Abstract

Tin selenide (SnSe) is considered a robust candidate for thermoelectric applications due to its very high thermoelectric figure of merit, ZT, with values of 2.6 in p-type and 2.8 in n-type single crystals. Sn has been replaced with various lower group dopants to achieve successful p-type doping in SnSe with high ZT values. A known, facile, and powerful alternative way to introduce a hole carrier is to use a natural single Sn vacancy, VSn. Through transport and scanning tunneling microscopy studies, we discovered that VSn are dominant in high-quality (slow cooling rate) SnSe single crystals, while multiple vacancies, Vmulti, are dominant in low-quality (high cooling rate) single crystals. Surprisingly, both VSn and Vmulti help to increase the power factors of SnSe, whereas samples with dominant VSn have superior thermoelectric properties in SnSe single crystals. Additionally, the observation that Vmulti are good p-type sources observed in relatively low-quality single crystals is useful in thermoelectric applications because polycrystalline SnSe can be used due to its mechanical strength; this substance is usually fabricated at very high cooling speeds.

Similar content being viewed by others

Introduction

The efficiency of thermoelectric devices is evaluated by the dimensionless figure of merit of the material, ZT = S2σT/κ, where S is the Seebeck coefficient, σ is the electrical conductivity, κ is the total thermal conductivity, and T is the absolute temperature. σ, S, and κ are interdependent quantities. To date, effort has been made to enhance ZT by increasing the power factor (PF = S2σ) by band engineering1,2,3 and by reducing κ by increasing the phonon scattering centers in superlattices, alloys, nanowires, nanotubes, other nanostructures2 and mixed phase structures4,5,6 such as nanostructured Bi2Te37, Na-doped PbTe8 (PbSe9), and Bi2Te3/Sb2Te3 superlattices10. However, these state-of-the-art thermoelectric materials contain elements that are rare and toxic. Therefore, over the past few decades, researchers have focused on finding alternative thermoelectric materials that are economically and environmentally friendly. In addition, controlling the intrinsic point defects in a semiconductor is an important strategy for tuning its electronic and thermoelectric properties. Since the defect chemistry in a semiconductor is dependent on both its intrinsic properties and its external conditions, controlling point defects to enhance thermoelectric performance is challenging11. It has been reported that Ag dopants help to suppress Te vacancies due to the increase in electron chemical potential, while Na dopants help to enhance the hole concentration in p-type PbTe, leading to an enhancement in PF and a simultaneous reduction in thermal conductivity12. The number of intrinsic vacancies can be controlled by tuning their formation energy. The Ge vacancy concentration and distribution have been successfully controlled by introducing Cr dopants into the GeTe matrix, which helps to reduce the Ge vacancy formation energy, while the carrier concentration remains optimized13. Similarly, the generation of many Sn vacancies in p-type SnTe has been successfully suppressed by Pb alloying to enhance the defect formation energy14. The vacancy concentration in half-Heuslers has also been controlled using doping/alloying experiments, whereas different dopants lead to different vacancy concentrations15.

Since the report of ZT = 2.6 in p-type SnSe16, SnSe has attracted significant attention. The high thermoelectric performance of undoped SnSe is attributed to its ultralow κ (< 0.4 Wm−1K−1 at 923 K) caused by the strong anharmonicity of its chemical bonds17,18. The most frequently used method of optimizing the carrier concentration of SnSe has been to replace Sn with various dopants (substitution). For p-type SnSe, alkali metals (e.g., Na19,20,21 and K22), I–B group metals (e.g., Ag4,20,23), and III-A group metals (e.g., In24) were used as acceptors. Recently, carbon fiber has been used to decouple the electrical and thermal transport in p-type polycrystalline SnSe, resulting in a ZT value of 1.3 at 823 K25. For n-type SnSe, V–A group metals (e.g., Bi26,27) and halogens (e.g., Cl, Br, and I5,28,29) were used as donors. However, it is fairly difficult to dope SnSe due to its anharmonic bonds4. The difficulty in doping SnSe limits the potential to explore its higher thermoelectric performance30. Thus far, it is still difficult to use SnSe in practical applications since the high cost production, weak mechanical and cleavable properties of SnSe single crystals, and the low performance of polycrystalline SnSe are attributed to the presence of a SnO2 layer at the grain boundary31.

