Abstract

We report the synthesis of networked polymers based on the radical ring-opening polymerization of vinyloxiranes. First, the radical ring-opening polymerization of monofunctional 2-phenyl-3-vinyloxirane was investigated. Then, we synthesized di- and trifunctional vinyloxiranes and examined the networked polymer synthesis via the radical ring-opening homopolymerization or copolymerization of these monomers. The obtained networked polymers contained vinyl ether structures in the main chain, which was confirmed by infrared analysis. In addition, we examined the radical ring-opening copolymerization of difunctional vinyloxirane and monofunctional vinyloxirane or adamantane-substituted vinylcyclopropane. Thermal gravimetric analysis revealed that the network formation increased their thermal stabilities.

Similar content being viewed by others

Introduction

Addition polymerizations of vinyl monomers are roughly classified into two types (i.e., ionic and radical polymerizations). Ionic polymerization is difficult to adapt for use in the industrial manufacturing of polymeric materials because it is highly sensitive to water, the solvents are limited, and both the monomers and solvents must typically be highly purified. However, these challenges do not affect radical polymerization. For example, this type of polymerization can readily proceed in water and is widely used in industry. However, the radical polymerization of conventional vinyl monomers, such as styrene and methyl methacrylate, is known to undergo 10–20% volume shrinkage,1 which causes warpage and cracking in the materials during the curing process. Therefore, the development of new systems with low volume shrinkage via radical polymerization is desirable.

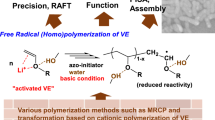

Radical ring-opening polymerizations (RROP) of cyclic monomers, such as cyclic allyl sulfides, spiro-dixylene,2 vinylcycropropane,3 unsaturated spiroorthocarbonates,4 cyclic ketene acetals5, 6, 7 and vinyloxirane,8 have attracted much attention due to their potential to afford polymers with main chains containing various functional groups (i.e., ester, ketone and ether). These polymerizations are also attractive because they are easily achieved with little volume shrinkage.

We reported that 2-phenyl-3-vinyloxirane (1) underwent complete RROP via selective cleavage of the carbon–carbon bond in the oxirane ring.9, 10 The RROP proceeded selectively due to stabilization of the carboradical by the adjacent phenyl group, which yielded polymer bearing alkenyl ether structures in the backbone (Scheme 1). In addition, our research group reported that 1,1-bis((1-adamantyloxy)carbonyl)-2-vinylcyclopropane (Ad-VCP) containing bulky substituents exhibited a positive volume change (+4.5±1.1%) in the polymerization.11 However, to the best of our knowledge, few studies on the synthesis or analysis of networked polymers of epoxide by RROP have been reported.9 Networked polymers that are prepared using this method are anticipated to exhibit low volume shrinking during curing and may be useful as adhesives, curing resins, or molding and filling materials.

In this study, we synthesized a multifunctional vinyloxirane monomer and studied its radical polymerization/copolymerization with monofunctional vinyloxirane or adamantane-substituted vinylcyclopropane (Ad-DVCP). Networked polymers with various crosslinking densities were obtained, and their heat resistance and volume change before and after curing were evaluated.

Experimental procedure

Materials

Terephthalaldehyde, isophthalaldehyde, dimethyl sulfide, allyl bromide, di-tert-butyl peroxide, trimethyl 1,3,5-benzenetricarboxylate and pyridinium chlorochromate were purchased from Tokyo Chemical Industry (Tokyo, Japan). Dimethyl sulfoxide, sodium hydride, celite and lithium aluminum hydride were purchased from Wako Pure Chemical Industry (Osaka, Japan). Chlorobenzene was purchased from Wako Pure Chemical and distilled prior to use.

