Abstract

Owing to the depth to which hard X-rays penetrate into most materials, it is commonly accepted that the only way to realize hard-X-ray mirrors with near 100% reflectance is under conditions of total external reflection at grazing incidence to a surface. At angles away from grazing incidence, substantial reflectance of hard X-rays occurs only as a result of constructive interference of the waves scattered from periodically ordered atomic planes in crystals (Bragg diffraction). Theory predicts that even at normal incidence the reflection of X-rays from diamond under the Bragg condition should approach 100%—substantially higher than from any other crystal. Here we demonstrate that commercially produced synthetic diamond crystals do indeed show an unprecedented reflecting power at normal incidence and millielectronvolt-narrow reflection bandwidths for hard X-rays. Bragg diffraction measurements of reflectivity and the energy bandwidth show remarkable agreement with theory. Such properties are valuable to the development of hard-X-ray optics, and could greatly assist the realization of fully coherent X-ray sources, such as X-ray free-electron laser oscillators1,2,3.

Similar content being viewed by others

Main

Diamond is a material with superlative physical qualities: high mechanical hardness, high thermal conductivity, high dispersion index, high radiation hardness, high hole and electron mobilities, low thermal expansion and chemically inert4. Technological applications of diamond crystals are increasing not only in the traditional fields of cutting, grinding and polishing tools, but also in high-tech applications, such as diamond-based electronic devices, wide-bandgap radiation detectors, ultraviolet-emitting diodes, biochemical sensors, high-pressure cells and thermal sinks, to name only a few. Very recently, diamond crystals have been identified as indispensable for the realization of X-ray free-electron laser oscillators (XFELOs), next-generation hard-X-ray sources of the highest average and peak brightness and extremely narrow bandwidth1,2. The special role of diamonds in the feasibility of the XFELOs is due to their outstanding reflectivity for hard X-rays in Bragg diffraction, thus far only predicted in theory (Fig. 1a).

a, Peak reflectivity RH. b, Crystal thickness LH required to attain the peak reflectivity RH. c, Energy width ΔEH. The upper set of points in a and c and the lower set in b represent the even Bragg reflections in diamond. The complementary set of points represents the odd reflections. The crosses indicate the theoretical results for the (995) Bragg reflection used in the experiment. Calculations are carried out using the dynamical theory of X-ray diffraction in thick crystals, as described, for example, in ref. 14.

The high reflectivity of crystals in Bragg diffraction is intimately connected with the perfect crystal structure. Progress in fabrication, characterization and X-ray optics applications of synthetic diamonds was substantial in the past decade5,6,7,8,9,10,11,12,13. Still the diamond crystals available commercially as a rule suffer from defects: dislocations, stacking faults, inclusions, impurities and so on. Synthetic high-purity (type IIa, low nitrogen content) crystals grown with a high-pressure, high-temperature technique are generally considered to have the highest crystal quality and the lowest density of defects among commercially available diamonds10,13. X-ray topography studies have demonstrated crystals with relatively large ≃4×4 mm2 defect-free areas13. However, critical outstanding questions remain open. Can the remarkably high reflectivity of diamond crystals that is predicted in theory be achieved in practice? Is the quality of the diamond crystals available at present sufficiently high for practical use as high-reflectivity X-ray mirrors for XFELOs and other highly advanced technology applications relying on high crystal perfection?

Here, we show that commercially available synthetic diamond crystals, of type IIa, have a high degree of perfection with ≈107 perfectly arranged, strictly periodic crystallographic planes of atoms. Almost theoretical values were measured for the spectral width ΔE=2.9 meV, and for the reflectivity R=89%, in Bragg diffraction at normal incidence to the reflecting atomic planes of hard X-rays with photon energy E=23.7 keV. The reflectivity is several times higher than the reflectivity of Si crystals under similar conditions. These findings open up vistas for entirely new highly advanced technology applications of diamonds and new opportunities in X-ray optics, in particular.