It is well known that SnSe intrinsically shows a p-type character. Our previous studies confirmed that the p-type nature of SnSe is attributed to a single Sn vacancy (VSn), implying that VSn works as a hole provider32,33,34,35. We speculated that the growth speed can control the quality of the samples, i.e., the number of material defects, and thus control the natural amount of VSn during the growth process. A systematic study on intrinsic defects in SnSe is necessary for optimum thermoelectric performance, which should be done in single crystal form. SnSe single crystals have been fabricated at various growth speeds by changing the cooling rate near the melting point of SnSe (861 °C) from 0.5 to 5 °C/h during growth using a temperature gradient technique27. We found that as the cooling rate increased, the dominant defect changed from a VSn at cooling rates of 0.5 and 1 °C/h to multiple vacancies, Vmulti, containing more than one Sn (Se) atom missing, at cooling rates of 2–5 °C/h. Surprisingly, not only VSn-dominant samples but also Vmulti-dominant samples showed p-type conduction with PFs comparable to those in previous reports16,27. Based on our results, the slow cooling rate is beneficial for the thermoelectric performance of SnSe single crystals.

The polycrystalline SnSe has high mechanical strength and can be used in thermoelectric applications. The observation that the Vmulti are good p-type sources in high cooling rate SnSe crystals is really important information for the thermoelectric application because polycrystalline SnSe which is usually fabricated at very high cooling rates can be used due to its high mechanical strength.

Materials and methods

Sample preparation

The SnSe samples were synthesized by a temperature gradient technique by heating the raw materials to 500 °C over 32 h and then to 950 °C over 45 h, soaking at this temperature for 15 h, cooling to 900 °C over 10 h, then cooling to 800 °C across the melting point of SnSe (861 °C) at various cooling rates (0.5, 1, 2, 3, 4, and 5 °C/h), and finally cooling to room temperature over 100 h. We used a slow heating rate to prevent explosion due to the high vapor pressure of Se.

Sample characterizations

We determined the carrier concentrations of the samples using a four-probe method. The values of σ and S were measured from 300 to 923 K using a ULVAC-RIKO ZEM3 system. The thermal diffusivities, D, were measured with a Netzsch LFA-457 (Germany) MicroFlash apparatus. The heat capacities, Cp, were obtained from ref. 11. The values of κ were calculated using the formula κ = DCpρ, where ρ is the mass density (measured by the Archimedes method). STM was conducted at 79 K with an in situ cleaving technique. X-ray diffraction (XRD), field emission scanning electron spectroscopy (FE-SEM), and electron probe microanalyzer experiments were used to investigate the structure, composition, and morphology of the samples.

Results and discussion

Structural characterization

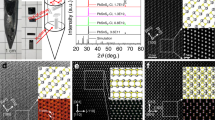

Figure 1a shows a photo of SnSe, which can be easily cleaved along the (bc) plane due to weak interlayer bonding. Our samples exhibit a lamellar microstructure, as shown in FE-SEM images (see Fig. S1a). Room temperature X-ray diffraction (XRD) patterns of cleaved planes of SnSe single crystals are shown in Fig. 1b, where all diffraction peaks can be indexed corresponding to the orthorhombic SnSe phase (space group Pnma). Only sharp (h00) peaks are observed, indicating the high crystallinity of our samples with the cleaved plane perpendicular to the a-axis. The lattice parameters of the samples were determined using powder XRD and are listed in Table 1.

Thermoelectric transport studies

Figure 2a–c shows the temperature dependence of σ, S, and PF of various SnSe single crystals prepared at 6 different cooling rates. All the samples had similar σ values in the mid-temperature range, while their σ values differed in the low- and high-temperature ranges. At temperatures ranging from 300 to 570 K, the σ of samples prepared at 5 °C/h increased with temperature, while those of other samples decreased. Above 570 K, σ of all the samples increased up to ~800 K, reached a maximum value at 876 K, and then decreased with temperature. The maximum σ values were 93.5, 85.8, 94.2, 91.4, 75.3, and 70.4 S cm−1 for samples prepared with cooling rates of 0.5, 1, 2, 3, 4, and 5 °C/h, respectively, comparable to the reported value (~ 85 S cm−1)17. The ln(σ) vs. 103/T curves of all samples showed two different slopes. The sample prepared with a cooling rate of 5 °C/h had two different negative slopes, while the other samples had positive slopes below 570 K and negative slopes above 570 K, indicating the complex activation energies of the carriers. These variations in σ vs. temperature up to 800 K were attributed to complex thermally activated carriers and/or activation energies or carrier mobilities. The behavior of σ above 800 K was attributed to the phase transition from Pnma (Eg = 0.829 eV) to Cmcm (Eg = 0.464 eV).