Measurements

The IR spectra were recorded on a Thermo Scientific Nicolet iS10 spectrometer (Thermo Fisher Scientific, Kanagawa, Japan) equipped with a Smart iTR Sampling Accessory (Thermo Fisher Scientific). The 1H (300 MHz) and 13C (75 MHz) NMR spectra were recorded on a JEOL AL300 NMR spectrometer in CDCl3 or dimethyl sulfide (DMSO-d6). The chemical shifts were determined using tetramethylsilane or the residual protons as the internal standards. The number-averaged molecular weight (Mn) and weight-averaged molecular weight (Mw) were estimated by size exclusion chromatography on a TOSOH HLC-8220 system (TOSOH Corporation, Tokyo, Japan) equipped with refractive index and ultraviolet (k=254 nm) detectors and three consecutive polystyrene gel columns (TSKgels (bead size, exclusion limited molecular weight); super-AW4000 (6 μm, >4 × 105), super-AW3000 (4 μm, >6 × 104) and super-AW2500 (4 μm, >2 × 103)). The system was operated at a flow rate of 0.5 ml min−1 using a N,N-dimethylformamide (DMF) solution consisting of lithium bromide (10 mm) as an eluent at 40 °C. Polystyrene standards were employed for calibration. The monomer and polymer densities were measured with a SHIMADZU AccuPyc1340 gas pycnometer (SHIMADZU Corporation, Kyoto, Japan).

Synthesis of 2-phenyl-3-vinyloxirane (1)

Monomer 1 was prepared according to a previously reported procedure with some modifications.8 The 1H NMR data of obtained monomer 1 were in agreement with previously reported data.

Radical opening polymerization of 1

Monomer 1 was prepared according to a previously reported procedure with some modifications.8 The 1H NMR data of obtained poly (1) were in agreement with previously reported data. Yield 42.3%. Mn=6600, Mw=20 400, and Mw/Mn=3.10.

Synthesis of bifunctional vinyloxirane (2)

Monomer 2 was prepared according to a previously reported procedure with some modifications.9 The 1H NMR data of obtained 2 were in agreement with previously reported data.

Synthesis of trifunctional vinyloxirane (3)

Synthesis of 1,3,5-tris(hydroxymethyl)benzene

1,3,5-tris(hydroxymethyl)benzene was prepared according to a previously reported procedure with some modifications.12 The 1H NMR data of obtained 1,3,5-tris(hydroxymethyl)benzene were in agreement with previously reported data.

Synthesis of 1,3,5-triformylbenzene

1,3,5-Triformylbenzene was prepared according to a previously reported procedure with some modifications.13 The 1H NMR data of obtained 1,3,5-triformylbenzene were in agreement with previously reported data.

Synthesis of 1,3,5-tris(2-vinylepoxyethyl)benzene (3)

Allyl bromide (900 mg, 7.44 mmol) and dimethyl sulfide (480 g, 7.72 mmol) in 0.45 ml of water were stirred at room temperature overnight. The unreacted dimethyl sulfide was removed at reduced pressure. 1,3,5-Triformylbenzene (200 mg, 1.23 mmol) in 1 ml of dimethyl sulfide (DMSO) was added to the solution at room temperature, and then, sodium hydroxide (300 mg, 7.50 mmol) in 0.45 ml of water was added dropwise to the solution with vigorous stirring. After the solution was stirred at room temperature overnight, the solution was extracted three times with ether, and the organic layer was dried over MgSO4. After the ether was evaporated, the residue was distilled in vacuo to yield 218 mg (Yield 63.0%) of 1, 3, 5-tris(2-vinylepoxyethyl)benzene (3).

1H NMR (CDCl3): 7.2 (3H, m), 5.7–5.3 (9H, m), 4.20–3.3(6H, m). 13C-NMR (CDCl3): 137.8, 134.9 131.6, 120.1, 63.1, 60.0, 58.7

IR (ATR): νmax=2987(w, C–H), 1639(w, C–H), 1607(w, C–H), 1465, 1407, 981, 924(s, C–H), 854(s, C–O),

Found: C, 76.57; H, 6.43%. Calcd for C18H18O3: C, 76.22; H, 6.08%.

Synthesis of networked polymer by radical ring-opening polymerization of 2 or 3

A typical procedure is as follows:

A mixture of 3 (564 mg, 2.00 mmol), di-tert-butyl peroxide (29.2 mg, 0.2 mmol) and chlorobenzene (1 ml) was charged in a 5 ml glass ampoule tube equipped with a magnetic stir bar. After the mixture was degassed under reduced pressure, the ampoule tube was sealed. The mixture was heated at 130 °C for 24 h with stirring. The obtained gel was washed via Soxhlet extraction with chloroform, and the residue was dried in vacuo to yield a solid consisting of networked polymer (544 mg, 96.4%).

