Abstract

An understanding of the phase transitions at the nanoscale is essential in state-of-the-art engineering1,2,3,4,5, instead of simply averaging the heterogeneous domains formed during phase transitions6,7. However, as materials are scaled down, the steepness of the phase transition rapidly increases8,9,10,11,12,13 and requires extremely high precision in the control method. Here, a three-terminal device, which could precisely control the phase transition electrically14,15,16,17,18,19, was applied for the first time to a scaled-down metal-insulator transition material VO2. The crossover from continuous to binary transitions with the scaled-down material was clarified, and the critical channel length was successfully elucidated via phase boundary energy. Notably, below the critical channel length, the spatial degrees of freedom degenerated, and the impact of drain voltage application disappeared in the phase transition, indicating zero-dimensionality of the VO2 channel. This zero-dimensionality could be the fundamental property in the scaled-down phase transition and have a significant impact on various fields that need nanoscale engineering.

Similar content being viewed by others

Introduction

Phase transition materials are important components of a wide range of functional devices, including memory, batteries, sensors, and neuromorphic computing1,2,3,4,5. During phase transitions, spatially heterogeneous domain structures are formed that affect material properties6,7. However, when phase transition materials are miniaturized to smaller than the size of individual domains, the phase transition becomes single-domain and exhibits different behavior8,9,10,11,12,13. Therefore, when designing functional devices using phase transition materials, it is essential to understand the effects of miniaturization.

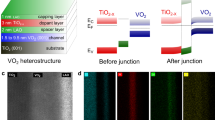

Controlling phase transitions using a three-terminal device14,15,16 can provide a novel opportunity for the study of scaled-down phase transitions, as shown in Fig. 1a. The three-terminal device can control the phase transition by applying a gate voltage to an insulating layer to accumulate electrons or holes in the phase transition material. It can electrically modulate the carrier concentration in the phase transition material, changing the free energy balance between phases and inducing the phase transition. Unlike simple two-terminal devices, the control terminals are completely isolated by an insulating layer, enabling control in a quasi-equilibrium state in a similar way to thermodynamic phase control. Controlling phases using three-terminal devices is a long-standing challenge in materials science and has been studied from various approaches, as represented by research on Mott transistors17,18,19. Some approaches using liquid gates can accumulate a large amount of charge using the electric double layer at the solid‒liquid interface and achieve a large control range18,19. However, they also have the fatal problem of unexpected electrochemical reactions, causing a complicated interpretation of the results20. On the other hand, those using solid gate dielectrics can achieve highly precise control near the transition point, although the control range is relatively small15,16. For example, a voltage control of 10 mV step corresponds to ultrahigh-precision control of several mK steps when converted to temperature. However, despite such promising properties, research using solid-state three-terminal devices is still in its infancy, and there has been no example of its application to the scaled-down phase transition. Past literature on VO2 three-terminal devices has used relatively long channels above 1 μm (see Fig. S1 in Supplementary Information for details) and has never systematically considered the scaling effect with the exception of only the channel width dependence21.

In this study, we focused on the metal-insulator transition of VO2 and systematically evaluated the effect of miniaturization using a three-terminal device. VO2 is a material that has been used in various applications, such as infrared sensors4, thermistors22, switches23, and neuromorphic elements24, because it induces a phase transition in a convenient temperature range above room temperature and changes electrical resistance by three orders of magnitude25. In a study of VO2 using a three-terminal device, the phase transition of the VO2 channel could be continuously controlled from the insulating state to the metallic state by applying a gate voltage near the transition temperature via TiO2 gate dielectrics15,16. Here, we found that scaling down the VO2 channel to the sub-μm scale resulted in a completely binary switching behavior instead of a continuous transition. The scaling-down effect was also successfully simulated by the phase transition transistor model, and the critical channel length could be explained by the phase boundary energy. Below the critical channel length, the spatial degrees of freedom of the channel degenerated, and the effect of drain voltage on the phase transition was nullified, showing zero-dimensionality as one of the most fundamental properties of scaled-down phase transitions.

