Abstract

Poly(ɛ-caprolactone)2-b-poly(L-lactide)2 miktoarm block copolymers were successfully synthesized via ring-opening polymerization using pentaerythritol as the initiator and a protection–deprotection procedure. 1H nuclear magnetic resonance (1H NMR) and size exclusion chromatography (SEC) were employed to characterize the miktoarm structure, molecular weight and molecular weight distribution. The microspheres of poly(ɛ-caprolactone)2-b-poly(L-lactide)2 ((PCL)2-b-(PLLA)2) were produced by an oil-in-water emulsion solvent extraction/evaporation method and studied with scanning electron microscopy (SEM). The hydrolytic degradation of microspheres with different architectures and compositions was performed at 37 °C in a phosphate-buffered saline solution (pH=7.4). The weight loss of the microspheres was strongly affected by the molecular architecture, chain length and composition. The compositional, or molar ratio, changes were monitored during the degradation using 1H NMR, SEC, differential scanning calorimetry and SEM, all of which suggested that the degradation proceeded from the surface to the interior and could be described using a combined degradation model with surface erosion and bulk degradation.

Similar content being viewed by others

Introduction

Biodegradable aliphatic polyesters, such as poly(ɛ-caprolactone) (PCL), polylactide (PLA) and polyglycolide, have attracted great attention in the biomedical field1, 2, 3 for use in applications such as degradable sutures, artificial prostheses, tissue engineering scaffolds and drug delivery systems.4, 5, 6, 7, 8, 9 However, the degradation rate of PCL was too slow for certain biomedical applications due to its high hydrophobicity and crystallinity. To enhance the degradation rate of PCL, PLA or polyglycolide was usually copolymerized with CL to decrease its crystallinity or increase its hydrophilicity. In particular, PLA exhibited a rapid degradation rate and good mechanical properties, compensating for the poor properties of PCL.10, 11, 12, 13, 14, 15 The linear block copolymers of PCL and PLA with well-defined structures exhibited better mechanical strength.12, 13, 14

Compared with the linear polymers, star polymers exhibited some unique properties, such as lower bulk viscosity and solution viscosity, lower crystallinity, a variety of end groups, and a small hydrodynamic radius. The core-arm structure of the star polymer was believed to be the main reason for their interesting properties, and it also required special preparation procedures. Generally, two methods were commonly employed to prepare the star polymers, that is, the ‘arm-first’ and ‘core-first’ methods. Compared with the ‘arm-first’ method, the ‘core-first’ method allowed for more control over the structure of star polymers because the arms were initiated from the predesigned core. Therefore, the ‘core-first’ method was applied in our work to ensure the desired miktoarm structure. Well-defined star-shaped, dendritic and cyclic PCL were studied due to their unique structures and properties compared with those of the linear polymer.16, 17, 18 Xie et al.17 synthesized star-shaped PCL with one to five arms by ring-opening polymerization (ROP). The multi-arm structure and limitations on the chain mobility were considered to be the primary factors influencing the characteristic crystallization and enzymatic degradation behavior of the star-shaped PCLs. Hao et al.19 has synthesized star-shaped PLLAs with sugar alcohols as the initiators and studied their crystallization kinetics. However, previous star polymers usually consisted of multiple arms with the same chemical composition. Therefore, studies on degradable miktoarm star polymers would be of great interest due to their possible unique properties and degradation behavior, which make them attractive for use in controlled release systems.

PCL and its copolymers were usually fabricated into microspheres, which had large surface areas beneficial for drug delivery. The degradation behavior of these microspheres had an important role in this controlled release system. Therefore, the microsphere degradation of PCL and its copolymers was extensively studied. Dong et al.20 successfully fabricated blank and BSA-loaded microspheres based on D,L-PLGA50 and PCL-b-D,L-PLGA50 copolymers. The four-arm star-shaped D,L-PLGA50 copolymer degraded faster than the linear one. The BSA-loaded star-shaped PCL-b-D,L-PLGA50 microspheres showed good release profiles with a nearly constant release from 20 to 110 days. Microspheres with a diameter of approximately 100 μm were prepared by Garkhal et al.21 from different PLA-co-PCL copolymers, and the degradation behaviors of the microspheres were studied for up to 108 days. Their results indicated that the PLA component degraded faster than PCL. The thermal and mechanical properties, and the degradation behavior of the copolymers could be tuned by adjusting the composition of PCL and PLA. Therefore, incorporation of PLA or the use of star-shaped polymers could accelerate the degradation of PCL microspheres, thus improving its potential for application in biomedical fields. Miktoarm star PCL–PLLA copolymers are expected to combine the advantages of both the PCL and PLA components and optimize the degradability of the biomaterials. However, the degradation behavior of star-shaped polyesters, especially the miktoarm polyester, has hardly been reported.