Total (100%) reflection is achieved in Bragg diffraction of X-rays from crystals provided, first, there are no losses in the crystal owing to, for example, photoabsorption, and, second, the crystal is sufficiently thick. Bragg diffraction is a coherent scattering process from periodically arranged atomic planes. The extinction length LHext measures the interaction depth of X-rays with the crystal lattice in Bragg diffraction. It is an invariant value for each Bragg reflection. Typically a crystal thickness of ≃10LHext is required to achieve total reflectivity14. Figure 1b shows the dynamical theory calculations for LH=10LHext for all allowed Bragg reflections in diamond, defined by the diffraction vector H (H=2π/dH, dH is the interplanar distance). For a larger H, that is, for a larger Bragg energy (EH=h c/2dH—photon energy at backscattering, with h as the Planck constant and c as the speed of light in vacuum), thicker crystals are required to achieve the maximum reflectivity (Fig. 1b).

The thicker the crystal, the smaller the energy width ΔE of the Bragg reflection (Fig. 1c). The relative energy width ΔE/E of the Bragg reflection is

where Nd=d/dH is the number of atomic planes through crystal thickness d (ref. 14). Thus, E/ΔE measures the quantity of the perfectly arranged atomic planes in the crystal contributing to Bragg diffraction; ΔE/E is a fingerprint of the crystal perfection.

In reality, photoabsorption always exists, and 100% reflectivity is never achievable. However, the peak reflectivity could be close to 100% provided the photoabsorption length Lph in the crystal is much larger than the extinction length: Lph≫LHext. This is fulfilled for crystals with a high Debye temperature and composed of low-Z atoms. The high Debye temperature ensures rigidity of the crystal lattice, and thus the smaller number of atomic planes required for maximum reflectivity. The low Z ensures larger photoabsorption lengths. Diamond, Be, BeO, Al2O3, SiC and so on are among attractive crystals. However, diamond, owing to the superlative qualities mentioned above, is most favourable. Figure 1a shows the peak reflectivity values in diamond in Bragg backscattering. More than 99% reflectivity is predicted by the dynamical theory calculations for Bragg reflections with EH>10 keV. Debye–Waller factors are calculated using a Debye temperature of 2,200 K. The results shown in Fig. 1 were calculated for backscattering, which is a representative case, with the smallest reflectivity for the given Bragg reflection.

To probe larger crystal depths, reflections with large Bragg energies EH have to be used. In the present studies, the (995) Bragg reflection is used with EH=23.765 keV. To achieve the theoretical reflectivity of RH=0.99, a crystal with d≥LH≃1 mm thickness is required. Such a crystal should show a Bragg reflection spectral width of ΔEH=2.3 meV (Fig. 2a). The dashed line in Fig. 2a shows for comparison the reflectivity from Si, the (19 7 5) Bragg reflection, for photons with a similar energy. The Debye temperature of Si (≃540 K), which is smaller than in diamond, reflects a less rigid atomic lattice, requiring more atomic planes (thicker crystals: d>LH≃3 mm) to attain maximum reflectivity. In silicon, LH becomes comparable to the photoabsorption length Lph and results in a significantly lower reflectivity, as compared with that of diamond.

A typical size of crystals used in these studies is ≃8×4 mm2 with a thickness d≃0.4 mm. The latter is, however, smaller than LH of the (995) Bragg reflection. For diamonds with d≃0.4 mm, theory predicts a larger value for the spectral width ΔEH(d)=2.8 meV, and a smaller although still very high value for peak reflectivity RH(d)=0.92 (Fig. 2b). The dashed line in Fig. 2b shows a much lower reflectivity of Si of the same thickness for comparison.

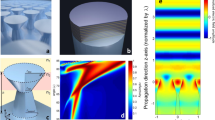

A white-beam X-ray topogram of a selected diamond is shown in Fig. 3a. The image is produced by the  Bragg reflection and indicates that the crystal is of relatively high quality in most of the central and upper regions. The main defects in these regions include a few dislocations (fine black lines), a relatively large stacking fault (the black ribbon) and some small stacking faults close to the dislocations. In the central part, there are a few millimetre-squared areas free of defects. In the lower part of the crystal, the crystalline quality is worse with stacking faults and dislocations mixed together.

Bragg reflection and indicates that the crystal is of relatively high quality in most of the central and upper regions. The main defects in these regions include a few dislocations (fine black lines), a relatively large stacking fault (the black ribbon) and some small stacking faults close to the dislocations. In the central part, there are a few millimetre-squared areas free of defects. In the lower part of the crystal, the crystalline quality is worse with stacking faults and dislocations mixed together.

a, White-beam X-ray topogram of the diamond crystal plate in transmission. b,c, Colour maps for the relative spectral width, ΔE/ΔEmin (b), and the relative peak reflectivity for the (995) Bragg reflection, R/Rmax (c), at different points on the diamond crystal, measured with a 23.765 keV X-ray photon beam of 0.7×0.7 mm2 cross-section. The beam footprint is larger than the pixels on the colour maps, and has been reduced in size to allow for direct comparison with the underlying white-beam topogram.