Materials and methods

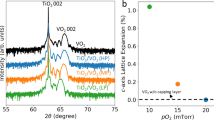

A schematic diagram of the fabricated device is shown in Fig. 1b. A 6 nm VO2 thin film was epitaxially grown on the Nb-doped TiO2 substrate and patterned as a channel. The source and drain electrodes were fabricated with the channel length (L = 240 or 490 nm) and the channel width (W = 600 nm), as shown in the atomic force microscope image in Fig. 1c. As shown in the band diagram in Fig. 1d, the Nb-doped TiO2 substrate was the gate electrode, and its interface region with the VO2 channel was depleted by several tens of nanometers, which could be viewed as a gate dielectric layer that isolates the gate from the channel. When a positive voltage was applied on the gate, the depletion layer expanded, and electrons accumulated in the VO2 channel, which could induce a metallic transition. The accumulated electron density with respect to VG = 0 V could be estimated as 1.9 × 1013 cm−2 at a VG of 1 V and 4.4 × 1013 cm−2 at a VG of 3 V (ref. 16). The relative dielectric constant of TiO2 (perpendicular to the (101) plane) was approximately 111, which was much higher than that of SiO2 or high-k materials15. The depletion layer rather than the entire substrate was used as the gate insulator. These two factors enabled the accumulation of a large number of electrons in our solid-state device, which was a unique characteristic of our device.

Methods

Device fabrication

A 6 nm VO2 thin film was epitaxially grown on a Nb 0.05 wt% doped TiO2 (101) substrate via pulsed laser deposition. The Au electrodes for the source and the drain were formed via e-beam lithography and lift-off. Then, a resist mask of the VO2 pattern was created, and the VO2 was etched with 0.4 M NaIO4 solution. As shown in the atomic force microscope image in Fig. 1c, the width of the Au electrode near the VO2 channel W is 600 nm, and the distance between the Au electrodes L is 240 nm or 490 nm for two different devices.

Results

Transfer characteristics

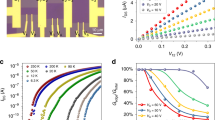

Figure 2 shows the temperature dependence and transfer characteristics of several devices with different channel lengths L. Figures 2a and 2d show the results for an L of 240 nm, and Figs. 2b and 2e show the results for an L of 490 nm. For comparison, the characteristics for the L of 50 μm device in ref. 16 are also shown in Figs. 2c and 2f with permission. As shown in Fig. 2a-c, the temperature dependence of the VO2 channel showed that there was a steep resistance change at approximately 320 K, irrespective of the L values. However, the temperature step of the measurement could not be lower than 50 mK due to temperature fluctuations, and the detailed L dependence could not be evaluated. Therefore, we set the temperature near the transition point and measured the gate voltage dependence, which achieved much higher accuracy. Figure 2f shows the drain current (ID) vs. the gate voltage (VG) for an L of 50 μm (W = 35 μm). The 10 mV step in VG corresponded to a 3 mK step in temperature15,16 and showed that the transition was essentially continuous (see the plot for 0.03 V drain voltage (VD)), although it was steep in the temperature dependence. This continuous transition meant that the channel size was sufficiently larger than the domain size of the phase transition, and the averaged characteristics of many domains with different transition temperatures were observed. Moreover, Fig. 2d shows ID vs. VG for the L of 240 nm device. The drain current jumped discontinuously even with high-precision measurement via VG (see the plot of VD = 0.0002 V). This results indicated that the domain size of the phase transition was comparable to the channel length, and the entire VO2 channel collectively metallized. In the L of 490 nm device (VD = 0.004 V), a partial discontinuity was observed, with a continuous resistance change at the same time. This result occurred because the channel size was slightly larger than the domain size of the phase transition and two types of extreme characteristics were mixed. Thus, the gate voltage dependence successfully elucidated the miniaturization effect in detail.

a–c Temperature dependence of the drain current (ID) in the three-terminal devices with different channel lengths (L), 240 nm, 490 nm, and 50 μm, respectively. The gate voltage (VG) is set to zero, and the drain voltages (VD) are set to 0.02 V, 0.02 V, and 0.005 V, respectively. d–f Transfer characteristics (ID vs. VG) and gate leakage characteristics (IG vs. VG) of the three-terminal devices with different L values. Panel f is adapted from ref. 16 with permission (license number 5438180614733). The measurement temperatures are 322.8 K, 322.8 K, and 323.5 K, respectively.

