygen annealing with further increasing TA and/or POA causes the apical oxygen vacancies to be filled in (with increasing oxygen content that moves the system toward/further into Regime III in Fig. 3). The metallic transport is gradually weakened due to the decrease in electron doping until the intrinsic (insulating) transport of the undoped bulk-like Sr2IrO4 eventually recovers. This phenomenon can explain why this metallic state only exists within a restricted parameter space of thermal annealing (circled region in Fig. 3).

Hereafter (somewhere in Regime III), the intrinsic hole-doped property may become apparent upon further oxygen annealing that can create interstitial oxygen atoms as acceptors. While the insulating transport at half-filling is expected to be weakened by hole doping, the rate of weakening appears lower than the case of electron doping according to bulk doping studies18,19,21,22.

Concerning the effect of 5% Ce doping, we note that it is sufficient to cause a major reduction in the resistivity and induce metallicity in bulk Sr2IrO420. In thin films, we have previously found that increasing Ce substitution leads to c-axis contraction and weakening of the magnetic order33, which is similar to the known effects of increasing Ce substitution in the bulk20. This finding implies that Ce is an effective electron donor in the Sr2IrO4 thin films. Consistent with this trend, our XPS measurement on the as-grown (Sr0.95Ce0.05)2IrO4 thin film shows a higher Ir3+ content than the pristine sample (Fig. S3). Surprisingly, our resistivity measurements show that 5% Ce doping strengthens the robust insulating state and weakens the new metallic state. The latter aspect, in particular, cannot be easily understood if the substituted Ce ions only serve as effective donors20 that can promote in-plane conduction. Instead, both aspects can be rationalized if Ce doping introduces additional defect scattering sites33 in the IrO2 planes that cannot be removed by oxygen annealing.

The above heuristic picture highlights the potentially central role played by the oxygen vacancies at different atomic sites in shaping the transport phase diagram of the Sr2IrO4 thin film due to the interplay between the robust insulating state and the new metallic state found in this study. This finding suggests that while the robust insulating state is likely dominated by the defect scattering effect of planar oxygen vacancies, the new metallic state likely reflects an intrinsic bulk-like property of the IrO2 planes with effective electron doping due to apical oxygen vacancies. This phenomenon provides a new perspective for a unified understanding of the puzzling transport properties of the Sr2IrO4 thin film. While this perspective should be scrutinized further in experiments with oxygen annealing, it suggests a new pathway for finding superconductivity in iridates by modifying this metallic state in the Sr2IrO4 thin film. Regarding directions for modification, our study suggests that Ce doping might not be sufficiently effective for Sr2IrO4 thin films. La doping is reported to reduce the thin film resistivity28,35, unlike Ce doping33. This finding seems to indicate that the defect scattering effect may not be as strong in the case of La doping, which is beneficial for the appearance of metallicity in oxygen-annealed Sr2IrO4 thin films. In any case, using properly oxygen-annealed thin films as substrates for ionic liquid gating experiments has a favorable outcome.

Conclusion

The effects of thermal annealing in a vacuum and oxygen atmosphere on the transport property of the Sr2IrO4 thin film are investigated. We show that the robust insulating state found in earlier experiments is enhanced by vacuum annealing and weakened by oxygen annealing. This state can even be destroyed after oxygen annealing under ~50 atm at ~570 °C in the pristine thin film, where a new metallic state appears near room temperature. A unified picture is proposed to understand these new transport findings on the Sr2IrO4 thin film, which highlights the potentially central role played by the oxygen vacancies at different atomic sites in the formation of the robust insulating state and the new metallic state and by their interplay. We establish the properly oxygen-annealed Sr2IrO4 thin film as a viable platform for finding superconductivity in iridates.

Note added after submission: It has been drawn to our attention that two earlier studies reported resistivity measurements based on electrochemical oxygen doping of Sr2IrO4 in different forms45 and vacuum annealing of polycrystalline Sr2IrO446, which is qualitatively consistent with the results reported in this work.

References

Lee, P. A., Nagaosa, N. & Wen, X. G. Doping a Mott insulator: physics of high temperature superconductivity. Rev. Mod. Phys. 78, 17–85 (2004).

Stewart, G. R. Superconductivity in iron compounds. Rev. Mod. Phys. 83, 1589–1652 (2011).

Keimer, B., Kivelson, S. A., Norman, M. R., Uchida, S. & Zaanen, J. From quantum matter to high-temperature superconductivity in copper oxides. Nature 518, 179–186 (2015).

Maeno, Y. & Hashimoto, H. Superconductivity in a layered perovskite without copper. Nature 372, 532–534 (1994).

