Abstract

Isotactic-poly(1-butene) (iPB1) shows superior mechanical properties after crystal–crystal transitions. Recently, Miyoshi et al. found that crystalline stems in metastable tetragonal crystal perform uniaxial rotational diffusions accompanying side-chain conformational transitions in the fast motional limit (correlation time, 〈τc〉 <10−7 s; Macromolecules 2010, 43, 3986–3989.). In this study, molecular dynamics in stable trigonal crystal is investigated by solid-state nuclear magnetic resonance, which indicates that crystalline stems and side-chain conformations are completely fixed up to melting points (〈τc〉 >10 s). In addition, lamellar thickness, 〈l〉 of iPB1 and a low isotacticity iPB1 (low_iPB1) with 〈mmmm〉=78%, respectively, were investigated by small-angle X-ray scattering. The low_iPB1 sample shows very week supercooling dependence of 〈l〉 (∼5 nm), whereas iPB1 shows strong supercooling dependence of 〈l〉 (10–28 nm). On the basis of molecular dynamics and 〈l〉 results, molecular dynamics effects on structures and unique mechanical property of iPB1 are discussed.

Similar content being viewed by others

Introduction

Isotactic poly(1-butene) (iPB1) is an industrially significant material because of its outstanding mechanical strength compared with chemically similar polyolefins, such as polyethylene (PE), isotactic-poly(propylene) (iPP) and isotactic-poly(4-methyl-1-pentene) (iP4M1P).1 In addition to having four polymorphs (I, I′, II and III),2, 3, 4, 5 iPB1 shows complex solid–solid transitions.6, 7, 8, 9, 10 As the samples crystallize from a melt in stationary conditions, a metastable tetragonal crystal of 113 helices (form II) is kinetically favored. This form II spontaneously transforms into a stable trigonal crystal of 31 helices (form I) at ambient temperature via a solid–solid transition.6, 7, 8, 9, 10 As a result, the bulk mechanical and physical properties are enhanced. These effects are caused neither by an increased crystallinity of the material, because the crystal fraction does not change during the transition, nor by variations of morphology.11, 12, 13, 14 Despite many structural investigations of the solid–solid transition of iPB1,6, 7, 8, 9, 10, 11, 12, 13, 14 the origin of its outstanding mechanical properties is not fully understood.

The molecular dynamics of polymers are highly related to chain packing and available spaces. Solid-state nuclear magnetic resonance (NMR) has been successfully applied to reveal the molecular dynamics of solid polymers in the amorphous and crystalline regions.15, 16, 17, 18, 19, 20 In the crystalline regions, the molecular dynamics of typical polyolefins such as PE,16 iPP17, 18 and iP4M1P19 were investigated by two- and one-dimensional exchange NMR, which can directly detect reorientations of magnetic anisotropic interactions that are due to molecular dynamics.15 These crystalline polymers commonly display slow, helical jump motions in the crystalline regions, which include discrete jump motions around the chain axes and translations of overall stems by one monomer unit. It was indicated that such overall motions in the crystalline region have important roles in crystallization, surface melting, mechanical properties and drawability.20

There are several solid-state NMR works on iPB1.21, 22, 23, 24, 25, 26, 27 Maring et al.22 using 1H second moments, detected reduced mobility of iPB following solid–solid transitions. Beckham et al.24 detected overall segmental motions in form II above Tg=−23 °C. Maring et al.23 investigated molecular dynamics in form I using high-resolution 13C NMR. They did not observe any evidence for molecular dynamics in form I in the mid 10 kHz range up to 90 °C. However, the detailed dynamic geometry and time-kinetic parameters of iPB1 have not yet been reported.

Very recently, Miyoshi et al.25, 26 revealed using 1H–1H dipolar patterns that crystalline stems in form II undergo continuous rotational diffusion around the chain axis, concomitant with lateral conformational transitions in the fast motional limit (correlation time, 〈τc〉 <10−7 s) at 100 °C. These dynamic characters are direct evidences for dynamically, conformationally disordered crystals.28

In this work, we will investigate the molecular dynamics of the stable form I of iPB using center band-only detection of exchange (CODEX)29 and modified wide-line separation NMR.30, 31, 32 As a result, it is found that crystalline stems in form I do not undergo any overall or side-chain motions, which reorient the principle axes of chemical shift anisotropy (CSA) up to Tm. On the basis of dynamics results in this and previous works,26 we will discuss the relationship between chain packing and the molecular dynamics of forms I and II. In addition, we will investigate how chain mobility influences the lamellar thickness, 〈l〉, of iPB1. Here we will use two samples of iPB1 and low isotactic PB1 (low_iPB1) (〈mmmm〉=78%). Very recently, De Rosa et al.33 found that low tacticity iPB bypasses crystallization into form II and directly crystallizes into the trigonal form (form I′). The two iPB1 samples used in this study display different crystallization mechanisms (through or bypassing form II). Thereby, we demonstrate that the lamellar thickness of iPB1 is highly dependent on the crystalline mobility. Through information about molecular dynamics and the 〈l〉–1/ΔT data obtained in this study, we conclude that unique crystallization and irreversible solid–solid transitions dominate the outstanding mechanical properties of iPB1.

