Abstract

This review focuses on the factors that determine the molecular weight of polyhydroxyalkanoate (PHA), an aliphatic polyester synthesized by bacteria for carbon and energy storage. PHA is a polymer with good thermoplastic, biodegradable, biocompatible and renewable properties. Therefore, it has attracted considerable attention as an environmentally friendly and biomedical material. Because the mechanical strength of PHA increases with its molecular weight, high-molecular-weight PHA polymers are preferred. The synthesis of high-molecular-weight PHA should consider the following factors: the concentration of PHA synthase, the occurrence of a chain transfer reaction, the catalytic activity of PHA synthase and the simultaneous degradation of PHA during biosynthesis. These factors have a direct impact on the molecular weight of PHA. Furthermore, the factors that affect the molecular weight of PHA during in vitro PHA polymerization and cultivation of PHA native and non-native bacteria are discussed.

Similar content being viewed by others

Introduction

Many bacterial species synthesize the aliphatic polyester polyhydroxyalkanoate (PHA) to store carbon and its reducing equivalents.1, 2, 3 Accumulated PHA accounts for ~30–50% of the dry weight of most bacterial cells. However, the well-known PHA producer Ralstonia eutropha (also known as Cupriavidus necator) is capable of accumulating PHA at over 90% of the dry cell weight. PHA accumulation is triggered by imbalances in nutrient conditions, such as excess carbon but limited nitrogen availability. PHA is degraded under starvation conditions to maintain cellular energy homeostasis. PHA has natural thermoplasticity in addition to biodegradability and biocompatibility, and it is produced from renewable biomass such as sugars and plant oils. Therefore, PHA has attracted attention not only as an environmentally friendly alternative to petroleum-based plastics but also as a biomedical material for surgical sutures or a scaffold for tissue engineering.

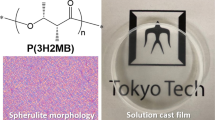

Microbial cells typically accumulate poly[(R)-3-hydroxybutyrate] (P(3HB)), a PHA that contains a repeating C4 monomeric unit. P(3HB) is a highly crystalline material with similar thermal properties to those of polypropylene, a commodity plastic produced from petroleum. The melting and glass-transition temperatures of P(3HB) are 177 and 4 °C, respectively.4 However, P(3HB) is typically quite brittle and less elastic (elongation at break=5%) than polypropylene (elongation at break=400%). The weight-average molecular weight (Mw) of P(3HB) synthesized by bacteria is generally in the range of 0.1–2.0 × 106. Ralstonia eutropha utilizes only three enzymes to synthesize P(3HB) from acetyl-coenzyme A (acetyl-CoA): 3-ketothiolase (PhaA, encoded by phaA), NADPH-dependent acetoacetyl-CoA reductase (PhaB, encoded by phaB) and PHA synthase (PhaC, encoded by phaC; Figure 1).5

Poly[(R)-3-hydroxybutyrate] (P(3HB)) biosynthesis from acetyl-coenzyme A and molecular-weight regulation with endogenous ethanol in E. coli.18

PHA with a high molecular weight is preferred because its mechanical strength is positively correlated with its molecular weight.6 Alternatively, the mechanical strength of ultrahigh-molecular-weight P(3HB) [UHMW-P(3HB)], which has a defined Mw>3.0 × 106 g mol−1,7 is much higher than that of P(3HB) because the long polymer chains are entangled; therefore, UHMW-P(3HB) can be used to develop high-strength fibers and films.6 The tensile strength and Young’s modulus of UHMW-P(3HB) fibers are 1.3 and 18.1 GPa, respectively, both of which are significantly higher than those of P(3HB) (Table 1). These high-molecular-weight PHAs are synthesized by controlling the factors involved in PHA polymerization; however, the precise mechanism remains unclear.

The production and applicability of PHA have been comprehensively reviewed by several researchers.1, 2, 3, 4, 6 The purpose of this review is to highlight recent advances in elucidating the factors affecting the molecular weight of PHA. Here, I propose four fundamental factors that are directly responsible for regulating the molecular weight of PHA.

PHA synthases

PHA synthases play a central role in PHA polymerization in the cell without the use of a template, unlike other biological macromolecules such as proteins and nucleotides. 3-Hydroxyacyl-CoA is the primary substrate of PHA synthase; specifically, only the R-enantiomer of 3-hydroxyacyl-CoA is polymerized by PHA synthase. PHA synthases polymerize the acyl moiety of the CoA substrate by releasing free CoA and generating long polyester chains that are stored as water-insoluble inclusions of PHA in cells.3, 8

PHA synthases are classified into four groups according to their substrate specificities and subunit compositions.8 Class I and II PHA synthases are composed of single subunits of PhaC (molecular mass=60–70 kDa) and contain a PhaC box sequence ([GS]-X-C-X-[GA]-G) in the active site.9 Class I PHA synthases, represented by the R. eutropha enzyme, mainly polymerize short-chain-length monomers (C3-C5), whereas class II PHA synthases, represented by the Pseudomonas oleovorans enzyme, polymerize medium-chain-length monomers (C6-C14). Although most class II PHA synthases do not accept the C4 monomer, some atypical synthases such as those produced by Pseudomonas sp. 61-3 and Pseudomonas stutzeri can polymerize the C4 monomer.10 Class III and IV PHA synthases, represented by the Allochromatium vinosum and Bacillus megaterium enzymes, respectively, consist of two heterosubunits. The catalytic subunit PhaC of class III and IV synthases (~40 kDa) requires the secondary subunits PhaE (~40 kDa) and PhaR (~20 kDa), respectively, for the full expression of the activity of PhaC.9

The molecular basis of PHA synthase has been extensively studied for the R. eutropha and A. vinosum PHA synthases. However, the X-ray crystal structure of PHA synthase remains unavailable because of difficulties in crystallizing the synthase.

