Abstract

The radical copolymerization of alkyl 2-norbornene-2-carboxylates, 1a–c, with alkyl (meth)acrylates, to produce copolymers with norbornane in the main chain, is described here. γ-Butyrolactone- and hydroxy group-containing norbornene-based monomers (1b and 1c, respectively) were freshly synthesized, and their radical copolymerization behavior with n-butyl acrylate was examined. Methyl 2-norbornene-2-carboxylate, 1a, and the new monomers, 1b and 1c, were employed as comonomers for radical terpolymerization with lactone- and adamantane-containing (meth)acrylates to produce copolymers that could be applied as new, more chemically robust 193-nm photoresist materials. The dissolution rate of the spin-coated copolymer films after exposure to a photoacid generator, a significant characteristic in the photoresist application, was measured for various exposure doses of 193-nm ArF laser light under standard conditions in an aqueous alkaline solution.

Similar content being viewed by others

Introduction

The vinyl addition polymerization reaction of norbornene is an important process for synthesizing a polymer with norbornane in the main chain, where the rigid repeating unit can often impart useful physical properties, such as high glass transition temperature (Tg), to the resultant (co)polymers.1, 2, 3 Whereas parent (unsubstituted) norbornene has been utilized as a monomer for vinyl polymerization,1, 2, 3 we have found and reported that substitution at the 2-position in 2-norbornene, with either an alkoxycarbonyl (ester) or a phenyl group, is quite effective for enhancing norbornene’s reactivity in conventional radical polymerization. Thus, such monomers can be efficiently copolymerized with alkyl acrylates.4, 5, 6 In particular, as a result of the incorporation of the norbornane framework into the main chain of poly(n-butyl acrylate) [poly(nBA)], via radical copolymerization with 2-substituted 2-norbornenes, Tg of the resultant copolymer is significantly higher than that of the poly(nBA) homopolymer.6 We have also demonstrated that the Tg-raising ability of the incorporation of 2-substituted 2-norbornenes, on a per-monomer unit scale, is significantly higher than that of the incorporation of styrene.6

Meanwhile, the synthesis of chemically robust photoresist materials for ArF laser (193 nm) light could be an appropriate application for the polymers derived from alkyl 2-norbornene-2-carboxylates. For a synthetic polymer to be appropriate for use as a 193-nm photoresist material, certain criteria should be met: (1) alicyclic units with a higher C/H ratio, such as norbornane and adamantane frameworks, should be introduced as a pendant group, for good dry etching resistance; and (2) incorporation of a polar group, such as lactone or hydroxyl groups, is also required for adhesion and compatibility with aqueous alkaline developing solutions.7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23 In addition, for greater resistance to dry etching, direct incorporation of alicyclic units into the polymer backbone (for example, via vinyl polymerization of norbornene derivatives) has been shown to be effective.8, 9, 10, 11, 12, 13, 14, 15 In that context, alkyl 2-norbornene-2-carboxylate derivatives are quite promising as one of the comonomers for the 193-nm photoresist polymer synthesis process, because of their copolymerizing ability with alkyl acrylates, resulting in the incorporation of the norbornane framework into the main chain and facile incorporation of various substituents into the ester moiety.

In addition to the previously known methyl 2-norbornene-2-carboxylate, 1a, we have prepared lactone-containing norbornene, 1b, and hydroxy group-containing norbornene, 1c, as new monomer candidates for the photoresist application. Together, the three alkyl 2-norbornene-2-carboxylates, 1a–c, were employed as a comonomer for terpolymerization with lactone- and adamantane-containing (meth)acrylates to produce a series of potential copolymers for the photoresist application. The preparation of the copolymers and data showing their potential for application as a 193-nm photoresist material (dissolution rate (DR) vs exposed dose curves) will be described.

Experimental Procedure

Materials

Methyl propiolate (Wako, Osaka, Japan, >97%), palladium on carbon (Pd/C) (Nacalai, Kyoto, Japan, 10%-Pd), propiolic acid (TCI, Tokyo, Japan, >97%), α-bromo-γ-butyrolactone (TCI, >95%), dimethylformamide (Kanto Chemical, Tokyo, Japan, dehydrated, >99.5%), dichloroethylaluminum (EtAlCl2; Kanto Chemical, 1.04 M solution in hexane) and trimethylsilyl iodide (Me3SiI; TCI, >95%), 1,1′-azobis(cyclohexane-1-carbonitrile) (VAZO; Wako, >95%) and propylene glycol methyl ether acetate (PGMEA; Nacalai, >98%) were used as received. 3-acryloyloxy-γ-butyrolactone (GBLA), 3-methacryloyloxy-γ-butyrolactone (GBLMA), 2-methyl-2-adamantyl acrylate (MAdA) and 2-methyl-2-adamantyl methacrylate (MAdMA) were supplied by Mitsubishi Rayon Co., Ltd.

Measurements

1H and 13C NMR spectra (at frequencies of 400 and 100 MHz, respectively) were recorded on a Bruker Avance 400 spectrometer (Bruker BioSpin, Yokohama, Japan), using tetramethysilane as an internal standard in chloroform-d (CDCl3), at room temperature (monomers) or at 50 °C (polymers). The repetition delay in the 1H NMR measurements was 8 s for all of the polymers. For terpolymers, the NMR spectra were measured in CDCl3 with a small amount of D2O, to avoid the influence of residual H2O signals in the calculation of their compositions.