In this study, a series of (PCL)2-b-(PLLA)2 miktoarm copolymers was synthesized by ROP with pentaerythritol as the initiator. Then, the copolymer microspheres with diameters of approximately 300 μm were produced by an oil-in-water emulsion solvent extraction/evaporation method. The hydrolytic degradation of these miktoarm copolymers was carried out in phosphate-buffered saline (PBS) (pH=7.4) at 37 °C. The chemical composition, thermal properties and surface morphology of the microspheres during degradation were determined by 1H nuclear magnetic resonance (1H NMR), size exclusion chromatography (SEC), differential scanning calorimetry (DSC) and scanning electron microscopy (SEM).

Materials and methods

Materials

ɛ-Caprolactone (ɛ-CL) (Aldrich, Milwaukee, WI, USA) was dried by CaH2 at ambient temperature and distilled under reduced pressure before use. L-Lactide (L-LA) was recrystallized in ethyl acetate/toluene and dried under vacuum before use. Pentaerythritol (Sinopharm Chemical Reagent Co., Ltd., Shanghai, China) was purified by recrystallization in dried methanol three times. Sn(Oct)2 was purchased from Acros (Geel, Belgium) and used without further purification. The other reactants and solvents were purchased from Shanghai Chemical Reagent Co. (Shanghai, China) and used after distillation.

Characterization

-

a)

1H NMR spectra were recorded on a Bruker AM-400 (400 MHz) spectrometer (Billerica, MA, USA) with tetramethylsilane as an internal standard and deuterated chloroform (CDCl3) as the solvent.

-

b)

SEC measurements were conducted using a Waters 1515 HPLC solvent pump (Waters, Shanghai, China) coupled to a Waters 2414 refractive index detector. Tetrahydrofuran was used as the eluent and delivered at a flow rate of 1.0 ml min−1 at 35 °C. The molecular weight was calibrated using polystyrene standards.

-

c)

DSC was carried out using a DSC 200PC/1/H (NETZSCH, Bayern, Germany) apparatus under a N2 flow of 10 ml min−1. The specimens were heated in sealed aluminum pans and monitored from −100 to 200 °C twice at heating and cooling rates of 10 K min−1.

-

d)

SEM was employed to study the microsphere morphologies. The (PCL)2-b-(PLLA)2 microspheres were covered by an ultrathin layer of gold, and then observed and micrographed with a JEOL JSM-6360LV scanning electron microscope (JEOL, Tokyo, Japan).

Experiments

Synthesis of benzalpentaerythritol (a)

Pentaerythritol (6.8 g, 0.05 mol) was dissolved in 100 ml H2O at 50 °C. Benzaldehyde (5.3 g, 0.05 ml) was added to the solution followed by hydrochloric acid (2 ml, 36%).22 The mixture was stirred for 8 h and kept overnight. The white solid product was filtered and then washed with distilled water and a sodium carbonate solution. Pure benzalpentaerythritol was obtained by recrystallization with toluene twice.

Yield: 75%. 1H NMR (δ, p.p.m., CDCl3): 3.57 (2H, CH2OH, d), 3.75 (2H, CH2OH, d), 3.80 (2H, CH2OH, d), 4.16 (4H, CCH2, d), 5.45 (1H, C6H5CH, s), 7.37–7.48 (5H, C6H5CH, m).