Model of PHA polymerization

The PHA synthase-catalyzed polymerization reaction, referred to as a model for the chain polymerization system, is thought to include initiation, propagation and termination steps.11, 12, 13 The proposed polymerization reaction is described using class I PHA synthase as a model as follows (Scheme 1).

The PhaC subunit exists in an inactive (for PHA polymerization) water-soluble single form immediately after translation of the PhaC protein in the cell. During the initiation step, two PhaC subunits are dimerized to form an active enzyme when an (R)-3HB-CoA monomer approaches. The active site of this dimer reacts with (R)-3HB-CoA before undergoing a chain propagation reaction.14, 15, 16 The active site of PHA synthase consists of two thiol groups, the origins of which remain unclear. Two theories have been proposed: the thiol groups are provided by the cysteine residue of the PhaC box in each PhaC subunit, or the thiol groups are provided by the PhaC subunit and CoA, respectively.16 In the propagation step, one thiol group binds to the incoming 3HB monomer, while the other binds to the propagating polymer chain. Propagation proceeds by transferring the growing chain between the thiol groups. In the termination step, PHA synthase loses its capacity to polymerize. Alternatively, a chain transfer (CT) reaction occurs when the polymer chain is transferred to a CT agent, resulting in covalent binding of the CT agent to the carboxy terminal of the P(3HB) chain. Water, 3HB and some hydroxy compounds have been proposed as potential naturally occurring CT agents.11, 13

Evidence of a chain transfer reaction

A significant amount of effort has been devoted to understanding the CT reaction with respect to the polymer chain kinetics during PHA biosynthesis.11 Because the CT reaction occurs at the end of the polymerization reaction, it is one of the factors responsible for determining the molecular weight of PHA. The CT reaction decreases the average molecular weight of the polymer and increases the number of polymer chains synthesized. Thus, the PHA chain number NP (l−1) increases as a result of an increase in the CT reaction as follows:

where NE and NCT are the number of active PHA synthase sites involved in PHA polymerization (l−1) and number of CT reactions (l−1), respectively. The PHA chain number, NP, can also be calculated using the following equation:17

where Y, Mn and NA denote the yield of synthesized PHA (g l−1), number average molecular weight of synthesized PHA (g mol−1) and Avogadro’s constant (mol−1), respectively. Therefore, accurate estimation of NE facilitates kinetic analysis of the CT reaction.5, 11, 17, 18

The polymer chain is transferred to a CT agent in the CT reaction, resulting in covalent binding of the CT agent to the carboxy terminus of the PHA chain. Therefore, structural analysis of the carboxylic end of PHA may provide detailed information regarding the CT reaction. Nuclear magnetic resonance (NMR) is a powerful tool that can be used to determine the chemical structure of polymers. However, end-structure analysis of high-molecular-weight polymers by 1H- and 13C-NMR faces several limitations such as weak signals from the polymer end. Madden et al. 13 introduced a method wherein end-group analysis of PHA could be conducted using 31P-NMR by derivatizing the PHA with 2-chloro-4,4,5,5-tetramethyl-1,3,2-dioxaphospholane, which enabled the selective detection of the hydroxy and carboxylic ends of PHA. This analysis demonstrated that the carboxylic end of the P(3HB) produced by R. eutropha cells grown on glycerol was capped by glycerol, suggesting that glycerol is the target agent of the CT reaction.

Low-molecular-weight polyethylene glycols (PEGs) are well-known artificial CT agents.19, 20, 21, 22 The use of PEG as a CT agent causes a reduction in PHA molecular weight; this has been extensively studied in many PHA-producing bacteria such as R. eutropha19, 20 and P. oleovorans.21, 23 Moreover, 1H-NMR analysis of lower-molecular-weight PHA suggested that PEG is incorporated at the carboxy terminus of the polymer via the CT reaction between the growing PHA chain and PEG hydroxy group.20, 21 Because PEG is a synthetic polymer and not a bacterial compound, it can be used to study the CT reaction as an exogenous CT agent.24

Properties of chain transfer agents

The CT agent must contain at least one hydroxy group, as the CT reaction is a transesterification reaction between the hydroxy group of the CT agent and carboxy group of the growing polymer chain-PHA synthase complex. As mentioned previously, water, 3HB and some hydroxy compounds are potential naturally occurring CT agents.11, 13 There is little evidence regarding the direct involvement of water in the CT reaction. In particular, the effect of water on changes in the chain-termination reaction rate in an aqueous environment and the differences between the CT reaction and hydrolysis of the polymeric chain after biosynthesis remain unclear. 3HB is another potential CT agent, but it shows low efficacy.13 The frequency of the CT reaction can be increased by increasing the concentrations of CT agents.13, 24, 25