In the next step, the Bragg reflectivity of the selected crystal was measured with highly monochromatic X-rays as a function of photon energy in nearly exact backscattering geometry. Figure 4 shows the experimental set-up. X-ray photons with energies close to the Bragg energy EH=23.765 keV of C(995) are monochromatized to a bandwidth ΔEx≃1 meV, which is smaller than the expected energy width ΔEH(d)=2.8 meV of the C(995) Bragg reflection.

(See the Methods section for details.) The diamond reflectivity measurements were carried out with E=23.7 keV X-rays. An extremely highly monochromatic X-ray beam was used with a bandwidth of ΔEx≃1 meV, smaller than the energy width of the studied C(995) reflection. The monochromatization is achieved by successive applications of two X-ray monochromators: the high-heat-load diamond monochromator and a Si HRM. The highly monochromatic beam impinges on the diamond crystal, placed at a distance ≃10 m downstream from the HRM. The (995) planes in the diamond crystal are oriented with a very small angular offset Θ≃4×10−4 rad from normal incidence. X-rays are reflected with a scattering angle deviating from 180∘ by 2Θ and detected by an avalanche photodiode APD1. The small deviation Θ from normal incidence ensures a negligible contribution of the angular spread in the incident beam on the reflectivity measurements. The APD2 detector is used to measure the absolute reflectivity.

Reflectivity curves as a function of the X-ray photon energy are measured with the X-ray beam illuminating different parts of the crystal. An avalanche photodiode APD1 is used as the X-ray detector. The colour maps of the relative energy widths and relative peak reflectivities are shown in Fig. 3b and c, respectively. The results reveal an inhomogeneous quality of the crystal. However, in agreement with the topography studies, the regions with a small defect density feature a narrow energy width and high reflectivity (red pixels), that is, high perfection.

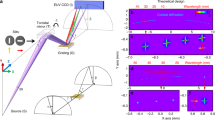

The filled circles in Fig. 5a show an experimental energy dependence of the Bragg reflectivity, representative among those with the narrowest energy width. The dependence is plotted on a logarithmic scale. Figure 5a, inset, shows the same dependencies on a linear scale. The energy width is ΔE=2.9 meV, which matches perfectly the expected ΔEH(d)=2.8 meV, if the photon energy spread ΔEx=1 meV is also taken into account. The oscillations on the wings in Fig. 5a are due to the interference of the waves reflected from the front and the rear crystal surfaces. This interference is another fingerprint of high crystal quality. The period is Ed=h c/2d (ref. 14). This simple relation allows one to directly ascertain the crystal thickness to be d=415(5) μm. The dotted line in Fig. 5a shows the results of the calculations of the reflectivity for a d=415(5)-μm-thick crystal, for perfectly monochromatic X-rays. The solid line represents similar calculations, assuming a 1 meV broad Gaussian distribution of X-ray photon energies, as in the experiment. The experimental curve in Fig. 5a is scaled to best fit the tails of the theoretical curve. The scaling factor is the only free parameter. Comparison shows a remarkable agreement between the measured and calculated dependencies, in the shape and the energy width. The only difference is that the peak value ≃0.87(1) of the scaled experimental curve is slightly smaller than the peak reflectivity of RH(d)=0.91, expected in theory.

a, Filled circles: experimental data. Dotted line: dynamical theory calculations for a 415-μm-thick crystal and perfectly monochromatic incident X-rays. Solid line: calculations for the X-rays with a 1 meV bandwidth, as in the experiment. Inset: The same dependencies shown on a linear scale. b, Results of the absolute reflectivity measurements.