Synthesis of benzalpentaerythritol-(PCL)2 (bzl-(PCL)2) (b)

A typical ROP of ɛ-CL was performed using benzalpentaerythritol as the initiator and Sn(Oct)2 as the catalyst. Briefly, the benzalpentaerythritol (initiator) was added to a 10-ml flask and kept for 1 h under reduced pressure. Then, dried ɛ-CL was injected into the flask to dissolve the initiator. The mixture was allowed to sit in an oil bath at 100 °C for 0.5 h. Sn(Oct)2 was transferred into the flask, and the reaction was carried out at 130 °C. After 24 h, the reaction was stopped by dissolving the mixture in tetrahydrofuran. The polymer solution was precipitated in cold petroleum ether. The white solid product was collected by filtration and then dried overnight under vacuum.

Yield: >90%. 1H-NMR (δ, p.p.m., CDCl3): 1.39 (2H, CH2CH2CH2O, m), 1.66 (4H, COCH2CH2, CH2CH2O, m), 2.33 (2H, COCH2, t), 3.65 (2H, CH2OH, t), 3.93 (2H, CHOCH2, s), 4.06 (2H, CH2CH2O, CCH2O, t), 5.45 (1H, C6H5CH, s), 7.37–7.48 (5H, C6H5CH, m).

Terminal modification of the hydroxyls on bzl-(PCL)2 (c)

Bzl-(PCL)2 and triethylamine were dissolved in dichloromethane (DCM) and placed in a 100-ml flask in an ice-water bath. Although the mixture was stirred for 1 h, bromoacetyl bromide was dropped slowly into the flask. The reaction was continued for 48 h under a nitrogen atmosphere. Then, the mixture was washed by a saturated sodium bicarbonate solution three times. The crude product was precipitated from the DCM solution in cold diethyl ether. Then, the white product, bzl-(PCL-Br)2, was collected by filtration and dried under vacuum.

Yield: >96%. 1H-NMR (δ, p.p.m., CDCl3): 1.39 (2H, CH2CH2CH2O, m), 1.66 (4H, COCH2CH2, CH2CH2O, m), 2.33 (2H, COCH2, t), 3.83 (2H, CHOCH2, s), 4.06 (2H, CH2CH2O, CCH2O, t), 4.25 (2H, COCH2Br, s), 5.45 (1H, C6H5CH, s), 7.37–7.48 (5H, C6H5CH, m).

Deprotection of bzl-(PCL-Br)2 (d)

Bzl-(PCL-Br)2 was dissolved in a tetrahydrofuran/methanol mixture (4:1 v/v), and then Pd(OH)2/C (10%) was added into the mixture under N2. Then, the reaction was flushed with H2 and allowed to proceed for 48 h at 40–50 °C under H2. Pd(OH)2/C was removed by centrifugation three times. The polymer solution was precipitated in cold diethyl ether, and the white solid product, hydroxyl-(PCL-Br)2 (d), was obtained. The product was dried under vacuum at room temperature.

Yield: 30–50%. 1H-NMR (δ, p.p.m., CDCl3): 1.39 (2H, CH2CH2CH2O, m), 1.66 (4H, COCH2CH2, CH2CH2O, m), 2.32 (2H, COCH2, t), 3.60 (2H, CCH2OH, s), 3.84 (2H, CHOCH2, s), 4.07 (2H, CH2CH2O, CCH2O, t), 4.25 (2H, COCH2Br, s).

Synthesis of (PCL)2-b-(PLLA)2 (e)

Hydroxyl-(PCL-Br)2 and L-LA were dissolved in dried toluene under Ar2 in a predetermined ratio and then transferred to a 25-ml flask. The mixture was kept at 60 °C for 0.5 h before Sn(Oct)2 was added. The reaction was carried out at 80–100 °C for 48 h. The obtained solution was precipitated in excess cold methanol. The white solid product was collected by filtration and dried overnight under vacuum at room temperature.

Yield: >82%. 1H-NMR (δ, p.p.m., CDCl3): 1.40 (2H, CH2CH2CH2O, m), 1.58 (3H, CHCH3, d) 1.67, (4H, COCH2CH2, CH2CH2O, m), 2.32 (2H, COCH2, t), 3.60 (2H, CCH2OH, s), 4.07 (2H, CH2CH2O, CCH2O, t), 4.25 (2H, COCH2Br, s), 5.20 (1H, CHCH3, t).