Synthesis of networked polymer by radical opening copolymerization of 1 and 2a

A typical procedure is as follows:

A mixture of 1 (128 mg, 0.88 mmol), 2a (375 mg, 1.75 mmol), di-tert-butyl peroxide (25.0 mg, 0.175 mmol) and chlorobenzene (1.3 ml) was charged in a 5 ml glass ampoule tube equipped with a magnetic stir bar. After the mixture was degassed under reduced pressure, the ampoule tube was sealed. The mixture was heated at 130 °C for 24 h with stirring. The obtained gel was washed via Soxhlet extraction with chloroform, and the residue was dried in vacuo to afford a solid consisting of networked polymer (482 mg, 96.0%).

Synthesis of the 1,1-bis((1-adamantyloxy)carbonyl)-2-vinylcyclopropane (Ad-VCP)

Ad-VCP was prepared according to a previously reported procedure with some modifications.11 The 1H NMR data of the obtained Ad-VCP were in agreement with previously reported data.

Synthesis of the 1,3-bis((1-adamantyloxycarbonyl-2-vinylcyclopropane-1-yl)carbonyloxy) adamantine (Ad-DVCP)

Ad-DVCP was prepared according to a previously reported procedure with some modifications.14 The 1H NMR data of the obtained Ad-DVCP were in agreement with previously reported data.

Copolymerization of 1 with Ad-VCP

Copolymerization of 1 with Ad-VCP using di-tert-butyl-peroxide (DTBP) in a PhCl solution was performed in the same manner as previously described by varying the feed ratio.

Copolymerization of 2 with Ad-DVCP

Copolymerization of 2 with Ad-DVCP using DTBP in a PhCl solution was performed in the same manner as previously described by varying the feed ratio.

Results and discussion

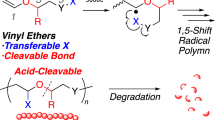

Synthesis of multifunctional vinyloxirane (2) or (3)

Difunctional vinyloxirane (2) was synthesized according to Scheme 2. Dimethyl sulfonium salt was prepared with allyl bromide and dimethyl sulfide, which was treated with terephthalaldehyde or isophthalaldehyde to afford the desired difunctional vinyloxiranes (2a or 2b). When o-phthalaldehyde was used as the starting material, the corresponding vinyloxirane monomer could not be obtained. Trifunctional vinyloxirane (3) was synthesized as shown in Scheme 3. 1,3,5-Tris(hydroxymethyl)benzene was used as the starting material, which was reduced with lithium aluminum hydride to afford the corresponding triol. Oxidation of the triol with pyridinium chlorochromate yielded the corresponding trialdehyde. Allyl epoxylation of the compound using a similar method afforded the desired 1,3,5-tris(2-vinylepoxyethyl)benzene (3).

Synthesis of networked polymer by radical opening homopolymerization of 2a or 2b or (3)

Homopolymerization of difunctional vinyloxirane 2a, 2b or 3 was carried out at 130 °C using 10 mol% DTBP as an initiator in chlorobenzene (Scheme 4). After 12 h, the solutions gradually turned to a gel state.

The obtained gels were crushed and washed with chloroform under reflux conditions to obtain networked polymers in high yield. The networked polymers were insoluble in typical organic solvents. Table 1 shows the heat resistance of the networked polymers based on TGA. The 10% weight loss temperatures of the networked polymers were higher than that of poly (1). The obtained networked polymers exhibited smaller absorption of the epoxide (875 cm−1). However, the ether group absorption appeared at 1000–1400 cm−1 (Figure 1). These results indicated the successful formation of alkenyl ether structures and networks in the main chain due to radical opening polymerization. Density measurements of poly (1) and the networked polymers were carried out on a AccuPyc 1340 at 25 °C. Based on the volume change (%) during polymerization=(monomer density)−(polymer density) × 100/(monomer density), the volume change during the RROP of vinyloxirane was estimated to be negative at –10%. Table 1 summarizes the results of the volume change during the polymerization. The networked polymers of 2a and 2b exhibited approximately 10% volume shrinkage, which was slightly smaller than that of vinyl monomers (e.g., styrene (14.5%), MMA (21.2%) or vinyl chloride (34.4%)). The substantial shrinking during the curing process was due to the possibility of partial ring-opening in the epoxide. In fact, the IR spectra of the networked polymers exhibited absorptions corresponding to the epoxide. The volume shrinking should be more effectively prevented for application as practical materials.