Experimental procedure

Samples

Two samples of iPB1 and one of iPP were used in this work. iPB1, with an average molecular weight of Mw=186 000, a polydispersity of Mw/Mn=3.3 and an isotacticity of 〈mmmm〉=92%, was purchased from Polysciences Inc. (Warrington, PA, USA). iPB, with a low isotacticity of 〈mmmm〉=78% and an average molecular weight of Mw=280 000, was kindly provided by Idemitsu Ltd (Sodegaura, Japan). The low isotacticity sample will be referred to as low_iPB. The low_iPB1 was used for investigating 〈l〉. iPP, with an average molecular weight of Mw=360 000, a polydispersity of Mw/Mn=3.3 and an isotacticity of 〈mmmm〉=97%, was purchased from Polyscience Inc.

We did not further purify any of the samples. The samples were melted between two cover glasses on a hot stage. The thickness of each sample was controlled to be 0.2 mm by inserting a metal spacer between the cover glasses. Each sample was first melted and then crystallized several times to erase the previous thermal history. In a typical experiment, the samples of iPB1 were melted for 5 min at 150 °C. The samples were then rapidly transferred to another hot stage that was preset to a required crystallization temperature, Tc, to allow for isothermal crystallization under nitrogen atmosphere. The sample was completely solidified, and full crystallization was confirmed by polarized optical microscopy. The equilibrium melting temperatures, Tm0, of iPB and low_iPB were determined to be 135±2 and 90±1 °C, respectively, in terms of a Hoffman–Weeks plot using Tc and Tm obtained using differential scanning calorimetry (DSC). iPP samples were crystallized at 150 °C.

Nuclear magnetic resonance

The 13C solid-state NMR experiments were performed using a Bruker Avance 300 spectrometer (Bruker, Rheinstetten, Germany) equipped with a 4 mm cross polarization magic-angle spinning (CPMAS) NMR probe. The 1H and 13C carrier frequencies were 300.1 and 75.6 MHz, respectively. The MAS frequency was set to 4000±3 Hz. The 90° pulses for 1H and 13C were 4.5–5.0 μs. The recycle delay and cross-polarization time were 2 s and 1 ms, respectively. High-power 1H two-pulse phase modulation decoupling with a field strength of 65 kHz was used over an acquisition time of 80 ms. The chemical shift was referenced to the CH signal of adamantine (29.5 p.p.m.) as an external reference. A phase-sensitive 1H–13C two-dimensional wide-line separation NMR spectrum was obtained in time-proportional phase increment (TPPI) mode. The data matrix had 512 points along the t2 dimension and 128 points along the t1 dimension, with a dwell time of 2 μs. A short cross-polarization of 50 μs was used for the polarization transfer step. Continuous-wave decoupling with a field strength of 55 kHz was applied in the t1 dimension to suppress 1H–13C heteronuclear interaction.26, 31, 32 The temperature in the sample was carefully calibrated using the temperature dependence of the 207Pb chemical shift of Pb(NO3)2.34

The CODEX experiments use the recoupling of the CSA interaction using 180° pulse trains in the two evolution periods sandwiching a mixing period, tmix.29 The effect is a signal decay due to the dephasing of the magnetization brought about by changes in the orientation-dependent CSA that results from a reorientational dynamic process during tmix. The magnetization evolves during the initial evolution period, Ntr/2 (where N=2, 4, 6 and so on), under the orientation-dependent CSA interaction, which is recoupled by two successive 180° pulses per MAS rotation period, tr. The magnetization after the first evolution period is stored along the z direction by a 90° pulse and does not dephase during tmix (which must be set to an integer multiple of tr). The magnetization evolves again after the 90° readout pulse during the second evolution period (Ntr/2) and is refocused at its end. The second mixing period, tz, serves as a z-filter and permits the cancellation of longitudinal relaxation. In our experiments, tz was set to one tr. Following the last 90° pulse, the signal was detected under 1H two pulse phase modulation decoupling. If there is no molecular motion during tmix, the evolutions in the two evolution periods will cancel each other out, and there will be no decay of the signal intensity. If there is molecular motion during tmix, the orientation-dependent frequency before and after tmix will be different, and the magnetization will not be completely refocused. The resulting dephasing leads to a decay of the signal intensity in the exchange spectrum (S). To remove the T1 and spin–spin relaxation (T2) effects during tmix and Ntr, a reference spectrum is acquired. It can be obtained simply by interchanging tmix and tz. The signal intensity in the reference spectrum (S0) is not sensitive to exchange processes but is only dominated by T1, T2 and pulse length errors. The motional correlation time and information about the motional geometry can be obtained by plotting the ratio (S/S0) versus tmix and (S/S0) versus Ntr, respectively. A more detailed description of the CODEX experiment can be found in deAzevedo et al.29 The MAS frequency was 4000±3 Hz. The 1H radio frequency (rf) field strength for continuous-wave decoupling during the 13C 180° pulse with a pulse length of 15 μs was set to 100 kHz. All other rf parameters were the same as for the CPMAS experiments. The reference and exchange measurements were obtained alternatively every 128 transients to suppress drift of the NMR spectrometer. The T1ρH filter was incorporated into the CODEX pulse program for suppression of the amorphous signal contribution to the CODEX results at ambient temperature and at −10 °C. In total, each spectrum was obtained by accumulating 1024 transients. The total experimental time for the measurement of the mixing time dependence up to 4 s was approximately 24 h. The total experimental time of a typical Ntr experiment was approximately 12 h.

Small angle X-ray scattering

Small angle X-ray scattering studies were performed using a CuKα radiation generated by a Rigaku Ultrax 4153A 172B X-ray diffractometer (Rigaku, Akishima, Japan) and a point-focusing small angle X-ray scattering camera. The camera length used was 740 mm, and the images were recorded using an image plate with an exposure time of 2.5 h. Digitized data were then read from the image plate using the image plate reader. Using image plate, very small changes in small angle X-ray scattering patterns could be observed with a very short exposure time. The corrected pattern of an empty sample holder was subtracted from each pattern. To calculate the long period and the lamellar thickness, a correlation function method by Rigaku R-axis software (Rigaku) was used.