Preparation of (PCL)2-b-(PLLA)2 microspheres

A modified oil-in-water emulsion solvent extraction/evaporation method23, 24 was employed to fabricate the (PCL)2-b-(PLLA)2 microspheres. Briefly, 50 mg PVA was dispersed in 100 ml distilled water, whereas 1 g (PCL)2-b-(PLLA)2 was dissolved in 10 ml DCM for the oil phase. Then, the oil phase was slowly dropped into the PVA solution with a stirring rate of 350 r.p.m. at room temperature to produce an oil-in-water emulsion. The mixture were set for 2 h to allow DCM to evaporate. The resulting (PCL)2-b-(PLLA)2 microspheres were filtered out and washed three times with deionized water. Then, the microspheres were vacuum-dried overnight.

Degradation of (PCL)2-b-(PLLA)2

Microspheres samples (50 mg) encapsulated in dialysis bags were subjected to hydrolytic degradation in a PBS solution (pH=7.4). Samples were removed at certain times for the SEM, DSC and TGA measurements and weight loss analysis. The weight loss (ΔM%) of each sample was calculated as follows:

where mi and mt are the initial sample weight and the dried sample weight at degradation time t, respectively.

Synthesis of linear PCL-b-PLLA

To compare the degradation behavior of the miktoarm (PCL)2-b-(PLLA)2 samples to that of linear polymers, linear bzl-PCL-b-PLLA was synthesized by ROP with benzyl alcohol as the initiator and Sn(Oct)2 as the catalyst. A typical ROP was carried out as described previously, and the product was precipitated in excess cold methanol and dried under vacuum overnight.

Results and Discussion

Miktoarm (PCL)2-b-(PLLA)2 and its particle formation

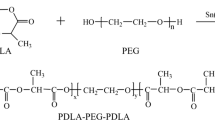

The ‘double-block’ miktoarm (PCL)2-b-(PLLA)2 copolymer was successfully synthesized with a pentaerythritol core by ROP and a protection–deprotection reaction. The four-step synthetic route is shown in Scheme 1. The products for each step were marked as (a) to (e) and characterized by 1H NMR as shown in Figure 1.

Polymerization of bzl-(PCL)2 (b) was carried out in a typical bulk ROP with Sn(Oct)2 as the catalyst. Then, bzl-(PCL-Br)2 (c) was synthesized from bzl-(PCL)2 (b) and bromoacetyl bromide by esterification in the presence of triethylamine. In Figure 1b, the peak r, which is the characteristic signal of the terminal hydroxyl group of bzl-PCL2, disappeared. Meanwhile, the peak k corresponding to the methylene group in bromoacetyl bromide appeared at 4.25 p.p.m. in Figure 1c. The absence of the signal of the terminal hydroxyl group indicated that the esterification reaction reached a high conversion of more than 96%. Hydroxyl-(PCL-Br)2 (d) was obtained by the deprotection of bzl-(PCL-Br)2 (c). Two catalysts, Pd/C and Pd(OH)2/C, were employed in the deprotection reaction with conversions of 78 and 98%, respectively. Therefore, Pd(OH)2/C exhibited excellent catalytic efficiency due to its high reactivity. A comparison of Figures 1c and d showed that the disappearance of peaks i and j was accompanied by the appearance of peak s, indicating that the deprotection of the benzyl group was complete. However, it should be noted that the yields were lower than 50% due to losses during the purification process. Furthermore, the number average molecular weight (Mn) of polymer (d) slightly decreased if the reaction time was longer than 3 days. The decrease in the molecular weight might be attributed to chain cleavage by transesterification.25 Finally, bulk and solution ROP of LLA were performed using Sn(Oct)2 as the catalyst to obtain (PCL)2-b-(PLLA)2 (e). However, in the bulk polymerization, PLLA was partially solidified because the reaction temperature of 130 °C was lower than its melting temperature of 160 °C. Thus, the Mn of the product was relatively low, and the PDI was high. If the reaction temperature was more than 160 °C, transesterification and thermal degradation might occur during polymerization. Therefore, in the final step, (PCL)2-b-(PLLA)2 was synthesized by solution polymerization, which was carried out at a lower reaction temperature (80 °C) without reactant solidification, transesterification or thermal degradation.