Direct measurements of the absolute reflectivity are carried out using detector APD2. It counts the photons scattered from a double-layered 2×20 μm low-absorbing (≃0.2%) Scotch Magic Tape, installed in the incident and reflected beams 0.25 m upstream from the diamond crystal (see Fig. 4). A value proportional to the net intensity I(E)=I0+IR(E) of X-ray photons incident on the crystal and reflected from the crystal is measured. The absolute crystal reflectivity is then determined as R(E)=[I(E)−I0]/[I0(1−A)], assuming that I0=I(E) when the photon energy is detuned from the reflection peak: E≃EH±20 meV. Taking into account absorption of photons propagating 0.5 m in air from the tape to the crystal and back, and in the tape, A=0.029. The filled circles in Fig. 5b show the results of the measurement. The peak reflectivity is determined as R=0.89±0.015, which is very close to the expected RH(d)=0.91 and is in agreement with the indirect measurements, shown in Fig. 5a.

The high X-ray reflectivity of diamond combined with its stability under high-heat-load conditions, and the recently demonstrated low thermal expansion of less than 10−8 K−1 at temperatures ≲100 K (ref. 15) makes diamond potentially valuable in the development of high-efficiency, high-resolution X-ray optics for use in next-generation fully coherent X-ray sources, such as XFELOs (refs 1, 2) and seeded X-ray free-electron lasers16. Moreover, high-reflectance normal incidence diamond X-ray mirrors could enable the realization of high-finesse X-ray Fabry–Pérot interferometers14,17—devices that will be useful as interference spectral filters (monochromators and analysers) for inelastic X-ray scattering spectroscopy with an unprecedented narrow bandwidth ΔE≲100 μeV (ΔE/E≲10−8) and large angular acceptance  .

.

Methods

The diamond reflectivity measurements were carried out with E=23.765 keV X-rays at undulator beamline IXS/XOR 30-ID of the Advanced Photon Source. An extremely highly monochromatic X-ray beam was used with a bandwidth of ΔEx≃1 meV, which is smaller than the energy width of the studied C(995) reflection, ΔEH(d)=2.8 meV. The monochromatization is achieved by successive applications of two X-ray monochromators. First, the high-heat-load diamond monochromator selects photons with a ≃1.7 eV bandwidth. In the second step, a Si high-resolution monochromator18 (HRM) selects photons to a desired bandwidth of ΔEx≃1 meV. The highly monochromatic beam ΔEx/E≃4×10−8 with an angular divergence of about 10 μrad(V)×20 μrad(H), and a cross-section of 0.7×0.7 mm2 impinges on the diamond crystal, placed at a distance ≃10 m downstream from the HRM. The crystal temperature is T=300 K. The (995) planes in the diamond crystal are oriented with a very small angular offset Θ≃4×10−4 rad from normal incidence. X-rays are reflected with a scattering angle deviating from 180∘ by 2Θ and detected by an avalanche photodiode APD1. The small deviation Θ from normal incidence ensures a negligible contribution of the angular spread in the incident beam on the reflectivity measurements.

Synchrotron white-beam topography was applied to select the crystal with the lowest density of defects, among the available samples. Imaging of the crystals was carried out at beamline X19C of the National Synchrotron Light Source, in transmission geometry.

A large interaction length of hard X-rays with crystals, typically more than 10 μm, see Fig. 1b, requires high perfection in the crystal volume rather than of the crystal surface. Diamond crystal plates with (111) orientation, of type IIa, are used in the studies, grown with a high-pressure, high-temperature technique by Sumitomo Electric Industries. Type IIa material has a low density of defects and less than 1 ppm concentration of impurities. Such an amount of impurities most probably has a negligible influence on the measured properties, well below the detection limit of the extremely sensitive method used.

References

Kim, K.-J., Shvyd’ko, Y. & Reiche, S. An X-ray free-electron laser oscillator with an energy recovery linac. Phys. Rev. Lett. 100, 244802 (2008).

Kim, K.-J. & Shvyd’ko, Y. Tunable optical cavity for an X-ray free-electron-laser oscillator. Phys. Rev. Phys. Spec. Top Accel. Beams 12, 030703 (2009).

Colella, R. & Luccio, A. Proposal for a free electron laser in the X-ray region. Opt. Commun. 50, 41–44 (1984).

Prelas, M. A., Popovici, G. & Bigelow, L. K. (eds) in Handbook of Industrial Diamonds and Diamond Films (Marcel Dekker, 1998).

Pal’yanov, Y., Malinovsky, Y., Borzdov, Y. M. & Khokryakov, A. F. Use of the ‘split sphere’ apparatus for growing large diamond crystals without the use of a hydraulic press. Dokl. Akad. Nauk SSSR 315, 233–237 (1990).