The efficacy of a CT agent is largely dependent on its molecular properties rather than on its concentration. A quantitative structure-activity relationship study revealed that hydroxy compounds with higher hydrophobicity exhibit higher efficacies as CT agents.26 The efficacies of less hydrophobic CT agents such as glycerol and PEG are relatively low compared with those of hydrophobic alcohols such as ethanol, propanol and butanol. The quantitative structure-activity relationship study also revealed that the efficacies of CT agents are not affected by the types of hydroxy groups (primary or secondary).26 However, the cellular uptake of exogenous CT agents depends on the hydrophobicity of the component; moreover, PHA synthases have structural limits for their acceptance of CT agents.26

Escherichia coli as a non-native PHA producer

PHA-native bacteria such as R. eutropha and P. oleovorans possess inherent PHA depolymerases that contribute to the mobilization of PHA; however, PHA degradation complicates the analysis of the molecular weight of synthesized PHA. Escherichia coli, a non-native PHA producer, has been used to study the CT reaction in vivo. The use of E. coli for studying the CT reaction in vivo is extremely advantageous because of the absence of PHA degradation enzymes27 and its well-developed genetic background. E. coli transformed with the biosynthetic genes phaCAB allows for the accumulation of P(3HB).5, 27

Unlike P(3HB) synthesized by native bacteria, P(3HB) synthesized by recombinant E. coli generally has a very high Mw of ~20 × 106 g mol−1.27, 28 This can be attributed to the lack of the CT reaction and PHA degradation during PHA biosynthesis. Recent studies have demonstrated that intracellular degradation of PHA affects the molecular weight of PHA in the native PHA producer R. eutropha. Deletion of several PHA depolymerase genes allows the production of high-molecular-weight PHA (Mw=3 × 106 g mol−1) in R. eutropha 29 as well as in recombinant E. coli. The simultaneous degradation of PHA may be a major factor determining the molecular weight of PHA in PHA-native bacteria.

Under CT reaction- and PHA degradation-free conditions, the concentration of PHA synthase controls the molecular weight of PHA, as observed for P(3HB) biosynthesis in recombinant E. coli.30, 31, 32 The molecular weight of PHA decreases with increasing PHA synthase concentrations. The same dependency has been observed in other studies using various types of recombinant E. coli.33, 34 PhaC likely forms an inclusion body when overexpressed in an E. coli host. Therefore, co-expression of molecular chaperones is effective for producing the active form of PHA synthase and can be used to control the synthase concentration.35

To improve the understanding of the CT reaction in E. coli, which harbors the minimum number of genes required for P(3HB) biosynthesis, the occurrence and progression of CT was evaluated using PEG as an exogenous CT agent.24 As a result, the carboxylic end of P(3HB) produced in the E. coli transformant was capped with PEGs, despite E. coli being a non-native PHA producer.24 This in vivo result indicates that PHA synthase directly reacts with the CT agent (PEG) without mediation by other native proteins involved in PHA metabolism. Furthermore, the yield of PEGylation (covalent attachment rate of the P(3HB) carboxy terminus to the PEG chain) was estimated to be as high as 88%. This suggests that the CT reaction in E. coli culture was mediated mainly by the external CT agent.

In contrast, kinetic analysis of P(3HB) revealed that the molecular weight of E. coli-synthesized P(3HB) remained nearly unchanged, whereas the number of polymer chains increased over time during P(3HB) accumulation.5 If P(3HB) were synthesized under CT reaction- and PHA degradation-free conditions, the molecular weight of the synthesized P(3HB) would increase over time, while the number of polymer chains would be independent of time. Therefore, termination with or without a CT agent occurred in E. coli cells under these culture conditions.5

Endogenous ethanol as CT agent in E. coli

As described above, the concentration of PHA synthase does not entirely account for the molecular weight of PHA synthesized in E. coli. Some studies have suggested that the CT reaction occurs in E. coli in the absence of exogenous CT agents.5, 18, 24, 33 The molecular weight of PHA is thought to be E. coli strain-dependent. For example, the molecular weights of PHA have been shown to differ when the derivative strains of E. coli K-12 used as hosts for PHA production were cultured under the same conditions.33 The XL1-Blue strain of E. coli is likely to produce high-molecular-weight PHA compared with the other previously reported strains.27, 33, 36

E. coli inherently produces relatively large amounts of ethanol under hypoxic and anaerobic conditions to maintain the cellular redox balance. Therefore, the E. coli strain-dependency of the PHA molecular weight may be explained by considering endogenous ethanol as a potential CT agent (Figure 1). High-molecular-weight PHA can be synthesized by ensuring sufficient culture aeration to facilitate cell growth while preventing ethanol production. This also demonstrates that the ethanol-producing ability of strain XL1-Blue was low and comparable to that of the alcohol dehydrogenase gene-deletion strain.18 Because of its low ethanol-producing ability, XL1-Blue tends to synthesize higher-molecular-weight PHA compared to other strains of E. coli.