Table 1 shows the parameters of the designed copolymers (e) with different chain lengths of PCL and PLA. The miktoarm samples were named mikto 1, 2 and 3 corresponding to CL/LA molar ratios of 1:0.5, 1:1 and 1:1.5, respectively. The linear PCL-b-PLLA copolymer was named linear. The CL/LA molar ratio in these copolymers was determined by integrating the bands assigned to PCL at 4.0 p.p.m. (peak a) and PLLA at 5.2 p.p.m. (peak p) in the 1H NMR spectra. The actual CL/LA molar ratios of each sample were 1:0.43, 1:0.89 and 1:1.38, which were nearly consistent with the theoretical values and indicated that the polymerization was carried out in a controlled manner. The miktoarm samples were prepared with number average molecular weights ranging from 12 000 to 20 000 g mol−1. The PDIs of mikto 1, 2 and 3 were in the range of 1.2 to 1.4. Figure 2 shows typical SEC traces of bzl-(PCL)2 (c) and mikto 2. As illustrated, the peak of mikto 2 shifted towards the higher molecular weight region, indicating that ROP of LA occurred.

The surface morphologies of the PCL and (PCL)2-b-(PLLA)2 microspheres before the degradation study were characterized by SEM as shown in Figure 3. Consistent with the literature results, the surfaces of the PCL microspheres were smooth and without fissures (Figures 3a and c),21, 26 which limited its release efficiency for drug delivery. The hydrophobicity of PCL resulted in the smooth surface of the produced microspheres.27, 28 Compared with the PCL microspheres, the (PCL)2-b-(PLLA)2 microspheres had rough morphologies full of channels. It was proposed that during the frozen-pumped process, moisture was removed from the PLLA segments, and brittle ruptures might have occurred as shown in detail in Figures 3b and d. The channels on the surface could probably provide more surface area to accelerate the surface erosion in potential controlled release systems.

In vitro degradation study of (PCL)2-b-(PLLA)2 microspheres

The degradation behaviors of the microspheres formed from linear PCL-b-PLLA and (PCL)2-b-(PLLA)2 mikto 1, 2 and 3 were investigated using a PBS buffer solution (pH=7.4). Various techniques, including 1H NMR, SEC, DSC and SEM, were used to monitor the degradation process. Figure 4 presents the weight loss of all samples versus degradation time. The mikto 1, 2 and 3 lost 30% of their initial weight after 150 days. The linear polymer microspheres underwent a similar weight loss as the miktos. The weight loss was linearly proportional to the degradation time in all cases. However, mikto 1 had a 5% lower weight loss than the other samples in the first 63 days. It was suggested that high LA content might result in fast degradation in the early stage of the degradation. Moreover, it was reported21 that no weight loss was observed for the microspheres of a PCL homopolymer within a degradation time of 108 days. Therefore, the introduction of PLLA could dramatically enhance the degradation rate of the PCL homopolymer.

In Figure 5, five SEC curves are shown corresponding to the degradation samples of mikto 2 after 7, 28, 49, 91 and 147 days. During the degradation period from 7 to 147 days, the molecular weight of mikto 2 decreased from 15 000 to 4000 g mol−1, and the PDI increased from 1.2 to 2.0. It should be noted that two stages were observed during the degradation. In the first 49 days, the macromolecular weight of mikto 2 was approximately constant with a value of 15 000 g mol−1, whereas the weight loss increased linearly. This stage was considered to consist of typical surface erosion of the microspheres.29 After 91 days, the molecular weight of mikto 2 ranged from 4000 to 7000 g mol−1, indicating that bulk degradation behavior of the microspheres occurred.29, 30

To study the variation of the PCL and PLLA components during the degradation, 1H NMR was used to monitor the CL/LA molar ratio. The integral ratios of peak a (CL) to peak p (LA) in Figure 1e were used to calculate the CL/LA molar ratio. Figure 6 shows the trace of the CL/LA molar ratio of mikto 2 versus degradation time. In the first 63 days, the rapid increase in the CL/LA molar ratio from 1.1 to 1.6 demonstrated that the PLLA chains degraded faster and earlier than PCL. However, during the next 90 days, the CL/LA molar ratio increased slowly from 1.6 to 1.8, indicating an accelerated degradation of PCL, which might be explained by the autocatalytic effect caused by the fast degradation of the PLLA chains.