Differential scanning calorimetry

All of the samples were measured with an updated computer interfaced Perkin-Elmer DSC-7 (Perkin-Elmer, Waltham, MA, USA). Both temperature and heat-flow levels were corrected by standard materials. Measurements of the melting points were performed at a heating rate of 10 °C min−1. To prevent thermal degradation, nitrogen gas was circulated around the sample pan.

Results and discussion

Molecular dynamics in form I

Figure 1 shows 13C CPMAS NMR spectra of iPB1 crystallized at 100 °C, signal assignments and a DSC chart. The Tm of this sample is 130 °C. At ambient temperature, the 13C crystalline signals of form I are very sharp and dominate the spectrum. Very broad signals with very low intensities appear at the bottom of the sharp crystalline signals. These are amorphous components. There are two reasons for broadening in the amorphous signals: structural disorders such as conformations and packings or a dynamic effect. The Tg of iPB1 is −23 °C. Thus, the dynamics frequency of thermally activated 13C amorphous segmental motions reaches the mid 10 kHz order at ambient temperature. If molecular dynamics reaches the 1H dipolar decoupling (DD) frequency (65 kHz in our experiment), maximum line broadening occurs in the spectrum. This interference effect leads to broadened amorphous signals. The side-chain and main-chain methylene (s-CH and m-CH2, respectively) carbons in the crystalline regions display doublet signals. Stereoregular polymers can adopt right- or left-handed helical chains. In addition, lateral groups have upward and downward orientations. This orientation disorder provides different atomic positions in s-CH2 and m-CH2 carbons and leads to doublet signals (packing effect).2, 23

At elevated temperature, the 13C line widths of the crystalline signals are almost invariant. Above 99±2 °C, narrowed amorphous signals (indicated by asterisks) appear in the spectra. At 128±2 °C, the crystal is mostly melted and only small crystalline signals and further narrowed amorphous signals are observed. At 136±2 °C, there is no 13C CPMAS signal, indicating complete melting. Through this temperature dependence, 13C line widths of all of the crystalline signals show no broadening up to Tm. This result indicates that molecular dynamics in the crystalline region (except for CH3 rotation) do not reach the mid 10 kHz range up to Tm.

Figure 2a shows the 1H MAS NMR spectrum for the form I-rich sample of iPB1 at 118 °C. The spectrum is dominated by a very sharp 1H signal corresponding to the amorphous component. The 1H spectrum amplified vertically by a factor of 20 is shown in Figure 2b. This amplified spectrum clearly shows signals for both the crystalline and the amorphous components. To observe functional 1H line shapes in the crystalline signals, the 1H–13C wide-line separation spectrum of the form I-rich sample was obtained. Here CP time of 50 μs was used to suppress the spin-diffusion effect.26, 31 In addition, 13C DD during the t1 detection period was applied to eliminate 1H–13C heteronuclear dipolar interactions.31, 32 These two modifications provide short range 1H–1H dipolar interactions that reflect the local mobility on functional levels. Figures 2c and d show 1H slice spectra in the main and side chains, respectively, obtained through the highly resolved 13C signals. The obtained line shapes were fitted using Gaussian functions. The best fitted results indicate that 1H full-line width at half height is 57, 57, 54 and 37 kHz, for m-CH2, CH, s-CH2 and CH3 protons, respectively. The small 1H full-line width at half height for CH3 protons is attributed to fast rotations of the CH3 groups in the crystals. The other 1H line shapes are the typical rigid ones of solid polymers. This means that the overall and side-chain conformations in form I do not undergo large amplitude motions over a 1H line width of ∼50 kHz at 118 °C. The small reduction of the 1H line width of s-CH2 compared with that of m-CH2 may be attributed to librational motions of the side chain. This observation is consistent with the former 13C T1 reduction of s-CH2 carbon.23

(a) Whole and (b) 1H MAS nuclear magnetic resonance spectrum amplified vertically by a factor of 20 and 1H slice date of 1H–13C MAS wide-line separation nuclear magnetic resonance spectra of (c) the main chains and (d) the side chains of the form I-rich sample at 118 °C. The dotted lines show the 1H slice date through 13C CH and CH3 signals, and the solid lines show the 1H ones through 13C m-CH2 and s-CH2 signals.

To further investigate the slow molecular dynamics in form I crystals, we applied CODEX measurements to iPB1. This method can evaluate slow dynamics in a frequency range of 10−1 to 103 Hz. This method probes the reorientation of the CSA principle axis directions, which are fixed on 13C atoms due to molecular dynamics. Before investigating the molecular dynamics of iPB1, our pulse program was tested using iPP, for which the crystalline stems perform helical jump motions with a jump angle of 120° at temperatures above 90 °C.17, 18 The structure and dynamics are shown in Figure 3a. Several works evaluated helical jump motions using the CODEX method.18, 19, 29

(a) The 31 helix of the isotactic-poly(propylene) (iPP) crystalline stem and the jump angle of the 31 helix (ϕ=120°). (b) Center bands only detection of exchange Ntr dependence of (S/S0) for the CH2 (○), CH (•Î) and CH3 (Δ) of the isotactic-poly(propylene) α2-rich form with tmix=200 ms at 114 °C. The solid curve shows a simulated result for a helical jump with a jump angle of 120° on CH2 carbon.