Radical ring-opening copolymerization of 1 and 2a

We carried out the copolymerization of 1 and 2a using DTBP as an initiator in chlorobenzene at 130 °C (Scheme 5). The corresponding copolymers of 1 and 2a were obtained as the MeOH-insoluble portion in high yields (Table 2). The obtained polymers were insoluble in typical organic solvents. The chemical structure of the obtained polymer was confirmed by infrared analysis. In the spectrum, the absorption due to the epoxide moiety at approximately 870 cm−1 weakened, and the peak attributed to the vinyl ether group at approximately 1000–1400 cm−1 increased in intensity. These results indicated that successful networked copolymer formation was achieved by radical ring-opening copolymerization of 1 and 2a. The ratios of 1 and 2a units in the networked polymers cannot be estimated. However, we believe that they may be in good agreement with the monomer feed ratios because the yield of the soluble part was sufficiently low for nearly complete copolymerization to occur.

This result indicated that thermal stability of the polymer increased due to crosslinking (entries 1–3). As 1 increased, the yields of the networked polymers slightly decreased, which may have been due to an increase in the copolymer solubility as the crosslinking density decreased (entries 4 and 5).

Figure 2 shows the TGA curves of the networked copolymers. The 5 and 10% weight loss temperatures of the networked copolymers decreased as the feed ratio of 1 increased. The densities of the copolymers were measured. The volume change (%) during the polymerization is listed in Table 2. Nearly the same volume changes as those for the homopolymerization of 1 or 2a were observed in the polymerizations. Unfortunately, we could not sufficiently reduce the volume shrinkage using only monomer 1 and 2a.

Radical ring-opening copolymerization of 1 and Ad-VCP

To more efficiently control volume shrinkage, we examined the copolymerization of 1 or 2a with Ad-VCP or Ad-DVCP, which have a bulky adamantyl substituent. We previously reported a large volume expansion during the polymerization.11, 14

Copolymerization of 1 with Ad-VCP was carried out in a PhCl solution at different feeds (wt%) using DTBP as a radical initiator (Scheme 6). The copolymerizations proceeded smoothly to afford the corresponding copolymers. Figure 3 shows the 1H NMR spectrum of the copolymer (1: Ad-VCP=50: 50). The copolymer compositions were determined by 1H NMR analysis of the obtained polymers. The results of the copolymerizations are summarized in Table 3.

Synthesis of networked polymer by radical opening copolymerization of 2a and Ad-DVCP

Copolymerizations of 2a with Ad-VCP were carried out in a PhCl solution at different ratios (wt%) using DTBP as a radical initiator (Scheme 7). In all cases, the copolymerizations proceeded smoothly with nearly complete consumption of each monomer at 130 °C for 24 h to yield the corresponding copolymers in quantitative yield. The volume change during the copolymerization was evaluated (Table 4) at different feed ratios.

Based on these results, we confirmed that the volume shrinkage could be significantly reduced compared with those from 2a (−9.93% volume shrinkage, run1 in Table 4) as the Ad-VCP feed ratio increased. The lowest volume shrinkage (−5.92%) was achieved when 75 wt % Ad-DVCP was used.

Summary

Ionic polymerizations have typically been used to polymerize oxiranes, and few studies on the synthesis of networked polymers by RROP of oxiranes have been reported. Our results indicated that RROP of multifunctional vinyloxiranes proceeded smoothly to yield networked polymers with alkenyl ether structures in the main chain. The as-prepared networked polymers exhibited a higher thermal stability due to a high crosslinking density. The difunctional monomers could be effectively copolymerized with a monofunctional monomer or Ad-DVCP. In the copolymerization of monomer 2a with Ad-DVCP, the volume shrinkage decreased to −5.92%, which was −4.01% less than that produced by the polymerization of 2a. The insight gained during this study may be useful for the development of novel networked polymers. These as-synthesized networked materials have the potential for use in various applications, such as sealants and adhesives.