The thermal properties of mikto 2 during degradation are presented in Figure 7. The Tm and ΔHm values of mikto 2 at different degradation times are summarized in Table 2. As shown in Figure 7, the Tm of the PCL segments was in the range from 45 to 51 °C, which deviated from the melting point (63.2 °C) of the PCL homopolymer.21 This result indicated that the Tm of PCL was influenced by the PLLA block. Moreover, a continuous decrease in the Tm of the PLLA chains from 160.7 to 145.7 °C was detected. The reduction in the PCL and PLLA crystallinity during degradation could be the main reason for the decreasing Tm, which was also confirmed by the decrease in the ΔHm values of the PCL and PLLA chains. In the work of Garkhal et al.21, the Tm of PCL was approximately 39 °C for a linear block copolymer with a CL/LA molar ratio at 1:1, while that of PLLA increased from 103 to 108 °C during the degradation. However, the Tm of PLLA decreased during the degradation in our study. The decrease in the PLLA Tm might be attributed to the star-shaped structure of the miktoarm block copolymer17, 19 and could probably be explained by the conclusion from Hao et al.19 that an increase in the arm number of star copolymers led to less-ordered crystalline regions, which formed at lower growth rates. Thus, the crystallinity of mikto 2 decreased, which finally led to the reduction in the Tm of PLLA.

SEM provided a direct overview of the morphology changes of the (PCL)2-b-(PLLA)2 microspheres during degradation. The surface of the microspheres initially had channels (Figure 8a). After 28 days, the surface became more rugged as shown in Figure 8b. Pores and holes were densely distributed on the surface of the microspheres. The holes in Figure 8b were probably attributed to the degradation of the PLLA domains because PLLA degraded faster than PCL.31 The microsphere matrix did not undergo any obvious changes at this early stage. It was suggested that the surface erosion might take place in this period. As shown in Figure 8c, the surface of the microspheres degraded into shell-like pieces after 49 days. The hydrolysis activity occurred in the interior of the microspheres. It was conjectured that the surface erosion occurred on the external part of the microsphere matrix, whereas bulk degradation of the matrix took place at the same time. After 91 days, the deformation of the microsphere shape was observed as shown in Figure 8d. The microspheres could not maintain their original morphologies and collapsed into pieces. At the same time, the SEC curve exhibited a multi-peak feature with a PDI value above 2.0.

The morphologies of the microspheres were observed to change from spheres to irregular broken parts during the degradation as shown in Figure 8e (0 day) and Figure 8f (91 days). The molecular weight decreased from 15 000 to 4000 g mol−1, and the PDI value was large. The results suggested that a combination of surface erosion and bulk degradation was observed in our degradation study.29, 31

Conclusions

(PCL)2-b-(PLLA)2 miktoarm block copolymers were successfully synthesized via protection–deprotection and ROP using pentaerythritol as the initiator. 1H NMR and SEC analyses confirmed the miktoarm structure. Microspheres of (PCL)2-b-(PLLA)2 were produced by an oil-in-water emulsion solvent extraction/evaporation method. SEM photographs showed that the morphologies of the (PCL)2-b-(PLLA)2 microspheres were rough and full of channels in contrast to the smooth surfaces of the PCL microspheres synthesized in this study.

The hydrolytic degradation of the copolymers was performed at 37 °C in a PBS solution (pH=7.4). The weight loss of the microspheres was linearly proportional to the degradation time. The Mn value of mikto 2 decreased from 15 000 to 4000 g mol−1 during two degradation stages, which suggested that the degradation proceeded from the surface to the interior and could be described by a combined degradation model of surface erosion and bulk degradation. This result was also confirmed by SEM photographs, which showed that the morphologies of the microspheres changed from spheroid particles to irregular broken parts during the degradation. Moreover, the compositional changes revealed the autocatalytic effect caused by the fast degradation of the PLLA chains. The reductions in Tm and ΔHm observed by DSC suggested that the miktoarm structure decreased the crystallinity of PCL and PLLA during the degradation.

Synthesis route of (PCL)2-b-(PLLA)2.

References

Woodruff, M. A. & Hutmacher, D. W. The return of a forgotten polymer - polycaprolactone in the 21st century. Prog. Polym. Sci 35, 1217–1256 (2010).

Pan, P. J. & Inoue, Y. Polymorphism and isomorphism in biodegradable polyesters. Prog. Polym. Sci. 34, 605–640 (2009).