Berman, L. E. et al. Diamond crystal X-ray optics for high-power-density synchrotron radiation beams. Nucl. Instrum. Methods Phys. Res. A 329, 555–563 (1993).

Sumiya, H. & Satoh, S. High-pressure synthesis of high-purity diamond crystal. Diamond Relat. Mater. 5, 1359–1365 (1996).

Fernandez, P. et al. Test of a high-heat-load double-crystal diamond monochromator at the Advanced Photon Source. Nucl. Instrum. Methods Phys. Res. A 400, 476–483 (1997).

Sellschop, J. P. F. et al. Synchrotron X-ray applications of synthetic diamonds. New Diamond Frontier Carbon Technol. 10, 253–258 (2000).

Sumiya, H., Toda, N. & Satoh, S. High-quality large diamond crystals. New Diamond Frontier Carbon Technol. 10, 233–251 (2000).

Zhong, Y. et al. Rocking curve FWHM maps of a chemically etched (001) oriented HPHT type Ib diamond crystal plate. J. Phys. D 40, 5301–5305 (2007).

Yabashi, M. et al. Diamond double-crystal monochromator for SPring-8 undulator beamlines. AIP Conf. Proc. 879, 922–925 (2007).

Burns, R. C. et al. HPHT growth and X-ray characterization of high-quality type IIa diamond. J. Phys. Condens. Matter 21, 364224 (2009).

Shvyd’ko, Y. X-ray Optics—High-Energy-Resolution Applications Vol. 98 (Optical Sciences, Springer, 2004).

Stoupin, S. & Shvyd’ko, Y. V. Thermal expansion of diamond at low temperatures. Phys. Rev. Lett. (2009, in the press).

Saldin, E. L., Schneidmiller, E. A., Shvyd’ko, Y. V. & Yurkov, M. V. X-ray FEL with a meV bandwidth. Nucl. Instrum. Methods Phys. Res. A 475, 375–362 (2001).

Shvyd’ko, Y. V. X-ray Resonators and Other Applications of Bragg Backscattering (Habilitationsschrift, DESY, 2002) <www-library.desy.de/diss02.html> (DESY-Thesis-2002-028).

Toellner, T. S. et al. Six-bounce 1 meV monochromator for 23.7 keV X-rays. (in the press).

Caticha, A. & Caticha-Ellis, S. Dynamical theory of X-ray diffraction at angles near π/2. Phys. Rev. B 25, 971–983 (1982).

Acknowledgements

The studies were carried out in the framework of the LDRD on XFELOs at Argonne National Laboratory. We are grateful to K.-J. Kim for the stimulated interest and discussions. We are indebted to R. Winarski and T. Graber for the loan of the diamond crystals. T. Toellner and D. Shu are acknowledged for the development of the high-resolution X-ray monochromator crucial for the presented studies. We acknowledge support of N. Zhang and M. Dudley in white-beam topography studies. Work was supported by the US Department of Energy, Office of Science, Office of Basic Energy Sciences, under Contract No. DE-AC02-06CH11357. NSLS was supported under Contract No. DE-AC-02-98CH10886.

Author information

Authors and Affiliations

Contributions

Y.V.S. planned and organized the experiments, analysed the data and wrote the paper. S.S. set up and carried out the main experiment, the white-beam topography studies and contributed to writing of the paper. X.H. carried out the white-beam topography studies. All authors have contributed to the experimental effort of this work.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

About this article

Cite this article

Shvyd’ko, Y., Stoupin, S., Cunsolo, A. et al. High-reflectivity high-resolution X-ray crystal optics with diamonds. Nature Phys 6, 196–199 (2010). https://doi.org/10.1038/nphys1506

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nphys1506

This article is cited by

-

Free-electron interactions with van der Waals heterostructures: a source of focused X-ray radiation

Light: Science & Applications (2023)

-

The MING proposal at SHINE: megahertz cavity enhanced X-ray generation

Nuclear Science and Techniques (2023)

-

BRIGHT: the three-dimensional X-ray crystal Bragg diffraction code

Nuclear Science and Techniques (2019)

-

Optimal parameter(s) for the synthesis of nitrogen-vacancy (NV) centres in polycrystalline diamonds at low pressure

Journal of Materials Science: Materials in Electronics (2019)

-

Review of fully coherent free-electron lasers

Nuclear Science and Techniques (2018)