Molecular weights (Mn) and molecular weight distributions (Mw/Mn) were measured by gel permeation chromatography (GPC) on a Jasco-ChromNAV system (JASCO Corporation, Tokyo, Japan), equipped with a differential refractometer detector using tetrahydrofuran as eluent at a flow rate of 1.0 ml min−1 at 40 °C, calibrated with poly(MMA). The column used for the GPC analyses was a combination of Styragel HR4 (Nihon Waters, Tokyo, Japan; 300 × 7.8 mm2 i.d., 5-μm average particle size, exclusion molecular weight of 600 K for polystyrene) and Styragel HR2 (Waters; 300 × 7.8 mm2 i.d., 5-μm average particle size, exclusion molecular weight of 20 K for polystyrene), and poly(MMA) standards (Shodex M-75, Tokyo, Japan, Mp=212 000, Mw/Mn=1.05, Mp=50 000, Mw/Mn=1.02, Mp=22 600, Mw/Mn=1.02, Mp=5720, Mw/Mn=1.06, Mp=2400, Mw/Mn=1.08) were used for the calibration.

Purification by preparative recycling GPC was performed on a JAI LC-918 R equipped with a combination of columns of JAIGEL-3H (600 × 20 mm2 i.d., exclusion molecular weight of 70 K for polystyrene) and JAIGEL-2H (600 × 20 mm2 i.d., exclusion molecular weight of 5 K for polystyrene) for polymers, using CHCl3 as eluent, at a flow rate of 3.8 ml min−1 at 25 °C. The sample solution, 3 ml containing ∼0.3 g of the crude product, was injected.

Temperature-modulated differential scanning calorimetry (DSC) analyses for the copolymers were performed using TA Instruments DSC Q-100 (New Castle, DE, USA), under nitrogen atmosphere, at a 4 °C min−1 heating rate, with a modulating rate of 0.64 °C per 60 s.

Elemental analyses were performed on a Yanako MT-5 analyzer (Tokyo, Japan) at the Integrated Center for Science in Ehime University.

Synthesis of 1a (as a mixture with 1a′)

Synthesis of methyl 2-norbornadiene-2-carboxylate, 2, by a Diels–Alder reaction of methyl propiolate with cyclopentadiene, was conducted according to the literature.24 Whereas Pd/C-catalyzed partial hydrogenation of 2 was reported in the literature,25 we allowed the reaction to proceed until 2 was completely consumed to produce a mixture of 1a and 1a′, which was purified by distillation. The composition of [1a]/[1a′] was determined from the relative signal intensities in the 1H NMR data (see Supplementary Figure S1 for the spectrum of a mixture with [1a]/[1a′]=1:0.37).

Preparation of 3-propioloyloxy-γ-butyrolactone 3

Under N2 atmosphere, potassium carbonate (K2CO3) (18.3 g, 97.5 mmol) and 110 ml of dimethylformamide were combined in a round-bottomed flask. Propiolic acid (6.0 ml, 98 mmol) was added to the mixture at room temperature and stirred for 30 min. After α-bromo-γ-butyrolactone (9.0 ml, 98 mmol) was added to the mixture, it was stirred for 4 h at 30 °C and then for 1 h at 50 °C. After 1 N HCl (50 ml) and diethylether (100 ml) were added to the mixture at room temperature, the organic layer was separated using a separating funnel, dried over Na2SO4 and concentrated under reduced pressure with a rotary evaporator. The remaining dimethylformamide in the residual liquid was removed by silica gel short column, with an eluent of AcOEt:CH2Cl2:hexane=1:2:2, and the residue was purified by preparative high pressure liquid chromatography with silica gel and the same eluent as above. 3 was obtained, at 34.0% yield, as pale-yellow liquid. The 1H NMR (400 MHz, CHCl3) assignments made were: δ=5.52 (t, 1H, J=9.2 Hz, –CHC(=O)–), 4.51 (m, 1H, –CH2OC(=O)–), 4.34 (m, 1H, –CH2OC(=O)–), 3.09 (s, 1H, H–C≡), 2.73 (m, 1H, –CH2CH2OC(=O)–) and 2.40 (m, 1H, –CH2CH2OC(=O)–). Similarly, for 13C NMR (100 MHz, CDCl3), the assignments were: δ=173.4 (C=O), 153.2 (C=O), 79.3 (≡C–C(=O)), 75.3 (H–C≡), 70.9 (–CHC(=O)–), 67.0 (–CH2CH2O–) and 30.5 (–CH2CH2O–). The assignment for the 13C NMR signals were confirmed by HMQC measurement. Anal calcd for C7H6O4:C, 54.55; H, 3.92. Found: C, 54.30; H, 3.87.