Although the use of a three-terminal device enabled highly precise control of the phase transition, the effect of VD, which was unique to three-terminal devices, needed to be considered correctly. From Fig. 2f, the transfer characteristics significantly changed as VD increased, and the continuous transition became discontinuous above a VD of 0.3 V. The origin of this discontinuity was investigated in detail in a previous paper13, which found that the gate-induced metallic transition triggered the positive feedback of Joule heating under the application of a large VD and resulted in a discontinuous transition. However, in the scaled-down VO2 channel (Fig. 2d), the effect of VD was almost negligible because in miniaturized devices, the metallic transition collectively proceeded throughout the VO2 channel, without the capacity for the positive feedback of Joule heating. In fact, the threshold VG for the metallic transition in Fig. 2d hardly changed with increasing VD. Thus, the metallic transition, which was initiated by the gate voltage, spread across the entire channel due to the collective nature of the phase transition. In other words, the spatial degree of freedom of the channel was degenerated, and the effect of the drain voltage was nullified, leading to a simple binary ON-OFF operation.

Simulation for intermediate channel length

In the case of the L of 490 nm device in Fig. 2e, the characteristics of continuous and discontinuous transitions were mixed, and the effect of VD was more complicated. To verify whether the characteristics for L = 490 nm were consistent with the phase transition transistor model16, we performed simulations, as shown in Fig. 3. Although the accurate domain structure was unknown, we divided the VO2 channel into three areas, and Fig. 3a shows an example to approximately reproduce the main features in Fig. 2e. Based on the characteristics for the sufficiently small VD (0.004 V) in Fig. 3b, three following assumptions were made: Area 1 had a relatively low transition temperature and showed a continuous transition, Area 2 underwent a discontinuous collective transition after the metallization of Area 1, and Area 3 exhibited multiple discontinuous transitions after the metallization of Area 2. With these assumptions, we could approximately reproduce the main features of the experimental data, as shown in Figs. 3c, 3d, and 3e (pink dots). See Fig. S2 in the Supplementary Information for more details. In the simulated plot, the negative transconductance region was observed where ID increased as VG decreased. This region was actually unstable against fluctuations and led to a discontinuous jump, as observed in the experimental data16. Thus, the seemingly complex transfer characteristics at L = 490 nm could be understood as an intermediate between two extreme limits.

a Simulation conditions with three different areas in the L = 490 nm VO2 channel. The following assumptions are made: Area 1 has a relatively low transition temperature and shows a continuous transition, Area 2 undergoes a discontinuous collective transition after the metallization of Area 1, and Area 3 exhibits multiple discontinuous transitions after the metallization of Area 2. Our proposed domain structure is just one of the various possible domain structures reproducing the experimental data. b Experimental data of the transfer characteristics at VD = 0.004 V. The transfer curve is divided into three VG regions (blue, green, and red shadows), and the ID variation in each region is attributed to the metallic transition in Areas 1, 2, and 3, respectively. c, d, e Experimental data (mark) and simulated data (pink dot) of the transfer characteristics at VD = 0.02 V, 0.1 V, and 0.5 V, respectively.

Discussion

The phase diagrams of the VO2 channel for different L values are summarized in Figs. 4a and 4b. In the long channel (Fig. 4b), a continuous transition governed by spatial heterogeneity was observed, while a discontinuous transition occurred with an increased VD. However, in the scaled-down channel (Fig. 4a), the discontinuous transition was originally achieved, and no change was observed with the increase in VD. Specifically, the behavior of the scaled-down three-terminal device was simplified to a binary ON/OFF switching operation regardless of the magnitude of VD.