Figure 3b shows the Ntr dependence of the CODEX (S/S0) for all of the functional signals of the α2-rich form18 of iPP with a tmix of 200 ms at 112 °C. The (S/S0) intensity ratios of all of the signals decay with increasing Ntr. This means that all of the functional signals participate in molecular dynamics. The decay curve of each carbon relies on the dynamic geometry, the CSA principle axis values and the orientations. The helical jump effects (a jump angle, ϕ=120°) on CH2 carbon was numerically simulated, and the simulated result is shown as a solid curve in Figure 3b. Here the CSA size and principle axis orientations reported by Nakai et al.35 were used for simulation. This simulation result reproduces the experimental (S/S0) decay curves well. This confirms that our CODEX pulse program properly works to evaluate molecular dynamics.

Figure 4a shows the CODEX reference (S0), exchange (S) and difference spectra (S0–S) of the iPB1 form I with tmix=200 ms and Ntr=2 ms at ambient temperature. The result clearly indicates that S0–S is nearly zero in all of the functional signals. The CSA principle axis values of all of the functional signals in iPB136 are very similar to other polyolefins.25, 35 Thus, this result demonstrates that there is no large amplitude motion in iPB1 during tmix=200 ms at ambient temperature. 13C–13C spin diffusion also leads to an (S/S0) decay curve at a longer tmix of more than 1 s even in natural abundance. Thus, spin diffusion correction is necessary to investigate slow dynamics at any tmix longer than 1 s.19

(a) The 13C center bands only detection of exchange reference, exchange and difference spectra for the isotactic-poly(1-butene) form I at a mixing time of 200 ms and Ntr=2.0 ms at ambient temperatures. (b, c) Center bands only detection of exchange tmix dependence of (S/S0)* and (d) Ntr dependence of the (S/S0) intensity ratios for m-CH2 (•), CH (○) and CH3 (*) with Ntr=2 ms at (b) ambient temperature and at (c, d) 118 °C.

Figures 4b and c show the tmix dependence of the (S/S0)* intensity ratios of m-CH2, CH and CH3 at ambient temperature and at 118 °C, respectively, where asterisk (*) represents the pure CODEX (S/S0) decay after spin-diffusion corrections. The spin-diffusion effect, (S/S0)SD, was obtained at −10 °C, where no motion is expected. (S/S0)* is described in terms of (S/S0)/(S/S0)SD. The (S/S0)* intensity ratios of m-CH2 and CH carbons do not decay up to tmix=4 s at a fixed Ntr=2 ms at ambient temperature. The (S/S0)* ratios of the CH3 signal at tmix⩾2 s are fluctuated and show large experimental errors. This is caused not by molecular dynamics but by a short 13C T1 value. At 118 °C, the (S/S0 (tmix))* intensity ratios of all of the functional signals show similar behaviors to those at ambient temperature. The tmix dependence of the CODEX (S/S0) intensity ratios is analyzed in terms of (S/S0)*=1−a(1−exp(−(tmix/〈τc〉)β)),29 where a is related to the available site number, p and β is the distribution width. Even at 118 °C, no essential reduction in the (S/S0)* intensity ratios was observed up to tmix=4 s. Figure 4c shows the best-fit solid curve with 〈τc〉=860±5000 s for the experimental data of CH. This long value is outside of the dynamic window in our experiments (⩽10 s). In this case, the fitted parameters to the experimental data no longer show physical meaning.

In the tmix experiment, Ntr was fixed to be 2 ms. This value is a typical condition to characterize large amplitude motions of the crystalline segments. In former works, helical jump motions of iPP and iP4M1P were analyzed using Ntr=2 ms.18, 19 Thus, the current CODEX result denies the presence of large amplitude motions in iPB1 form I in the slow dynamic range even at very high temperatures just before Tm. If iPB1 may have small amplitude motions, the decay curve requires a longer Ntr to detect the molecular dynamics. Figure 4d shows the Ntr dependence of the (S/S0) intensity rations for m-CH2, CH and CH3 13C signals with tmix=200 ms at 118 °C. The (S/S0) intensity ratios of all of the signals do not decay with increasing Ntr up to 4.5 ms. The solid line in Figure 4d represents a jump angle of 0°, which is consistent with the experimental results within the error. This means there is essentially no molecular dynamics in both the main and the side chains in the slow dynamic range. Thus, the dependence of both the tmix and the Ntr on the CODEX experiments indicates that there are no overall or side-chain motions that induce reorientations of the CSA principle axes of all of the functional signals of form I up to Tm. These dynamics results are consistent with the results of 1H line widths and 13C line widths under DD.

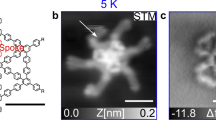

Further, the molecular dynamics of form I′ was also investigated using the 13C line width under DD and CODEX. The 13C line widths under DD were invariant up to the melting point (78 °C). The CODEX Ntr dependencies of m-CH2, CH and CH3 signals with tmix=200 ms at 75 °C are shown in Figure 5. None of the signals display a decay up to Ntr=4.5 ms. The CODEX tmix dependencies of all of the signals with Ntr=2 ms at 75 °C also indicate no decay of any of the signals up to tmix=4 s (data are not shown). These experimental results indicate that, although there is a significant difference in the melting points between forms I and I′, the dynamics characteristics of form I′ are very similar to that of form I.