Preparation of 4 (intermediate product)

Under N2 atmosphere, EtAlCl2 (1.04 M solution in hexane, 21 ml, 22 mmol) and toluene (50 ml) were combined in a round-bottomed flask. After a toluene/3 solution (50 ml per 11.1 g, 72.3 mmol) was added to the solution at room temperature, the mixture was heated to 70 °C, and freshly prepared cyclopentadiene (7.2 ml, 87 mmol) was added dropwise. After the addition, the reaction mixture was stirred for 2 h at 70 °C. After the mixture was cooled to room temperature, 1 N HCl (50 ml) was added. After diethyl ether (100 ml) was added, the organic layer was separated using a separating funnel, dried over Na2SO4 and concentrated under reduced pressure with an evaporator to produce grayish liquid as a crude product of 4, which was used for the hydrogenation without further purification.

Preparation of 1b

Under N2 atmosphere, crude 4 (4.1 g), Pd/C (125 mg) and ethyl acetate (120 ml) were combined in a round-bottomed flask, and the mixture was degassed via freeze-pump-thaw cycling three times. At the end of the degassing procedure, 1 atm of H2 was introduced, instead of N2, at 0 °C, and the mixture was stirred for 100 min. After the remaining catalyst was removed by filtration, volatiles were removed under reduced pressure. The residue was purified by high pressure liquid chromatography on silica gel with an eluent of hexane:AcOEt:CH2Cl2=3:1:1 to produce pure 1b (3.2 g) as a colorless solid. The 1H NMR (400 MHz, CHCl3) assignments made were: δ= 7.07 (s, 1H, –CH=), 5.47 (q, J=8.4 Hz, 1H, –OCHC(=O)–), 4.49 (t, J=9.2 Hz, 1H, –CH2CH2O–), 4.33 (q, J=9.6 Hz, 1H, –CH2CH2O–), 3.29 (s, 1H, –CHC(–CO2–lactone)=C), 3.06 (s, 1H, –CHCH=C(–CO2–lactone)), 2.74 (m, 1H, –CH2CH2O–), 2.33 (m, 1H, –CH2CH2O–), 1.76 (m, 2H, CHCH2CH2CH), 1.52 (m, 1H, bridge head CH2), 1.23 (d, J=8.4 Hz, 1H, bridge head CH2) and 1.11 (m, 2H, CHCH2CH2CH). Similarly, for 13C NMR (100 MHz, CDCl3), the assignments were: δ= 173.0 (C=O), 163.4 (C=O), 149.6 (–CH=), 139.3 (=C–CO2–), 67.3 (–OCHC=O), 65.1 (–CH2O–), 48.2 (bridge head), 43.7 (–CHCH=), 41.9 (–CHC(–CO2–)=CH–), 29.1 (–CHCH2CH2O–), 24.5 (–CHCH2CH2CH–) and 24.4 (–CHCH2CH2CH–). The above assignments were confirmed using COZY and HMQC spectra. Anal. calcd for C12H14O4·0.25 H2O: C, 64.85; H, 6.35. Found: C, 64.57; H, 6.48.

Preparation of 1c (as a mixture with 1c′)

The Diels–Alder reaction, to synthesize 5, and Pd/C-catalyzed hydrogenation of 5, to synthesize a mixture of 6 and 6′, was performed in procedures similar to those described above for the preparation of 4 and 1b, respectively. The composition ratio of [6]/[6′] was determined from its 1H NMR spectrum (see Supplementary Figure S2 for the spectrum of a mixture with [6]/[6′]=1:0.69). Under N2 atmosphere, a mixture of 6 and 6′ (9.19 g, ∼46 mmol) and CHCl3 (12 ml) were combined in a Schlenk tube. After pyridine (1.5 ml, 18 mmol) and Me3SiI (10.5 ml, 73.5 mmol) were added to the solution, the mixture was left to stand at 60 °C for 64 h without stirring. MeOH (60 ml) was added to the mixture, and it was stirred for 1 h at room temperature. After volatiles were removed under reduced pressure, the residue was extracted with 200 ml of diethylether. After the solvent was removed under reduced pressure, the residue was purified by preparative high pressure liquid chromatography, on silica gel with an eluent of AcOEt:hexane=3:2, and preparative GPC, to produce a mixture of 1c and 1c′ as colorless oil (5.90 g, ∼71% yield). The composition of 1c:1c′ was determined by 1H NMR (see Supplementary Figure S3 for the spectrum of a mixture with [1c]/[1c′]=1:0.40). Anal. calcd for C10H14O3 (1c)·0.21 C10H16O3 (1c′)·0.4 H2O: C, 63.72; H, 8.03 (the composition of [1c]:[1c′]=1:0,21 for the sample was determined by 1H NMR). Found: C, 63.63; H, 7.68.

Polymerization procedure

As a representative procedure, terpolymerization of 1a, GBLA and MAdMA (run 1 in Table 1) was described as follows.

Under a N2 atmosphere, 1a (1.77 g, 11.6 mmol), GBLA (0.80 g, 5.1 mmol), MAdMA (1.20 g, 5.12 mmol) and VAZO (26 mg, 0.11 mmol) were combined in a Schlenk tube. After PGMEA (3.3 ml) was added, the mixture was degassed via three cycles of the freeze-pump-thaw procedure. The mixture was heated to 110 °C and stirred for 13.5 h. After the mixture was cooled to room temperature, volatiles were removed under reduced pressure, and the residue was purified by preparative GPC, with CHCl3 as an eluent. The terpolymer was obtained in a 53% yield as a colorless solid.