Even when E. coli strains are cultured in the same concentration of ethanol, the molecular weights of PHA vary depending on the PHA synthase employed for PHA production. Among the PHA synthases examined to date, A. caviae synthase (PhaCAc) is the most sensitive to the effect of ethanol on the molecular weight of PHA,37 producing low-molecular-weight PHA even at low ethanol concentrations, although it has the potential to produce very high-molecular-weight PHA.29, 38 In contrast, Delftia acidovorans and Halomonas elongata synthases are less sensitive to ethanol, producing high-molecular-weight PHA in normal E. coli strains.34, 37, 39

Endogenous ethanol induces random alcoholytic cleavage of the PHA chain other than the CT reaction in the presence of class IV synthases such as B. cereus and B. megaterium synthases, in turn reducing the molecular weight of PHA and broadening the molecular-weight distribution during post-PHA synthesis.40, 41, 42, 43 This unique property of class IV synthases enables the synthesis of low-molecular-weight and end-structure-regulated PHA.44

In vitro polymerization of PHA

In 1994, Gerngross et al. overexpressed R. eutropha PHA synthases in E. coli to produce sufficient amounts of pure enzyme in a soluble form.14 This opened up new avenues for the in vitro synthesis of PHA. Subsequently, they polymerized P(3HB) in vitro using purified R. eutropha PHA synthase and 3HB-CoA.45 This study revealed that P(3HB) synthesized in vitro had a significantly higher Mw (>10 × 106) than P(3HB) synthesized in vivo. In addition, the concentration of PhaC was an important factor regulating the molecular weight of P(3HB).45 This was attributed to the lack of the CT reaction and PHA degradation during in vitro polymerization, as observed in recombinant E. coli. Thus, the induction of a CT reaction in vitro will aid in understanding the nature of the CT reaction. However, the low yield of PHA synthesized in vitro hindered the characterization of its end structures by NMR. High yields of P(3HB) could not be achieved by in vitro polymerization, as free CoA released after polymerization is known to inhibit PhaC activity. This limitation was overcome by developing a new system for in vitro PHA synthesis by recycling CoA.46, 47, 48

In our previous study, P(3HB) was efficiently polymerized in vitro by recycling CoA using a transesterification reaction between free CoA and the monomer precursor (crotonic anhydride).49 The Mw and polydispersity index (Mw/Mn) of the synthesized P(3HB) were determined to be 6.4 × 106 g mol−1 and 1.6, respectively, by gel permeation chromatography. Furthermore, the absolute molecular weight, Mw(MALLS), of P(3HB) was measured to be 5.8 × 106 g mol−1 by gel permeation chromatography-multi-angle laser light scattering (MALLS). The molecular weight of P(3HB) synthesized in vitro was very high. The stoichiometry of in vitro P(3HB) polymerization is shown in Table 2. Assuming that a PhaC dimer forms an active site, PhaC dimer produced the P(3HB) polymer chain at a stoichiometry of approximately 1:1. This observation strongly suggests that the CT reaction is minimal during in vitro polymerization. Interestingly, the molecular-weight distribution of P(3HB) synthesized in vitro was identical to that of P(3HB) synthesized in E. coli, as shown in Figure 2, indicating the similarity of these two polymerization systems.

Molecular-weight distribution of poly[(R)-3-hydroxybutyrate] (P(3HB)) synthesized by (A) R. eutropha (PHA native bacteria) (Mw=0.77 × 106, Mw/Mn=2.2), (B) recombinant E. coli XL1-Blue harboring phaCAB genes (Mw=6.1 × 106, Mw/Mn=1.7), and (C) under in vitro conditions (Mw=6.4 × 106, Mw/Mn=1.6).49

If the rate of initiation of in vitro polymerization was much higher than the rate of chain propagation (fast initiation), the polydispersity index of synthesized PHA would be similar to that of ideal living polymerization with a Poisson distribution of molecular weight according to equation (3):50

where Pn denotes the degree of polymerization. The Mw/Mn and Pn of in vitro synthesized PHA were 1.6 and 45 000, respectively (Table 2). The high value of Mw/Mn suggests that the rate of initiation of in vitro polymerization is very low (slow initiation). Slow initiation may be closely related to the mechanism with which PhaC changes the active form of the enzyme; however, this remains to be verified.

Induction of the CT reaction in vitro was confirmed by adding PEGs (molecular weight=200–400) to the in vitro polymerization system.48 1H-NMR analysis of the resultant P(3HB) revealed that the carboxylic end of P(3HB) was covalently linked to PEGs, providing direct evidence of the in vitro CT reaction. In contrast, PEG, with an average molecular weight of 1000, was not incorporated at the carboxylic end of P(3HB) because of the structural limits of PHA synthase for accepting CT agents.48

As an exception, during in vitro polymerization of P(3HB) with PHA synthase from A. vinosum, CT to water or the hydrolysis of the polymer chain was observed (Table 2).51 In support of this in vitro observation, A. vinosum synthase has been proposed to catalyze the hydrolytic cleavage of ester bonds.52, 53, 54

Catalytic activity of PHA synthase

The catalytic activity of PHA synthase also affects the molecular weight of PHA. The relationship between the molecular weight of PHA and catalytic activity of PHA synthase was investigated using various mutants of the R. eutropha PHA synthase.33 The results suggested that PhaC(F420S), a mutant with a high catalytic activity, can synthesize higher-molecular-weight P(3HB) compared with wild type or mutants with lower catalytic activities.