The 13C center bands only detection of exchange reference Ntr dependence of the (S/S0) intensity ratios for m-CH2 (•), CH (○) and CH3 (*) of low isotacticity isotactic-poly(1-butene) with tmix=2 ms at 75 °C just before the onset of melting (78 °C). The solid line represents a jump angle of 0° around the helical axis.

iPB1 versus other crystalline polymers

Time-kinetic parameters and the geometry of molecular dynamics reflect on their own conformations and chain packing with neighboring molecules (available dynamic space). Our previous results revealed that the crystalline stems in form II undergo uniaxial rotational diffusion along with the side-chain conformational transitions in the fast motional limit (〈τc〉 <10−7 s) at 100 °C.26 Following the subsequent solid–solid transition, the molecular dynamics drastically changes from fast-limit overall dynamics to no overall dynamics on the NMR time scale (>10 s). This solid–solid transition also accompanies a drastic change in the side-chain dynamics from a fast-limit conformational transition to no transition (>10 s) even at a temperature close to Tm. These drastic mobility changes, both overall and in the side chains, should be simply related to available spaces in the crystalline field. According to crystallographic data,2, 3 the solid–solid transition leads to 15% contraction in the ab plane and 12% extension along the c axis (chain axis). Such densification leads to a huge dynamic gradient between forms II and I.

Here it would be interesting to compare the geometry and the time-kinetic parameters of the molecular dynamics observed in forms I and II with those of similar polyolefins. PE (orthorhombic),16 iPP (α2 form)17, 18 and iP4M1P (form I)19 commonly show helical jump motions in the crystalline regions. The helical jump motion accompanies jump rotations of overall stems to neighboring sites and translation of overall stems by one monomer unit. Such discrete jump motions are attributed to a well-defined periodicity of chain conformations and packings in the crystalline regions. With regard to the time-kinetic parameters of these dynamics, 〈τc〉 of the helical jump motions of PE, iPP and iP4M1P were estimated to be 10−5, 5 × 10−2 and 8 × 10−4 s, respectively, at 118 °C using reported activation energies and correlation times.16, 18, 19 Though the dynamic geometries are different, it is understood that both the overall dynamics in form II (〈τc〉 <10−7 s) and the absence of overall motions in form I (〈τc〉 >10 s) at 118 °C are much faster and slower, respectively, than 〈τc〉=10−2–10−5 s of the helical jump of three polymers at 118 °C. Therefore, it is understood that the dynamic characteristics (geometry and kinetics) of both forms of iPB1 are largely different from those of similar polyolefins.

Similar types of molecular dynamics (geometry and kinetics) to those in form II were observed in other conformationally disordered crystals such as PE in the hexagonal phase under high pressure37 and 1,4-trans-polybutadiene in the high temperature phase.38 Here chain stems commonly undergo uniaxial rotational diffusions in the fast motional limit.37, 38 Such unique fast dynamics for PE in the hexagonal packing, 1,4-trans-polybutadiene in the high temperature phase, and form II of iPB are highly related to local structural disorders in both chain packing and conformation.

Compared with dynamic analyses in mobile crystals, there are very few results providing information about immobile polymer dynamics up to the melting point. English and coworkers39 clarified that nylon does not show overall stem motions in the crystalline region up to its melting point. Nylon possesses NH and CO groups in a repeating unit and shows cooperative hydrogen bonding between stems. In addition, the repeating unit is much longer than in simple polyolefins. These two structural factors highly restrict the overall motions of the stems in nylon.20, 39 In contrast, iPB1 consists of (i) nonpolar hydrocarbons, (ii) short-length monomer units and (iii) regular helical conformations. These structures are common in similar polyolefins. Thus, only chain packing is a structural factor that restricts both the overall and the side-chain dynamics in form I. In particular, form I of iPB1 has very tight packing structures compared with other polyolefins.

On the basis of molecular dynamics, Hu and Schmidt-Rohr20 categorized semi-crystalline polymers as either mobile crystals or fixed crystals. iPB1 achieves both extremely fast and slow-limit dynamics characteristics through a unique two-step process: (i) crystallization into form II and (ii) an irreversible solid–solid transition into form I. We will further investigate how unique molecular dynamics in both forms influence the structures and properties of iPB1.

Mobility effects on lamellar thickness

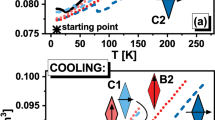

Very recently, De Rosa et al.33 reported that the low isotacticity sample directly crystallizes into form I′ from the melt state. Here the stereoregularity effects on lamellar thickness 〈l〉 were investigated. Figure 6a shows the 〈l〉–1/ΔT relation of two iPB1 samples with different stereoregularity. iPB1 experiences crystallization into form II and a subsequent solid–solid transition into form I 〈l〉 was obtained following the solid–solid transition. This sample shows a very wide 〈l〉 range from 10 nm at Tc=50 °C to 28 nm at Tc=110 °C. The best fit to the experimental data provides a slope of 624±4 nm K−1. Low_iPB1 directly crystallizes into form I′. The 〈l〉–1/ΔT relation shows a different line with a null slope of 32±3 nm K−1. The 〈l〉 range is only 4.6–5.3 nm. Therefore, two samples show largely different 1/ΔT dependencies of 〈l〉.