Lithographic performance evaluation

Resist solution was prepared by dissolving polymer (10 or 8.5 wt%) and triphenylsulfonium triflate, TPSOTf, (2 wt% with respect to polymer) in a mixture of PGMEA, ethyl lactate (EL) and methylethylketone (MEK) (PGMEA:EL:MEK=80:15:5, by weight). The solution was filtered through a 0.2 μm filter and spin-coated onto silicon wafers, whose surfaces were treated with hexamethyldisilazane, to obtain ∼300 μm-thick films, which were annealed at 120 °C for 60 s. The resist-coated substrates were exposed, using an ArF flood exposure instrument (Litho Tech Japan VUVES-4500mini, Kawaguchi, Japan). After the exposed substrates were post exposure-annealed at 110 °C for 60 s, they were developed using 2.38 wt% tetramethylammonium hydroxide solution at 23.5 °C for 60 s. The DR of the films was measured using a development rate monitor (Litho Tech Japan RDA-800)

Results and Discussion

Monomer synthesis

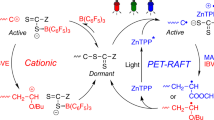

Scheme 1 illustrates the synthetic routes for the alkyl 2-norbornene-2-carboxylates, 1a–c. For the synthesis of a methyl ester monomer, 1a, although, in our previous publication,5 we used a procedure that involved metalation of parent norbornene at the 2-position followed by substitution with alkyl chloroformate, we have found that a procedure using Pd/C-catalyzed hydrogenation of an ester-substituted norbornadiene derivative 2 is more efficient,24, 25 particularly for large-scale preparations. As shown in the scheme, the hydrogenation of a Diels–Alder adduct of cyclopentadiene with methyl propiolate, 2, produces a mixture of 1a and an overreacted compound 1a′. The ratio of the two components, 1a and 1a′, was determined from the signal intensities of each component in the 1H NMR spectrum (see Supplementary Figure S1 for the sample with a [1a]/[1a′] of 1:0.37) and was dependent on the reaction period for the hydrogenation. As it was not possible for us to isolate 1a from the mixture and because the presence of the overreacted compound 1a′ did not affect the radical copolymerization of 1a, the mixture was used for the polymerization, with the composition of two components determined by 1H NMR being taken into consideration.

For the synthesis of a monomer containing a γ-butyrolactone moiety, 1b, α-bromo-γ-butyrolactone, was reacted with propiolic acid, in the presence of K2CO3 to produce a lactone-containing ester, 3, which was then reacted with cyclopentadiene to give a norbornadiene derivative, 4. When the norbornadiene, 4, was subjected to Pd/C-catalyzed hydrogenation, only the desired monohydrogenated norbornane, 1b, was obtained, most likely because of the steric hindrance around the unreacted C=C caused by the γ-butyrolactone moiety.

Next, a hydroxy group-containing monomer, methoxyethyl propiolate (1c), was reacted with cyclopentadiene to produce a corresponding norbornadiene, 5, which was then hydrogenated with H2 in the presence of Pd/C catalyst. In this case, as in the preparation of 1a, the product was revealed to be a mixture of the desired compound, 6, and an overreacted norbornane derivative, 6′. Deprotonation of the –OMe group, with trimethylsilyl iodide, in the presence of pyridine,26 produced the desired compound, 1c, as a mixture with an overreacted compound 1c′, where the quantitative progress of the deprotonation was confirmed by the disappearance of the MeO– signal in the 1H NMR spectrum. The composition of the mixture was determined from its 1H NMR spectrum (see Supplementary Figure S3 for the sample with a [1c]/[1c′] of 1:0.40).

Radical copolymerization of alkyl 2-norbornene-2-carboxylates, 1b and 1c, with nBA

In our previous publications,5, 6 we have reported that radical copolymerization of 1a with nBA produced copolymers with a norbornane framework in the main chain. The reactivity of 1a is much lower than that of nBA, with monomer reactivity ratios of r1 (1a)=0.023 and r2 (nBA)=1.33, which indicate that the presence of a 1a–1a sequence is almost negligible in the copolymer main chain. Tg measurement of the resultant copolymers revealed that the incorporation of the norborane framework into the poly(nBA) main chain is effective for raising Tg.6 However, copolymerization of 1a with MMA did not proceed, most likely because the steric congestion between 1a and MMA is too severe for the copolymerization reaction to occur. While homopolymerization of 1b and 1c and their copolymerization with MMA did not proceed, the copolymerization behavior of the new norbornene-based monomers, 1b and 1c, with nBA was investigated in this section.

Table 1 shows the copolymerization results of 1b and 1c with nBA initiated with VAZO at 110 and 85 °C with various monomer feed ratios. When the bulk copolymerization of 1b with nBA with monomer feed ratios of [1b]/[nBA]=∼1:3 to 1:1 was conducted at 110 °C, copolymers with Mn<10 000 were obtained and their compositions, determined from 1H NMR, corresponded to the feed ratios (runs 1–3). Both Mn and polymer yield diminished with increased feed ratio of 1b, as was observed in the copolymerization of 1a with nBA.5, 6 However, by decreasing the reaction temperature to 85 °C, Mn of the products increased, with the compositions remaining the same as those at 110 °C (runs 4 and 5). Figure 1 shows the 1H NMR spectrum of poly(1b-co-nBA) obtained in run 2 in Table 1. Signals for CH (5.1∼5.7 p.p.m.) and CH2 (3.8–4.2 p.p.m.) in the lactone ring and OCH2 (3.8–4.2 p.p.m.) and CH3 (0.95 p.p.m.) from nBA units are separate. Thus, the composition of the two monomer units in the copolymers can be determined from the signal intensities.

