Abstract

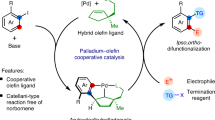

Tremendous effort has been directed toward the design of an organic ligand framework around the catalytically active metal center of homogeneous catalyst precursors. This work is aimed at controlling not only the reactivity of the metal catalysts for α-olefin polymerization but also the molecular weight, molecular weight distribution, polymer microstructure and monomer content of the copolymers. Among the catalyst precursor categories, non-bridged half-metallocene complexes supported by a variety of chelating ligands are attractive catalyst motifs for ethylene homopolymerization, ethylene/α-olefin copolymerization and stereoselective polymerization of α-olefins. These motifs are attractive in terms of their rather simple synthetic protocols and the wide range of potential architectural designs of the attached ligands. This review article summarizes recent developments regarding non-bridged half-metallocene complexes of group 4–6 metals with anionic chelating ligands. In contrast to the conventional metallocene initiators Cp2MX2 (Cp=η5-C5H5), half-metallocene complexes of the type CpM(L^L)X2 (L^L=chelating ligands) offer the advantage of catalyst modification. Steric and/or electronic modification of the coordination environment can be achieved by changing one cyclopentadienyl ligand of a metallocene complex to another ligand, such as three-, four-, five-, six- or seven-membered chelates having bidentate or tridentate coordinations and being monoanionic, dianionic or trianionic. Half-metallocene complexes with a four-membered chelating ring are focused on due to their unique dynamic behaviors of metal-centered racemization and chain transfer. The structural uniqueness of the metal complexes, the effects of the chelate ring sizes on their productivity and the activation processes of the metal complexes with cocatalysts are highlighted.

Similar content being viewed by others

Introduction

The development of single-site catalysts and catalyst precursors active in α-olefin polymerization is currently a highly popular topic in the field of polymer chemistry due to the high demand for well-defined poly(olefin)s in the petrochemical industry.1 Since the development of Kaminsky’s metallocene/methylaluminoxane (MAO) catalyst system, remarkable efforts in both academia and industry have been directed toward modifying the cyclopentadienyl (Cp) ligand architecture of metallocene-type complexes of group 4 metals to control their polymerization performance in terms of the molecular weight, molecular weight distribution, polymer microstructure and the monomer content of the copolymers.2, 3, 4 In addition, C1-, C2- and Cs-symmetric ansa-metallocene complexes have also been investigated for precise regulation of the polymer stereochemistry.5

Recent achievements have been ascribed to the use of various organic ligands containing heteroatoms as donors on supporting ligands at the metal centers of polymerization catalysts. A large number of non-metallocene complexes containing ligands with donors from all over the periodic table were prepared and tested as precatalysts for olefin polymerization.6, 7, 8, 9 Between metallocene and non-metallocene catalysts, half-metallocene complexes proved to be unique catalysts due to their appropriately sized open coordination site.10 In particular, the constrained geometry catalysts of titanium, which produce highly branched polyethylene (PE) by ethylene polymerization, inspired polymer chemists to design and prepare various types of bridging and non-bridging half-metallocene complexes with monodentate supporting ligands on combination with Cp or its derivatives.11 For bridging half-metallocene complexes, the coordination sphere can be tuned by modifying the bridging spacer. For example, a short bridging spacer opens more vacant sites for approaching monomers to the metal center. In contrast, the monomer coordination site is more flexibly tuned by using a non-bridged half-metallocene structure due to the wide applicability of the additional ancillary ligands. In this review, we provide an overview of the recent development of non-bridged half-metallocene complexes of group 4–6 metals supported by multidentate ligands and their catalytic behavior for the polymerization of α-olefins. In these reactions, ancillary ligands such as monoanionic amido, aryloxido and sulfido ligands have crucial roles not only for increasing catalytic activity but also for controlling the microstructure of poly(ethylene) and poly(olefins).

Half-metallocene group 4 metal complexes with monoanionic four-membered chelating rings

Half-metallocene complexes of the type (η5-C5R5)MX2(L^L) (M=Ti, Zr, Hf; L^L=monoanionic chelating ligands) are representative structural motifs for mixed-ligated half-metallocene complexes (Scheme 1). Among the wide variety of (η5-C5R5)M(L^L)X2 complexes, half-metallocene complexes with a four-membered chelating ring have been extensively investigated because of the availability of various amidinate, guanidinate and iminophosphoramidate ligands. This section reviews half-metallocene catalysts that have anionic chelating ligands, which form four-membered chelating rings.

The first examples of such structural units are a series of half-metallocene complexes of group 4 metals with N,N′-bis(trimethylsilyl)- or N,N′-bis(aryl)benzamidinate ligands (Figure 1).12, 13, 14, 15, 16 The benzamidinate-supported complexes (η5-C5R5)ZrX2[NR1C(Ph)NR1] (1a–d) (X=Cl, Me, CH2Ph) are active in the polymerization of ethylene on the addition of excess MAO, B(C6F5)3 or [Ph3C][B(C6F5)4]; however, their catalytic activities are rather low (up to 60 kg-PE (mol cat)−1 h−1 atm−1). Collins and co-workers17 prepared half-metallocene zirconium complexes CpZrCl2[(R2)2P(NR1)2] (2a–b) with iminophosphoramide ligands by the reaction of CpZr(NMe2)3 with the corresponding iminophosphoramine and subsequent chlorination using [Me2NH][HCl] (Figure 1). The ethylene polymerization activity was low on activation with MAO at 50 °C, because MAO could not sufficiently methylate the catalyst precursors 2a–b at a low temperature. In contrast, at elevated temperatures, 2a–b/MAO or 2a–b/[Ph3C][B(C6F5)4]/MAO exhibited higher catalytic activity and produced PE up to 180 kg-PE (mol cat)−1 h−1 atm−1.

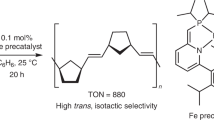

The most remarkable contribution was Sita’s half-metallocene complexes of group 4 metals with asymmetric acetamidinate ligands. Typically, the (η5-C5R5)TiMe2[NR1C(Me)NtBu] (3a–h) complexes are prepared by the reaction of (η5-C5R5)TiMe3 with asymmetric carbodiimides, R1N=C=NtBu, through insertion of the carbodiimides into metal–carbon bonds to form η3-acetamidinate moieties (equation 1).18, 19, 20 The corresponding zirconium and hafnium complexes are similarly prepared. Titanium complexes of the type (η5-C5R5)TiMe2[NR1C(Me)NR2] (3a–h) had moderate catalytic activity (up to 22 kg (mol cat)−1 h−1 atm−1) for the polymerization of ethylene on activation with MAO.18 In contrast, the zirconium complexes 4a–c and 5a–c were effective catalysts for the polymerization of α-olefins and non-conjugated dienes (Figure 2). For example, the dimethylzirconium complexes 4a and 4b initiate the living polymerization of 1-hexene with a narrow molecular weight distribution after activation with [PhNMe2H][B(C6F5)4]. The stereochemistry of poly(1-hexene) is controlled by selecting the symmetry of the half-zirconocene precursors. In fact, the C1-symmetric half-zirconocene complex 4b, which has different substituents attached to the nitrogen atoms of the acetamidinate ligand, catalyzed the stereospecific living polymerization of 1-hexene at −10 °C to give isotactic-rich poly(1-hexene) (Mw/Mn=1.03, [mmmm]>95%).20 Furthermore, in the presence of [PhNMe2H][B(C6F5)4], the zirconium complexes 5a–c catalyzed the polymerization of vinylcyclohexane at −10 °C to give poly(vinylcyclohexane) with a very narrow molecular weight distribution (Mw/Mn=1.04–1.10). It is noteworthy that all of the polymers were highly isotactic ([mmmm]>95%) even when the Cs-symmetric precatalysts 5a and 5b were used in the presence of [PhNMe2H][B(C6F5)4], suggesting that the polymerization proceeded via a typical chain-end controlled mechanism. The living polymerization ability of 4a–c and 5a–c was further utilized for the synthesis of block polymers. Complex 5b combined with [PhNMe2H][B(C6F5)4] polymerized both 1-hexene and vinylcyclohexane in a living manner to produce triblock poly(vinylcyclohexane)-poly(1-hexene)-poly(vinylcyclohexane) with an isotactic-rich poly(vinylcyclohexane) segment after sequential addition of the corresponding monomers.21 In addition, the complexes 4a–c acted as catalyst precursors for the cyclopolymerization of non-conjugated dienes, such as 1,5-hexadiene, to produce poly(methylene-1,3-cyclopentane) with a high trans ring content (up to 82% trans content) and a high degree of isotacticity.22

The most important fundamental aspect of the dissymmetric bidentate acetamidinate ligands attached to (η5-C5R5)M fragments is their ability to racemize the stereogenic metal center in neutral dialkyl complexes through either (1) a four-coordinated intermediate by the dissociation of one nitrogen donor (ligand-dissociation process) and/or (2) a five-coordinated distorted trigonal bypyramidal intermediate (ligand-flipping process), as schematically shown in Figure 3.18, 19, 23, 24, 25 Because the racemization of (η5-C5R5)MMe2[NR1C(Me)NR2] (R1≠R2) complexes proceeds at a range of temperatures on the NMR (nuclear magnetic resonance) time scale, a barrier for the racemization at the metal center has been estimated. For example, barriers for the racemization at the coalescence temperature (223–308 K) of the titanium complexes (η5-C5R5)TiMe2[NR1C(Me)NR2] (3a–h) are in the range of 11.0–15.2 kcal mol−1, showing that metal-centered racemization proceeds under mild conditions (Table 1).18 In addition, the barrier of the metal-centered racemization is not only influenced by the substituents on the Cp ring and nitrogen atoms of the amidinate ligands but also by the distal substituent on the central carbon of the amidinate ligands, allowing for the living and isotactic polymerization of 1-hexene by tuning the substituents on the amidinate ligands (Table 2).26

