Abstract

Poly(arylene sulfone)s (PASs) containing a 9,9′-spirobifluorene (SBF) skeleton in the main chain were synthesized in high yields by the oxidation of the corresponding poly(arylene thioether)s. The PASs exhibited good thermal stability (Tg 257–370 °C, Td5>400 °C under nitrogen) and showed high solubility in ordinary organic solvents, such as CHCl3, N-methylpyrrolidone (NMP) and N,N-dimethyl formamide (DMF). All films of PASs showed higher refractive indices in the range of 1.65–1.67 at 587.6 nm than those of commercially available polysulfone, whereas they hardly showed birefringence. These excellent optical and thermal properties are derived from the C2 symmetry and high aromatic component of the SBF moiety.

Similar content being viewed by others

Introduction

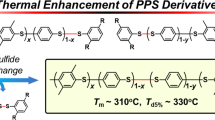

A Cardo structure is defined as the structure with aryl substituents at the quaternary carbon center of the alicyclic moiety to occupy different planes. These Cardo structures have attracted a considerable interest because of their unique properties. 9,9-Diarylfluorene (DAF) is a representative Cardo structure. DAF-containing polymers have been extensively studied in terms of characteristic properties such as low optical anisotropy, low crystallinity, thermal stability and high refractive index.1 On the other hand, 9,9′-spirobifluorene (SBF) has a similar structure to DAF and is composed of a condensed aromatic skeleton that seems attractive as a repeating structure of polymers for high refractive index materials (Figure 1). Therefore, SBF-containing polymers (SBF polymers) can be regarded as Cardo polymers like DAF-containing polymers (DAF polymers). There have been a few reports on polymers containing the SBF skeleton, which is introduced by linking the 2 and 2′ positions of SBF with a spacer unit into the polymer main chain.2, 3, 4, 5, 6, 7 Actually, the polymers showed a high refractive index and a low birefringence in addition to high thermal stability and high solubility. These properties resemble those of polymers containing a DAF skeleton.8, 9, 10

We recently reported the synthesis of poly(arylene thioether)s (PTEs) containing the SBF skeleton that showed a high refractive index (1.68–1.73) and a very low birefringence in addition to high thermal stability and high solubility.3 Although the PTEs were amorphous and created tough transparent polymer films, it was impossible to prevent yellowing, probably due to the charge transfer interaction between the polymer chains along with the extended conjugated structure. According to our previous approach for DAF polymers for decoloring, we attempted to decrease the coloring by the oxidation of the PTEs to the corresponding polysulfones.11 Several poly(arylene sulfone)s are widely used as ultra-high-performance engineering plastics in a variety of industrial fields because of their excellent properties, such as high thermal stability, high hydrolytic stability, low flammability, high stability toward both acid and base, size precision and so on.12, 13, 14 In this paper, we describe the preparation and properties of SBF-containing PASs derived from the oxidation of the corresponding PTEs. The results revealed that the SBF polymers actually had excellent chemical, physical and optical properties like the DAF polymers.

Experimental procedure

Materials

9,9′-SBF-2,2′-bis(N,N-dimethylcarbamothioate) (1) and PTEs were prepared according to the literature.3 Other materials were commercially available and used without further purification.

Measurements

1H- and 13C nuclear magnetic resonance (NMR) spectra were recorded on a JEOL AL-400 spectrometer (JEOL, Tokyo, Japan) using CDCl3 as the solvent and tetramethylsilane as an internal standard. The molecular weight and its distribution were estimated by size exclusion chromatography (SEC) on a JASCO Gulliver system (JASCO, Tokyo, Japan) equipped with two consecutive linear polystyrene gel columns (Tosoh TSK-gel GMHXL and G5000HXL; TOSOH, Tokyo, Japan) at 30 °C (flow rate 0.85 ml min–1) according to polystyrene standards, using CHCl3 as the eluent. The glass transition temperatures (Tg) were measured with a Shimadzu DSC-60 instrument (Shimadzu, Kyoto, Japan) at a heating rate of 10 °C min–1 under a nitrogen flow of 50 ml min–1. Thermogravimetric analysis was performed with a Shimadzu TGA-50 instrument at a heating rate of 10 °C min–1 under a nitrogen atmosphere and in an air atmosphere (flow rate 50 ml min–1). The solubility of the polymers was evaluated by using 3 mg of polymer to 1 ml of solvent. Fourier transform infrared (IR) spectra were recorded on a JASCO FT/IR-460 Plus spectrophotometer. Melting points were measured with a Stuart Scientific SMP3 (Bibby Scientific, Stone, UK). Ultraviolet-visible (UV-vis) spectra were recorded on a JASCO V-550 UV-vis spectrometer. The refractive indices of the polymers were measured with an Abbe refractometer (DR-M2/1550, ATAGO Co. Ltd, Tokyo, Japan). The birefringence values of the films were evaluated by taking the pictures of the film placed between two cross-axis polarizing films. Retardations were measured using a polarized optical microscope (OPTIPHOTO-POL, Nikon Co. Ltd, Tokyo, Japan) under the cross-Nicols (588 nm). The transmittance of the films was evaluated using a UV-visible spectrophotometer (JASCO V-550) across a scanning range of 300–700 nm.

