Abstract

To study microscopically the kinetics of polarization reversal in vinylidene fluoride and trifluoroethylene copolymers, the piezoresponse force microscope was modified to apply voltage pulses for the purpose of time-slicing and to obtain time-resolved measurements. Reversed domains were clearly distinguished and found to change with pulse duration. It was discovered that there were predetermined nucleation sites, each with respective nucleation times. This situation allowed for the determination of the nucleation rate and growth speed separately. Thus, for the first time, the microscopic model for the kinetics of polarization reversal was established from an experimental basis. The dependence of the nucleation rate and the growth speed on the electric field strength were also investigated, and both nucleation and growth processes were shown to have almost the same activation field strengths as the switching time. This phenomenon explains the time-field equivalence in the switching characteristics holding for a wide range of electric fields.

Similar content being viewed by others

Introduction

Vinylidene fluoride and trifluoroethylene (VDF/TrFE) copolymers are promising polymeric ferroelectric materials. Their basic physics and applications have been widely studied for several decades.1 One of the most important properties in ferroelectric materials is the switching property,2, 3, 4, 5, 6 which reflects the mechanism of polarization reversal. The kinetics of this process is generally understood by considering the nucleation and growth of reversed domains.7, 8 The time development of macroscopic polarization can be formulated by the Avrami theory.7, 8, 9 The change in polarization as a function of time t is called the switching curve and is described as follows:

where Pr is the remanent polarization. The switching time τs and Avrami index n are dependent on the nucleation mode, nucleation rate, growth speed and growth dimension. The switching curves for VDF/TrFE copolymers are well fitted by (1), and curves obtained for extruded films give an Avrami index of 5.2 A large index value suggests an existence of an induction time such that reversed domains start to nucleate only after a certain time. With the assumption of an induction time, the switching curve for VDF/TrFE copolymers can be fitted with equation 1 by shifting the origin of time and with n=2.3 However, n becomes less than 1 in very thin films. In this case, the roughness of the surface is relatively large. When the roughness of the surface creates a distribution in the electric field, the switching curve can be reproduced with n=2 by introducing a switching time distribution curve, owing to the variations in thickness, in equation 1.4 Thus, an Avrami index of 2 is likely for the polarization reversal in this material. There are two extreme cases for the kinetic model that gives n=2: one is the homogeneous nucleation with one-dimensional growth model, and the other is the heterogeneous nucleation with two-dimensional growth model.10 Macroscopic measurement of ΔP(t) is insufficient to obtain kinetic parameters and to determine which kinetic model applies. Thus, macroscopic measurement should be complemented by microscopic observation. Such microscopic observation has been achieved in ferroelectric ceramics where a single crystal can be obtained for the microscopic measurement of reversed domains.8 However, this method has not been applied to polymeric ferroelectrics.

Recently, new imaging techniques have been developed by integrating various principles with scanning probe microscopy (SPM). Piezoresponse force microscopy (PFM) is one type of SPM that measures the two-dimensional distribution of piezoelectric activity and is a powerful technique for studying the local behavior of ferroelectric materials.11, 12 Many studies have been reported for inorganic ferroelectrics.12 Rodriguez et al.13 studied the local relaxation of piezoelectric activity in Langmuir-Blodgett films of VDF/TrFE copolymers. Noda et al.14 locally poled a VDF/TrFE oligomer thin film using a cantilever. Microscopic studies of the switching process have also been reported. Gruverman et al.15, 16, 17 studied the nucleation behavior of domains in Pb(Zr,Ti)O3.15–17 Gysel et al.18 compared the switching curves of VDF/TrFE copolymers from PFM images. However, the details of the nucleation and growth process of domains in VDF/TrFE copolymers are yet to be reported. In this paper, we report on the measurement of the local switching behavior in VDF/TrFE copolymers by time-resolved PFM and report the nucleation rate and growth speed of domains undergoing polarization reversal. This is the first report of microscopic parameters in the polarization reversal kinetics of ferroelectric polymers. We also report the dependence of these parameters on the electric field and discuss the mechanism of polarization reversal.