Two possible mechanisms might contribute to the largely different slopes in the 〈l〉–1/ΔT relation for the two samples. One is a purely chemical effect on 〈l〉. Another is a physical mobility effect in different crystalline forms. There are several works addressing the chemical effects with regard to the lamellar thickness of semi-crystalline polymers.40, 41 Cheng et al.40 investigated the effects of stereoregularity (〈mmmm〉=78–99%) on the 〈l〉 of iPP at various Tcs. We replotted their results in addition to a recent result on the 〈l〉 of iPP19 over a wide temperature range in Figure 6b. The low isotacticity samples show thinner lamellar thickness than do those of high isotacticity. Nevertheless, the 〈l〉–1/ΔT relations of all of the samples are described in terms of one universal line. A similar result was obtained in syndiotactic-poly(propylene-octene) copolymers by Strobl.41 These results indicate that chemical disorder influences 〈l〉 values, but does not change the slope of the universal line of 〈l〉–1/ΔT. Thus, the largely different slopes of the two iPB1 samples must be attributed to a huge difference in mobility between forms I′ and II. Extremely fast dynamics in form II leads to large variations in 〈l〉 at different crystallization temperatures. In contrast, the direct crystallization of form I′ into a fixed crystal results in very thin lamellae with 〈l〉= approximately 5 nm. This small thickness is reasonably explained in terms of the immobility of the crystalline stems in form I′.

Polymorphism

Here we consider the polymorphism of forms I and I′. So far, several works have focused on the structural difference between forms I and I′. Among the previous characterizations, only DSC detected a large difference in the Tms (Tm=130 °C for form I and 80–95 °C for form I′).33, 42 This result provided direct evidence that form I′ and I are different polymorphs. It was suggested from a large difference in their Tms that form I′ is structurally disordered form I.42 Molecular dynamics is quite sensitive to local environments. If structural disorders are included in form I′, significant molecular dynamics might be expected. Our current results, however, did not show any dynamics evidence in form I′ up to Tm or in form I. These local dynamics results are consistent with the static structures obtained using XRD, which indicated that both crystalline forms are the same trigonal crystals consisting of 31 helices.33 These locally static and dynamic structures are not consistent with the structural views of form I′ using DSC. As shown above, there is a large difference in the 〈l〉 values between forms I and I′. The Gibbs-Thomson equation indicates that there is a strong correlation between Tm and 〈l〉. Thus, a large difference in melting points between forms I and I′ is reasonably explained in terms of a huge difference in 〈l〉 values. Form I is always produced after passing through the extremely mobile crystal, form II. In contrast, form I′ is formed by direct crystallization (bypassing form II). Thus, the huge mobility difference between forms I (I′) and II (>8 orders of magnitude) leads to largely different 〈l〉 and Tm values. In other words, there are different crystallization mechanisms that either pass through or bypass form II and lead to the observed large differences in the Tm and 〈l〉 values between forms I and I′.

Material properties

The mechanical properties of bulk samples are affected by crystallinity, lamellae thickness, morphology and chain mobility. Here we explain how (i) a unique crystallization into form II and (ii) the subsequent solid–solid transition into form I results in the superior material properties of iPB1. As discussed above, crystallization into form II leads to very thick lamellae at low supercooling (for example, 〈l〉=28 nm at ΔT=25 °C). In contrast, direct crystallization into immobile crystals (form I′) results in very thin lamellae with 〈l〉= approximately 5 nm. This means that immobile crystals cannot produce thick lamellae. The two step process of (i) crystallization into an extremely mobile mesophase and (ii) an irreversible solid–solid transition into the immobile crystal of form I is the only the way to produce very thick lamellae for immobile crystals. Subsequently, storage at ambient temperature induces ‘irreversible’ solid–solid transitions from the metastable form II into the stable form I. Azzurri et al. reported that forms II–I transitions do not change the lamellar thickness or the crystallinity.13 Form I crystals preserve the lamellae thickness and crystallinity that is induced by extremely high chain mobility in form II, depending on the crystallization temperature. As explained above, form I is a fixed crystal, which is largely different from the similar polyolefins PE,16 iPP17, 18 and iP4M1P19 (mobile crystals). There is a strong correlation between thermally activated molecular dynamics in the crystalline regions and dissipation of the bulk mechanical property.16 Thus, Hu and Schmidt-Rohr20 indicated that local overall dynamics in the crystalline regions are the origin of reduction of the bulk mechanical property and the drawability. The absence of molecular dynamics in form I can reasonably explain the superior mechanical properties and low drawability of iPB1 even at very high temperatures.1, 43 Direct crystallization into form I′ also leads to a fixed crystal. However, thin lamellae thickness leads to low melting temperatures. Therefore, it is concluded that only the two-step process of (i) unique crystallization and (ii) an irreversible solid–solid transition leads to high crystallinity, thick crystal lamellae and the superior mechanical properties of iPB1.

Conclusion

In this work, it was demonstrated that both forms I and II of iPB show unique molecular dynamics when compared with other semi-crystalline polymers. Form II shows continuous rotational diffusion along with side-chain conformational transitions in the fast motional limit (〈τc〉 <10−7 s) at 100 °C. This is direct evidence that form II is a conformationally disordered crystal. Following the irreversible solid–solid transition, the crystalline stems in form I do not undergo any overall or side-chains dynamics up to the melting point in the slow motional limit (〈τc〉 >10 s). This immobility was reasonably explained in terms of densifications of the crystalline regions. These huge dynamic contrasts have critical roles for both the structural organization and the material properties of iPB1. Extremely fast dynamics easily leads to very thick lamellae at very high temperatures. Following the solid–solid transition, the immobility of the crystalline stems in thick lamellae is a reason for the maintained bulk mechanical strength at very high temperatures. Comparison of local dynamics in iPB1 with those in similar polyolefins can reasonably explain why only iPB1 shows superior mechanical properties among polyolefins.