The behavior of the gate-induced phase transition is shown for channel lengths L and the drain voltage VD in Fig. 4c. The heterogeneous continuous transition and the collective binary transition were separated by the critical channel length LC, which could be regarded as the static domain size of the phase transition. According to the past literature7, the static domain size depended on two competing factors: heterogeneity (spatial fluctuations of free energy) and domain boundary energy. The heterogeneity could be inferred from the transition width of the long channel device as ΔTMIT ~ 0.15 K in terms of temperature. Then, the heterogeneity in terms of free energy could be calculated as SMITΔTMIT, where SMIT is the entropy difference between the metallic phase and the insulating phase; this was reported to be 9 × 105 JK−1m−2 (ref. 26). For the domain boundary energy Eb, a value of 0.03 Jm−2 was used as a reference27,28. Then, the critical channel length (or domain size) was approximately given by the ratio of these two factors as LC = Eb/(SMITTMIT) (ref. 28). This equation could be interpreted in the following way: a larger Eb correlated to a larger domain size (LC) due to the suppression of domain boundary formation and a larger heterogeneity (TMIT) correlated to a smaller LC due to the potential for an individual transition at each location. This equation led to an LC of 340 nm and was consistent with the experimental results. Specifically, the scaled-down VO2 channel underwent a collective transition due to the instability of the phase boundary.

Conclusion

In summary, we evaluated the metal-insulator transition of a scaled-down VO2 channel using a three-terminal device that enabled electrical control with high precision. The results showed a crossover from a continuous transition to a simple binary transition with the scaled-down material. This observation was only possible due to the extreme high precision of the three-terminal control; in the temperature control, the transition of the VO2 channel appeared to be steep regardless of the channel length due to its coarse precision. The spatial degree of freedom in the channel was found to degenerate with miniaturization, and the impact of drain voltage application disappeared in the phase transition. This meant that the channel effectively became zero-dimensional, which was a unique property of the scaled-down phase transitions. Zero-dimensionality of phase transitions, which nullified some of the applied stimuli, could facilitate the development of state-of-the-art devices and materials, delivering a significant impact on a wide range of science and engineering.

Data availability

The data that support the findings of this study are available from the authors upon reasonable request.

References

Yuasa, S., Nagahama, T., Fukushima, A., Suzuki, Y. & Ando, K. Giant room-temperature magnetoresistance in single-crystal Fe/MgO/Fe magnetic tunnel junctions. Nat. Mater. 3, 868–871 (2004).

Scott, J. F. & Araujo, C. A. P. Ferroelectric memories. Science 246, 1400–1405 (1989).

Kim, S.-W., Seo, D.-H., Ma, X., Ceder, G. & Kang, K. Electrode materials for rechargeable sodium-ion batteries: potential alternatives to current lithium-ion batteries. Adv. Energy Mater. 2, 710–721 (2012).

Jerominek, H. et al. Micromachined uncooled VO2-based IR bolometer arrays. Proc. Infrared Detect. Focal Plane Arrays Iv. 2746, 60–71 (1996).

Tuma, T., Pantazi, A., Gallo, M. L., Sebastian, A. & Eleftheriou, E. Stochastic phase-change neurons. Nat. Nanotech. 11, 693–699 (2016).

Song, Y., Chen, X., Dabade, V., Shield, T. W. & James, R. D. Enhanced reversibility and unusual microstructure of a phase-transforming material. Nature 502, 85–88 (2013).

Yajima, T., Ninomiya, Y., Nishimura, T. & Toriumi, A. Drastic change in electronic domain structures via strong elastic coupling in VO2 films. Phys. Rev. B. 91, 205102 (2015).

Cowburn, R. P., Koltsov, D. K., Adeyeye, A. O., Welland, M. E. & Tricker, D. M. Single-domain circular nanomagnets. Phys. Rev. Lett. 83, 1042–1045 (1999).

Lopez, R., Haynes, T. E., Boatner, L. A., Feldman, L. C. & Haglund, R. F. Jr Size effects in the structural phase transition of VO2 nanoparticles. Phys. Rev. B. 65, 224113 (2002).

Zhai, H.-Y. et al. Giant discrete steps in metal-insulator transition in perovskite manganite wires phys. Phys. Rev. Lett. 97, 167201 (2006).