Anisimov, V. I., Bukhvalov, D. & Rice, T. M. Electronic structure of possible nickelate analogs to the cuprates. Phys. Rev. B 59, 7901–7906 (1999).

Lee, K. W. & Pickett, W. E. Infinite-layer LaNiO2: Ni1+ is not Cu2+. Phys. Rev. B 70, 165109 (2004).

Chaloupka, J. & Khaliullin, G. Orbital order and possible superconductivity in LaNiO3/LaMO3 superlattices. Phys. Rev. Lett. 100, 016404 (2008).

Hansmann, P. et al. Turning a nickelate Fermi surface into a cupratelike one through heterostructuring. Phys. Rev. Lett. 103, 016401 (2009).

Li, D. et al. Superconductivity in an infinite-layer nickelate. Nature 572, 624–627 (2019).

Kim, B. J. et al. Novel Jeff = 1/2 Mott state induced by relativistic spin–orbit coupling in Sr2IrO4. Phys. Rev. Lett. 101, 076402 (2008).

Kim, B. J. et al. Phase-sensitive observation of a spin-orbital Mott state in Sr2IrO4. Science 323, 1329–1332 (2009).

Moon, S. J. et al. Dimensionality-controlled insulator–metal transition and correlated metallic state in 5d transition metal oxides Srn+1IrnO3n+1 (n = 1, 2, and ∞). Phys. Rev. Lett. 101, 226402 (2008).

Cao, G. & Schlottmann, P. The challenge of spin–orbit-tuned ground states in iridates: a key issues review. Rep. Prog. Phys. 81, 042502 (2018).

Wang, F. & Senthil, T. Twisted Hubbard model for Sr2IrO4: magnetism and possible high temperature superconductivity. Phys. Rev. Lett. 106, 136402 (2011).

Meng, Z. Y., Kim, Y. B. & Kee, H. Y. Odd-parity triplet superconductivity in multi-orbital materials with strong spin-orbit coupling: applications to doped Sr2IrO4. Phys. Rev. Lett. 113, 177003 (2014).

Kim, Y. K., Sung, N. H., Denlinger, J. D. & Kim, B. J. Observation of a d-wave gap in electron-doped Sr2IrO4. Nat. Phys. 12, 37–41 (2015).

Yan, Y. J., Ren, M. Q., Xu, H. C., Xie, B. P. & Feng, D. L. Electron-doped Sr2IrO4: an analogue of hole-doped cuprate superconductors demonstrated by scanning tunneling microscopy. Phys. Rev. X 5, 041018 (2015).

Ge, M. et al. Lattice-driven magnetoresistivity and metal-insulator transition in single-layered iridates. Phys. Rev. B 84, 100402 (2011).

Chen, X. et al. Influence of electron doping on the ground state of (Sr1−xLax)2IrO4. Phys. Rev. B 92, 075125 (2015).

Huang, H., Ji, P., Xie, Y., Han, H. & Ge, B. Exploration of the bond angle and charge carrier density by rare-earth doping in Sr2IrO4. Phys. Rev. Mater. 4, 115001 (2020).

Qi, T. F. et al. Spin-orbit tuned metal-insulator transitions in single-crystal Sr2Ir1−xRhxO4(0 ≤ x ≤1). Phys. Rev. B 86, 125105 (2012).

Chikara, S. et al. Charge partitioning and anomalous hole doping in Rh-doped Sr2IrO4. Phys. Rev. B 95, 060407 (2017).

Ueno, K. et al. Electric-field-induced superconductivity in an insulator. Nat. Mater. 7, 855–858 (2008).

Scherwitzl, R. et al. Electric-field control of the metal–insulator transition in ultrathin NdNiO3 films. Adv. Mater. 22, 5517–5520 (2010).

Ye, J. T. et al. Liquid-gated interface superconductivity on an atomically flat film. Nat. Mater. 9, 125–128 (2010).

Nakano, M. et al. Collective bulk carrier delocalization driven by electrostatic surface charge accumulation. Nature 487, 459–462 (2012).

Leighton, C. Electrolyte-based ionic control of functional oxides. Nat. Mater. 18, 13–18 (2019).

Ravichandran, J. et al. Ambipolar transport and magneto-resistance crossover in a Mott insulator, Sr2IrO4. J. Phys.: Condens. Matter 28, 505304 (2016).

Lu, C. et al. Dual gate control of bulk transport and magnetism in the spin–orbit insulator Sr2IrO4. Phys. Rev. B 91, 104401 (2015).

Jeong, J. et al. Suppression of metal–insulator transition in VO2 by electric field-induced oxygen vacancy formation. Science 339, 1402–1405 (2013).