Temperature dependence (a–c) and cooling rate dependence at selected temperatures (d–f) of electrical conductivity (σ), Seebeck coefficient (S), and thermoelectric power factors (PF) of SnSe single crystals along the b-axis. The inset of a shows ln(σ) vs. 103/T curves for all samples. The inset of b shows the Hall data of all samples at 300 K.

All samples had positive S values over the whole temperature range, indicating dominant hole conduction. The value of S increased with increasing temperature up to 520 K, then decreased as the temperature was increased to 876 K, and finally increased again at temperatures above 876 K (Fig. 2b). This behavior of S is consistent with that of σ. The S values of all samples also deviated in the low temperature range (530–612 µV/K at 300 K) but were more consistent at higher temperatures. The positive hole conduction behavior was confirmed by Hall measurements, with a carrier concentration level of 1017 cm−3 at room temperature for all samples (inset of Fig. 2b, Fig. S7a, and Table 1).

The calculated PF showed a similar temperature dependence on σ (Fig. 2c). Deviating PF values were obtained at low and high temperature ranges, while closer PF values were obtained in the middle temperature range. The obtained maximum PF values were 11.2, 8.1, 10.2, 9.0, 8.2, and 7.4 µWcm−1K−2 at 876 K for samples prepared with cooling rates of 0.5, 1, 2, 3, 4, and 5 °C/h, respectively, comparable to the reported value (10.1 µWcm−1K−2)17. The samples prepared at 0.5 and 2 °C/h had similar values.

To clarify the influence of the cooling rate on transport properties, we plotted the cooling-rate-dependent transport parameters at selected temperatures, as shown in Fig. 2d–f. The cooling rate had less effect on σ at 567, 617, and 669 K. At low and high temperatures (< 567 K and > 669 K), σ varied differently with cooling rate for samples with cooling rates ≤ 1 °C/h (region I) vs. > 2 °C/h (region II). In Fig. 2d–f, these two regions are separated by a black dashed line. The value of S had a strong cooling rate dependence at low temperatures and a lower cooling rate dependence at moderate and high temperatures. S also varied differently with cooling rate in regions I and II. As a result, the calculated PFs exhibited two distinct trends with cooling rate. The cooling rate had a strong effect on the PFs at low and high temperatures, while it had less of an effect at intermediate temperatures. These observations indicate a discontinuity in the transport parameters vs. cooling rate. To verify these results, we grew five different single crystals at a cooling rate of 1 °C/h and studied their transport properties (Fig. S2). These samples confirmed the presence of the discontinuity in transport vs. cooling rate in SnSe single crystals, as clearly denoted by the solid lines in the figures.

STM microscopic studies

To understand the discontinuity behavior in transport data, we conducted scanning tunneling microscopy (STM) measurements to investigate the defect characteristics of these samples. All samples were exfoliated inside an ultrahigh vacuum chamber to obtain clean surfaces for STM analysis. All STM analyses were conducted at 79 K. Figure 3a–d shows STM images taken from the same samples with cooling rates of 0.5, 1, 2, and 5 °C/h. Many defects were observed in all samples, as shown in Fig. 3a–d. Intriguingly, the nature of the defects differed strikingly between the samples in region I (cooling rate of 0.5–1 °C/h) and region II (cooling rate of 2–5 °C/h). VSn is usually known to be dominant among various types of defects, and VSn is also responsible for the p-type characteristic of SnSe32. Indeed, VSn is predominantly observed in the samples prepared with a cooling rate of 0.5–1 °C/h. Figure 3e(i, ii) shows atomistic images of representative VSn instances taken from the marked areas of (i, ii) in Fig. 3a,b. In the STM topography, Sn atoms were visible as bright spots, while Se atoms were located in dark regions and were not visible32.

a–d STM images of SnSe single crystals prepared with cooling rates of 0.5, 1, 2, and 5 °C/h; e atomistic images of a representative defect in each sample taken from the marked areas of (i–iv) of (a–d). Imaging conditions: a Vb (sample bias) = −1.5 V, and It (tunneling current) = 30 pA; b Vb = −2 V, and It = 30 pA; c Vb = −1.5 V, and It = 30 pA; d Vb = −1.4 V, and It = 30 pA.