Film preparation

Polymer films of the PASs were prepared for the evaluation of the refractive index and birefringence with a casting method using the NMP solutions of the corresponding polymers at 150 °C. The films used for the evaluation of transmittance were prepared by a spin-coating method, using the CHCl3 solutions of the corresponding polymers at room temperature (film thickness: 13–25 μm).

Typical procedure for the synthesis of PAS, PAS1

A suspension of PTE, PTE1 (0.540 g, 0.867 mmol) in HCOOH (11 ml) was held in a 30-ml round-bottom flask and then heated to 50 °C. H2O2 (30% aqueous, 5.5 ml) was added dropwise to the mixture and kept at the same temperature for 2 h. After cooling to room temperature, the precipitates were collected by filtration to give the corresponding polymer PAS1 as a white solid in a 93% yield (0.560 g).

PAS1: Mw 17 000, Mw/Mn 1.4, Tg 293 °C, Td5 510 °C, 1H NMR (400 Hz, CDCl3, 298 K) δ 7.97 (d, J=7.9 Hz, 2H), 7.92 (d, J=7.9 Hz, 2H), 7.88 (d, J=7.3 Hz, 2H), 7.84 (d, J=8.7 Hz, 4H), 7.74(d, J=8.7 Hz, 4H), 7.40 (dd, J=7.3, 7.3 Hz, 2H), 7.30 (s, 2H), 7.17 (dd, J=7.3, 7.3 Hz, 2H), 6.64 (d, J=7.3 Hz, 2H); IR (KBr): υ 3060, 1671, 1596, 1398, 1321, 1150, 1091, 928, 720, 608 cm−1.

PAS2: A white solid (93%) Mw 50 000, Mw/Mn 1.4, Tg 279 °C, Td5 541 °C, 1H NMR (400 Hz, CDCl3, 298 K) δ 7.99 (d, J=8.3 Hz, 2H), 7.94 (d, J=8.3 Hz, 2H), 7.89 (d, J=7.6 Hz, 2H), 7.86 (d, J=8.6 Hz, 4H), 7.82 (d, J=8.6 Hz, 4H), 7.80 (s, 4H), 7.42 (dd, J=7.6, 7.6 Hz, 2H), 7.33 (s, 2H), 7.18 (dd, J=7.6, 7.6 Hz, 2H), 6.66 (d, J=7.6 Hz, 2H); IR (KBr) υ 3060, 1664, 1596, 1398, 1322, 1268, 1149, 1091, 924, 745, 695, 617 cm−1.

PAS3: A white solid (94%) Mw 32 000, Mw/Mn 1.4, Tg 257 °C, Td5 488 °C, 1H NMR (400 Hz, CDCl3, 298 K) δ 8.00 (d, J=8.3 Hz, 2H), 7.98 (brd, 2H), 7.93–7.89 (m, 4H), 7.85 (d, J=8.3 Hz, 2H), 7.82–7.80 (m, 5H), 7.41 (dd, J=7.6, 7.6 Hz, 2H), 7.35 (s, 2H), 7.18 (dd, J=7.6, 7.6 Hz, 2H), 6.65(d, J=7.6 Hz, 2H), 1.31 (s, 9H); IR (KBr) υ 3062, 1670, 1590, 1397, 1324, 1247, 1151, 1092, 1003, 710, 613 cm−1.

PAS4: A white solid (92%) Mw 19 000, Mw/Mn 1.2, Tg 326 °C, Td5 473 °C,1H NMR (400 Hz, CDCl3, 298 K) δ 8.18 (d, J=8.0 Hz, 4H), 7.97 (d, J=7.9 Hz, 2H), 7.92 (d, J=7.9 Hz, 2H), 7.88–7.86 (m, 6H), 7.40 (dd, J=7.6, 7.6 Hz, 2H), 7.30 (s, 2H), 7.16 (dd, J=7.6, 7.6 Hz, 2H), 6.63 (d, J=7.6 Hz, 2H); IR (KBr) υ 3052, 1542, 1407, 1322, 1150, 1092, 1014, 754, 617 cm−1.