Albertsson, A. C. & Varma, I. K. Recent developments in ring opening polymerization of lactones for biomedical applications. Biomacromolecules 4, 1466–1486 (2003).

Nouvel, C., Dubios, P., Dellacherie, E. & Six, J. L. Controlled synthesis of amphiphilic biodegradable polylactide-grafted dextran copolymers. J. Polym. Sci. Pol. Chem. 42, 2577–2588 (2004).

Numata, K., Srivastava, R. K., Wistrand, A. F., Albertsson, A. C., Doi, Y. & Abe, H. Branched Poly(lactide) synthesized by enzymatic polymerization: effects of molecular branches and stereochemistry on enzymatic degradation and alkaline hydrolysis. Biomacromolecules 8, 3115–3125 (2007).

Xu, X. L., Chen, X. S., Liu, A. X., Hong, Z. K. & Jing, X. B. Electrospun Poly(l-lactide)-grafted hydroxyapatite/poly(l-lactide) nanocomposite fibers. Eur. Polym. J. 43, 3187–3196 (2007).

Tokiwa, Y. & Calabia, B. P. Biodegradability and biodegradation of polyesters. J. Polym. Environ. 15, 259–267 (2007).

Kunioka, M., Ninomiya, F. & Funabashi, M. Novel Evaluation method of biodegradabilities for oil-based polycaprolactone by naturally occurring radiocarbon-14 concentration using accelerator mass spectrometry based on ISO 14855-2 in controlled compost. Polym. Degrad. Stab. 92, 1279–1288 (2007).

Hou, Y., Chen, J., Sun, P. J., Gan, Z. H. & Zhang, G. Z. In situ investigations on enzymatic degradation of poly(ɛ-caprolactone). Polymer (Guildf) 48, 6348–6353 (2007).

Duda, A., Biela, T., Libiszowski, J., Penczek, S., Dubois, P., Mecerreye, D. & Jerome, R. Block and random copolymers of ɛ-caprolactone. Polym. Degrad. Stab. 59, 215–222 (1998).

Ikada, Y. & Tsuji, H. Biodegradable Polyesters for medical and ecological applications. Macromol. Rapid. Commun. 21, 117–132 (2000).

Qian, H. T., Bei, J. Z. & Wang, S. G. Synthesis, characterization and degradation of ABA block copolymer of L-lactide and ɛ-caprolactone. Polym. Degrad. Stab. 68, 423–429 (2000).

Zhao, Z. X., Yang, L., Hu, Y. F., He, Y., Wei, J. & Li, S. M. Enzymatic degradation of block copolymers obtained by sequential ring opening polymerization of L-lactide and ɛ-caprolactone. Polym. Degrad. Stab. 92, 1769–1777 (2007).

Huang, M. H., Li, S. M. & Vert, M. Synthesis and degradation of PLA–PCL–PLA triblock copolymer prepared by successive polymerization of ɛ-caprolactone and DL-lactide. Polymer (Guildf) 45, 8675–8681 (2004).

Huang, M. H., Li, S. M., Hutmacher, D. W., Coudane, J. & Vert, M. Degradation characteristics of poly(ɛ-caprolactone)-based copolymers and blends. J. Appl. Polym. Sci. 102, 1681–1687 (2006).

Liu, F., Zhao, Z. X., Yang, J., Wei, J. & Li, S. M. Enzyme-catalyzed degradation of poly(l-lactide)/poly(ɛ-caprolactone) diblock, triblock and four-armed copolymers. Polym. Degrad. Stab. 94, 227–233 (2009).

Xie, W. Y., Jiang, N. & Gan, Z. H. Effects of multi-arm structure on crystallization and biodegradation of star-shaped poly(ɛ-caprolactone). Macromol. Biosci. 8, 775–784 (2008).

Hoskins, J. N. & Grayson, S. M. Synthesis and degradation behavior of cyclic poly(ɛ-caprolactone). Macromolecules 42, 6406–6413 (2009).

Hao, Q. H., Li, F. X., Li, Q. B., Li, Y., Jia, L., Yang, J., Fang, Q. & Cao, A. M. Preparation and crystallization kinetics of new structurally well-defined star-shaped biodegradable poly(l-lactide)s initiated with diverse natural sugar alcohols. Biomacromolecules 6, 2236–2247 (2005).