To determine the mechanism, the cationic complex [(η5-C5Me5)ZrMe[NtBuC(Me)NEt]][B(C6F5)4] (6b) was prepared by treating 4b with [HNMe2Ph][B(C6F5)4]. Because the metal center of 6b was coordinatively unsaturated, its dimerization proceeded easily in the absence of Lewis bases to form a methyl-bridged dimeric complex, [{(η5-C5Me5)Zr[NtBuC(Me)NEt]}2(μ-Me)2][B(C6F5)4]2 ([6b]2). In solution, the monomer–dimer equilibrium between 6b and [6b]2 and the exchange of the methyl groups bound to the zirconium atom were very rapid. Eventually, a mixture of a 13C-labeled cationic methyl complex (6b-13C) and a non-labeled cationic methyl complex with the N,N′-diisopropylacetamidinato ligand (6d) resulted in the fully 13C-scrambled mixture 6b, 6b-13C, 6d and 6d-13C (Scheme 2). Accordingly, it can be assumed that a polymer chain exchange reaction between active and/or dormant metal centers proceeds in the same manner.27, 28

To confirm metal-centered racemization during the polymerization reaction, a neutral dialkyl complex and a cationic alkyl complex were mixed to determine whether a degenerative living polymerization proceeded (Figure 4).25, 29, 30, 31 A living polymerization is considered degenerative if reversible deactivation occurs during polymerization, that is, if the dormant species forms reversibly. The aforementioned test reaction was a 1:1 mixture of the cationic methylzirconium species [Zr]+-Me (6b) and the neutral dimethylzirconium complex Me-[Zr]-Me (4b), to which monomers such as propene were added. As schematically outlined in Figure 4, the cationic methyl-zirconium species 6b reacted with propene to afford [Zr]+-P, and a subsequent alkyl exchange reaction between [Zr]+-P and Me-[Zr]-Me produced an additional [Zr]+-Me and a dormant dialkyl species, P-[Zr]-Me, through monocationic μ-alkyl dimeric species A. The entire polymerization process is schematically shown in Scheme 3. The initial cationic catalyst 6b afforded the cationic active species [Zr]+-P (B) with an isotactic polypropene block after the addition of a monomer. A subsequent alkyl exchange reaction between [Zr]+-P and Me-[Zr]-P produced an additional [Zr]+-P and a dormant dialkyl species, P-[Zr]-Me, through a monocationic μ-alkyl dimeric species A, as described in Figure 4. The dormant methyl-polymeryl species, P-[Zr]-Me, was then racemized, and subsequent demethylation by other cationic alkyl species produced cationic alkyl species with different configuration, leading to the formation of isotactic polymeryl chains with mmrm stereoerror (Scheme 3). The frequency of the stereoerror in the polypropenes is controllable by changing the amount of the borate activator, leading to a different concentration of neutral dialkylzirconium species. A series of bimetallic complexes with linking amidinate ligands, [(η5-C5Me5)ZrMe2][NtBuC(Me)N]-(CH2CH2)n-[NC(Me)NtBu][(η5-C5Me5)ZrMe2] (7a–c in Figure 5), were investigated in association with the degenerative transfer living polymerization.32 Shorter linkers, that is, keeping the two metal centers in close proximity, led to an increased energy barrier for epimerization due to steric interactions, and therefore resulted in a smaller degree of stereoerror in the polymer.

Conceptual scheme for degenerative living polymerization.25

Steric congestion around the metal center is another important factor. For example, the N,N-diethylacetamidinate-supported half-metallocene complexes of hafnium exhibit a unique behavior in the chain transfer polymerization of α-olefins in combination with excess amounts of main group metal alkyl reagents such as ZnEt2 and AlR3 (R=Me, Et, nPr, nBu). Main group alkyls serve as ‘surrogate’ metal sites because the chain transfer between the hafnium center and the main group alkyls is reversible, leading to the formation of main group metal compounds with growing polymer chains (Scheme 4). Typically, when (η5-C5Me5)HfMe2[NEtC(Me)NEt] is activated by 1 equiv [HNMe2Ph][B(C6F5)4] under a propene atmosphere in the presence of different amounts of ZnEt2, the molecular weight of the polymer is highly dependent on the ratio of the hafnium precatalyst and ZnEt2 (Table 3).33, 34, 35 Decreasing the amount of ZnEt2 results in an increase in the molecular weight of the polypropene while maintaining the catalytic activity and narrow molecular weight distribution (Mw/Mn<1.10).

Furthermore, ZnEt2 mediates the reversible transfer of polymer chains between the catalytically active hafnium center of (η5-C5Me5)HfMe2[NEtC(Me)NEt]/[HNMe2Ph][B(C6F5)4] and trialkylaluminum reagents (such as AliBu3) as a primary surrogate (Scheme 5). In this ternary, living, coordinative chain transfer polymerization, it is notable that the addition of AliBu3 reduced the required amount of ZnEt2. In this approach, a variety of end-functionalized polyolefins was accessible after appropriately quenching the polymer-bound aluminum species.36 As ZnEt2 mediated the reversible chain transfer between the two catalytically active metal centers of [(η5-C5Me5)Hf(R){NEtC(Me)NEt}][B(C6F5)4] and [(η5-C5H5)Zr(R){NCyC(Me)NCy}][B(C6F5)4], a unique ‘chain-shuttling’ polymerization occurred between hafnium and zirconium catalysts, producing poly(ethylene-co-α-olefin)s with different segments of α-olefin incorporation (Scheme 6).37 Thus, such dynamic, bimolecular chain transfer processes have been systematically applied to these half-metallocene amidinate complexes, leading to the production of new types of polyolefin materials. Controlling the dynamic processes between catalysts or a catalyst and main group metal alkyls by changing the different molar ratio of activator or different main group elements enable us to produce many materials, such as stereoblock and stereogradient polymers, from one catalyst.38

Half-metallocene group 4 metal complexes with monoanionic five- and six-membered chelating rings

Half-metallocene complexes with five- and six-membered chelating rings have been less explored compared with those bearing a monoanionic four-membered chelating ring, presumably due to the suppressed reactivity caused by the steric effects of the five- and six-membered chelating rings. Nonetheless, several precatalysts active in α-olefin polymerization have been reported to date.

Group 4 metal complexes bearing both Cp and pyridylalkoxide ligands were the first reported examples of half-metallocene complexes with monoanionic five-membered chelating rings (Figure 6).39 Dichloride complexes, (η5-C5H5)M{NC5H4(CR2O)-2}Cl2 (8a: M=Ti, R=iPr; 8b: M=Ti, R=Ph; 9a: M=Zr, R=iPr; 9b: M=Zr, R=Ph), were prepared by the reaction of (η5-C5H5)MCl3 with the lithium salt of the corresponding ligands. Complexes 8a and 8b exhibited moderate activity (16–140 kg-PE (mol cat)−1 h−1 atm−1) in the polymerization of ethylene in the presence of excess MAO. We investigated the α-olefin polymerization performance of group 4 metal complexes with iminopyrrole ligands.40, 41, 42, 43, 44 Treatment of (η5-C5Me5)MMe3 with (N-alkyl/aryl-iminomethyl)pyrrols afforded various half-metallocene dimethyl complexes (10a, 11a, 12a–c) with five-membered dissymmetric chelating iminopyrrolyl ligands (Figure 6).45, 46 Among the series of (η5-C5Me5)M(R-pyr)Me2 (R-pyr=(N-alkyl/aryl-iminomethyl)pyrrolyl) complexes, the hafnium complexes (η5-C5Me5)Hf(R-pyr)Me2 (12a–c) produced isotactic poly(1-hexene) on activation with [Ph3C][B(C6F5)4] (Table 4). The molecular weights of the poly(1-hexene)s obtained from 12a/[Ph3C][B(C6F5)4] at 25 °C were almost constant when the reaction time was extended, and the 1H NMR spectra of the resulting poly(1-hexene)s showed resonances corresponding to internal alkene protons, suggesting that β-H elimination was the terminal step (runs 1 and 2). Notably, the same polymerization conditions for 12a–c/[Ph3C][B(C6F5)4] below 0 °C produced poly(1-hexene)s with very narrow molecular weight distributions (Mw/Mn<1.10), and no alkenes formed in the polymer chain, suggesting a living polymerization (runs 3–5, 7, 8 and 11). Substituents on the imine-nitrogen atom of the ligand enhanced the catalytic activity and increased the isotacticity of the polymers. The isotacticity of poly(1-hexene)s obtained from 12c/[Ph3C][B(C6F5)4] was moderately high due to the relatively fast racemization rate around the catalytically active metal center compared with 12a and 12b (runs 5 and 8 vs 11).

Because the iminopyrrolyl complexes 10a, 11a and 12a exhibit fluxional behavior due to site-exchange racemization similar to the process of the four-membered system shown in Figure 3, the thermodynamic parameters of the racemization were estimated by variable temperature NMR measurements. The ring-flipping mechanism (mode A) occurs through a distorted trigonal-bipyramidal intermediate, whereas the ligand-dissociation mechanism (mode B) proceeds through a three-legged piano-stool geometry after dissociation of the imine moiety. The positive ΔS‡ value of 10a assignable to a ligand-dissociation mechanism (mode B) is ascribed to both the small ionic radii of titanium and the large chelating ring. In contrast, zirconium and hafnium favor a five-coordinated trigonal-bipyramidal intermediate (mode A), as confirmed by the negative ΔS‡ values for the racemization process (Table 5).