PAS5: A white solid (94%) Mw 29 000, Mw/Mn 1.7, Tg 370 °C, Td5 425 °C,1H NMR (400 Hz, CDCl3, 298 K) δ 7.98 (d, J=7.8 Hz, 2H), 7.92 (d, J=7.8 Hz, 2H), 7.89 (d, J=7.4 Hz, 2H), 7.84 (d, J=9.0 Hz, 4H), 7.81 (d, J=9.0 Hz, 4H), 7.42 (dd, J=7.4, 7.4 Hz, 2H), 7.36 (d, J=8.6 Hz, 2H), 7.31 (s, 2H), 7.21 (d, J=8.6 Hz, 2H), 7.18 (dd, J=7.4, 7.4 Hz, 2H), 6.65 (d, J=7.4 Hz, 2H), 2.16 (s, 6H); IR (KBr) υ 3058, 1672, 1594, 1446, 1400, 1322, 1149, 1091, 976, 583 cm−1.

PAS6: A white solid (90%) Mw 21 000, Mw/Mn 1.3, Tg 257 °C, Td5 532 °C, 1H NMR (400 Hz, CDCl3, 298 K) δ 8.00 (d, J=8.2 Hz, 2H), 7.96 (d, J=8.2 Hz, 2H), 7.92–7.81 (m, 20H), 7.43 (dd, J=7.6, 7.6 Hz, 2H), 7.34 (s, 2H), 7.19 (dd, J=7.6, 7.6 Hz, 2H), 6.67 (d, J=7.6 Hz, 2H); IR (KBr) υ 3060, 1666, 1596, 1399, 1268, 1151, 1091, 921, 754, 696, 614, 586 cm−1.

Results and discussion

Synthesis of 9,9′-SBF-containing PASs

The synthesis of SBF-containing PTEs as a starting polymer was carried out by the polycondensation of masked 2,2′-dithiol-9,9′-SBF with difluoroarenes according to our previous report.6 Treatment of PTEs with 30% aqueous H2O2 in HCOOH at 50 °C for 2 h afforded the corresponding PASs in high yields (Table 1). The structures of PASs were characterized by Fourier transform infrared and 1H NMR spectroscopy (See Supplemetary Information). All polymers showed characteristic signals at 1398 and 1091 cm−1 originating from a stretching vibration of the SO2 group. The completion of the reaction was clearly confirmed by the chemical shift of the 1H NMR spectrum (Figure 2). The chemical shifts of aromatic protons adjacent to the sulfone groups were shifted to much lower fields compared with those of their precursor PTEs, depending on the strong electron-withdrawing inherence of the sulfone groups. The SEC profile showed little change in molecular weight or molecular weight distribution before and after oxidation, suggesting that the oxidation reaction did not induce cleavage or a serious change of the polymer main chain of PASs.

Solubility

The solubilities of PASs in various organic solvents are summarized in Table 2. All polymers except for PAS6 were highly soluble in polar solvents such as DMF and dimethyl sulfoxide because the SBF-containing PTEs of the precursor were insoluble, which was consistent with the high polarity of PASs. This result indicates that the SBF structure is favorable to improve the solubility of polysulfones. The high solubility of SBF is probably attributed to a suppression of the π–π stacking by the steric hindrance between the polymer backbone due to the perpendicularly crossed two fluorene units at the spiro carbon center. On the other hand, PAS6 showed less solubility, probably due to the intra- and intermolecular π–π stacking depending on the very long and rigid spacer.

Thermal properties

The thermal properties of the PASs were characterized by thermogravimetric analysis and differential scanning calorimetry. The Tgs were in a range from 257 to 370 °C, which was higher in a range of 40–60 °C than those of PTEs (Table 3). Meanwhile, the thermal decomposition temperature (Td5) of PASs in a N2 atmosphere were in a range from 425 to 541 °C. Comparing the Td5s in N2 atmosphere with those in the air, little difference was observed except for PAS4, which strongly indicated the oxidation resistance of the sulfone group. The Tgs and Td5s of PASs were much higher than those of commercial polysulfones (Udel-1700 (Solvay S. A., Bruxelles, Belgium): Tg 190 °C, Td10 523 °C; PES-5200P (Sumitomo Chemical Co. Ltd., Tokyo, Japan): Tg 220 °C). The high Tg and high Td5 of PASs clearly suggest that the introduction of not only sulfone groups but also rigid SBF skeleton moieties would induce the high thermal stability of PASs.

Transparency

Except for PAS6 with long spacers, the transmittance of the films reached 80% over 400 nm (Figure 3). The transparency of PASs is attributed to their amorphous nature owing to the SBF moiety. The cutoff wavelengths were ∼340–360 nm, which were lower than those of SBF-containing PTEs (330–380 nm)6 because of the decrease of the effective conjugation length of PAS.

Optical properties

Table 4 summarizes the refractive indices and birefringence values of PASs. As expected, the refractive indices at a typical wavelength of 588 nm were quite high: 1.67 (PAS1), 1.66 (PAS2), 1.66 (PAS3), 1.67 (PAS4), 1.65 (PAS5) and 1.67 (PAS6). The refractive index of PAS2 (1.66) was higher than that of DAF-containing polysulfone (DAF-PAS2) (1.65) (Figure 4). Furthermore, the birefringence was very low due to the optical isotropy of the SBF skeleton based on the perfectly C2 symmetric structure.