Interestingly, the samples prepared at 2–5 °C/h (region II) revealed a very different defect nature in which the dominant defects were complex vacancies consisting of more than one Sn atom vacancy. These instances of Vmulti were present in various sizes and shapes, as shown in Fig. 3e (iii, iv), taken from area (iii, iv) in Fig. 3c, d. More examples of those defects in the region I and II samples are also provided in Fig. S5. With the increase in solidification speed (cooling rate) above 2 °C/h, multi-vacancies are dominant, and the size of the multi-vacancies increases. We conclude that the electrical properties of the region II samples were mainly caused by Vmulti, while VSn played the major role in the region I samples. Therefore, the discontinuity observed in the transport in Fig. 2 was attributed to the change in defect characteristics from VSn in high-quality single crystals (region I) to Vmulti in relatively low-quality single crystals (region II). As shown in Fig. 2, the region II samples had p-type PF values (10.2 µWcm−1K−2) that were comparable to those of the region I samples (11.2 µWcm−1K−2), indicating that the Vmulti, dominant in the region II samples, also worked as a good acceptors for producing the hole carriers required for thermoelectric performance.

Conclusions

We introduced an alternative, facile, and much more powerful method via the engineering of vacancies to introduce hole carriers in SnSe. With the help of transport and STM studies, we discovered that VSn are dominant in high-quality SnSe single crystals, while Vmulti are dominant in low-quality single crystals. Surprisingly, both VSn and Vmulti are good p-type sources in SnSe with comparable PF values. The Vmulti become the dominant and p-type source when the cooling rate increases, which is expected in polycrystalline SnSe. This information provides a deeper understanding of the nature of the defects in SnSe.

References

Liu, W. et al. Convergence of conduction bands as a means of enhancing thermoelectric performance of n-type Mg2Si1–xSnx solid solutions. Phys. Rev. Lett. 108, 1–5 (2012).

Pei, Y. et al. Convergence of electronic bands for high performance bulk thermoelectrics. Nature 473, 66–69 (2011).

Girard, S. N. et al. High performance Na-doped PbTe–PbS thermoelectric materials: Electronic density of states modification and shape-controlled nanostructures. J. Am. Chem. Soc. 133, 16588–16597 (2011).

Chen, C.-L., Wang, H., Chen, Y.-Y., Day, T. & Snyder, G. J. Thermoelectric properties of p-type polycrystalline SnSe doped with Ag. J. Mater. Chem. A 2, 11171–11176 (2014).

Zhang, Q. et al. Studies on Thermoelectric Properties of n-type Polycrystalline SnSe1–xSx by Iodine Doping. Adv. Energy Mater. 5, 1–8 (2015).

Tang, G. et al. Rock-salt-type nanoprecipitates lead to high thermoelectric performance in undoped polycrystalline SnSe. RSC Adv. 7, 8258–8263 (2017).

Son, J. S. et al. N-type nanostructured thermoelectric materials prepared from chemically synthesized ultrathin Bi2Te3 nanoplates. Nano Lett. 12, 640–647 (2012).

Jood, P. et al. Na doping in PbTe-solubility, band convergence, phase boundary mapping, and thermoelectric properties. J. Am. Chem. Soc. 142, 15464–15475 (2020).

Wang, H., Pei, Y., Lalonde, A. D. & Snyder, G. J. Heavily doped p-type PbSe with high thermoelectric performance: An alternative for PbTe. Adv. Mater. 23, 1366–1370 (2011).

Venkatasubramanian, R., Siivola, E., Colpitts, T. & O’Quinn, B. Thin-film thermoelectric devices with high room-temperature figures of merit. Nature 413, 597–602 (2001).

Liu, Z. Shaping the role of germanium vacancies in germanium telluride: Metastable cubic structure stabilization, band structure modification, and stable N-type conduction. NPG Asia Mater. 12, 66 (2020).

Jang, H. et al. Regulating Te vacancies through dopant balancing via excess Ag enables rebounding power factor and high thermoelectric performance in p-type PbTe. Adv. Sci. 8, 2100895 (2021).

Shuai, J., Sun, Y., Tan, X. & Mori, T. Manipulating the Ge vacancies and Ge precipitates through Cr doping for realizing the high-performance GeTe thermoelectric material. Small 16, 1906921 (2020).

Pang, H. et al. Realizing N‑type SnTe thermoelectrics with competitive performance through suppressing Sn vacancies. J. Am. Chem. Soc. 143, 8538–8542 (2021).

Maclaren, D. A. & Bos, J. G. Low thermal conductivity and promising thermoelectric performance in AxCoSb (A = V, Nb or Ta) half-Heuslers with inherent vacancies. J. Mater. Chem. C 7, 6539–6547 (2019).