The half-titanocene complexes 13a–g bearing iminoindole ligands were synthesized by treating (η5-C5R5)TiCl3 (R=H, Me) or (η5-C5H4Me)TiCl3 with the sodium salts of iminoindole ligands. The catalytic activity of the complexes was tested for the polymerization of ethylene and copolymerizations of ethylene/1-hexene and ethylene/methyl 10-undecanoate.47 On activation with MAO (100 equiv), the titanium complexes with a Cp ligand showed moderate activity (152–512 kg-PE (mol cat)−1 h−1 atm−1). The corresponding titanium complexes with methyl-substituted Cp ligands exhibited even lower catalytic activity (up to 88 kg-PE (mol cat)−1 h−1 atm−1) due to the steric hindrance of the substituted Cp ligands. It is noteworthy that the copolymerization of ethylene and polar monomers, such as esters, was catalyzed by late transition metal catalysts because of their tolerance toward the ester functional group.48 The copolymerization of ethylene and methyl 10-undecenoate was catalyzed by complexes 13a–g, which are the first examples of early transition metal catalysis. In this catalytic system, however, pretreatment of methyl 10-undecanoate with alkylaluminum reagents was necessary for consistent reproducibility. Moreover, the resulting poly(ethylene-co-methyl 10-undecenoate)s contained ∼1 mol% of methyl 10-undecenoate units.

The half-zirconocene complexes containing the phosphine-(thio)phenolate ligands (η5-C5R5)ZrCl2(X^PPh2)(THF) (14: R=H, Me; X=O, S) were synthesized by the reaction of (η5-C5R5)ZrCl3 with the sodium salt of the phosphine-(thio)phenolate ligands (eq. 2).49 The complexes 14a–i adopt a six-coordinate, distorted octahedral geometry around the zirconium center with a five-membered chelating ring. Substituents on the aromatic ring of the phosphine-(thio)phenolate ligands affected the configuration of 14a–i: the chalcogen donor occupied the equatorial position and the phosphorous atom of the chelating ligand was located at the axial site. In the presence of excess modified MAO (MMAO), these zirconium complexes (14a–i) were examined for use as catalysts for ethylene polymerization, and the results are summarized in Table 6. Substituents at the R1 position affected the catalytic performance, and a trimethylsilyl group at the R1 position clearly improved the catalytic activity compared with phenyl- and tert-butyl-substituted ligands. Changing the donor element from oxygen to sulfur slightly decreased the catalytic activity. The pentamethylcyclopentadienyl complexes 14a–e showed lower activity and produced higher molecular weight polymers than the Cp-analogous 14f–i, as the bulky (η5-C5Me5) ligand decelerated both the ethylene insertion and the chain transfer reaction. The Cp-based complexes 14f–i were less bulky, therefore these complexes promoted the copolymerization of ethylene and 1-hexene with high activity.

Selected half-metallocene complexes with six-membered chelating rings are depicted schematically in Figure 7.50, 51, 52, 53 In 2003, Bochmann and Lancaster50 reported the half-metallocene complexes of titanium and zirconium with phenoxy-imine (15a–c and 16a–c) and phenoxy-amine ligands (17–19), which they prepared by treating (η5-C5H5)MCl3 (M=Ti, Zr) with the lithium salts of phenoxy-imine and -amine ligands in tetrahydrofuran (THF), respectively. These complexes have a six-membered chelating ring, except for 19, whose amine moiety dissociates from the metal center due to steric congestion in solution. Complexes 15–19 have moderate activity (2–210 kg-PE (mol cat)−1 h−1 atm−1) for the polymerization of ethylene on combination with excess MAO. The catalytic activity of the phenoxy-imine complexes 15a–c and 16a–c is slightly higher than that of phenoxy-amine complexes 17–19.

The β-enaminoketonato half-metallocene complexes of titanium (20a–d) were also prepared by reacting (η5-C5H5)TiCl3 with the corresponding free ligand in the presence of NEt3 as a base.51 The catalyst system 20a–d/MMAO was active for the homopolymerization of ethylene and also for the copolymerization of ethylene and norbornene. As a result, an unexpected additive effect was observed: the addition of norbornene (∼2000 equiv to Ti) to the reaction mixture improved the catalytic activity, and the resulting ethylene/norbornene copolymers had high molecular weights and relatively narrow Mw/Mn values (2.02–2.93). In contrast, a large excess of norbornene (∼10 000 equiv to Ti) severely decreased the catalytic activity.

The half-metallocene complexes possessing phosphine oxide-(thio)phenolate ligands 21–23 exhibit moderate-to-high catalytic activity toward ethylene polymerization (up to 3320 kg-PE (mol cat)−1 h−1 atm−1) on activation with a cocatalyst system of [Ph3C][B(C6F5)4] and AliBu3, yielding PE with a unimodal molecular weight distribution. A unique feature is that the best catalytic performance for each complex was observed at a high temperature (75 °C).52, 53 Notably, 23a–g, bearing only one chloride ligand, exhibited high catalytic activity after activation with MMAO. Similar catalytic behavior was also observed for the half-metallocene complexes 24 and 25, which were supported by two phenoxy-imine ligands and one chloride ligand.54, 55 Scheme 7 shows the activation process of monochloro complex 23b by AlMe3 according to DFT calculations. In the first stage, 23b reacts with AlMe3 to form the monomethyl species A. The subsequent reaction of A with AlMe3 affords the Zr/Al species B. Next, the oxygen atom of the phenoxy moiety interacts with the additional AlMe3 to form a μ-methyl-bridged heterobimetallic species. After π-complexation of ethylene, dissociation of the weakly interacting AlMe3 moiety from zirconium generates C. In relation to this mechanism, Stephan and co-workers56 reported that an aryloxide ligand was removed from titanium when excess AlMe3 was added to CpTi(OAr)2Cl complexes, resulting in the transfer of one aryloxide ligand to the aluminum center and yielding CpTi(OAr)Me2 and [Me2Al]2(μ-OAr)2 complexes.

Tridentate ligand coordination to half-metallocene units provides another class of catalysts for olefin polymerization. A monoanionic quinoline-amino-phenolate tridentate ligand was introduced to a half-zirconocene complex to give 26, which was comprized of both a five-membered and a six-membered chelating ring.57 Complex 26 was active in the polymerization of ethylene on activation with excess MAO, and the best catalytic activity (403 kg-PE (mol cat)−1 h−1 atm−1) was achieved at 75 °C in the presence of 1000 equiv MAO.

Half-metallocene group 4 metal complexes with monoanionic three-membered chelating rings

Three-membered chelates are attractive structural motifs because there is little steric congestion around the reactive metal center. Monoanions of hydrazine, pyrazole, hydroxylamine and phosphinoamines were introduced to half-metallocene fragments as shown in Figure 8.58, 59, 60, 61 Complexes 27a–c, 28a–g and 30a–c possess a four-legged piano-stool geometry around the titanium atoms, whereas complexes 29a–f adopt a trigonal bipyramidal geometry in which the (η5-C5Me5) ligand and a nitrogen atom occupy the axial positions. Ethylene polymerization activity of 27a–c in the presence of excess MAO was low (up to 55 kg-PE (mol cat)−1 h−1 atm−1), whereas η2-pyrazolato-coordinated complexes 28a–g had high ethylene polymerization activity in combination with excess d-MAO. Among the (η5-C5H5) titanium complexes 28a–d with η2-pyrazolato ligands, catalytic activity was improved by increasing the size of R1 (R1=Ph (28d), up to 200 kg-PE (mol cat)−1 h−1 atm−1). In contrast, the activity of the (η5-C5Me5) analogs 28e–g was increased by decreasing the steric bulk on the η2-pyrazolato ligands (R1=H, up to 1500 kg-PE (mol cat)−1 h−1 atm−1).

The η2-(N,O)-chelated hydroxyaminato complexes 29a–f were examined as precatalysts for the polymerization of propene in the presence of [Ph3C][B(C6F5)4]/Al(iBu)3. The propene polymerization activity of 29a was comparable to that of other metallocene and half-metallocene complexes of group 4 metals. The obtained polymers were atactic poly(propene)s with a narrow molecular weight distribution (Mw/Mn≈2). N,N-Dialkyl-substituted hydroxyaminato complexes 29a and 29b showed higher propene polymerization activity than the N-alkyl-N-aryl-substituted complexes 29c–f. The cocatalyst had clear effects on the ethylene polymerization activity of the η2-(N,P)-chelated phosphinamide complexes 30a–c. When MMAO was used as the cocatalyst, the catalytic activity was low (up to 64 kg-PE (mol cat)−1 h−1 atm−1), whereas the catalytic activity of 30a/[Ph3C][B(C6F5)4]/Al(iBu)3 was dramatically improved by changing the Ti/Al ratio. The highest activity was observed with Ti/Al=1/200 (2516 kg-PE (mol cat)−1 h−1 atm−1).