1H NMR spectrum of poly(1b-co-nBA) in CDCl3 (run 2 in Table 1).

The results of copolymerization of hydroxy group-containing norbornene, 1c, with nBA are summarized in runs 6–9 in Table 1. Notably, the 1c compositions in the copolymers are higher than the values corresponding to the monomer feed ratios in all runs.27 In all other aspects, the copolymerization behavior of 1c with nBA is similar to that of 1a and 1b. Figure 2 shows the 1H NMR spectrum of poly(1c-co-nBA) obtained in run 8 in Table 1. In a range of 3.6–4.4 p.p.m., signals for –OCH2CH2O– in 1c and –OCH2– in nBA were observed as broad peaks. We can calculate the signal intensity for the –OCH2– in nBA from that of the –CH3 signal, observed at 0.94 p.p.m., independently of other signals. Thus, the composition of the two repeating units in the copolymer can be determined from the relative intensity of these signals.

1H NMR spectrum of poly(1c-co-nBA) in CDCl3 (run 8 in Table 1).

The radical copolymerization behavior of 1b and 1c with nBA demonstrate that 1b and 1c can also be copolymerized with alkyl acrylates. The information obtained here is useful for the synthesis of copolymers for application as photoresist materials, with an appropriate comonomer composition and Mn, as described in the following section.

Preparation of copolymers for photoresist applications

Scheme 2 illustrates the chemical structure of a representative photoresist polymer, 7, based on alkyl (meth)acrylates. In this polymer, the adamantane framework in the repeating units, from 3-hydroxy-1-adamantyl methacrylate (HAdMA) and MAdMA, has an essential role in increasing the mechanical strength (higher Tg) and dry etching resistance, whereas the hydroxy group in HAdMA and the lactone ring in α-methacryloyloxy-γ-butyrolactone (GBLMA) impart the required hydrophilicity to the polymer. In addition, after irradiation with 193-nm laser light to generate acidic reagents from photoacid generator, the MAdMA unit should be cleaved to give a methacrylic acid repeating unit, which is necessary for the exposed region to be dissolved into an alkaline developing solution. For this application, the composition and Mn for suitable resist application has been revealed to be HAdMA/GBLMA/MAdMA=1:2:2 and ∼5000–10 000, respectively.

In our attempt to prepare a new series of photoresist polymers, based on related alkyl (meth)acrylate monomers including 1a–c, we have tried to employ 1a–c instead of HAdMA in 7 and thus to improve the dry etching resistance owing to the incorporation of an alicyclic unit in the polymer main chain. However, as described above, because 1a–c are not copolymerizable with alkyl methacrylates, we used γ-butyrolactone- and adamantane-incorporating acrylate monomers instead of the methacrylate counterpart used in 7 (Table 2). For evaluation of the effect of incorporating 1a–c and practical use as photoresist materials, the target Mn and composition were considered to be 5000–10 000 and 1a–c/GBL(M)A/MAd(M)A=1:2:2, respectively.

Terpolymerizations of comonomer combinations of 1a–c/GBLA/MAdMA and 1a–c/GBLMA/MAdA were conducted with propylene glycol monomethyl ether acetate (PGMEA) as the solvent at 110 °C to produce copolymers incorporating the three repeating units. To obtain copolymers with a composition and Mn in the aforementioned expected range, the polymerization conditions were adjusted, and the results of the synthesis of copolymers are summarized in Table 2. The samples obtained in runs 1–3,5,7 and 8 (8–13) were subjected to DR measurements to evaluate their suitability for the photoresist application.

For example, when 1a was used as a norbornene-based monomer, copolymers with a composition and Mn close to the expected values were obtained with a feed ratio of [1a]/[GBL(M)A]/[MAd(M)A]=3:1.5:1.5 (runs 1 and 2). Figure 3 shows the 1H NMR spectrum of the copolymer obtained in run 1, where signals for OCH3 from 1a and CH and CH2O in the lactone ring from GBLA were observed independently Thus, the composition ratio of [1a]/[GBLA] can be determined from the signal intensities. As all of the other signals derived from 1a and GBLA and all signals from MAdMA should be included in the region 0.9–3.0 p.p.m., we can calculate the intensity of all of the signals from MAdMA by subtracting the intensities ascribed to 1a and GBLA from the whole value of the region. To avoid being influenced by the H2O signal at ∼1.6 p.p.m., these spectra were obtained in the presence of a small amount of D2O. Consequently, the composition of [1a]/[GBLA]/[MAdMA] was determined to be 1:2.3:2.7 for the sample in run 1. The composition of the copolymer in run 2 was determined in a similar manner (see Supplementary Figure S4 for 1H NMR spectrum for 9).

1H NMR spectrum of poly(1a-co-GBLA-co-MAdMA) in CDCl3/D2O (run 1 in Table 2).