Experimental procedure

Thin films of VDF/TrFE random copolymers with a VDF content of 75 mol% (supplied by Kureha Corporation, Tokyo, Japan) were fabricated by spin-coating onto substrates of glass slides with evaporated gold for the lower electrodes. Gold upper electrodes were also deposited by vacuum evaporation (Figure 1a). The effective area of the electrodes was 0.1 × 0.1 mm. Samples were annealed at 140 °C in the atmosphere for 1 h. The thickness was estimated at 87 nm by scratching a sample and measuring the depth of the scratch with a Nanopics 2100 atomic force microscope (SII NanoTechnology, Tokyo, Japan).

The experimental setup for PFM measurements. (a) The sample configuration. (b) Block diagram of PFM operation. (c) Sequence for time-resolved PFM measurements. The height of the final pulse was adjusted to the electric field. A full color version of this figure is available at Polymer Journal online.

An SPI3800N/SPA400 scanning probe microscope (SPM) (SII NanoTechnology) was used for time-resolved PFM measurements. Figure 1b illustrates the experimental setup. To change the state of polarization in a sample, the Mode Switch was set to position A in which a sequence of voltage pulses was generated by an Agilent 33220A function/arbitrary waveform generator (Agilent Technologies, Inc., Santa Clara, CA, USA) while an HSA4101 high-speed bipolar amplifier (NF Corporation, Yokohama, Japan) was applied to the lower electrode. The upper electrode was connected to a charge amplifier with an integrating circuit using an OPA627AM operational amplifier (Texas Instruments, Dallas, TX, USA). To conduct measurements by PFM imaging, the switch was set to position B where a sinusoidal voltage with a frequency of 10 kHz and amplitude of 4 V was applied by a built-in oscillator in the SPM controller. The cantilever was kept in contact with the sample surface using the contact mode and the oscillation of the surface height owing to the local piezoresponse was detected. The amplitude Δz and phase θ of the piezoresponse were extracted by a lock-in amplifier within the SPM controller. A PFM image was obtained by mapping the in-phase component Δzcosθ, while the topographic image was obtained simultaneously.

The experimental sequence for time-resolved PFM measurements is shown in Figure 1c. Pulses of positive and negative voltages with 50 ms duration and an amplitude corresponding to an electric field strength of 120 MV m−1 were alternately applied over 10 times to initialize polarization to a negatively polarized state. This process erases the effect of imprint, which is the dependence of switching kinetics on electrical history. A pulse of positive voltage and duration tp was applied 10 s after the initialization. The electric field strength generated by this last pulse ranged from 90 to 230 MV m−1 followed by topographic and PFM image measurement. This sequence was repeated with varying tp although the same initialization process and waiting time was applied to obtain comparative results. The charge response was also measured as a function of time upon application of voltage pulses. The electric displacement D, which can be calculated from the charge divided by the electrode area, changes upon application of a voltage pulse, as illustrated in the inset of Figure 2. The remaining part ΔP is twice the amount of polarization that was reversed during the time tp. The temporal changes of the electric displacement with various tp values are plotted in Figure 2 together with the switching curve in addition to a plot of ΔP against tp. Similar trends are observed in ΔP and the switching curve with the vertical shift corresponding to the dielectric polarization. Thus, the state after applying a pulse of duration tp can also be assumed as the state at time tp during the polarization reversal.

The electric displacement D vs the logarithm of time for an electric field strength of 120 MV m−1 and various tp (thin lines) compared with the switching curve (bold line). ΔP (open circles) is also plotted against tp. (inset) The electric displacement D upon an application of a pulse and the definition of ΔP. A full color version of this figure is available at Polymer Journal online.