Half-metallocene group 4 metal complexes with dianionic and trianionic chelating ligands

The introduction of dianionic chelating ligands to half-titanocene fragments is distinctively featured by the formation of monochloro and monoalkyl complexes (Figure 9).62, 63, 64 The complexes 31–33 were active in the polymerization of ethylene and α-olefins in the presence of excess amounts of MAO or AlR3/[Ph3C][B(C6F5)4]. To elucidate the activation step for the monochloro complex 31a, we investigated the additive effect of the cocatalysts with 31b for ethylene polymerization (Table 7).62 A mixture of 31a and [Ph3C][B(C6F5)4] in the presence of Al(iBu)3 (100 equiv) showed the highest ethylene polymerization activity, indicating that the two components were indispensable in this catalyst-activation process. Otherwise, the catalytic activity of 31b with only [Ph3C][B(C6F5)4] or Al(iBu)3 was very low (run 1 vs runs 6 and 7). Changing Al(iBu)3 to AlMe3 almost completely suppressed the catalytic activity due to inefficient catalyst activation (run 2, vide infra). When complex 31a was treated with excess amounts of MAO, MMAO or dried MMAO (d-MMAO) under an ethylene atmosphere, the catalyst showed moderate activity (runs 3–5). The better catalytic activity of 31a/MMAO and 31a/d-MMAO may be attributed to the importance of an isobutyl group attached to the aluminum atom in the cocatalyst. On the other hand, a mixture of 31a and Al(C6F5)3 showed no ethylene polymerization activity (run 8). Therefore, the roles of both [Ph3C][B(C6F5)4] and Al(iBu)3 in the reaction with the benzyltitanium complex 31c as the catalyst precursor were investigated. Scheme 8 shows a plausible pathway for the generation of the catalytically active species. The addition of Al(iBu)3 to 31c resulted in the formation of the bimetallic species 34c, where the amido-nitrogen atom of the pyrrolylamido ligand bridged the titanium and aluminum atoms. The subsequent reaction of 34c with [Ph3C][B(C6F5)4] generated triphenylmethane, isobutene and the cationic benzyltitanium species 35c through H abstraction from the isobutyl group attached to the aluminum atom. During the H abstraction reaction, the aluminum atom covalently bonded to the amido-nitrogen atom to form complex 35c, which was active for further insertion of ethylene into the titanium–carbon bond. The low catalytic activity of 31b/[Ph3C][B(C6F5)4]/AlMe3 is rationally ascribed to the difficulty of abstracting H from the methyl group attached to the aluminum.

The dianionic tridentate ligands O^N^O=NR2(CH2CHR1O)2 and the trianionic tetradentate ligands N(^O)3=N(CH2CHR1O)3 were introduced to (η5-C5Me5)M fragments to give (η5-C5Me5)MCl(O^N^O) (36a–e for M=Ti; 37a for M=Zr) and (η5-C5Me5)M[(N^O)3] (38a–d for M=Ti; 39a for M=Zr; 40a for M=Hf), respectively (Figure 10).65, 66, 67, 68, 69, 70, 71 The complexes 36a–e and 37a became active catalysts for ethylene polymerization on treatment with MMAO, although their catalytic activity was low (10–65 kg-PE (mol cat)−1 h−1 atm−1). The catalyst-activation pathway of these complexes with the aluminum cocatalyst has not yet been elucidated. The triethanolamine non-halide complexes 38a, 39a and 40a exhibited much higher activities (for Ti: up to 740 kg-PE (mol cat)−1 h−1 atm−1, for Zr: up to 260 kg-PE (mol cat)−1 h−1 atm−1, for Hf: up to 42 kg-PE (mol cat)−1 h−1 atm−1) for ethylene polymerization in the presence of MAO, compared with the (η5-C5Me5)TiCl3/MAO system.66 The titanium complexes 38a–d are reported to assist the syndiospecific polymerization of styrene.65, 67, 68, 69, 70, 71

Benzimidazolyl-based tridentate ligands were developed by Sun et al., who prepared the half-titanocene complexes 41–43 (Figure 11) as catalyst precursors for ethylene polymerization and ethylene/α-olefin copolymerization. The complexes 41a–g bearing (η5-C5H5) or (η5-C5H4Me) and benzimidazolyl-pyridyl ligands were active (480–660 kg-PE (mol cat)−1 h−1 atm−1) for ethylene polymerization in the presence of excess MAO, whereas the same catalytic system was inactive in the ethylene/α-olefin copolymerization.72 The methyl substituents on the Cp ring reduced the catalytic activity for complexes 41h–m due to the steric protection around the relatively crowded metal center (140–300 kg-PE (mol cat)−1 h−1 atm−1). Furthermore, the amount of MAO strongly affected the catalytic activity. When 750 equiv MAO was applied to complex 41a, PE was not obtained; however, PE production was improved (260 kg-PE (mol cat)−1 h−1 atm−1 at 80 °C) in the presence of 1500 equiv MAO. In addition, the catalytic activity was four times higher when 10 000 equiv MAO was used (1060 kg-PE (mol cat)−1 h−1 atm−1 at 80 °C). The complexes 42a–h and 43a–f catalyzed both ethylene homopolymerization and ethylene/α-olefin copolymerization.73, 74 In the case of ethylene polymerization with 42a–h and 43a–f, increasing the amount of MAO to 30 000 equiv and elevating the reaction temperature to 80 °C resulted in high catalytic activity (up to 650 kg-PE (mol cat)−1 h−1 atm−1). Notably, 43a–f furnished linear high-density PE with high Tm values (131–135 °C) and much higher molecular weights than those of PE obtained from 41a–m and 42a–h. The degree of 1-hexene or 1-octene incorporation in the ethylene/α-olefin copolymers was controllable by changing the ligand substituents in 42a–h and 43a–f. Under identical copolymerization conditions with ethylene and 1-hexene, 42a–h/MAO produced copolymers with ∼2 mol% content of 1-hexene, whereas 43a–f/MAO afforded higher amounts of 1-hexene incorporation for copolymers (up to 4.3 mol%).

Half-metallocene group 5 metal complexes with anionic chelating ligands

In the late 1960s, chloride and acetylacetonate complexes of vanadium were reported to be active for α-olefin polymerization on treatment with excess alkylaluminum reagents.75, 76 Ligand architectures around the vanadium atom were extensively investigated for controlling stereoselectivity (2,1-insertion) and the living nature of polymerization.77, 78, 79 In contrast to the homoleptic complexes of vanadium, group 5 metal complexes bearing suitable organic ligands have been less developed, except for our reports on the half-metallocene complexes of niobium and tantalum with substituted butadiene, 1-azabutadiene and 1,4-diazabutadiene ligands.80, 81, 82

Surprisingly, metallocene complexes of niobium and tantalum, (η5-C5H5)2MCl2 (M=Nb, Ta), are catalytically inactive in the polymerization of ethylene, even when combined with excess MAO. Group 5 metal diene fragments, (η5-C5R5)M(η4-diene), which are isoelectronic to (η5-C5R5)2M (M=group 4 metals), are unique structural motifs that show catalytic activity in living ethylene polymerization, yielding PE with a very narrow molecular weight distribution.83, 84 The catalyst precursors (η5-C5R5)MCl2(η4-diene) (M=Nb (44: R=H, 45: R=Me), Ta (46: R=H, 47: R=Me)) and their dimethyl derivatives 48–51 were prepared by reacting (η5-C5R5)MCl4 with 1,3-diene compounds of magnesium in THF and methylating the corresponding complexes with 2 equiv MeMgI. By adding 2 equiv of the magnesium-diene reagents to (η5-C5R5)MCl4, the corresponding bis(diene) complexes of niobium and tantalum (52–55) were obtained (Figure 12).85, 86, 87

The half-metallocene diene complexes of niobium and tantalum act as catalysts for living polymerization of ethylene in the presence of 500 equiv of MAO (Table 8). The dichloro- and dimethyl-tantalum complexes 47a and 51a/MAO exhibited almost the same catalytic activity, suggesting the formation of the same catalytically active cationic alkyl species in the reaction mixture (runs 10 and 11 vs 13 and 14). The structure of the diene ligands affected the catalytic activity. For example, niobium and tantalum complexes with 1,3-butadiene- or 2,3-dimethyl-1,3-butadiene-derived ligands had relatively high catalytic activity compared with complexes having a 2-methyl-1,3-butadiene-derived ligand (runs 3, 4 and 7). Methyl substituents on the Cp ligand stabilized the catalytically active species. At room temperature, the catalytic activity of the (η5-C5Me5) complex 47a was higher than that of the (η5-C5H5) complex 46a (runs 8 and 10). On the other hand, complex 46a had higher catalytic activity at −20 °C compared with the polymerization reaction conducted at room temperature, due to the low stability of the catalytically active cationic alkyl species derived from 46a (runs 8 vs 9). Notably, the narrow molecular weight distribution (Mw/Mn=1.05–1.51) of PE was obtained at −20 °C by this series of niobium and tantalum complexes in the presence of MAO (500 equiv). In addition, the plot of the reaction time vs the molecular weight for PE obtained with 51a/MAO revealed a linear relationship while maintaining a narrow molecular weight distribution, clearly demonstrating the living nature of the ethylene polymerization. Treatment of 51b with B(C6F5)3 in C6D6 led to the formation of a cationic methyl species [(η5-C5Me5)TaMe(η4-isoprene)][MeB(C6F5)3] that was active for ethylene polymerization without any other additives. This species, however, had low catalytic activity.

When the bis(diene) complexes 52–55 were utilized as catalyst precursors, the catalytic activity was essentially the same as that of the corresponding mono(diene) complexes (runs 5–7 vs 15–17). On the basis of the Mn and Mw/Mn values of the PE obtained from 45c and 53c, the initiation efficiency of 53c was higher (78–92%) than that of 45c (27–34%). This result was consistent with the stability of the diene-coordinated aluminum species generated during the activation by MAO.

Some metallocene complexes of group 3 and group 4 metals initiate living polymerization of methyl methacrylate (MMA) and methyl acrylate to yield syndiotactic polymers.88 Furthermore, half-metallocene tantalum complexes containing two-electron-reduced N,N′-disubstituted-1,4-diaza-1,3-butadiene and MMA ligands (56) were reported to act as catalyst precursors for MMA polymerization in the presence of 1 equiv of AlMe3 as the cocatalyst.89 Polymerization below 0 °C produced syndiotactic-rich poly(MMA) in a high yield with a narrow molecular weight distribution (Mw/Mn=1.2). The molecular weight of poly(MMA) linearly increased with consumption of the monomer, indicating living polymerization behavior. Control experiments for the reaction of 56 and 1 equiv of AlMe3 at −20 °C revealed that the carbon atom bound to tantalum in 56 was transmetallated to aluminum to form the catalytically active tantalum-enolate species 57, although 57 was decomposed at room temperature to give the catalytically inactive dimethyl complex 58 (Scheme 9).