The copolymerization reaction using 1b proceeded with a feed ratio of [1b]/[GBL(M)A]/[MAd(M)A]=1:1:1 (runs 3 and 5). As shown in the 1H NMR spectrum for the copolymer in run 3 in Figure 4, because signals for CH and CH2O in the lactone rings from both 1b and GBLA appear at the same positions, it is impossible to determine the exact composition of [1b]/[GBLA], and accordingly, the ratio of the three components of [1b]/[GBLA]/[MAd(M)A] in the copolymer (see Supplementary Figure S5 for 1H NMR spectrum for 11). However, because we need at least an estimated value for the composition, we performed the copolymerization reaction using monomers whose reactivity in the copolymerization could be similar to GBL(M)A to acquire some relevant information on the composition. We substituted cyclohexyl acrylate (cHA) for GBLA and isopropyl methacrylate (iPMA) for GBLMA, given the assumption that the cyclohexyl and isopropyl groups would behave similarly to the lactone counterpart. In fact, copolymerization of GBLA with cHA and of GBLMA with isopropyl methacrylate produced copolymers with almost a 1:1 composition of the copolymer repeating units, suggesting that the above assumption with respect to the monomer reactivity is reasonable. Thus, copolymerization using cHA and iPrMA, instead of GBLA and GBLMA, respectively, was performed under the same conditions as those in runs 3 and 5, and the results were labeled as runs 4 and 6. In these copolymerizations, the compositions can be determined from 1H NMR, because OCH signals in cHA and iPrMA appeared independently from OCH and OCH2 signals in lactone ring (see Supplementary Figures S7 and S8). The compositions in runs 4 and 6 could be rough estimates for those in runs 3 and 5, respectively, and these values were in our expected range.

1H NMR spectrum of poly(1b-co-GBLA-co-MAdMA) in CDCl3/D2O (run 3 in Table 2).

Figure 5 shows the 1H NMR spectrum of the product obtained by the copolymerization in run 7 in Table 2, in which the hydroxy group-containing norbornene, 1c, was used as a comonomer. In this spectrum, in addition to the lactone-derived signals at 5.1–5.6 and 4.2–4.6 p.p.m., there are signals ascribed to –OCH2CH2O–, derived from 1c, at 4.0–4.4 (overlapping with one of lactone-derived signals) and 3.7–3.9 p.p.m., and based on the intensities of these signals, we can determine the composition ratio of [1c]/[GBLA]. Thus, as in the manner similar to that described above for copolymers in runs 1 and 2, it is possible to calculate the intensity of signals derived from the MAdMA repeating unit based on the intensity in the 0.9–3.1 p.p.m. range. As listed in Table 2, copolymers with the desired composition and Mn for the photoresist application were obtained by copolymerizations with feed ratios of [1c]/[GBLA]/[MAdMA]=1.5:1:1 and [1c]/[GBLMA]/[MAdA]=1:0.5:0.9, respectively (see Supplementary Figure S6 for 1H NMR spectrum for 13).

1H NMR spectrum of poly(1c-co-GBLA-co-MAdMA) in CDCl3/D2O (run 7 in Table 2).

Glass transition temperatures of the polymers, 8–13, were measured using DSC with temperature modulation, and are listed in Table 3. Compared with the high Tg (180 °C) of 7, which is composed of only methacrylate repeating units, the Tgs of 8–13 are lower because these compounds contain acrylate units, which significantly lower the transition temperature. The relatively low Tg (142 °C) of 8 can be ascribed to its higher acrylate content (GBLA: 38 mol%), compared with 9 (MAdA: 31 mol%, Tg=161 °C). Although the exact comonomer compositions of 10 and 11 are unknown, the high Tg of 10 (175 °C) could be ascribed to the presence of lactone, instead of a MeO group, attached to the norbornane unit. The value is the closest of all values to that of the methacrylate polymer, 7, which shows the strong Tg-raising effect of the repeating unit derived from 1b. Tg values for 12 and 13 became significantly lower than those of 8–11, as expected from the incorporation of CH2CH2OH-containing ester group.

Lithographic performance evaluation

As one of the important characteristics for photoresist materials, the DR for different exposure doses of 193-nm ArF laser light was investigated for polymers 8–13. Each copolymer together with triphenylsulfonium triflate (TPSOTf), as a photoacid generator, was dissolved in a solvent mixture of PGMEA, EL and MEK, and then spin-coated onto silicon wafers. After annealing at 120 °C, the film was exposed with 193-nm ArF laser light at various exposure doses and post-annealed at 110 °C. Then, the DR was measured with 2.38 wt% tetramethylammonium hydroxide aqueous solution. The results are shown in Figure 6 as plots of the DR against exposure dose. Table 3 lists the sensitivities of the copolymers that are defined as the exposure dose at which DR reaches 5 nm s−1, as determined from the plots in the figures.