References

Gedde, U. W., Viebke, J., Leijström, H. & Ifwarson, M. Long term properties of hot-water polyolefin pipe-a review. Polym. Eng. Sci. 34, 1773–1787 (1994).

Natta, G., Corradini, P. & Bassi, I. W. Crystal structure of isotactic poly-alpha-butene. Nuov. Chim. Suppl. 15, 52–67 (1960).

Turner-Jones, A. Polybutene-1-type II crystalline form. J. Polym. Sci. Part B 1, 455–456 (1963).

Petraccone, V., Pirozzi, B., Frasci, A. & Corradini, P. Polymorphism of isotactic poly-α-butene conformational analysis of the chain and crystalline structure of form 2. Eur. Polym. J. 12, 323–327 (1976).

Cojazzi, G., Malta, V., Celotti, G. & Zannetti, R. Conformational flexibility of isotactic poly-1-olefins. Makromol. Chem. 177, 915–926 (1976).

Tuner-Jones, A. Cocrystallization in copolymers of α-olefins II-butene-1 copolymers and polybutene type II/I crystal phase transition. Polymer 7, 23–59 (1966).

Gohil, R. M., Milles, M. J. & Petermann, J. On the molecular mechanism of the crystal transition (tetragonal-hexagonal) in polybutene-1. J. Macromol. Sci. Phys. B21, 189–201 (1982).

Nakamura, K., Aoike, T., Usaka, K. & Kanamoto, T. Phase transformation in poly(1-butene) upon drawing. Macromolecules 32, 4975–4982 (1999).

Maruyama, M., Sakamoto, Y., Nozaki, K., Yamamoto, T., Kajioka, H., Toda, A. & Yamada, K. Kinetic study of the II-I phase transition of isotactic polybutene-1. Polymer 51, 5532–5538 (2010).

Lotz, B., Mathieu, C., Thierry, A., Lovinger, A. J., De Rosa, C., Ruiz de Ballesteros, O. & Auriemma, F. Chirality constraints in crystal-crystal transformations: isotactic poly(1-butene) versus syndiotactic polypropylene. Macromolecules 31, 9253–9257 (1998).

Meng, Y. & Rieger, J. Synchrotoron ultrasmall-angle X-ray scttering studies on tensile defroamtion of poly(1-butene). Macromolecules 37, 9481–9488 (2004).

Tosaka, M., Kamijo, T., Tsuji, M., Kohjiya, S., Ogawa, T., Isoda, S. & Kobayashi, T. High-resolution transmission electron microscopy of crystal transformation in solution-grown lamellae of isotactic polybutene-1. Macromolecules 33, 9666–9672 (2000).

Azzurri, F., Flores, A., Alfonso, G. C., Sics, I., Hsiao, B. S. & Balta Calleja, F. J. Polymorphism of isotactic polybutene-1 as revealed by microindentation hardness. Part II: correlations to microstructure. Polymer 44, 1641–1645 (2003).

Di Lorenzo, M. L., Righetti, M. C. & Wunderlich, B. Influence of crystal polymorphism on the three-phase structure and on the thermal properties of isotactic poly(1-butene). Macromolecules 42, 9312–9320 (2009).

Schmidt-Rohr, K. & Spiess, H. W. Multidimensional Solid-State NMR and Polymers (Academic Press, London, 1994).

Hu, W. G., Boeffel, C. & Schmidt-Rohr, K. Chain flips in polyethylene crystallites and fibers characterized by dipolar C-13 NMR. Macromolecules 32, 1611–1619 (1999).

Schaefer, D., Spiess, H. W., Suter, U. W. & Fleming, W. W. Two-dimensional solid-state NMR studies of ultraslow chain motion: glass transition in atactic poly(propylene) versus helical jumps in isotactic poly(propylene). Macromolecules 23, 3431–3439 (1990).

Miyoshi, T., Mamun, A. & Hu, W. Molecular ordering and molecular dynamics in isotactic-poly(propylene) characterized by SS-NMR. J. Phys. Chem. B 114, 92–100 (2010).

Miyoshi, T., Pascui, O. & Reichert, D. Slow chain dynamics in isotactic-poly(4-methyl-1-pentene) crystallites near the glass transition temperature characterized by solid-state C-13 MAS exchange NMR. Macromolcules 37, 6460–6471 (2004).

Hu, W- G. & Shimidt-Rohr, K. Polymer ultradrawability: the crucial role of α-relaxation chain mobility in the crystallites. Acta. Polym. 50, 271–285 (1999).

Belfiore, A. A., Schiling, C. A., Tonelli, A. E., Lovinger, A. J. & Bovey, F. A. Magic angle spinning carbon-13 NMR spectroscopy of three crystalline forms of isotactic-poly(1-butene). Macromolecules 17, 2561–2565 (1984).

Maring, D., Meurer, B. & Weill, G. 1H NMR Studies of molecular relaxations of poly-1-butene. J. Polym. Sci. Part B 33, 1235–1247 (1995).

Maring, D., Whilhelm, M., Spiess, H. W., Meurer, B. & Weill, G. Dynamics in the crystalline polymorphic forms I and II and III of isotactic poly-1-butene. J. Polym. Sci. Part B 38, 2611–2624 (2000).

Beckham, H. W., Schmidt-Rohr, K. & Spiess, H. W. conformational disorder and its dynamics within the crystalline phase of the form II polymorph of isotactic poly(1-butene). ACS Symp. Ser. 598, 243–253 (1995).