Half-metallocene group 6 metal complexes with anionic chelating ligands

Chromium-based catalyst systems have attracted considerable attention for their widespread commercial use in heterogeneous ethylene polymerization catalysis using CrO3 on silica (Phillips catalyst)90 and Cp2Cr on silica (Union Carbide catalyst).91, 92 Several half-chromocene complexes bearing neutral or monoanionic ligands as models for such heterogeneous catalysts have been developed.93, 94, 95, 96, 97, 98, 99, 100, 101, 102 Some cationic alkylchromium complexes were reported by Theopold et al.103, 104 as homogeneous model complexes for chromium-based ethylene polymerization catalysts. The reaction of [(η5-C5Me5)CrR1]2(μ-Cl)2 (59, R1=Me, Et) with TlPF6 in the presence of Lewis bases afforded [(η5-C5Me5)CrR1(L)][PF6] (60, R1=Me, Et; L=py, 3,5-lutidine, 2,2′-bipyridyl, PMe3, 1,2-bis(diphenylphosphino)ethane (dppe), 1,2-bis(dimethylphosphino)methane (dmpe); Scheme 10). When the dimeric methylchromium complex was used as the starting material, the resulting cationic methylchromium complex 61 with two coordinating THF molecules was isolated and structurally characterized. Complex 61 exhibited catalytic ethylene polymerization activity, and the resulting PEs had rather narrow molecular weight distributions (Mw/Mn=1.41–4.60) and little branching, suggesting that 61 was a single-site catalyst.

The acetylacetonato derivatives, (η5-C5R5)Cr(acac)X (62, R=H, Me; X=Cl, Br), were prepared by treating (η5-C5R5)CrX2 with sodium acetylacetonate in THF.105 Excess AlEt3 and ClAlEt2 (Cr/Al=1/300) proved to be the best cocatalysts for the activation of 62, although the catalytic activities were very low (∼1 kg-PE (mol cat)−1 h−1 atm−1). Phenoxy-imine ligands were used for bidentate support to give (η5-C5Me5)CrCl[2,4-tBu2-6-(CH=NR)C6H2O] (R=tBu (63a), Ph (63b), 2,6-iPr2C6H3 (63c)). The ethylene polymerization activities of these complexes similarly improved on activation with a slight excess of AlMe3 (Table 9).106, 107, 108 The substituent on the nitrogen atom of the phenoxy-imine ligand significantly affected the catalytic activity: the catalytic activity of 63a with an alkyl substituent on the imine moiety was higher than that of 63b–c bearing aromatic rings. For all of the complexes, the catalytic activity was decreased with an increase in the amount of AlR3, indicating that the alkyl-bridged heterobimetallic chromium–aluminum species and a mononuclear chromium complex were in equilibrium in the reaction mixture (Scheme 11). Remarkably, the type of alkyl group in trialkylaluminum also influenced the catalytic behavior: bulky R groups attenuated the polymerization rate by impeding the approach of ethylene to the chromium center.

β-Ketoiminate, β-diketiminate, hydroxyindanimine and binaphthyl-based Schiff base ligands were used as six-membered chelating ligands on half-metallocene complexes of chromium (Figure 13).109, 110 Under an atmospheric pressure of ethylene, the activity of 64a–e and 65 depended on the cocatalyst: adding excess MAO had no effect on ethylene polymerization activity, whereas AlEt3 (25 equiv) activated these complexes to give PE (up to 153 kg-PE (mol cat)−1 h−1 atm−1). Similarly, the complexes 66a–e were active for the polymerization of ethylene (up to 168 kg-PE (mol cat)−1 h−1 atm−1) in combination with AlEt3. When a binaphthyl backbone was used as a ligand motif to synthesize the dinuclear half-metallocene complexes 67a–c, the catalytic activity for ethylene polymerization was improved compared with the mononuclear analogs.

Poli et al.111, 112, 113, 114 reported that the 17-electron diene complexes of molybdenum (η5-C5R5)Mo(η4-diene)X2 (68) have very low catalytic ethylene polymerization activity (<0.02 kg-PE (mol cat)−1 h−1 atm−1) on treatment with excess MAO, presumably due to the low polarity and high strength of the molybdenum–carbon bond. In sharp contrast to the above-mentioned coordination–insertion polymerization systems, a controlled radical polymerization reaction was achieved with half-metallocene complexes of chromium(II) having monoanionic nacnac ligands (69a–e).115, 116, 117 The key reaction step involved the reductive cleavage of the carbon–halogen bond of the initiator to form CpCr(X)(nacnac) (70a–e) and CpCr(R)(nacnac) (71a–e), both of which formed in the reaction of 69a–e with the generated organic and halo radicals (Scheme 12). Thus, the complexes 71a–e dissociated with the low-oxidation state metal species 69a–e and an organic radical, the latter of which initiated the controlled radical polymerization of styrene, acrylates and vinyl acetate.

Conclusion

A variety of effective and selective half-metallocene catalysts of group 4–6 metals are now available for α-olefin polymerization reactions. Therefore, atactic poly(α-olefin)s, poly(ethylene/α-olefin) as well as stereoselective, stereogradient and stereoblock poly(α-olefin)s can be efficiently synthesized. The influence of the structures of the half-metallocene catalyst complexes with chelating ligands on the properties of the generated polymers is now under intense investigation to develop new classes of polymerization catalysts. The substituents on the Cp ring, the chelating ring size and the donor elements in the chelating ring are important factors for controlling the propagation step in the growing polymer chains. In addition, the fluxional behavior of various chelating ligands attached to the metal center has an important role in regulating the stereoselectivity of the polymerization. Future efforts to fine-tune the catalyst architecture may open new avenues toward the creation of unique poly(α-olefin)-based materials.

Structural motif of (η5-C5R5)MX2(L^L).

Scrambling of a labeled methyl group in cationic zirconium complexes.

Synthesis of isotactic polypropene with mmrm stereoerror through degenerative transfer living polymerization with (η5-C5Me5)ZrMe2[NtBuC(Me)NEt]/[HNMe2Ph][B(C6F5)4] as a catalyst precursor. A full color version of this figure is available at Polymer Journal online.

Living coordinative chain transfer polymerization of α-olefins by (η5-C5Me5)HfMe2[NEtC(Me)NEt]/[HNMe2Ph][B(C6F5)4] and ZnR2.34 A full color version of this figure is available at Polymer Journal online.

Ternary living coordinative chain transfer polymerization of α-olefins by (η5-C5Me5)HfMe2[NEtC(Me)NEt]/[HNMe2Ph][B(C6F5)4]/ZnR2/AlR3.36

Living coordinative chain transfer polymerization of α-olefins by (η5-C5Me5)HfMe2[NEtC(Me)NEt]/[HNMe2Ph][B(C6F5)4]/(η5-C5H5)ZrMe2[NCyC(Me)NCy]/[HNMe2Ph][B(C6F5)4] and ZnR2.37 A full color version of this figure is available at Polymer Journal online.

Proposed reaction pathway for generating catalytically active cationic alkyl species from the monochloro complex.

AliBu3-mediated activation pathway for the generation of catalytically active cationic alkyl species.

Activation pathway for the generation of the catalytically active tantalum-enolate species.

Half-chromocene complexes as ethylene polymerization catalysts.

Half-metallocene chromium complexes under catalytic polymerization conditions (AlR3/C2H4).

Controlled radical polymerization by means of half-metallocene chromium complexes.

References

Gladysz, J. A. (ed.). Frontiers in metal-catalyzed polymerization (special issue). Chem. Rev. 100, 4 (2000).

Sinn, H. & Kaminsky, W. Ziegler-Natta catalysis. Adv. Organomet. Chem. 18, 99–149 (1980).

Kaminsky, W ., Miri, M ., Sinn, H. & Woldt, R. Bis(cyclopentadienyl)zirkon-verbindungen und aluminoxan als Ziegler-Katalysatoren für die polymerisation und copolymerisation von olefinen. Makromol. Chem. Rapid Commun. 4, 417–421 (1983).

Scheirs, J. & Kaminsky, W. Metallocene-Based Polyolefins, (Wiley, 2000).

Brintzinger, H. H ., Fischer, D ., Mulhaupt, R ., Rieger, B. & Waymouth, R. M. Stereospecific olefin polymerization with chiral metallocene catalysts. Angew. Chem. Int. Ed. 34, 1143–1170 (1995).

Rieger, B ., Baugh, L. S ., Kacker, S. & Striegler, S. Late Transition Metal Polymerization Catalysis, (Wiley, 2003).

Coates, G. W ., Hustad, P. D. & Reinartz, S. Catalysts for the living insertion polymerization of alkenes: access to new polyolefin architectures using Ziegler-Natta chemistry. Angew. Chem. Int. Ed. 41, 2236–2257 (2002).

Gibson, V. C. & Spitzmesser, S. K. Advances in non-metallocene olefin polymerization catalysis. Chem. Rev. 103, 283–315 (2003).

Domski, G. J ., Rose, J. M ., Coates, G. W ., Bolig, A. D. & Brookhart, M. Living alkene polymerization: new methods for the precision synthesis of polyolefins. Prog. Polym. Sci. 32, 30–92 (2007).

McKnight, A. L. & Waymouth, R. M. Group 4 ansa-cyclopentadienyl-amido catalysts for olefin polymerization. Chem. Rev. 98, 2587–2598 (1998).

Nomura, K ., Liu, J ., Padmanabhan, S. & Kitiyanan, B. Nonbridged half-metallocenes containing anionic ancillary donor ligands: new promising candidates as catalysts for precise olefin polymerization. J. Mol. Cat. A Chem. 267, 1–29 (2007).

Chernega, A. N ., Gómez, R. & Green, M. L. H. Mono-η-cyclopentadienyl-benzamidinato compounds of titanium, zirconium and hafnium. J. Chem. Soc. Chem. Commun. 1415–1417 (1993).