Results and Discussion

Grain structures were observed for VDF/TrFE copolymers in the spin-coated thin films. The grain size increased with the annealing temperature when annealed above the Curie temperature and became anisotropic in shape as the annealing temperature approached the melting point.19 An annealing temperature in this experiment of 140 °C was just below the melting point. Figure 3a shows a topographic image of the sample in a region in the absence of an upper electrode. Grains of elongated shape with an approximate length of 500 nm and width of 100 nm were observed. It is possible that each grain is a lamella with the polymer chain nearly perpendicular to the long axis as reported by Wu et al.20 For the time-resolved PFM measurements, the surface coated with a layer of evaporated gold of approximately 50 nm thickness was scanned. The topographic image of the gold surface is shown in Figure 3b. In the presence of an upper electrode, the electric field is uniform compared with the case in which the cantilever was used as an upper electrode.11, 15 Thus, the polarization reversal process under a uniform electric field can be studied and the field dependence of the process can be explored. Although the grain structure under the gold layer cannot be directly observed, the correlation of the domain image to the grain structure beneath is evident in the anisotropy of the domain image as shown later (Figure 4).

The PFM images for various tp values are shown in Figure 4. The bright and dark colors indicate local piezoelectric responses corresponding to the positively and negatively polarized states, respectively. In initialized samples, which had been negatively polarized, almost the entire imaging area displayed a dark color. However, bright regions appeared following the application of a positive pulse. As the duration of the last positive pulse became longer, the number of bright regions increased and each region became larger until the entire area was occupied. Some regions showed no piezoelectric activity and remained unchanged during the polarization reversal, suggesting non-ferroelectric regions may correspond to amorphous regions. By carefully inspecting the changes in the PFM images with respect to tp, it was found that almost all domains were located at the same sections of the sample and that the size of each domain increased monotonically with tp. As the borders of domains were blurred, the shape of each domain was not clear at first but gradually became anisotropic. Each domain grew to one-third of the length and the same width as the grain with the length increasing linearly as the time elapsed from its nucleation. This result suggests that each domain nucleates at a predetermined time and grows at a constant speed. This phenomenon allows us to trace the growth process of each domain.

The resolution of PFM is limited for various reasons.21, 22 The domain deforms to the opposite direction at each side of the domain boundary. As the deformation should be smoothly connected at the boundary, a transition layer should result in a blurring of the PFM image at the boundary. In addition, a gold layer of approximately 50 nm in thickness at the surface also contributes to blurring the boundary. By expressing the blurring effects through the resolution function  , the function for the PFM image,

, the function for the PFM image,  , is given by the convolution of the piezoelectric activity distribution,

, is given by the convolution of the piezoelectric activity distribution,  , and the resolution function:

, and the resolution function:

Although  should be obtained to treat the growth process quantitatively, the deconvolution was not practical because of the noise in the PFM image. The most probable size was thus determined by comparing the function for the PFM image with the calculated convolution (2) for various domain sizes. The resolution function was thoroughly studied by Kalinin et al.21, 22 and can be approximated by a Gaussian function,

should be obtained to treat the growth process quantitatively, the deconvolution was not practical because of the noise in the PFM image. The most probable size was thus determined by comparing the function for the PFM image with the calculated convolution (2) for various domain sizes. The resolution function was thoroughly studied by Kalinin et al.21, 22 and can be approximated by a Gaussian function,  where r is the radial component. The resolution a is a phenomenological parameter depending on various blurring factors and was estimated at 50 nm so that the calculated convolution reproduced the profile at the boundary of a domain that was large and yet well isolated from other domains.

where r is the radial component. The resolution a is a phenomenological parameter depending on various blurring factors and was estimated at 50 nm so that the calculated convolution reproduced the profile at the boundary of a domain that was large and yet well isolated from other domains.