Dong, C. M., Guo, Y. Z., Qiu, K. Y., Gu, Z. W. & Feng, X. D. In vitro degradation and controlled release behavior of D,L-PLGA50 and PCL-b-D,L-PLGA50 copolymer microspheres. J. Control. Release. 107, 53–64 (2005).

Garkhal, K., Verma, S., Jonnalagadda, S. & Kumar, N. Fast degradable poly(L-lactide-co-ɛ-caprolactone) microspheres for tissue engineering: synthesis, characterization, and degradation behavior. J. Polym. Sci. Pol. Chem. 45, 2755–2764 (2007).

Xie, Z. G., Lu, C. H., Chen, X. S., Chen, L., Wang, Y., Hu, X. L., Shi, Q. & Jing, X. B. Synthesis and characterization of novel poly(ester carbonate)s based on pentaerythritol. J. Polym. Sci. Pol. Chem. 45, 1737–1745 (2007).

Pouëssel, A. A., Bibby, D. C., Julienne, M. C. V., Hindré, F. & Benoît, J. P. A novel in vitro delivery system for assessing the biological integrity of protein upon release from PLGA microspheres. Pharm. Res. 19, 1046–1051 (2002).

Bae, S. E., Son, J. S., Park, K. & Han, D. K. Fabrication of covered porous PLGA microspheres using hydrogen peroxide for controlled drug delivery and regenerative medicine. J. Control. Release 133, 37–43 (2009).

Dubois, P., Barakat, I., Jerome, R. & Teyssie, B. Macromolecular engineering of polylactones and polylactides. 12. study of the depolymerization reactions of poly(ɛ-caprolactone) with functional aluminum alkoxide end groups. Macromolecules 26, 4407–4412 (1993).

Takei, T., Yoshida, M., Hatate, Y., Shiomori, K. & Kiyoyama, S. Preparation of polylactide/poly(ɛ-caprolactone) microspheres enclosing acetamiprid and evaluation of release behavior. Polym. Bull 61, 391–397 (2008).

Chen, D. R., Chen, H. L., Bei, J. Z. & Wang, S. G. Morphology and biodegradation of microspheres of polyester-polyether block copolymer based on polycaprolactone/polylactide/poly(ethylene oxide). Polym. Int. 49, 269–276 (2000).

Chen, C. C., Chueh, J. Y., Tseng, H., Huang, H. M. & Lee, S. Y. Preparation and characterization of biodegradable PLA polymeric blends. Biomaterials 24, 1167–1173 (2003).

Burkersroda, F. V., Schedl, L. & Gopferich, A. Why degradable polymers undergo surface erosion or bulk erosion. Biomaterials 23, 4221–4231 (2002).

Park, J. H., Ye, M. L. & Park, K. Biodegradable polymers for microencapsulation of drugs. Molecules 10, 146–161 (2005).

Gopferich, A. Polymer bulk erosion. Macromolecules 30, 2598–2604 (1997).

Acknowledgements

This research was supported by the Fundamental Research Funds for the Central Universities (WD0913008, WD1014017), the ‘Shu Guang’ Project of Shanghai Municipal Education Commission, the Natural Science Foundation of Shanghai (11ZR1409200), the National Natural Science Foundation of China (51103041), the Shanghai Leading Academic Discipline Project (B502), the Shanghai Key Laboratory Project (08DZ2230500) and the Scientific Research Foundation for the Returned Overseas Chinese Scholars, State Education Ministry.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhang, X., Xiao, Y. & Lang, M. Synthesis and degradation behavior of miktoarm poly(ɛ-caprolactone)2-b-poly(L-lactone)2 microspheres. Polym J 45, 420–426 (2013). https://doi.org/10.1038/pj.2012.166

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2012.166

Keywords

This article is cited by

-

A hybrid coating of polydopamine and nano-hydroxyapatite enhances surface properties of 3D printed poly(lactic-co-glycolic acid) scaffolds

Journal of Materials Science (2022)

-

PLA/EVA/Teak Wood Flour Biocomposites for Packaging Application: Evaluation of Mechanical Performance and Biodegradation Properties

Journal of Packaging Technology and Research (2018)