Buijink, J. K ., Noltemeyer, M. & Edelmann, F. T. Metall-N,N'-bis(trimethylsilyl)benzamidinate: Synthese und Kristallstruktur von Bis[N,N-bis(trimethylsilyl)benzamidinato)chroni(II), [PhC(NSiMe3)2]2Cr. Z. Naturforsch. 46B, 1328–1332 (1991).

Gómez, R ., Green, M. L. H. & Haggitt, J. L. Unexpected reactions of pentafluorophenylboron compounds with η-cyclopentadienyl(benzamidinato)zirconium derivatives. J. Chem. Soc. Chem. Commun. 2607–2608 (1994).

Gómez, R ., Duchateau, R ., Chernega, A. N ., Teuben, J. H ., Edelmann, F. T. & Green, M. L. H. Mono-η-7-cyclopentadienyl-benzamidinato chloro compounds of titanium, zirconium and hafnium. J. Organomet. Chem. 491, 153–158 (1995).

Richter, J ., Edelmann, F. T ., Noltemeyer, M ., Schmudt, H.-G ., Shmulinson, M. & Eisen, M. S. Metallocene analogues containing bulky heteroallylic ligands and their use as new olefin polymerization catalysts. J. Mol. Cat. A Chem. 130, 149–162 (1998).

Vollmerhaus, R ., Shao, P ., Taylor, N. J. & Collins, S. Synthesis of and ethylene polymerization using iminophosphonamide complexes of group 4. Organometallics 18, 2731–2733 (1999).

Sita, L. R. & Babcock, J. R. Rapid access to dimethylcyclopentadienyltitanium(IV) amidinate, (C5R5)TiMe2[NR1C(R2)NR3] (R=H and Me; R2=Me), libraries. Organometallics 17, 5228–5230 (1998).

Koterwas, L. A ., Fettinger, J. C. & Sita, L. R. Stereospecific syntheses, metal configurational stabilities, and conformational analyses of meso-(R,S)- and (R,R)-(η5-C5R5)Ti(CH3)2-N,N’-bis(1-phenylethyl)acetamidinates for R=H and Me. Organometallics 18, 4183–4190 (1999).

Jayaratne, K. C. & Sita, L. R. Stereospecific living Ziegler−Natta polymerization of 1-hexene. J. Am. Chem. Soc. 122, 958–959 (2000).

Keaton, R. J ., Jayaratne, K. C ., Henningsen, D. A ., Koterwas, L. A. & Sita, L. R. Dramatic enhancement of activities for living Ziegler−Natta polymerizations mediated by “exposed” zirconium acetamidinate initiators: the isospecific living polymerization of vinylcyclohexane. J. Am. Chem. Soc. 123, 6197–6198 (2001).

Jayaratne, K. C ., Keaton, R. J ., Henningsen, D. A. & Sita, L. R. Living Ziegler−Natta cyclopolymerization of nonconjugated dienes: new classes of microphase-separated polyolefin block copolymers via a tandem polymerization/cyclopolymerization strategy. J. Am. Chem. Soc. 122, 10490–10491 (2000).

Keaton, R. J ., Koterwas, L. A ., Fettinger, J. C. & Sita, L. R. Regarding the stability of d0 monocyclopentadienyl zirconium acetamidinate complexes bearing alkyl substituents with β-hydrogens. J. Am. Chem. Soc. 124, 5932–5933 (2002).

Zhang, Y ., Keaton, R. J. & Sita, L. R. A case for asymmetric hydrozirconation. J. Am. Chem. Soc. 125, 8746–8747 (2003).

Zhang, Y ., Keaton, R. J. & Sita, L. R. Degenerative transfer living Ziegler−Natta polymerization: application to the synthesis of monomodal stereoblock polyolefins of narrow polydispersity and tunable block length. J. Am. Chem. Soc. 125, 9062–9069 (2003).

Zhang, Y ., Reeder, E. K ., Keaton, R. J. & Sita, L. R. Goldilocks effect of a distal substituent on living Ziegler−Natta polymerization activity and stereoselectivity within a class of zirconium amidinate-based initiators. Organometallics 23, 3512 (2004).

Keaton, R. J ., Jayaratne, K. C ., Fettinger, J. C. & Sita, L. R. Structural characterization of zirconium cations derived from a living Ziegler−Natta polymerization system: new insights regarding propagation and termination pathways for homogeneous catalysts. J. Am. Chem. Soc. 122, 12909–12910 (2000).

Jayaratne, K. C. & Sita, L. R. Direct methyl group exchange between cationic zirconium Ziegler−Natta initiators and their living polymers: ramifications for the production of stereoblock polyolefins. J. Am. Chem. Soc. 123, 10754–10755 (2001).

Harney, M. B ., Zhang, Y. & Sita, L. R. Discrete, multiblock isotactic–atactic stereoblock polypropene microstructures of differing block architectures through programmable stereomodulated living Ziegler–Natta polymerization. Angew. Chem. Int. Ed. 45, 2400–2404 (2006).

Harney, M. B ., Zhang, Y. & Sita, L. R. Bimolecular control over polypropene stereochemical microstructure in a well-defined two-state system and a new fundamental form: stereogradient polypropene. Angew. Chem. Int. Ed. 45, 6140–6144 (2006).

Crawford, K. E. & Sita, L. R. Stereoengineering of poly(1,3-methylenecyclohexane) via two-state living coordination polymerization of 1,6-heptadiene. J. Am. Chem. Soc. 135, 8778–8781 (2013).

Zhang, W. & Sita, L. R. Investigation of dynamic intra- and intermolecular processes within a tether-length dependent series of group 4 bimetallic initiators for stereomodulated degenerative transfer living Ziegler–Natta propene polymerization. Adv. Synth. Catal. 350, 439–447 (2008).

Zhang, W. & Sita, L. R. Highly efficient, living coordinative chain-transfer polymerization of propene with ZnEt2: practical production of ultrahigh to very low molecular weight amorphous atactic polypropenes of extremely narrow polydispersity. J. Am. Chem. Soc. 130, 442–443 (2008).

Zhang, W ., Wei, J. & Sita, L. R. Living coordinative chain-transfer polymerization and copolymerization of ethene, α-olefins, and α,ω-nonconjugated dienes using dialkylzinc as “surrogate” chain-growth sites. Macromolecules 41, 7829–7833 (2008).

Wei, J ., Hwang, W ., Zhang, W. & Sita, L. R. Dinuclear bis-propagators for the stereoselective living coordinative chain transfer polymerization of propene. J. Am. Chem. Soc. 135, 2132–2135 (2013).

Wei, J ., Zhang, W. & Sita, L. R. Aufbaureaktion redux: scalable production of precision hydrocarbons from AlR3 (R=Et or iBu) by dialkyl zinc mediated ternary living coordinative chain-transfer polymerization. Angew. Chem. Int. Ed. 49, 1768–1772 (2010).

Wei, J ., Zhang, W ., Wickham, R. & Sita, L. R. Programmable modulation of co-monomer relative reactivities for living coordination polymerization through reversible chain transfer between “tight” and “loose” ion pairs. Angew. Chem. Int. Ed. 49, 9140–9144 (2010).

Sita, L. R Ex uno plures (“out of one, many”): new paradigms for expanding the range of polyolefins through reversible group transfers. Angew. Chem. Int. Ed. 48, 2464–2472 (2009).

Doherty, S ., Errington, R. J ., Jarvis, A. P ., Collins, S ., Clegg, W. & Elsegood, M. R. J. Polymerization of ethylene by the electrophilic mixed cyclopentadienylpyridylalkoxide complexes [CpM{NC5H4(CR2O)-2}Cl2] (M=Ti, Zr, R=Ph, Pri). Organometallics 17, 3408–3410 (1998).

Mashima, K. & Tsurugi, H. Uniqueness and versatility of iminopyrrolyl ligands for transition metal complexes. J. Organomet. Chem. 690, 4414–4423 (2005).

Matsuo, Y ., Mashima, K. & Tani, K. Synthesis and characterization of bis(iminopyrrolyl)zirconium complexes. Chem. Lett. 29, 1114–1115 (2000).

Tsurugi, H ., Yamagata, T ., Tani, K. & Mashima, K. Unusual enhancement of ethylene polymerization activity of benzyl zirconium complexes by benzylation of the imino moiety of 2-(N-aryliminomethyl)pyrrolyl ligand. Chem. Lett. 32, 756–757 (2003).

Tsurugi, H ., Matsuo, Y. & Mashima, K. Preparation and characterization of iminopyrrolyl hafnium complexes as catalyst precursors for α-olefin polymerization. J. Mol. Catal. A Chem. 254, 131–137 (2006).

Tsurugi, H. & Mashima, K. Preparation and characterization of a zwitterionic (iminopyrrolyl)zirconium complex with benzylaluminate anion and its catalytic performance for 1-hexene polymerization. Organometallics 25, 5210–5212 (2006).

Yasumoto, T ., Yamagata, T. & Mashima, K. Isoselective living polymerization of 1-hexene catalyzed by half-metallocene dimethyl complexes of hafnium with bidentate N-substituted (iminomethyl)pyrrolyl ligands. Organometallics 24, 3375–3377 (2005).

Yasumoto, T ., Yamamoto, K ., Tsurugi, H. & Mashima, K. Isospecific polymerization of 1-hexene by C1-symmetric half-metallocene dimethyl complexes of group 4 metals with bidentate N-substituted iminomethylpyrrolyl ligands. Dalton Trans. 42, 9120–9128 (2013).

Zuo, W ., Zhang, M. & Sun, W.-H. Imino-indolate half-titanocene chlorides: synthesis and their ethylene (co-)polymerization. J. Polym. Sci. A Polym. Chem. 47, 357–372 (2009).

Boffa, L. S. & Novak, B. M. Copolymerization of polar monomers with olefins using transition-metal complexes. Chem. Rev. 100, 1479–1494 (2000).