Miyoshi, T., Hayashi, S., Imashiro, F. & Kaito, A. Side-chain conformation and dynamics for the form II polymorph of isotactic poly(1-butene) investigated by high-resolution solid-state C-13 NMR spectroscopy. Macromolecules 35, 6060–6063 (2002).

Miyoshi, T., Mamun, A. & Reichert, D. Fast dynamics and conformations of polymer in a conformational disordered crystal characterized by 1H-13C WISE NMR. Macomoelcules 43, 3986–3989 (2010).

Miyoshi, T., Hayashi, S., Imashiro, F. & Kaito, A. Chain dynamics, conformations, and phase transformations for form III polymorph of isotactic poly(1-butene) investigated by high-resolution solid-state C-13 NMR spectroscopy and molecular mechanics calculations. Macromolecules 35, 2624–2632 (2002).

Wunderlich, B., Moller, B., Grebowicz, J. & Baur, H. conformational motion and disorder in low and high molecular mass crystals. Adv. Polym. Sci. 87, 1 (1988).

deAzevedo, E. R., Hu, W. G., Bonagamba, T. J. & Schmidt-Rohr, K. Centerband-only detection of exchange: efficient analysis of dynamics in solids by NMR. J. Am. Chem. Soc. 121, 8411–8412 (1999).

Schmidt-Rohr, K., Clauss, J. & Spiess, H. W. Correlation of structure, mobility, and morphological information in heterogeneous polymer materials by 2-dimensional wideline-separation NMR-pectroscopy. Macromolecules 25, 3273–3277 (1992).

Tekely, P., Palmas, P. & Mutzenhardt, P. Elimination of heteronuclear dipolar interaction effects from C-13 detected proton spectra in wideline separation nuclear magnetic-resonance spectroscopy. Macromolecules 26, 7363–7365 (1993).

Qiu, X. & Mirau, A. P. WIM/WISE NMR studies of chain dynamics in solid polymers and blends. J. Magn. Reson. 142, 183–189 (2000).

De Rosa, C., Auriemma, F., deBallesteros, O. R., Exposito, F., Laguzza, D., Girolamo, R. D. & Resconi, L. Crystallization properties and polymorphic behaviors of istactic poly(1-butene) from metallocene catalysts: the crystallization of form I from the melt. Macromolecules 42, 8286–8297 (2009).

Takahashi, T., Kawashima, H., Sugisawa, H. & Baba, T. 207Pb chemical shift thermometer at high temperature for magic angle spinning experiments. Solid State NMR 15, 119–123 (1999).

Nakai, T., Ashida, J. & Terao, T. Determination of the 13C chemical shift tensors in isotactic polypropylene via the two-dimensional powder pattern in rotating solids. Magn. Reson. Chem. 27, 666–668 (1989).

Liu, S. F., Mao, J. D. & Schmidt-Rohr, K. A robust technique for two-dimensional separation of undistorted chemical-shift anisotropy powder patterns in magic-angle-spinning NMR. J. Magn. Reson. 155, 15–28 (2002).

de Langen, M. & Prins, K. O. Mobility of polyethylene chains in the orthorhombic and hexagonal phases investigated by NMR. Chem. Phys. Lett. 299, 195–200 (1999).

Möller, M Structure and dynamics of the high temperature polymorph of trans-1,4-polybutadiene. Macromol. Chem. Rapid Commun. 9, 107–114 (1988).

Hirschinger, J., Miura, H., Gardner, K. H. & English, A. D. Segmental dynamics in the crystalline phase of nylon 66: solid state deuterium NMR. Macromolecules 23, 2153–2169 (1990).

Cheng, S. Z. D., Janimak, J. J., Zhang, A. & Hsieh, E. T. Isotacticity effect on crystallization and melting in polypropylene fractions: 1. Crystalline structures and thermodynamic property changes. Polymer 32, 648–655 (1991).

Strobl, G. Colloquium: laws controlling crystallization and melting in bulk polymers. Rev. Mod. Phys. 81, 1287–1330 (2009).

Boor, J. Jr & Youngman, E. A. Polymorphism in poly(1-butene): apparent direct formation of modification I. J. Polym. Sci. Patr B 2, 903–907 (1964).

Sawai, D., Anyashiki, T., Nakamura, K., Hisada, N., Ono, T. & Kanaoto, T. Ultradrawing above the static melting temperature of ultra-high molecular weight isotactic poly(1-butene) having low ductility in the crystalline state. Polymer 48, 363–370 (2007).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Miyoshi, T., Mamun, A. Critical roles of molecular dynamics in the superior mechanical properties of isotactic-poly(1-butene) elucidated by solid-state NMR. Polym J 44, 65–71 (2012). https://doi.org/10.1038/pj.2011.66

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2011.66

Keywords

This article is cited by

-

Influence of pre-generated form i polybutylene-1 on form ii/i phase transition during solvent vapor annealing

Journal of Polymer Research (2023)

-

Competition between crystal growth and intracrystalline chain diffusion determines the lamellar thickness in semicrystalline polymers

Nature Communications (2022)

-

The enhanced II–I transition behaviors of an isotactic polybutene-1 alloy by a TAB-3

Journal of Materials Science (2021)

-

Polymorphic Transition of Pre-oriented Polybutene-1 under Tensile Deformation: In Situ FTIR Study

Chinese Journal of Polymer Science (2020)

-

Time-resolved micro-indentation hardness measurement to probe the Form II/Form I crystal polymorphism in random copolymers of butene-1 with either ethylene or propylene

Colloid and Polymer Science (2015)