We assumed a model structure of a domain and compared the simulated PFM image calculated by equation (2). The lamella was approximated by a cuboid geometry while the chain direction was assumed to be parallel to the substrate and perpendicular to the long side of the lamella. The growth process of a reversed domain should differ for each of the three directions in a lamella. The elementary process of the polarization reversal is the rotation of a dipole in a chain. As the dipoles are connected, the rotation of dipoles may propagate as a kink along the chain.23 In addition, as the reversed dipole makes a strong electric field in the direction of the applied field, the domains may grow preferentially towards a direction normal to the substrate.7 Thus, it is reasonable to assume that a nucleated domain grows towards the direction of the chain and normal to the substrate rather quickly after nucleation, resulting in a plate-shaped domain perpendicular to the long side of the lamella, which then grows along the long side one-dimensionally. On the basis of this hypothesis, the shape of a reversed domain is assumed to be, at first, a thin plate-like cuboid with a height h and a length l at a cross-section perpendicular to the long side of the lamella with a narrow width w as illustrated in Figure 5a. The height h and the length l are the thickness of the sample and the thickness of the lamella, respectively. The width w increases with time. Figure 5c shows a comparison of a PFM image and the best-fit calculated convolution (equation 2) showing the profiles along the short side (left) and long side (right) of a prolonged domain, as shown in Figure 5b. For all tp values, the PFM image of a reversed domain can be fitted well by this model with h and l fixed and w increasing with the time elapsed after the nucleation of the domain. Thus, the hypothesis of plate-like domains can reproduce the PFM image and the values of w can be estimated. The width w of a domain is plotted against tp in Figure 5d. After the nucleation, the width initially increased linearly with tp at a growth speed of 2.4 × 10−2 m s−1 until its collision with other domains. The domain size eventually grew to approximately 200 nm and was approximately one-third of the long side of a lamella indicating that several domains nucleated into a single lamella. For several domains, the same analysis was applied and growth speed was obtained for each domain. The values of growth speed were dispersed within a factor of 2 and were averaged.

The analysis for obtaining the growth speed. (a) The model of a reversed domain in a lamella for the calculation of  . (b) The domain for which the profiles of piezoresponse were calculated. The profiles were calculated along the solid line for the short side and along the broken line for the long side. (c) Comparison of the PFM profile for tp=20 μs for the measured (circles) and calculated (solid lines) piezoresponse with w=220 nm. Left figure for the short side and right figure for the long side. (d) The width w plotted against tp at a 120 MV m−1 electric field strength. The initial slope after the nucleation gives the growth speed. A full color version of this figure is available at Polymer Journal online.

. (b) The domain for which the profiles of piezoresponse were calculated. The profiles were calculated along the solid line for the short side and along the broken line for the long side. (c) Comparison of the PFM profile for tp=20 μs for the measured (circles) and calculated (solid lines) piezoresponse with w=220 nm. Left figure for the short side and right figure for the long side. (d) The width w plotted against tp at a 120 MV m−1 electric field strength. The initial slope after the nucleation gives the growth speed. A full color version of this figure is available at Polymer Journal online.

By counting the number of domains for each tp, the number of nuclei per unit area N and the nucleation rate, R=dN/dt, were determined (Figure 6). After an induction time of approximately 1 μs, the number of nuclei initially increased with tp. As described above, the nucleation was deterministic. In the classical theory of crystallization,10 such deterministic nucleation occurs at heterogeneous locations simultaneously (that is, heterogeneous nucleation). In the case where there is no such heterogeneity, nucleation occurs stochastically at random places with a certain probability as the thermodynamic activation process and the number of nuclei increase with time (that is, homogeneous nucleation). However, the nucleation process did not proceed strictly according to heterogeneous or homogeneous processes in this study. Although the nucleation site was predetermined, each nucleation site had different nucleation times resulting in an increase in the number of nuclei statistically similar to homogeneous nucleation. Thus, an Avrami index of 2 is successfully explained by a model of one-dimensional domain growth with distributed nucleation times.