Tang, X.-Y ., Long, Y.-Y ., Wang, Y.-X ., Liu, J.-Y. & Li, Y.-S. Synthesis and characterization of phosphine-(thio)phenolate-based half-zirconocenes and their application in ethylene (co-)polymerization. Dalton Trans. 43, 222 (2014).

Bott, R. K. J ., Hughes, D. L ., Schormann, M ., Bochmann, M. & Lancaster, S. J. Monocyclopentadienyl phenoxy-imine and phenoxy-amine complexes of titanium and zirconium and their application as catalysts for 1-alkene polymerization. J. Organomet. Chem. 665, 135–149 (2003).

Liu, S.-R ., Li, B.-X ., Liu, J.-Y. & Li, Y.-S. Synthesis, structure and ethylene (co)polymerization behavior of new nonbridged half-metallocene-type titanium complexes based on bidentate β-enaminoketonato ligands. Polymer 51, 1921–1925 (2010).

Liu, J.-Y ., Liu, S.-R ., Li, B.-X ., Li, Y.-G. & Li, Y.-S. Synthesis and characterization of novel half-metallocene-type group iv complexes containing phosphine oxide–phenolate chelating ligands and their application to ethylene polymerization. Organometallics 30, 4052–4059 (2011).

Tang, X.-Y ., Wang, Y.-X ., Liu, S.-R ., Liu, J.-Y. & Li, Y.-S. Monochloro non-bridged half-metallocene-type zirconium complexes containing phosphine oxide-(thio)phenolate chelating ligands as efficient ethylene polymerization catalysts. Dalton Trans. 42, 499 (2013).

Huang, J ., Lian, B ., Qian, Y ., Zhou, W ., Chen, W. & Zheng, G. Syntheses of titanium(IV) complexes with mono-Cp and Schiff base ligands and their catalytic activities for ethylene polymerization and ethylene/1-hexene copolymerization. Macromolecules 35, 4871–4874 (2002).

Sanz, M ., Cuenca, T ., Galakhov, M ., Grassi, A ., Bott, R. K. J ., Hughes, D. L ., Lancaster, S. J. & Bochmann, M. Monocyclopentadienyl bis(phenoxo-imino) zirconium complexes as precatalyst species for olefin polymerization. Stereospecific methylation of an imino group with formation of a zirconium−amido bond. Organometallics 23, 5324–5331 (2004).

Firth, A. V ., Stewart, J. C ., Hoskin, A. J. & Stephan, D. W. Ancillary aryloxide ligands in ethylene polymerization catalyst precursors. J. Organomet. Chem. 591, 185–193 (1999).

Bergamo, A. L ., das Chagas, R. P. & Casagrande, O. L. Jr . Half-metallocene zirconium complex bearing tridentate [N,N,O] ligand and its use in homo- and copolymerization of ethylene. Catal. Commun. 42, 113–115 (2013).

Tabernero, V ., Cuenca, T. & Herdtweck, E. Hydrazonide titanium derivatives: synthesis, characterization and catalytic activity in olefin polymerization. Molecular structure of [Ti(η5-C5H4SiMe3)Cl(μ-N2CPh2)]2 . J. Organomet. Chem. 663, 173–182 (2002).

Saeed, I ., Katao, S. & Nomura, K. Synthesis and structural analysis of half-titanocenes containing η2-pyrazolato ligands, and their use in catalysis for ethylene polymerization. Inorg. Chem. 48, 5011–5020 (2009).

Dove, A. P ., Xie, X. & Waymouth, R. M. Cyclopentadienyl titanium hydroxylaminato complexes as highly active catalysts for the polymerization of propylene. Chem. Commun. 2152–2154 (2005).

Qi, C ., Zhang, S. & Sun, J. Synthesis, structure and ethylene polymerization behavior of titanium phosphinoamide complexes. J. Organomet. Chem. 690, 2941–2946 (2005).

Yasumoto, T ., Yamagata, T. & Mashima, K. Olefin polymerization catalyst derived by activation of a neutral monoalkyl titanium complex with an aminopyrrole ligand using triisobutylaluminum and trityl borate. Chem. Lett. 36, 1030–1031 (2007).

Alesso, G ., Tabernero, V ., Mosquera, M. E. G. & Cuenca, T. Studies on the active species in olefin polymerisation generated from phenoxo-amido titanium “chiral-at-metal” compounds. J. Organomet. Chem. 696, 2330–2337 (2011).

Maupoey, M. G ., Cuenca, T ., Frutos, L. M ., Castano, O. & Herdtweck, E. Monocyclopentadienyl and ansa-monocyclopentadienylalkoxo complexes of titanium containing the 2,2‘-methylenebis(6-tert-butyl-4-methylphenoxo) ligand. Synthesis, characterization, and polymerization catalyst behavior. Molecular structure of Ti(η5-C5H5)(η2-MBMP)Cl, Ti(η5-C5Me5)(η2-MBMP)Cl, and Ti(η5-C5H4SiMe2-η1-MBMP)Cl2 . Organometallics 22, 2694–2704 (2003).

Kim, Y ., Han, Y. & Do, Y. New half-sandwich metallocene catalysts for polyethylene and polystyrene. J. Organomet. Chem. 634, 19–24 (2001).

Lee, K.-S ., Kim, Y ., Ihm, S.-K ., Do, Y. & Lee, S. New group 4 half sandwich complexes containing triethanolamine ligand for polyethylene. J. Organomet. Chem. 691, 1121–1125 (2006).

Chen, J ., Zheng, Z.-J ., Pan, L ., Pan, D. & Li, Y.-S. Syndiospecific polymerization of styrene with Cp*TiCl((OCH(R)CH2)2NAr)/MMAO. J. Polym. Sci. A Polym. Chem. 43, 1562–1568 (2005).

Kim, Y ., Hong, E ., Lee, M. H ., Kim, J ., Han, Y. & Do, Y. (Pentamethylcyclopentadienyl)titanatrane: a new class of catalyst for syndiospecific polymerization of styrene. Organometallics 18, 36–39 (1999).

Kim, Y. & Do, Y. Preparation of syndiotactic poly(4-tert-butyldimethyl-silyloxystyrene) and poly(4-hydroxystyrene). Macromol. Rapid Commun. 21, 1148 (2000).

Kim, Y ., Han, Y ., Lee, M. H ., Yoon, S. W ., Choi, K. H ., Song, B. G. & Do, Y. New half-metallocene catalysts generating polyethylene with bimodal molecular weight distribution and syndiotactic polystyrene. Macromol. Rapid Commun. 22, 573–578 (2001).

Kim, Y ., Han, Y ., Hwang, J.-W ., Kim, M. W. & Do, Y. New titanatranes: characterization and styrene polymerization behavior. Organometallics 21, 1127–1135 (2002).

Zuo, W ., Zhang, S ., Liu, S ., Liu, X. & Sun, W.-H. Half-titanocene complexes bearing dianionic 6-benzimidazolylpyridyl-2-carboximidate ligands: synthesis, characterization, and their ethylene polymerization. J. Polym. Sci. A Polym. Sci. 46, 3396–3410 (2008).

Liu, S ., Yi, J ., Zuo, W ., Wang, K ., Wang, D. & Sun, W.-H. N-(2-benzimidazolylquinolin-8-yl)benzamidate half-titanocene chlorides: Synthesis, characterization and their catalytic behavior toward ethylene polymerization. J. Polym. Sci. A Polym. Sci. 47, 3154–3169 (2009).

Sun, W.-H ., Liu, S ., Zhang, Z ., Zeng, Y ., Wang, W. & Liang, T. Syntheses, characterization, and the ethylene (Co-)polymerization screening of 2-benzimidazolyl-N-phenylquinoline-8-carboxamide half-titanocene chlorides. Organometallics 29, 732–741 (2010).

Zambelli, A ., Natta, G ., Pasquon, I. & Signorini, R. Stereospecific catalysts for the head-to-tail polymerization of propylene to a crystalline syndiotactic polymer. J. Am. Chem. Soc. 84, 1488–1490 (1962).

Doi, Y ., Ueki, S. & Keii, T. "Living" coordination polymerization of propene initiated by the soluble V(acac)3-Al(C2H5)2Cl system. Macromolecules 12, 814–819 (1979).

Doi, Y ., Suzuki, S. & Soga, K. A perfect initiator for “living” coordination polymerization of propene: Tris(2-methyl-1,3-butanedionato)vanadium/diethylaluminium chloride system. Makromol. Chem. Rapid Commun. 6, 639–642 (1985).

Doi, Y ., Suzuki, S. & Soga, K. Living coordination polymerization of propene with a highly active vanadium-based catalyst. Macromoleules 19, 2896–2900 (1986).

Doi, Y ., Suzuki, S ., Hizal, G. & Soga, K. Living coordination polymerization of propylene and synthesis of tailor-made polymers. Transition Met. Catal. Polym. 2, 182–194 (1988).

Mashima, K ., Tanaka, Y. & Nakamura, A. Synthesis, characterization and reactions of ethylene complexes bearing Ta(η5-C5R5)(η4-buta-1,3-diene) fragments (R = H, Me). J. Organomet. Chem. 502, 19–23 (1995).

Nakamura, A. & Mashima, K. ‘Supine’ or ‘prone’ ligands: geometric preference of conjugated diene, 1-azadiene, and 1,4-diazadiene ligands on half-metallocene complexes of early transition metals. J. Organomet. Chem. 621, 224–230 (2001).

Mashima, K. & Nakamura, A. Adaptable coordination modes of conjugated 1,3-diene: uniqueness of s-trans coordination. J. Organomet. Chem. 663, 5–12 (2002).