Krause, S. et al. Magnetization reversal of nanoscale islands: how size and shape affect the arrhenius prefactor. Phys. Rev. Lett. 103, 020404 (2014).

Sinwani, O., Reiner, J. W. & Klein, L. Monitoring superparamagnetic Langevin behavior of individual SrRuO3 nanostructures. Phys. Rev. B. 89, 100403 (2012).

Tsuji, Y., Kanki, T., Murakami, Y. & Tanaka, H. Single-step metal–insulator transition in thin film-based vanadium dioxide nanowires with a 20 nm electrode gap. Appl. Phys. Exp. 12, 025003 (2019).

Ahn, C. H., Triscone, J.-M. & Mannhart, J. Electric field effect in correlated oxide systems. Nature 424, 1015–1018 (2003).

Yajima, T., Nishimura, T. & Toriumi, A. Positive-bias gate-controlled metal–insulator transition in ultrathin VO2 channels with TiO2 gate dielectrics. Nat. Commun. 6, 10104 (2015).

Yajima, T. & Toriumi, A. Observation of the Pinch-Off Effect during Electrostatically Gating the Metal-Insulator Transition. Adv. Elec. Mater. 8, 2100842 (2021).

Eblen-Zayas, M., Bhattacharya, A., Staley, N. E., Kobrinskii, A. L. & Goldman, A. M. Ambipolar gate effect and low temperature magnetoresistance of ultrathin La0.8Ca0.2MnO3 films. Phys. Rev. Lett. 94, 037204 (2005).

Bollinger, A. T. et al. Superconductor–insulator transition in La2 2 xSrxCuO4 at the pair quantum resistance. Nature 472, 458–460 (2011).

Nakano, M. et al. Collective bulk carrier delocalization driven by electrostatic surface charge accumulation. Nature 487, 459–462 (2012).

Jeong, J. et al. Suppression of metal-insulator transition in VO2 by electric field–induced oxygen vacancy formation. Science 339, 1402–1405 (2013).

Sasaki, T., Ueda, H., Kanki, T. & Tanaka, H. Electrochemical gating-induced reversible and drastic resistance switching in VO2 nanowires. Sci. Rep. 5, 17080 (2015).

Yajima, T., Tanaka, T., Samata, Y., Uchida, K. & Toriumi, A. High-speed low-energy heat signal processing via digital-compatible binary switch with metal-insulator transitions. IEEE Int. Electron Devices Meet. 19, 903–906 (2019).

Zhou, Y. & Ramanathan, S. Mott memory and neuromorphic devices. Proc. Ieee. 103, 1289–1310 (2015).

Yi, W. et al. Biological plausibility and stochasticity in scalable VO2 active memristor neurons. Nat. Commun. 9, 4661 (2018).

Morin, F. J. Oxide which show a metal-to-insulator transition at the Neel temperature. Phys. Rev. Lett. 3, 34–36 (1959).

Park, J. H. et al. Measurement of a solid-state triple point at the metal–insulator transition in VO2. Nature 500, 431–434 (2013).

Wu, J. et al. Strain-induced self organization of metal-insulator domains in single-crystalline VO 2 nanobeams. Nano Lett. 6, 2313–2317 (2006).

Yajima, T., Nishimura, T. & Toriumi, A. Identifying the collective length in VO2 metal–insulator transitions. Small 13, 1603113 (2017).

Acknowledgements

This research was supported by JSPS KAKENHI 20H02615 and was also partially supported by the Japan Science and Technology Agency (Grant No. JPMJCR19K2).

Author information

Authors and Affiliations

Contributions

T.Y. and Y.S. performed device fabrication, measurements, and analyses. T.Y. performed the simulation, and S.H., S.P.P., and A.T. contributed to planning and discussion.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yajima, T., Samata, Y., Hamasuna, S. et al. Zero-dimensionality of a scaled-down VO2 metal-insulator transition via high-resolution electrostatic gating. NPG Asia Mater 15, 39 (2023). https://doi.org/10.1038/s41427-023-00486-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41427-023-00486-9