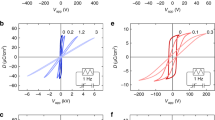

The above procedure was applied for the same sample for varying field strengths. The switching curves are shown in the inset of Figure 7a. As the field strength increased, the curve shifted to shorter times in the semi-logarithmic plot (the time field equivalence law). The logarithm of the switching time τs, which is defined as the time at which the switching curve becomes steepest, is plotted against the inverse of the electric field E in Figure 7a. The linear region of this plot is described by the exponential law, τs=τs0exp(Ea/E), where τs0 and Ea are constants corresponding to the ultimate switching time and the activation field strength, respectively. These results are essentially the same as reported previously.4 In this work, the nucleation rate and the growth speed are obtained separately. The logarithms of the nucleation rate and the growth speed are plotted in Figure 7b. It was found that both the nucleation rate and the growth speed have almost the same activation field strength as the overall switching time. The switching time as well as the shape of the switching curve depend both on the nucleation rate and the growth speed2 and if the electric field dependence of these processes are different, the time field equivalence will not realize. In this study, it is shown for the first time that the nucleation rate and the growth speed have the same dependence on the electric field and thus the time field equivalence holds for a wide range of electric fields.

The field dependence of the switching characteristics. (a) The field dependence of the switching time τs. (inset) The switching curves for the electric fields. (b) The field dependence of the nucleation rate R (circles) and the growth speed v (triangles). A full color version of this figure is available at Polymer Journal online.

In summary, we studied the time dependence of PFM measurements during the polarization reversal in VDF/TrFE copolymer films by time-slicing using a voltage pulse. We found that reversed domains were formed and their areas increased with time. We analyzed the PFM images in detail and obtained microscopic kinetic measurements which revealed predetermined nucleation sites, each with respective nucleation times. The nuclei can be regarded as plate-like initially and to grow one-dimensionally along the long side of the lamella. As the number of nuclei increased with time, the overall process gave an Avrami index of 2, which is consistent with experimental switching curves. The nucleation rate and growth speed dependence on the electric field obeys an exponential law with the same activation field strength as the switching curve. This phenomenon explains the wide range of fields with a time-field equivalence. We have thus established a microscopic model for the polarization reversal in the VDF/TrFE copolymer.

References

Furukawa, T. Ferroelectric properties of vinylidene fluoride copolymers. Phase Transitions 18, 143–211 (1989).

Furukawa, T., Date, M., Ohuchi, M . & Chiba, A. Ferroelectric switching characteristics in a copolymer of vinylidene fluoride and trifluoroethylene. J. Appl. Phys. 56, 1481–1486 (1984).

Kano, K., Kodama, H., Takahashi, Y . & Furukawa, T. Analysis of ferroelectric switching process in VDF/TrFE copolymers. Mat. Res. Soc. Symp. Proc 600, 89–93 (1999).

Nakajima, T., Abe, R., Takahashi, Y . & Furukawa, T. Intrinsic switching characteristics of ferroelectric ultrathin vinylidene fluoride/trifluoroethylene copolymer films revealed using Au electrode. Jpn. J. Appl. Phys. 44, L1385–L1388 (2005).

Ishii, H., Nakajima, T., Takahashi, Y . & Furukawa, T. Ultrafast polarization switching in ferroelectric polymer thin films at extremely high electric fields. Appl. Phys. Express 4, 031501 (2011).

Ishii, H., Nakajima, T., Furukawa, T . & Okamura, S. Polarization switching dynamics of vinylidene fluoride/trifluoroethylene copolymer thin films under high electric field at various temperatures. Jpn J. Appl. Phys. 52, 041603 (2013).

Lines, M. E . & Glass, A. M. in Principles and Applications of Ferroelectrics and Related Materials Ch. 4, (Oxford: New York, NY, USA, 1977).

Strukov, B. A . & Levanyuk, A. P. in Ferroelectric Phenomena in Crystals Ch. 10, (Springer-Verlag: Berlin, Germany, 1998).

Ishibashi, Y . & Takagi, Y. Note on ferroelectric domain switching. J. Phys. Soc. Jpn. 31, 506–510 (1971).

Keller, A. in Polymers, Liquid Crystals, and Low-Dimensional Solids ed. March N., Tosi M. Ch. 2, (Plenum Press: New York, NY, USA, 1984).

Kholkin, A. L., Kalinin, S. V., Roelofs, A . & Gruverman, A. in Scanning Probe Microscopy, Vol.1, Electrical and Electromechanical Phenomena at the Nanoscale ed. Kalinin S., Gruverman A. Ch. I.6, (Springer: New York, NY, USA, 2007).