Zhao, L.-D. et al. Ultralow thermal conductivity and high thermoelectric figure of merit in SnSe crystals. Nature 508, 373–377 (2014).

Lee, S. et al. Resonant bonding leads to low lattice thermal conductivity. Nat. Commun. 5, 1–8 (2014).

Li, C. W. et al. Orbitally driven giant phonon anharmonicity in SnSe. Nat. Phys. 11, 1063–1069 (2015).

Zhao, L. et al. Ultrahigh power factor and thermoelectric performance in hole- doped single-crystal SnSe. Science 351, 141–144 (2016).

Peng, K. et al. Broad temperature plateau for high ZTs in heavily doped p-type SnSe single crystals. Energy Environ. Sci. 9, 454–460 (2016).

Wei, T.-R. et al. Thermoelectric transport properties of pristine and Na-doped SnSe1−xTex polycrystals. Phys. Chem. Chem. Phys. 17, 30102–30109 (2015).

Wei, T. R. et al. Distinct impact of alkali-ion doping on electrical transport properties of thermoelectric p-type polycrystalline SnSe. J. Am. Chem. Soc. 138, 8875–8882 (2016).

Jin, M. et al. Single crystal growth of Sn0.97Ag0.03Se by a novel horizontal Bridgman method and its thermoelectric properties. J. Cryst. Growth 460, 112–116 (2017).

Kim, J. H. et al. Indium substitution effect on thermoelectric and optical properties of Sn1–xInxSe compounds. J. Alloy. Compd. 682, 785–790 (2016).

Yang, G. et al. Enhancing the thermoelectric performance of polycrystalline SnSe by decoupling electrical and thermal transport through carbon fiber incorporation. ACS Appl. Mater. Interfaces 12, 12910–12918 (2020).

Nguyen, V. Q. et al. Thermoelectric properties of hot-pressed Bi-doped n-type polycrystalline SnSe. Nanoscale Res. Lett. 13, 4–10 (2018).

Duong, A. T. et al. Achieving ZT=2.2 with Bi-doped n-type SnSe single crystals. Nat. Commun. 7, 1–6 (2016).

Wang, X. et al. Optimization of thermoelectric properties in n-type SnSe doped with BiCl3. Appl. Phys. Lett. 108, 1–6 (2016).

Chang, C. et al. Raising thermoelectric performance of n-type SnSe via Br doping and Pb alloying. RSC Adv. 6, 98216–98220 (2016).

Xiao, Y. & Zhao, L. D. Seeking new, highly effective thermoelectrics. Science 367, 1196–1197 (2020).

Zhou, C. et al. Polycrystalline SnSe with a thermoelectric figure of merit greater than the single crystal. Nat. Mater. 20, 1378–1384 (2021).

Duvjir, G. et al. Origin of p-type characteristics in a SnSe single crystal. Appl. Phys. Lett. 110, 262106 (2017).

Wu, D. et al. Direct observation of vast off -stoichiometric defects in single crystalline SnSe. Nano Energy 35, 321–330 (2017).

Zhou, Y. et al. Influence of defects on the thermoelectricity in SnSe: A comprehensive theoretical study. Phys. Rev. B 97, 1–8 (2018).

Huang, Y. et al. First-principles study on intrinsic defects of SnSe. RSC Adv. 7, 27612–27618 (2017).

Acknowledgements

This work was supported by the National Research Foundation of Korea [NRF-2019R1F1A1058473, NRF-2019R1A6A1A11053838, and NRF-2020K1A4A7A02095438].

Author information

Authors and Affiliations

Contributions

V.Q.N., T.H.N., and V.T.D. synthesized the single crystals and characterized the carrier concentration. V.Q.N., A.T.D., and S.C. determined the crystal structure. C.C., L.D.Z., J.H.P., and S.D.P. measured the thermoelectric transport and thermal diffusivity. T.T.L. and J.K. conducted the STM experiments. S.C. and J.K. initiated the study and edited the manuscript. V.Q.N. wrote the paper with discussions and comments from all the authors. S.C. supervised the project.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Nguyen, V.Q., Trinh, T.L., Chang, C. et al. Unidentified major p-type source in SnSe: Multivacancies. NPG Asia Mater 14, 42 (2022). https://doi.org/10.1038/s41427-022-00393-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41427-022-00393-5

This article is cited by

-

Enhanced thermoelectric performance of SnSe by controlled vacancy population

Nano Convergence (2023)