Figure 6a shows the plots of DR against exposure dose for copolymers 8 and 9, derived from 1a, in addition to the plot for the reference photoresist polymer, 7. We can clearly observe in the figure a 10-fold increase in the maximum DR value and a significant increase in the sensitivity of copolymer 8 compared with those values for the reference copolymer 7. The difference in the dissolution behavior of 8 compared with 7 can be ascribed to the incorporation of alkyl acrylate framework into the main chain, which should significantly increase the flexibility of the whole polymer chain, resulting in more efficient dissolution behavior. However, although the main chain has an alkyl acrylate-derived unit similar to 8, the dissolution behavior of 9 almost remains the same as that of 7. The reason for this outcome can be assumed as follows. As described above, because the norbornene-based monomer, 1a, cannot be copolymerized with alkyl methacrylates, the comonomer combination of 1a/GBLMA/MAdA is used for synthesizing 9, and the repeating unit from MAdA (acrylate) has a much higher probability of having a 1a-derived unit in its adjacent positions than that from MAdMA (methacrylate) in 8. Accordingly, the acid-producing Ad-containing unit (MAdA) in 9 is located in a more rigid environment in the main chain, resulting in a lower DR and sensitivity compared with 8, parameters that coincidentally remain in the similar range as that in 7, as shown in Figure 6a. The dissolution behavior of 1b-containing polymers, 10 and 11, shown in Figure 6b, is similar to those of 8 and 9, respectively, except that the sensitivity of 11 was lower than that of 7 for unknown reasons.

Figure 6c shows the dissolution behavior of copolymers 12 and 13, with the hydroxy-containing norbornane repeating unit derived from 1c. Both of these polymers had maximum DRs reaching ∼10 000 nm s−1, which suggests that the influence of the higher flexibility imparted by the hydroxyethyl side chain dominates, as was also demonstrated by the aforementioned low Tg values. However, the sensitivity of these polymers was lower than that of 7; this result can be ascribed to the effect of the polar –OH group, which inhibits the transformation of an adamantyl group to a carboxyl group, by interacting with the acid (H+) generated from the photoacid generator in a hydrophilic interaction.28

These dissolution behaviors suggest that the copolymers 8–13, containing a norbornane backbone, can be seriously considered as attractive candidates for 193-nm photoresist applications.

Conclusions

We have demonstrated that radical copolymerization of alkyl 2-norbornene-2-carboxylate with alkyl (meth)acrylates is an efficient method for incorporating a norbornane backbone into (meth)acrylate-based polymers. The introduction of various ester groups into the monomer will enable us to modify the properties of the resultant copolymers. Copolymerization of the norbornene-based monomers with (meth)acrylate bearing lactone- and adamantane-containing monomers produced copolymers that exhibited promising results in the DR vs exposure measurements.

Preparation of alkyl 2-norbornene-2-carboxylates, 1a–c.

Structure of representative photoresist polymer.

References

Janiak, C. & Lassahn, P. G. Metal catalysts for the vinyl polymerization of norbornene. J. Mol. Catal. A: Chem. 166, 193–209 (2001).

Janiak, C. & Lassahn, P. G. The vinyl homopolymerization of norbornene. Macromol. Rapid Commun. 22, 479–492 (2001).

Blank, F. & Janiak, C. Metal catalysts for the vinyl/addition polymerization of norbornene. Coordin. Chem. Rev. 253, 827–861 (2009).

Nozaki, K. Radical polymerization of a related monomer, 2-norbornene-2-carbonitrile, has been reported (Fujitsu Co.) Jpn. Kokai Tokkyo Koho 3476783 (2003).

Ihara, E., Honjyo, S., Itoh, T., Inoue, K. & Nodono, M. Radical copolymerization of alkyl 2-norbornene-2carboxylate with alkyl acrylates: facile incorporation of norbornane framework into poly(alkyl acrylate)s. J. Polym. Sci., Part A: Polym. Chem. 45, 4597–4605 (2007).

Ihara, E., Honjyo, S., Kobayashi, K., Ishii, S., Itoh, T., Inoue, K., Momose, H. & Nodono, M. Radical copolymerization of methyl 2-norbornene-2-carboxylate and 2-phenyl-2-norbornene with styrene, alkyl acrylate, and methyl methacrylate: facile incorporation of norbornane framework into polymer main chain and its effect on glass transition temperature. Polymer 51, 397–402 (2010).

Ito, H. Chemical amplification resists for microlithography. Adv. Polym. Sci. 172, 37–475 (2005).

Okoroanyanwu, U., Shimokawa, T., Byers, J. & Willson, C. G. Alicyclic polymers for 193 nm resist applications: synthesis and characterization. Chem. Mater. 10, 3319–3327 (1998).

Okoroanyanwu, U., Shimokawa, T., Byers, J. & Willson, C. G. Alicyclic polymers for 193 nm resist applications: lithographic evaluation. Chem. Mater. 10, 3328–3333 (1998).

Kim, J. B., Lee, B. W., Kang, J. S., Seo, D. C. & Roh, C. H. Poly(t-butyl-3α-(5-norbornene-2-carbonyloxy)-7α,12α-dihydroxy-5β-cholan-24-oate-co-maleic anhydride) for a 193-nm photoresist. Polymer 40, 7423–7426 (1999).

Kim, J. B., Lee, J. J. & Kang, J. S. Poly(5-((2-trimethylsilyl-2-propyl)oxycarbonyl)-norbornene-co-maleic anhydride) for 193-nm lithography. Polymer 41, 6939–6942 (2000).

Hwang, S. H., Lee, K. K. & Jung, J. C. A novel organic bottom anti-reflective coating material for 193 nm excimer laser lithography. Polymer 41, 6691–6694 (2000).