Conclusion

A series of novel high-performance SBF-containing PASs in the main chain were synthesized via the oxidation of PTEs with H2O2 in HCOOH. The PASs showed high thermal stability (Td5>400 °C under a N2 atmosphere, Tg>250 °C) because of the sulfone group and 9,9′-SBF skeleton and were highly soluble in ordinary organic solvents in spite of the rigid polymer chain caused by the sulfone group. The PASs were decolored and exhibited much larger refractive indices as a result of the high atom refraction of the SBF skeleton and much lower degree of birefringence than those of DAF-containing polysulfones. This paper showed that the SBF skeleton is quite a desirable structure in improving the optical and thermal properties of PASs to provide high-performance polymers with excellent optical properties.

References

Koyama, Y., Nakazono, K., Hayashi, H. & Tataka, T. 9,9-diarylfluorene moiety incorporated into polymer main chains: an essential skeleton exhibiting prominent physical, chemical, and optical properties. Chem. Lett. 39, 2–9 (2010).

Seto, R., Sato, T., Kojima, T., Hosokawa, K., Koyama, Y., Konishi, G. & Takata, T. 9,9′-Spirobifluorene-containing polycarbonates: transparent polymers with high refractive index and low birefringence. J. Poly. Sci.A Polym. Chem. 48, 3658–3667 (2010).

Seto, R., Sato, T., Kojima, T., Koyama, Y. & Takata, T. Synthesis and optical property of polyester and polycarbonate containing a spirobifluorene moiety in the main chain. Polymer Prepr. 58, 4C1-02 (2009).

Okuda, H., Seto, R., Koyama, Y. & Takata, T. J. Poly. Sci. A Polym. Chem. (in press).

Ready, D. S., Shu, C.- F. & Wu, F.- I. Synthesis and characterization of soluble polyimides derived from 2,2′-bis(3,4-dicarboxyphenoxy)-9,9′-spirobifluorene dianhydride. J. Polym. Sci.A Polym. Chem. 40, 262–268 (2002).

Wu, S.- C. & Shu, C.- F. Synthesis and properties of soluble aromatic polyamides derived from 2,2′-bis(4-carboxyphenoxy)-9,9′-spirobifluorene. J. Polym. Sci. A Polym. Chem. 41, 1160–1166 (2003).

Chiang, C.- L. & Shu, C.- F. Synthesis and characterization of new polyquinolines containing 9,9′-spirobifluorene units. Chem. Mater. 14, 682–687 (2002).

Hu, Z. Q., Wang, M. L., Li, S. J., Liu, X. & Wu, J. H Ortho alkyl substituents effect on solubility and thermal properties of fluorenyl cardo polyimides. Polymer 46, 5278–5283 (2005).

Sakurai, K. & Fuji, M. Optical properties of a low birefringence polyester containing fluorene side chain I. Polym. J. 32, 676–682 (2000).

Hasio, S. H. & Li, C. T. Synthesis and characterization of new fluorene-based poly(ether imide)s. J. Polym. Sci.A Polym. Chem. 37, 1403–1412 (1999).

Surasak, S. & Takata, T. Synthesis and property of poly(arylene sulfone)s containing 9,9-diarylfluorene moiety in the main chain. Polym. J. 39, 731–736 (2007).

Cassidy,, E. P. Thermally Stable Polymer (Marcel Dekker, New York, 1980).

Duda, A. & Penczek, S. Encycl. Sulfer-containing polymers. Polym. Sci. Eng. 16, 246–368 (1989).

Johnson, N. R., Farnham, G. A., Callendinning, A. R., Hale, F. W. & Merrian, N. C. Poly(aryl ethers) by nucleophilic aromatic substitution. I. Synthesis and properties. J. Polym. Sci.A Polym. Chem 5, 2375–2398 (1967).

Acknowledgements

The work was financially supported by a Grant-in-Aid for Scientific Research (A) (number 18205014) from the Ministry of Education, Culture, Sports, Science and Technology, Japan. The fellowship to RS from JSPS for Young Japanese Scientists is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supplementary Information accompanies the paper on Polymer Journal website

Supplementary information

Rights and permissions

About this article

Cite this article

Okuda, H., Seto, R., Koyama, Y. et al. Poly(arylene sulfone)s containing 9,9′-spirobifluorene: synthesis and excellent optical properties. Polym J 42, 795–798 (2010). https://doi.org/10.1038/pj.2010.77

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2010.77

Keywords

This article is cited by

-

Synthesis and properties of pendant fluorene moiety-tethered aliphatic polycarbonates

Polymer Journal (2015)