Investigations of the PHA synthases from D. acidovorans and H. elongata indicated that these synthases produced higher-molecular-weight P(3HB) (Mw(MALLS)=4.2–8.0 × 106 g mol−1) compared with the R. eutropha PHA synthase (Mw(MALLS)=2.1–2.7 × 106 g mol−1) in an E. coli host.34, 37, 55 The catalytic activities of these synthases may be very high; however, this was not observed in in vitro kinetic analysis. In vitro kinetic analysis of the D. acidovorans synthase revealed that this enzyme had a lower substrate affinity and slightly higher maximum reaction rate compared with the R. eutropha synthase.34

The differences between the in vivo and in vitro polymerizations is the lag time before the start of polymerization in vitro shown by purified PhaC homodimer-type synthase. This lag time may be attributed to the dimerization of PhaC subunits to create an active form of the enzyme.14 Therefore, lag eliminators such as Hecameg and TritonX-100 must be added to the assay mixture for in vitro kinetic analysis.45, 56 The lag-eliminating efficiency and optimal concentrations of lag eliminators differ with the type of synthase used, which complicates the comparison of kinetics between these synthases. In addition, PHA granule-binding proteins such as PhaP and PhaM modulate the activity of PHA synthase in vivo.57, 58, 59 It is important to note that the catalytic activity of PHA synthase is easily influenced by such environmental factors.

Factors affecting the molecular weight of PHA

In conclusion, various factors affecting the molecular weight of PHA are summarized in this review. The studies mentioned above suggest that the molecular weight of PHA is determined by four fundamental factors: the concentration of PHA synthase, occurrence of the CT reaction, catalytic activity of PHA synthase and simultaneous degradation of PHA during biosynthesis (Table 3).

In vitro PHA synthesis occurs under CT reaction- and PHA degradation-free conditions; therefore, the molecular weight of the resultant PHA is very high. The molecular weight is influenced mainly by the concentration of PHA synthase. In addition, the CT reaction can be induced in vitro in the presence of CT agents.

The polymerization of PHA in non-native E. coli also occurs under CT reaction- and PHA degradation-free conditions, similarly to its occurrence under in vitro conditions. Therefore, the molecular weight of the resulting PHA is very high and is influenced by the concentration of PHA synthase. However, endogenous ethanol can also function as a CT agent depending on the cellular conditions. Moreover, the sensitivity of PHA synthase towards the CT agent can vary according to the type of enzyme employed, resulting in PHA with different molecular weights, even under similar culture conditions. Notably, to obtain a sufficient yield of UHMW-P(3HB), PHA synthase should have high catalytic activity in vivo while maintaining the concentration at a low level.

The factors described above are involved in regulating the PHA molecular weight in PHA native bacteria. Simultaneous degradation of PHA is the largest contributor to this regulation, as the deletion of PHA depolymerase genes facilitates the production of high-molecular-weight PHA.29

The molecular weight of PHA has been controlled by regulating the culture conditions, such as pH and temperature, for PHA-producing bacteria.27, 28, 33, 36 These environmental conditions affect the four factors that are directly involved in molecular-weight regulation. However, little is known about the hydrolytic activity of PHA synthase, such as that shown by A. vinosum PHA synthase51, 52, 53, 54 (Table 2). A further understanding of molecular-weight regulation will facilitate the biosynthesis of PHAs with desired molecular weights for a variety of applications.

Proposed model of poly[(R)-3-hydroxybutyrate] (P(3HB)) polymerization. CoA-SH, free coenzyme A; E-SH, PHA synthase (enzyme) subunit; E2-SH, dimerized PHA synthase (active); E2*-SH, dimerized PHA synthase (inactive); HO-X, chain transfer (CT) agent; 3HB, 3-hydroxybutyryl monomer.

References

Sudesh, K., Abe, H. & Doi, Y. Synthesis, structure, and properties of polyhydroxyalkanoates: biological polyesters. Prog. Polym. Sci. 25, 1503–1555 (2000).

Lu, J., Tappel, R. C. & Nomura, C. T. Mini-review: biosynthesis of poly(hydroxyalkanoates). J. Macromol. Sci. Part C Polym. Rev. 49, 226–248 (2009).

Jendrossek, D. Polyhydroxyalkanoate granules are complex subcellular organelles (carbonosomes). J. Bacteriol. 191, 3195–3202 (2009).

Tsuge, T. Metabolic improvements and use of inexpensive carbon sources in microbial production of polyhydroxyalkanoates. J. Biosci. Bioeng. 94, 579–584 (2002).

Kahar, P., Agus, J., Kikkawa, Y., Taguchi, K., Doi, Y. & Tsuge, T. Effective production and kinetic characterization of ultra-high-molecular-weight poly[(R-3-hydroxybutyrate] in recombinant Escherichia coli. Polym. Degrad. Stab. 87, 161–169 (2005).

Iwata, T. Strong fibers and films of microbial polyesters. Macromol. Biosci. 5, 689–701 (2005).

Kusaka, S., Iwata, T. & Doi, Y. Microbial synthesis and physical properties of ultra-high molecular weight poly[(R-3-hydroxybutyrate]. J. Macromol. Sci. Pure Appl. Chem. A 35, 319–335 (1998).