Jung, J. C., Jung, M. H., Lee, G. & Baik, K. H. Amine gradient process for DUV lithography. Polymer 42, 161–165 (2001).

Lee, J. H., Ahn, K. D. & Cho, I. Novel multi-alicyclic polymers for enhancing plasma etch resistance in 193 nm lithography. Polymer 42, 1757–1761 (2001).

Hoskins, T., Chung, W. J., Agrawal, A., Ludovice, P. J., Henderson, C. L., Seger, L. D., Rhodes, L. F. & Shick, R. A. Bis(trifluoromethyl)carbinol-substituted polynorbornenes: dissolution behavior. Macromolecules 37, 4512–4518 (2004).

Nozaki, K., Kaimoto, Y., Takahashi, M., Takechi, S. & Abe, N. Molecular design and synthesis of 3-oxocyclohexyl methacrylate for ArF and KrF excimer laser resist. Chem. Mater. 6, 1492–1498 (1994).

Pasini, D., Klopp, J. M. & Fréchet, J. M. J. Design, synthesis, and characterization of carbon-rich cyclopolymers for 193 nm microlithography. Chem. Mater. 13, 4136–4146 (2001).

Klopp, J. M., Pasini, D., Byers, J. D., Willson, C. G. & Fréchet, J. M. J. Microlithographic assessment of a novel family of transparent and etch-resistant chemically amplified 193-nm resists based on cyclopolymers. Chem. Mater. 13, 4147–4153 (2001).

Diakoumakos, C. D., Raptis, I., Tserepi, A. & Argitis, P. Free-radical synthesis of narrow polydispersed 2-hydroxyethyl methacrylate-based tetrapolymers for dilute aqueous base developable negative photoresists. Polymer 43, 1103–1113 (2002).

Kim, J. B., Ko, J. S., Choi, J. H., Jang, J. H., Oh, T. H., Kim, H. W. & Lee, B. W. Synthesis and lithographic evaluation of poly[(methacrylic acid tert-butyl cholate ester)-co-(γ-butyrolactone-2-yl methacrylate)]. Polymer 45, 5397–5401 (2004).

Fukuhara, T., Shibasaki, Y., Ando, S., Kishimura, S., Endo, M., Sasago, M. & Ueda, M. Synthesis of poly[N-(1-adamantyl)vinylsulfonamide-co-2-(2-methyl)adamantyl methacrylate] for 193 nm lithography. Macromolecules 38, 3041–3043 (2005).

Lou, Q., Kishpaugh, M. A. & Shipp, D. A. Synthesis of statistical and block copolymers containing adamantyl and norbornyl moieties by reversible addition-fragmentation chain transfer polymerization. J. Polym. Sci., Part A: Polym. Chem. 48, 943–951 (2010).

Ridaoui, H., Dirani, A., Soppera, O., Ismailova, E., Brochon, C., Schlatter, G., Hadziioannou, G., Tiron, R., Bandelier, P. & Sourd, C. Chemically amplified photoresists for 193-Nm photolithography: effect of molecular structure and photonic parameters on photopatterning. J. Polym. Sci., Part A: Polym. Chem. 48, 1271–1277 (2010).

Nishino, H., Nakamura, A. & Inoue, Y. Synchronous enantiomeric enrichment of both reactant and product by absolute asymmetric synthesis using circularly polarized light. Part 1. Theoretical and experimental verification of the asymmetric photoisomerization of methyl norbornadiene-2-carboxylate to methyl quadricyclane-1-carboxylate. J. Chem. Soc., Perkin Trans. 2, 1693–1700 (2001).

Ghosh, T. & Bartlett, P. D. Chemical reactivity of the three-sulfur ring in norbornanetrithiolanes. The S3 transfer reaction. J. Am. Chem. Soc. 110, 7499–7506 (1988).

Jung, M. E. & Lyster, M. A. in Organic Syntheses Collect. (ed. Noland W. E.,) Vol. 6, 353–357 (John Wiley & Sons, Hoboken, NJ, USA, 1988).

Greenley, R. Z. The higher relative reactivity of hydroxyethyl methacrylate (HEMA) than that of MMA in radical copolymerization with nBA was reported: r1 (nBA)=0.09, r2 (HEMA)=4.75; r1 (nBA)=0.11, r2 (MMA)=2.86 in Polymer Handbook (eds Brandrup J., Immergut E. H., Grulke E. A., ) 4th edn., Ch. II, 181–308 (Wiley, Hoboken, NJ, USA, 1999).

Momose, H., Wakabayashi, S., Fujiwara, T., Ichimura, K. & Nakauchi, J. Effect of end group structures of methacrylate polymers on ArF photoresist performances. J. Proc. SPIE-Int. Soc. Opt. Eng. 4345, 695–702 (2001).

Acknowledgements

We thank Venture Business Laboratory in Ehime University for its assistance with NMR measurements.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supplementary Information accompanies the paper on Polymer Journal website

Supplementary information

Rights and permissions

About this article

Cite this article

Ihara, E., Ishii, S., Yokoyama, K. et al. Synthesis of polymers with a norbornane backbone by radical copolymerization of alkyl 2-norbornene-2-carboxylates for photoresist applications. Polym J 45, 606–613 (2013). https://doi.org/10.1038/pj.2012.180

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2012.180