Mashima, K ., Fujikawa, S. & Nakamura, A. Polymerization of ethylene catalyzed by a tantalum system Ta(.eta.3-C5Me5)(.eta.4-diene)(CH3)2/MAO: an isoelectronic analog for group 4 metallocene catalyst (MAO = methylaluminoxane). J. Am. Chem. Soc. 115, 10990–10991 (1993).

Mashima, K ., Fujikawa, S ., Tanaka, Y ., Urata, H ., Oshiki, T ., Tanaka, E. & Nakamura, A. Living polymerization of ethylene catalyzed by diene complexes of niobium and tantalum, M(.eta.5-C5Me5)(.eta.4-diene)X2 and M(.eta.5-C5Me5)(.eta.4-diene)2 (M = Nb and Ta), in the presence of methylaluminoxane. Organometallics 14, 2633–2640 (1995).

Yasuda, H ., Tatsumi, K ., Okamoto, T ., Mashima, K ., Lee, K ., Nakamura, A ., Kai, Y ., Kanehisa, N. & Kasai, N. Unique bonding and geometry in .eta.-cyclopentadienyltantalum-diene complexes. Preparation, x-ray structural analyses, and EHMO calculations. J. Am. Chem. Soc. 107, 2410–2422 (1985).

Okamoto, T ., Yasuda, H ., Nakamura, A ., Kai, Y ., Kanehisa, N. & Kasai, N. Synthesis and catalysis of novel mono- and bis(diene) complexes of niobium and x-ray structures of binuclear [Nb(.mu.-Cl)(C5H5)(s-cis-butadiene)]2 and mononuclear Nb(C5H5)(s-cis-2,3-dimethylbutadiene)2 . J. Am. Chem. Soc. 110, 5008 (1998).

Okamoto, T ., Yasuda, H ., Nakamura, A ., Kai, Y ., Kanehisa, N. & Kasai, N. Synthesis, x-ray structure and nucleophilic properties of mixed bis(diene)tantalum complexes Ta(.eta.5-C5R5)(.eta.4-C4H6)(.eta.4-C6H10). Organometallics 7, 2266–2273 (1988).

Chen, E. Y.-X. Coordination polymerization of polar vinyl monomers by single-site metal catalysts. Chem. Rev. 109, 5157–5214 (2009).

Matsuo, Y ., Mashima, K. & Tani, K. Half-metallocene tantalum complexes bearing methyl methacrylate (MMA) and 1,4-diaza-1,3-diene ligands as MMA polymerization catalysts. Angew. Chem. Int. Ed. 40, 960–962 (2001).

Clark, A. Olefin polymerization on supported chromium oxide catalysts. Catal. Rev. 3, 145–173 (1970).

Karol, F. J ., Karapinka, G. L ., Wu, C ., Dow, A. W ., Johnson, R. N. & Carrick, W. L. Chromocene catalysts for ethylene polymerization: scope of the polymerization. J. Polym. Sci. A-1 10, 2621 (1972).

Karol, F. J ., Brown, G. L. & Davison, J. M. Chromocene-based catalysts for ethylene polymerization: kinetic parameters. J. Polym. Sci. Polym. Chem. Ed. 11, 413 (1973).

Bhandari, G ., Rheingold, A. L. & Theopold, K. H. Correlations between structure, magnetism, and polymerization activity of paramagnetic benzylchromium complexes. Chem. Eur. J. 1, 199–203 (1995).

Bhandari, G ., Kim, Y ., McFarland, J. M ., Rheingold, A. L. & Theopold, K. H. Paramagnetic (Benzyl)chromium complexes as homogeneous ethylene polymerization catalysts. Organometallics 14, 738–745 (1995).

Liang, Y ., Yap, G. P. A ., Rheingold, A. L. & Theopold, K. H. Constrained geometry chromium catalysts for olefin polymerization. Organometallics 15, 5284–5286 (1996).

Heintz, R. A ., Leelasubcharoen, S ., Liable-Sands, L. M ., Rheingold, A. L. & Theopold, K. H. Structure and reactivity of trimethylsilylmethyl complexes of chromium, including the 13-electron alkyl Cp*Cr(CH2SiMe3)2 . Organometallics 17, 5477–5485 (1998).

Theopold, K. H. Homogeneous chromium catalysts for olefin polymerization. Eur. J. Inorg. Chem. 15–24 (1998).

Gibson, V. C ., Mastroianni, S ., Newton, C ., Redshaw, C ., Solan, G. A ., White, A. J. P. & Williams, D. J. A five-coordinate chromium alkyl complex stabilised by salicylaldiminato ligands. J. Chem. Soc. Dalton Trans. 1969–1971 (2000).

Döhring, A ., Göhre, J ., Jolly, P. W ., Kryger, B ., Rust, J. & Verhovnik, G. P. J. Donor-ligand-substituted cyclopentadienylchromium(III) complexes: a new class of alkene polymerization catalyst. 1. Amino-substituted systems. Organometallics 19, 388–402 (2000).

MacAdams, L. A ., Kim, W.-K ., Liable-Sands, L. M ., Guzei, I. A ., Rheingold, A. L. & Theopold, K. H. The (Ph)2nacnac ligand in organochromium chemistry. Organometallics 21, 952–960 (2002).

Mani, G. & Gabbaï, F. P. A neutral chromium(III) catalyst for the living “Aufbaureaktion”. Angew. Chem. Int. Ed. 43, 2263–2266 (2004).

MacAdams, L. A ., Buffone, G. P ., Incarvito, C. D ., Rheingold, A. L. & Theopold, K. H. A chromium catalyst for the polymerization of ethylene as a homogeneous model for the phillips catalyst. J. Am. Chem. Soc. 127, 1082–1083 (2005).

Thomas, B. J. & Theopold, K. H. Cationic chromium(III) alkyls as olefin polymerization catalysts. J. Am. Chem. Soc. 110, 5902–5903 (1988).

Thomas, B. J ., Hon, S. K ., Schulte, G. K ., Sendlinger, S. C. & Theopold, K. H. Paramagnetic alkylchromium compounds as homogeneous catalysts for the polymerization of ethylene. J. Am. Chem. Soc. 113, 893–902 (1991).

Heinemann, O ., Jolly, P. W ., Kruger, C. & Verhovnik, G. P. J. A facile access to CpCr (acac)Cl and related systems. J. Organomet. Chem. 553, 477–479 (1998).

Xu, T ., Mu, Y ., Gao, W ., Ni, J ., Ye, L. & Tao, Y. Highly active half-metallocene chromium(III) catalysts for ethylene polymerization activated by trialkylaluminum. J. Am. Chem. Soc. 129, 2236–2237 (2007).

Sun, M ., Mu, Y ., Wu, Q ., Gao, W. & Ye, L. Synthesis, structures and ethylene polymerization behavior of half-metallocene chromium(III) catalysts bearing salicylaldiminato ligands. New J. Chem. 34, 2979–2987 (2010).

Sun, M ., Xu, T ., Gao, W ., Liu, Y ., Wu, Q ., Mu, Y. & Ye, L. Large ultra-high molecular weight polyethylene spherical particles produced by AlR3 activated half-sandwich chromium(III) catalysts. Dalton Trans. 40, 10184 (2011).

Huang, Y.-B. & Jin, G.-X. Half-sandwich chromium(III) complexes bearing β-ketoiminato and β-diketiminate ligands as catalysts for ethylene polymerization. Dalton Trans. 38, 767–769 (2009).

Huang, Y.-B ., Yu, W.-B. & Jin, G.-X. Half-sandwich chromium(III) catalysts bearing hydroxyindanimine ligands for ethylene polymerization. Organometallics 28, 4170–4174 (2009).

Wang, L.-S ., Fettinger, J. C. & Poli, R. Cyclopentadienylmolybdenum(II) and -(III) complexes containing diene and allyl ligands. 1. Isomeric preferences and isomerization rates in a pair of redox-related organometallic complexes. J. Am. Chem. Soc. 119, 4453–4464 (1997).

Grognec, E. L ., Poli, R. & Wang, L.-S. Stable 17-electron Mo(III) complexes containing alkyl ligands. Inorg. Chem. Commun. 2, 95–97 (1999).

Grognec, E. L ., Poli, R. & Richard, P. Dialkyl(butadiene)cyclopentadienylmolybdenum(III) complexes. Synthesis, characterization, and reactivity. Organometallics 19, 3842–3853 (2000).

Grognec, E. L. & Poli, R. Diene-containing half-sandwich MoIII complexes as ethylene polymerization catalysts: experimental and theoretical studies. Chem. Eur. J. 7, 4572–4583 (2001).

Champouret, Y ., Baisch, U ., Poli, R ., Tang, L ., Conway, J. L. & Smith, K. M. Homolytic bond strengths and formation rates in half-sandwich chromium alkyl complexes: relevance for controlled radical polymerization. Angew. Chem. Int. Ed. 47, 6069–6072 (2008).

Champouret, Y ., MacLeod, K. C ., Baisch, U ., Patrick, B. O ., Smith, K. M. & Poli, R. Cyclopentadienyl chromium β-diketiminate complexes: initiators, ligand steric effects, and deactivation processes in the controlled radical polymerization of vinyl acetate. Organometallics 29, 167–176 (2010).

Champouret, Y ., MacLeod, K. C ., Smith, K. M ., Patrick, B. O. & Poli, R. Controlled radical polymerization of vinyl acetate with cyclopentadienyl chromium β-diketiminate complexes: ATRP vs OMRP. Organometallics 29, 3125–3132 (2010).

Acknowledgements

HT acknowledges financial support by a Grant-in-Aid for Young Scientists (A). KY expresses his special thanks for the financial support provided by the JSPS Research Fellowship for Young Scientists.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tsurugi, H., Yamamoto, K., Rochat, R. et al. Non-bridged half-metallocene complexes of group 4–6 metals with chelating ligands as well-defined catalysts for α-olefin polymerization. Polym J 47, 2–17 (2015). https://doi.org/10.1038/pj.2014.82

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2014.82