Rehm, B. H. A. Polyester synthases: natural catalysts for plastics. Biochem. J. 376, 15–33 (2003).

Tsuge, T., Hyakutake, M. & Mizuno, M. Class IV polyhydroxyalkanoate (PHA) synthases and PHA-producing Bacillus. Appl. Microbiol. Biotechnol. 99, 6231–6240 (2015).

Taguchi, S. & Tsuge, T. Natural Polyester‐Related Proteins: Structure, Function, Evolution and Engineering, Protein Engineering Handbook Vol. 1 & 2 877–914 (Wiley-VCH, Weinheim, 2008).

Kawaguchi, Y. & Doi, Y. Kinetics and mechanism of synthesis and degradation of poly(3-hydroxybutyrate) in Alcaligenes eutrophus. Macromolecules 25, 2324–2329 (1992).

Yamanaka, K., Kimura, Y., Aoki, T. & Kudo, T. End-group analysis of bacterially produced poly(3-hydroxybutyrate): discovery of succinate as the polymerization starter. Macromolecules 42, 4038–4046 (2009).

Madden, L. A., Anderson, A. J., Shah, D. T. & Asrar, J. Chain termination in polyhydroxyalkanoate synthesis: Involvement of exogenous hydroxy-compounds as chain transfer agents. Int. J. Biol. Macromol. 25, 43–53 (1999).

Gerngross, T. U., Snell, K. D., Peoples, O. P., Sinskey, A. J., Csuhai, E., Masamune, S. & Stubbe, J. Overexpression and purification of the soluble polyhydroxyalkanoate synthase from Alcaligenes eutrophus: Evidence for a required posttranslational modification for catalytic activity. Biochemistry 33, 9311–9320 (1994).

Zhang, S., Yasuo, T., Lenz, R. W. & Goodwin, S. Kinetic and mechanistic characterization of the polyhydroxybutyrate synthase from Ralstonia eutropha. Biomacromolecules 1, 244–251 (2000).

Stubbe, J. & Tian, J. Polyhydroxyalkanoate (PHA) homeostasis: the role of the PHA synthase. Nat. Prod. Rep. 20, 445–457 (2003).

Koizumi, F., Abe, H. & Doi, Y. Molecular weight of poly(3-hydroxybutyrate) during biological polymerization in Alcaligenes eutrophus. J. Macromol. Sci. A 32, 759–774 (1995).

Hiroe, A., Hyakutake, M., Thomson, N. M., Sivaniah, E. & Tsuge, T. Endogenous ethanol affects biopolyester molecular weight in recombinant Escherichia coli. ACS Chem. Biol. 8, 2568–2576 (2013).

Shi, F., Ashby, R. & Gross, R. A. Use of poly(ethylene glycol)s to regulate poly(3-hydroxybutyrate) molecular weight during Alcaligenes eutrophus cultivations. Macromolecules 29, 7753–7758 (1996).

Shi, F., Gross, R. A. & Rutherford, D. R. Microbial polyester synthesis: effects of poly(ethylene glycol) on product composition, repeat unit sequence, and end group structure. Macromolecules 29, 10–17 (1996).

Sanguanchaipaiwong, V., Gabelish, C. L., Hook, J., Scholz, C. & Foster, L. J. R. Biosynthesis of natural-synthetic hybrid copolymers polyhydroxyoctanoate-diethylene glycol. Biomacromolecules 5, 643–649 (2004).

Foster, L. J. R. Biosynthesis, properties and potential of natural synthetic hybrids of polyhydroxyalkanoates and polyethylene glycols. Appl. Microbiol. Biotechnol. 75, 1241–1247 (2007).

Kim, O. Biological effects of poly(ethylene glycol) on the microbial poly(β-hydroxyalkanoates) produced by Pseudomonas microorganisms. J. Polym. Res. 7, 91–96 (2000).

Tomizawa, S., Saito, Y., Hyakutake, M., Nakamura, Y., Abe, H. & Tsuge, T. Chain transfer reaction catalyzed by various polyhydroxyalkanoate synthases with poly(ethylene glycol) as an exogenous chain transfer agent. Appl. Microbiol. Biotechnol. 87, 1427–1435 (2010).

Thomson, N. M., Hiroe, A., Tsuge, T., Summers, D. K. & Sivaniah, E. Efficient molecular weight control of bacterially synthesized polyesters by alcohol supplementation. J. Chem. Technol. Biotechnol. 89, 1110–1114 (2014).

Tsuge, T., Ko, T., Tago, M. & Abe, H. Effect of glycerol and its analogs on polyhydroxyalkanoate biosynthesis by recombinant Ralstonia eutropha: a quantitative structure-activity relationship study of chain transfer agents. Polym. Degrad. Stab. 98, 1586–1590 (2013).

Kusaka, S., Abe, H., Lee, S. Y. & Doi, Y. Molecular mass of poly[(R-3-hydroxybutyric acid] produced in a recombinant Escherichia coli. Appl. Microbiol. Biotechnol. 47, 140–143 (1997).

Choi, J. & Lee, S. Y. High level production of supra molecular weight poly((R-3hydroxybutyrate) by metabolically engineered Escherichia coli. Biotechnol. Bioprocess Eng. 9, 196–200 (2004).