Setter, N., Damjanovic, D., Eng, L., Fox, G., Gevorgian, S., Hong, S., Kingon, A., Kohlstedt, H., Park, N. Y., Stephenson, G. B., Stolitchnov, I., Taganstev, A. K., Taylor, D. V., Yamada, T . & Streiffer, S. Ferroelectric thin films: Review of materials, properties, and applications. J. Appl. Phys. 100, 051606 (2006).

Rodriguez, B. J., Jesse, S., Kim, J., Ducharme, S . & Kalinin, S. V. Local probing of relaxation time distributions in ferroelectric polymer nanomesas: Time-resolved piezoresponse force spectroscopy and spectroscopic imaging. Appl. Phys. Lett. 92, 232903 (2008).

Noda, K., Ishida, K., Kubono, A., Horiuchi, T., Yamada, H . & Matsushige, K. Molecular ferroelectricity of vinylidene fluoride oligomer investigated by atomic force microscopy. Jpn J. Appl. Phys. 40, 4361–4364 (2001).

Gruverman, A., Rodriguez, B. J., Kingon, A. I., Nemanich, R. J., Cross, J. S . & Tsukada, M. Spatial inhomogeneity of imprint and switching behavior in ferroelectric capacitors. Appl. Phys. Lett. 82, 3071–3073 (2003).

Gruverman, A., Rodriguez, B. J., Dehoff, C., Waldrep, J. D., Kingon, A. I., Nemanich, R. J . & Cross, J. S. Direct studies of domain switching dynamics in thin film ferroelectric capacitors. Appl. Phys. Lett. 87, 082902 (2005).

Dehoff, C., Rodriguez, B. J., Kingon, A. I., Nemanich, R. J., Gruverman, A . & Cross, J. S. Atomic force microscopy-based experimental setup for studying domain switching dynamics in ferroelectric capacitors. Rev. Sci. Instrum 76, 023708 (2005).

Gysel, R., Stolichnov, I., Tagantsev, A. K., Setter, N . & Mokry, P. Restricted domain growth and polarization reversal kinetics in ferroelectric polymer thin films. J. Appl. Phys. 103, 084120 (2008).

Furukawa, T., Nakajima, T . & Takahashi, Y. Factors governing ferroelectric switching characteristics of thin VDF/TrFE copolymer films. IEEE Trans. Dielec. Electr. Insul 13, 1120–1131 (2009).

Wu, Y. J., Li, X. H., Weng, Y. Y., Hu, Z. J . & Jonas, A. M. Orientation of lamellar crystals and its correlation with switching behavior in ferroelectric P(VDF-TrFE) ultra-thin films. Polymer 55, 970–977 (2014).

Kalinin, S. V., Jesse, S., Rodriguez, B. J., Shin, J., Baddorf, A. P., Lee, H. N., Borisevich, A . & Pennycook, S. J. Spatial resolution, information limit, and contrast transfer in piezoresponse force microscopy. Nanotechnology 17, 3400–3411 (2006).

Morozovska, A. N., Eliseev, E. A . & Kalinin, S. V. The piezoresponse force microscopy of surface layers and thin films: effective response and resolution function. J. Appl. Phys. 102, 074105 (2007).

Dvey-Aharon, H., Sluckin, T. J . & Taylor, P. L. King propagation as a model for poling in poly(vinylidene fluoride). Phys. Rev. B 21, 3700–3707 (1980).

Acknowledgements

We are grateful to Mr N. Moriyama of Kureha Corporation for providing us with copolymer samples. This work is partly supported by a Grant-in-Aid for Scientific Research from the Japan Society for the Promotion of Science.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Takahashi, Y., Tomoda, N. & Furukawa, T. Quantitative analysis of the nucleation and growth of ferroelectric domains during the polarization reversal in thin films of vinylidene fluoride and trifluoroethylene copolymer. Polym J 47, 249–254 (2015). https://doi.org/10.1038/pj.2014.109

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2014.109