Radical ring-opening polymerization of 1.

Synthesis of bifunctional vinyloxirane compounds.

Synthesis of a trifunctional vinyloxirane compound.

Synthesis of networked polymers of trifunctional vinyloxirane via radical opening polymerization.

Synthesis of networked copolymers of 1 and 2a by radical ring-opening polymerization.

Radical copolymerization of 1 with Ad-VCP using di-tert-butyl-peroxide (DTBP) as an initiator.

Radical copolymerization of 2a with Ad-DVCP using DTBP as an initiator.

References

Endo, T. Possibility to avoid shrinkage during polymerization—synthesis of monomers that expand on polymerization. Kobunshi 27, 108–111 (1978).

Errede, L. A. The chemistry of xylylenes. X. Some polymers and telomers of spiro-di-o-xylylene. J. Polym. Sci. 49, 253 (1961).

Cho, I. & Ahn, K. D. Polymerizations of substituted cyclopropanes. I. Radical polymerization of 1,1-disubstituted 2-vinylcyclopropanes. J. Polym. Sci. Polym. Chem. Ed 17, 3169 (1979).

Endo, T. & Bailey, W. J. Free radical ring-opening polymerization. J. Polym. Sci. Polym. Chem. Ed 13, 2525 (1975).

Bailey, W. J., Ni, Z. & Wu, S. R. Synthesis of poly-ε-caprolactone via a free radical mechanism. Free radical ring-opening polymerization of 2-methylene-1,3-dioxepane. Macromolecules 15, 711 (1982).

Bailey, W. J., Wu, S. R. & Ni, Z. Synthesis and free radical ring-opening polymerization of 2-methylene-4-phenyl-1,3-dioxolane. Macromol. Chem. 183, 1913 (1982).

Endo, T., Okawara, M., Bailey, W. J., Azuma, K., Nate, K. & Yokono, H. Photoinitiated ring-opening polymerization of 2-methylene-1,3-dioxepane. J. Polym. Sci. Polym. Lett. Ed 21, 373 (1983).

Cho, I. & Kim, J. B. Exploratory ring-opening polymerization. VIII. Radical ring-opening polymerization of 2-phenyl-3-vinyloxirane: a C-C bond scission polymerization of the epoxide ring. J. Polym. Sci. Polym. Lett. Ed 21, 433–436 (1983).

Endo, T. & Kanda, N. Syntheses of 2-phenyl-3-vinyloxirane derivatives that undergo radical ring-opening polymerization. J. Polym. Sci. Polym. Chem. Ed. 23, 1931–1938 (1985).

Koizumi, T., Moriya, O., Urata, Y., Nojima, Y. & Endo, T. Radical ring-opening polymerization behavior of halogenated phenyl-3-vinyloxiranes. J. Polym. Sci. A Polym. Chem. 31, 3489–3492 (1993).

Sugiyama, J., Kayamori, N. & Shimada, S. Free radical ring-opening polymerization of 1,1-Bis[(1-adamantyloxy)carbonyl]-2-vinylcyclopropane. Macromolecules 29, 1943–1950 (1996).

Castaldi, M. P., Gibson, S. E., Rudd, M. & White, A. J. P. A new approach to enantiopure C3-symmetric molecules. Chem. Eur. J 12, 138–148 (2006).

Pandey, P., Katsoulidis, A. P., Eryazici, I., Wu, Y., Kanatzidis, M. G. & Nguyen, S. T. Imine-linked microporous polymer organic frameworks. Chem. Mater. 22, 4974–4979 (2010).

Chiba, H., Kitazume, K., Yamada, S. & Endo, T. Synthesis and radical polymerization of adamantane-containing bifunctional vinylcyclopropane undergoing volume expansion on polymerization. J. Polym. Sci. A Polym. Chem 54, 39–43 (2016).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Maeda, S., Matsumoto, K. & Endo, T. Design of networked polymers based on radical ring-opening polymerization of vinyloxiranes. Polym J 49, 363–368 (2017). https://doi.org/10.1038/pj.2016.125

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2016.125