Arikawa, H., Sato, S., Fujiki, T. & Matsumoto, K. A study on the relation between poly(3-hydroxybutyrate) depolymerases or oligomer hydrolases and molecular weight of polyhydroxyalkanoates accumulating in Cupriavidus necator H16. J. Biotechnol. 227, 94–102 (2016).

Sim, S. J., Snell, K. D., Hogan, S. A., Stubbe, J., Rha, C. & Sinskey, A. J. PHA synthase activity controls the molecular weight and polydispersity of polyhydroxybutyrate in vivo. Nat. Biotechnol. 15, 63–67 (1997).

Sim, S. J., Sneel, K. D., Kim, B. W., Rha, K. C. & Sinskey, A. J. Increased poy-β-hydroxybutyrate (PHB) chain length by the modulation of PHA synthase activity in recombinant Escherichia coli. Biotechnol. Lett. 23, 2057–2061 (2001).

Agus, J., Kahar, P., Abe, H., Doi, Y. & Tsuge, T. Altered expression of polyhydroxyalkanoate synthase gene and its effect on poly[(R-3-hydroxybutyrate] synthesis in recombinant Escherichia coli. Polym. Degrad. Stab. 91, 1645–1650 (2006).

Agus, J., Kahar, P., Abe, H., Doi, Y. & Tsuge, T. Molecular weight characterization of poly[(R-3-hydroxybutyrate] synthesized by genetically engineered strains of Escherichia coli. Polym. Degrad. Stab. 91, 1138–1146 (2006).

Hiroe, A., Ushimaru, K. & Tsuge, T. Characterization of polyhydroxyalkanoate (PHA) synthase derived from Delftia acidovorans DS-17 and the influence of PHA production in Escherichia coli. J. Biosci. Bioeng. 115, 633–638 (2013).

Thomson, N. M., Saika, A., Ushimaru, K., Sangiambut, S., Tsuge, T., Summers, D. K. & Sivaniah, E. Efficient production of active polyhydroxyalkanoate synthase in Escherichia coli by coexpression of molecular chaperones. Appl. Environ. Microbiol. 79, 1948–1955 (2013).

Bocanegra, J. K., da Cruz Pradella, J. G., Da Silva, L. F., Taciro, M. K. & Gomez, J. G. C. Influence of pH on the molecular weight of poly-3-hydroxybutyric acid (P3HB) produced by recombinant Escherichia coli. Appl. Biochem. Biotechnol. 170, 1336–1347 (2013).

Hiroe, A., Shiraishi, M., Mizuno, K. & Tsuge, T. Behavior of different polyhydroxyalkanoate synthases in response to the ethanol level in Escherichia coli cultures. Polym. J. 47, 767–770 (2015).

Ushimaru, K., Watanabe, Y., Hiroe, A. & Tsuge, T. A single-nucleotide substitution in phasin gene leads to enhanced accumulation of polyhydroxyalkanoate (PHA) in Escherichia coli harboring Aeromonas caviae PHA biosynthetic operon. J. Gen. Appl. Microbiol. 61, 63–66 (2015).

Tsuge, T., Takase, K., Taguchi, S. & Doi, Y. An extra large insertion in the polyhydroxyalkanoate synthase from Delftia acidovorans DS-17: its deletion effects and relation to cellular proteolysis. FEMS Microbiol. Lett. 231, 77–83 (2004).

Agus, J., Kahar, P., Hyakutake, M., Tomizawa, S., Abe, H., Tsuge, T., Satoh, Y. & Tajima, K. Unusual change in molecular weight of polyhydroxyalkanoate (PHA) during cultivation of PHA-accumulating Escherichia coli. Polym. Degrad. Stab. 95, 2250–2254 (2010).

Tomizawa, S., Hyakutake, M., Saito, Y., Agus, J., Mizuno, K., Abe, H. & Tsuge, T. Molecular weight change of polyhydroxyalkanoate (PHA) caused by the PhaC subunit of PHA synthase from Bacillus cereus YB-4 in recombinant Escherichia coli. Biomacromolecules 12, 2660–2666 (2011).

Hyakutake, M., Tomizawa, S., Mizuno, K., Abe, H. & Tsuge, T. Alcoholytic cleavage of polyhydroxyalkanoate chains by class IV synthases induced by endogenous and exogenous ethanol. Appl. Environ. Microbiol. 80, 1421–1429 (2014).

Hyakutake, M., Tomizawa, S., Mizuno, K., Hisano, T., Abe, H. & Tsuge, T. A common active site of polyhydroxyalkanoate synthase from Bacillus cereus YB-4 is involved in polymerization and alcoholysis reactions. Appl. Microbiol. Biotechnol. 99, 4701–4711 (2015).

Hyakutake, M., Tomizawa, S., Sugahara, I., Murata, E., Mizuno, K., Abe, H. & Tsuge, T. Carboxy-terminal modification of polyhydroxyalkanoate (PHA) via alcoholysis reaction catalyzed by class IV PHA synthase. Polym. Degrad. Stab. 117, 90–96 (2015).

Gerngross, T. U. & Martin, D. P. Enzyme-catalyzed synthesis of poly[(R-(−)-3-hydroxybutyrate]: formation of macroscopic granules in vitro. Proc. Natl Acad. Sci. USA 92, 6279–6283 (1995).