Li, M. et al. Suppression of ionic liquid gate-induced metallization of SrTiO3(001) by oxygen. Nano Lett. 13, 4675–4678 (2013).

Souri, M. et al. Crossover between Mott and Efros–Shklovskii variable-range hopping in Sr2IrO4 epitaxial thin films by misfit strain and isovalent doping. J. Appl. Phys. 126, 185101 (2019).

Zhang, Y. et al. Effect of Ce doping on the structural, transport and magnetic properties of Sr2IrO4 epitaxial films. J. Phys. D: Appl. Phys. 54, 405304 (2021).

Wen, F. et al. Interface-engineered hole doping in Sr2IrO4/LaNiO3 heterostructure. N. J. Phys. 21, 103009 (2019).

Li, M. Y. et al. Tuning the electronic structure of Sr2IrO4 thin films by bulk electronic doping using molecular beam epitaxy. Chin. Phys. Lett. 32, 057402 (2015).

Lu, C. & Liu, J. M. The Jeff = 1/2 antiferromagnet Sr2IrO4: a golden avenue toward new physics and functions. Adv. Mater. 32, 1904508 (2020).

Alenitsyn, A. G., Butikov, E. I. & Kondratyev, A. S. Concise Handbook of Mathematics and Physics 331–332 (CRC Press, Boca Raton, 1997).

Matsunaka, D., Rodulfo, E. T. & Kasai, H. Effects of oxygen-vacancies in high-temperature cuprate superconductors. Solid State Commun. 134, 355–360 (2005).

Hiroi, Z., Kobayashi, N. & Takano, M. Probable hole-doped superconductivity without apical oxygens in (Ca, Na)2CuO2CI2. Nature 371, 139 (1994).

Naito, M., Krockenberger, Y., Ikeda, A. & Yamamoto, H. Reassessment of the electronic state, magnetism, and superconductivity in high-Tc cuprates with the Nd2CuO4 structure. Physica C 523, 28–54 (2016).

Adler, S. B. Chemical expansivity of electrochemical ceramics. J. Am. Ceram. Soc. 84, 2117–2119 (2001).

Aschauer, U., Pfenninger, R., Selbach, S. M., Grande, T. & Spaldin, N. A. Strain-controlled oxygen vacancy formation and ordering in CaMnO3. Phys. Rev. B 88, 054111 (2013).

Ullmann, H. & Trofimenko, N. Estimation of effective ionic radii in highly defective perovskite type oxides from experimental data. J. Alloy. Compd. 316, 153–158 (2001).

Bhatti, I. N., Rawat, R., Banerjee, A. & Pramanik, A. K. Temperature evolution of magnetic and transport behavior in 5d Mott insulator Sr2IrO4: significance of magneto-structural coupling. J. Phys.: Condens. Matter 27, 016005 (2014).

Fruchter, L. et al. Electrochemical oxygen intercalation into Sr2IrO4. J. Phys. Chem. Solids 112, 1–7 (2018).

Sharma, P., Singh, S., Kuga, K., Takeuchi, T. & Bindu, R. Synthesis and structural link to the electronic and magneto-transport properties of spin–orbit Mott insulator Sr2IrO4. J. Phys.: Condens. Matter 34, 435402 (2022).

Acknowledgements

The work at Westlake University was supported by the National Key R&D Program of China (Grant No. 2022YFA1402200), National Natural Science Foundation of China (Grants Nos. 12274353, 11874053, 12174318), Zhejiang Provincial Natural Science Foundation of China (LZ19A040001), Foundation of Westlake Multidisciplinary Research Initiative Center (MRIC20210101), and Westlake Instrumentation and Service Center for Physical Sciences. The work at East China Normal University (ECNU) was supported by the National Natural Science Foundation of China (Grant No. 11874149).

Author information

Authors and Affiliations

Contributions

R.-H.H. conceived the project, secured funding, and guided the investigations. Y.-S.Z. grew the sample under the guidance of P.-H.X. and C.-G.D. Z.S. conducted the annealing experiments with help from J.-Y.S. and B.L. and analyzed the data. Z.S. and R.-H.H. wrote the manuscript with input from J.W. and P.-H.X. All authors contributed to the discussions.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Song, Z., Zhang, YS., Shen, JY. et al. Realizing metallicity in Sr2IrO4 thin films by high-pressure oxygen annealing. NPG Asia Mater 15, 43 (2023). https://doi.org/10.1038/s41427-023-00489-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41427-023-00489-6

This article is cited by

-

Electron Doping and Enhanced Conductivity in Vacuum Annealed Sr2-xLaxIrO4

Journal of Superconductivity and Novel Magnetism (2024)