Jossek, R. & Steinbüchel, A. In vitro synthesis of poly(3-hydroxybutyric acid) by using an enzymatic coenzyme A recycling system. FEMS Microbiol. Lett. 168, 319–324 (1998).

Han, X., Satoh, Y., Tajima, K., Matsushima, T. & Munekata, M. Chemo-enzymatic synthesis of polyhydroxyalkanoate by an improved two-phase reaction system (TPRS). J. Biosci. Bioeng. 108, 517–523 (2009).

Tomizawa, S., Sato, S., Lan, J. C. W., Nakamura, Y., Abe, H. & Tsuge, T. In vitro evidence of chain transfer to tetraethylene glycols in enzymatic polymerization of polyhydroxyalkanoate. Appl. Microbiol. Biotechnol. 97, 4821–4829 (2013).

Tomizawa, S., Yoshioka, M., Ushimaru, K. & Tsuge, T. Preparative synthesis of poly[(R-3-hydroxybutyrate]; monomer for enzymatic cell-free polymerization. Polym. J. 44, 982–985 (2012).

Saldivar-Guerra, E. & Vivaldo-Lima, E. Handbook of Polymer Synthesis, Characterization, and Processing. Chapter 7, (John Wiley and Sons, Hoboken, 2013).

Jossek, R., Reichelt, R. & Steinbüchel, A. In vitro biosynthesis of poly (3-hydroxybutyric acid) by using purified poly(hydroxyalkanoic acid) synthase of Chromatium vinosum. Appl. Microbiol. Biotechnol. 49, 258–266 (1998).

Chen, C., Cao, R., Shrestha, R., Ward, C., B. Katz, B. B., Fischer, C. J., Tomich, J. M. & Li, P. Trapping of intermediates with substrate analog HBOCoA in the polymerizations catalyzed by Class III polyhydroxybutyrate (PHB) synthase from Allochromatium vinosum. ACS Chem. Biol. 10, 1330–1339 (2015).

Zhang, W., Shrestha, R., Buckley, R. M., Jewell, J., Bossmann, S. H., Stubbe, J. & Li, P. Mechanistic insight with HBCH2CoA as a probe to polyhydroxybutyrate (PHB) synthases. ACS Chem. Biol. 9, 1773–1779 (2014).

Tian, J., Sinskey, A. J. & Stubbe, J. Class III polyhydroxybutyrate synthase: involvement in chain termination and reinitiation. Biochemistry 44, 8369–8377 (2005).

Ilham, M., Nakanomori, S., Kihara, T., Hokamura, A., Matsusaki, H., Tsuge, T. & Mizuno, K. Characterization of polyhydroxyalkanoate synthases from Halomonas sp. O-1 and Halomonas elongata DSM2581: Site-directed mutagenesis and recombinant expression. Polym. Degrad. Stab. 109, 416–423 (2014).

Ushimaru, K., Sangiambut, S., Thomson, N., Sivaniah, E. & Tsuge, T. New insights into activation and substrate recognition of polyhydroxyalkanoate synthase from Ralstonia eutropha. Appl. Microbiol. Biotechnol. 97, 1175–1182 (2013).

Cho, M., Brigham, C. J., Sinskey, A. J. & Stubbe, J. Purification of polyhydroxybutyrate synthase from its native organism, Ralstonia eutropha: implications for the initiation and elongation of polymer formation in vivo. Biochemistry 51, 2276–2288 (2012).

Ushimaru, K., Motoda, Y., Numata, K. & Tsuge, T. Phasin proteins activate Aeromonas caviae polyhydroxyalkanoate (PHA) synthase but not Ralstonia eutropha PHA synthase. Appl. Environ. Microbiol. 80, 2867–2873 (2014).

Pfeiffer, D. & Jendrossek, D. PhaM is the physiological activator of PHB synthase (PhaC1) in Ralstonia eutropha. Appl. Environ. Microbiol. 80, 555–563 (2014).

Acknowledgements

This work was partially supported by funding from JST, CREST.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Tsuge, T. Fundamental factors determining the molecular weight of polyhydroxyalkanoate during biosynthesis. Polym J 48, 1051–1057 (2016). https://doi.org/10.1038/pj.2016.78

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2016.78

This article is cited by

-

Characterization of P(3HB) from untreated raw palm oil mill effluent using Azotobacter vinelandii ΔAvin_16040 lacking S-layer protein

World Journal of Microbiology and Biotechnology (2023)

-

Enhanced production of polyhydroxyalkanoate with manipulable and reproducible 3-hydroxyvalerate fraction by high alcohol tolerant Cupriavidus malaysiensis USMAA2-4 transformant

Bioprocess and Biosystems Engineering (2022)

-

High natural PHA production from acetate in Cobetia sp. MC34 and Cobetia marina DSM 4741T and in silico analyses of the genus specific PhaC2 polymerase variant

Microbial Cell Factories (2021)

-

Thermal properties of poly(3-hydroxy-2-methylbutyrate-co-3-hydroxybutyrate) copolymers with narrow comonomer-unit compositional distributions

Polymer Journal (2021)

-

Evaluating haloarchaeal culture media for ultrahigh-molecular-weight polyhydroxyalkanoate biosynthesis by Haloferax mediterranei

Applied Microbiology and Biotechnology (2021)